Patents

Literature

44results about How to "Realize automatic metering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

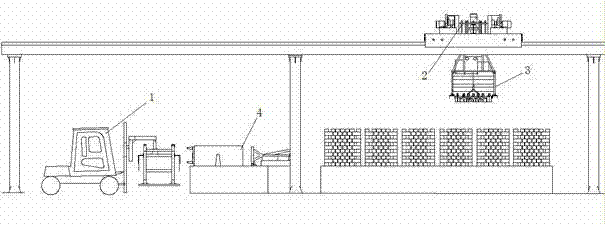

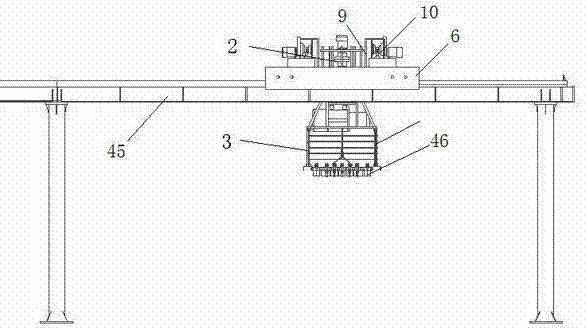

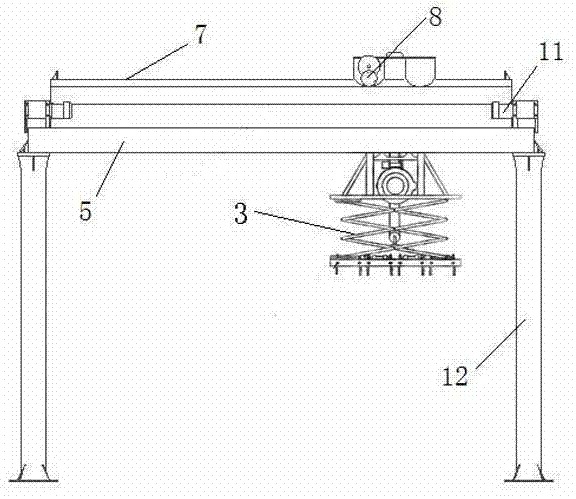

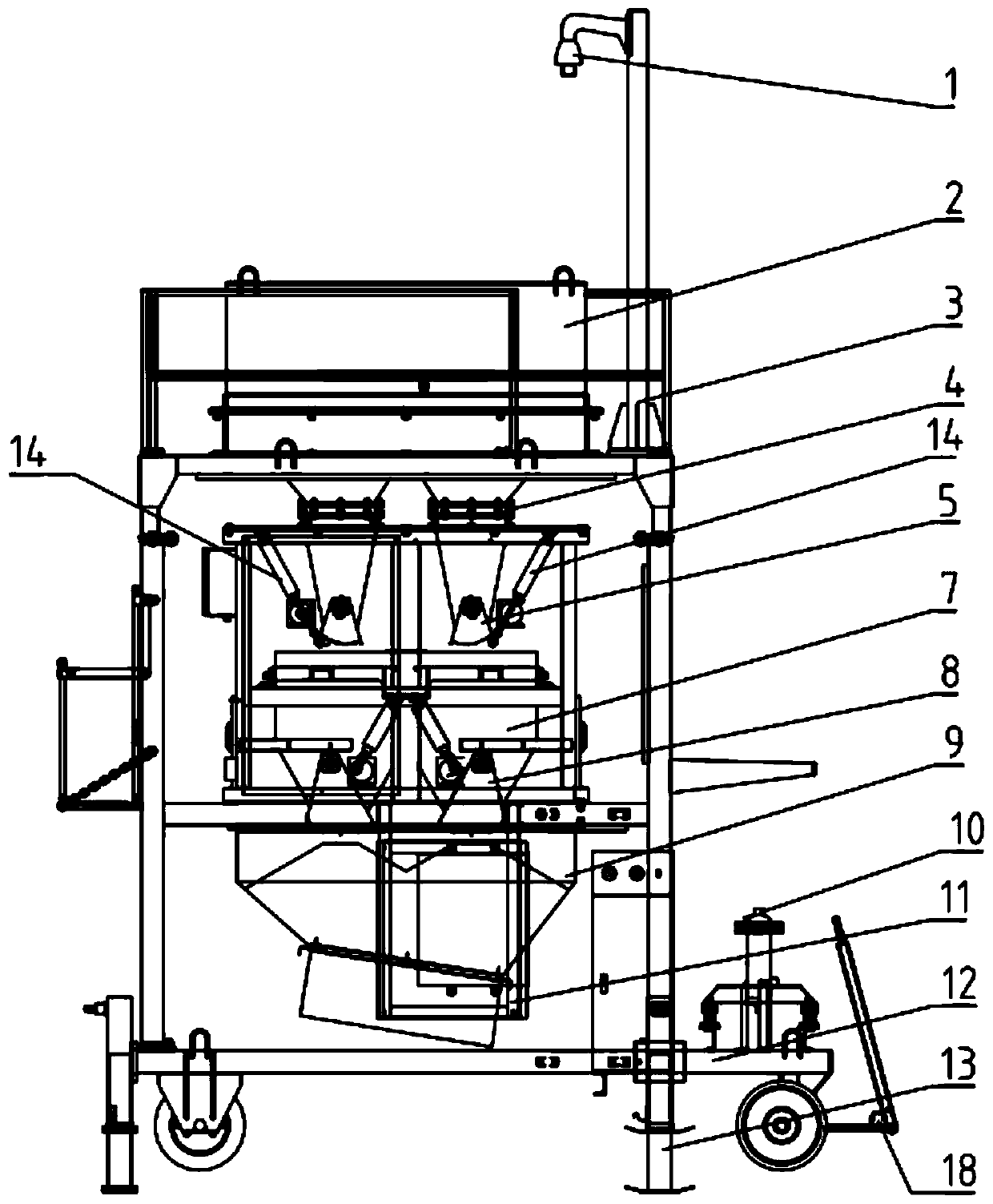

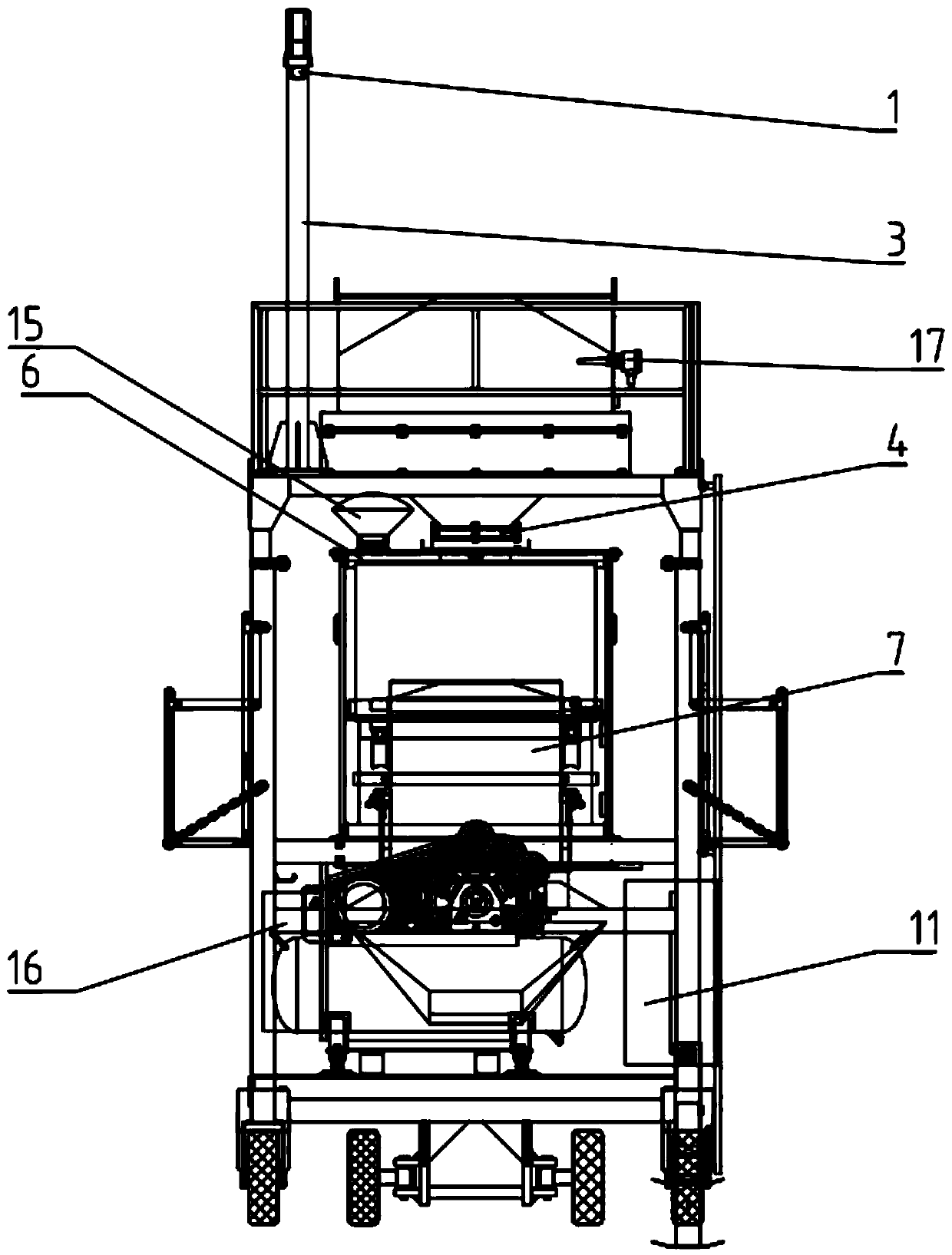

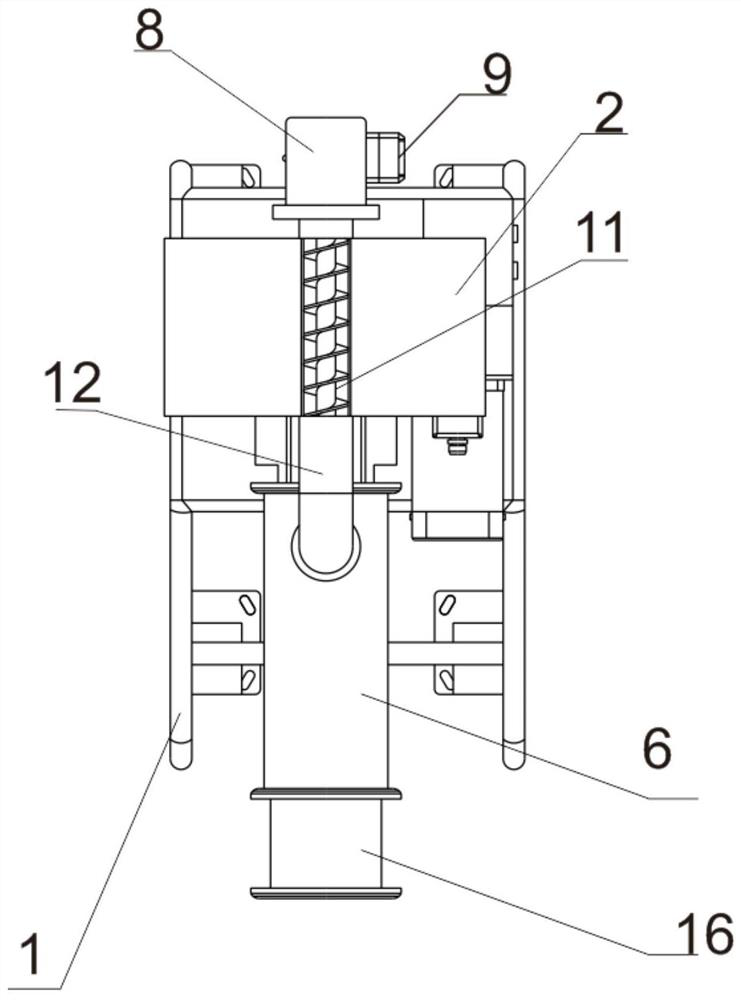

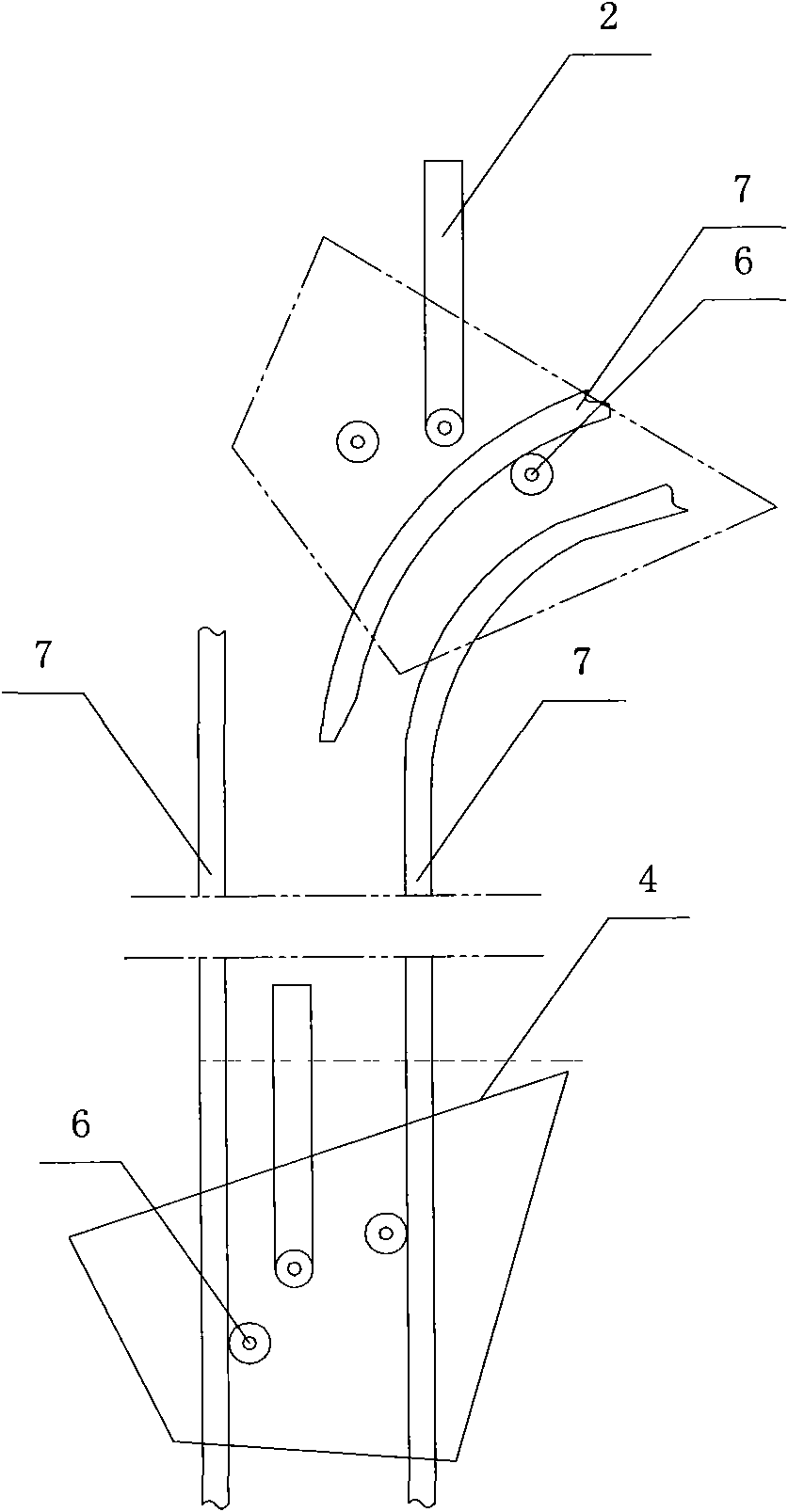

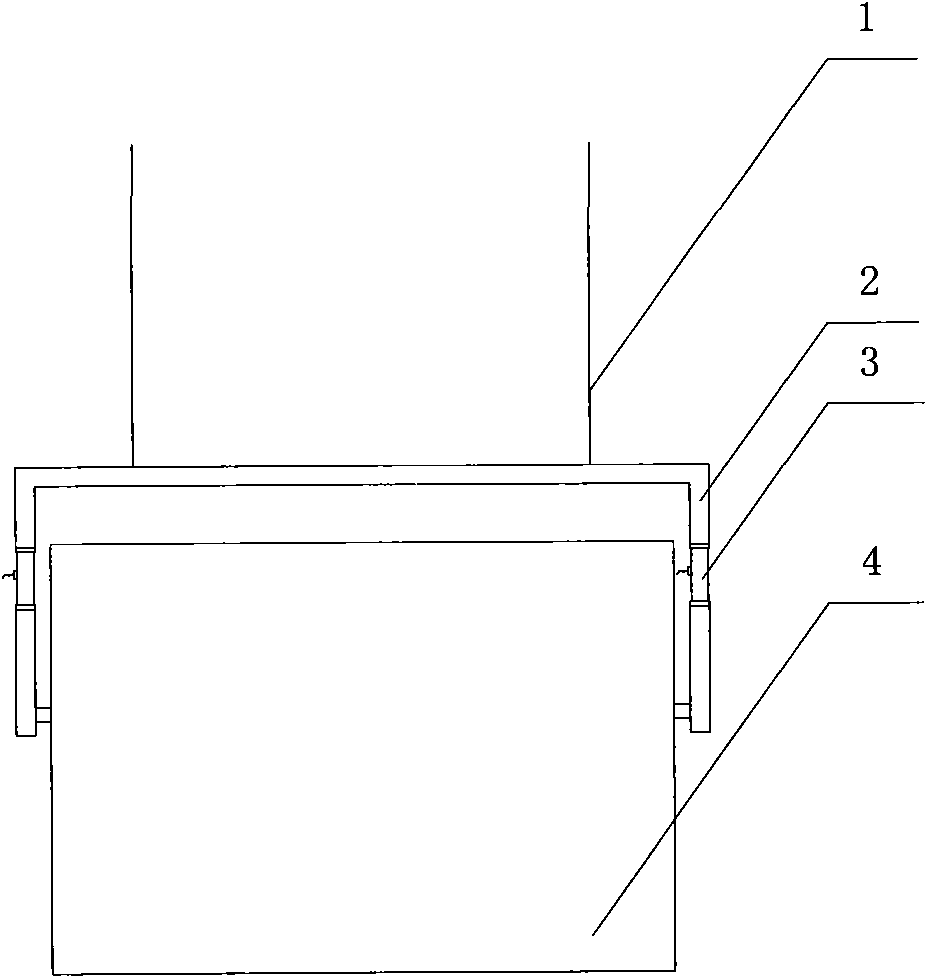

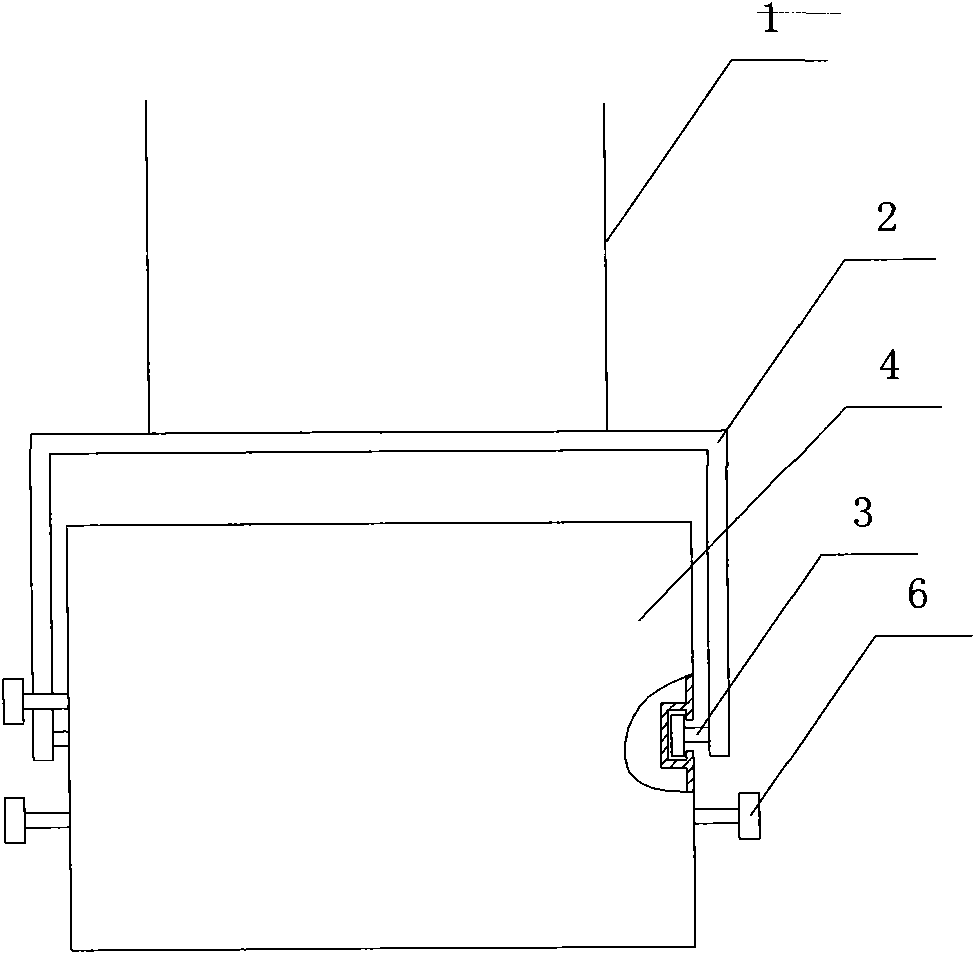

Intelligent brick unloading machine

InactiveCN102649510AHigh degree of automationRealize automatic meteringStacking articlesDe-stacking articlesBrickEngineering

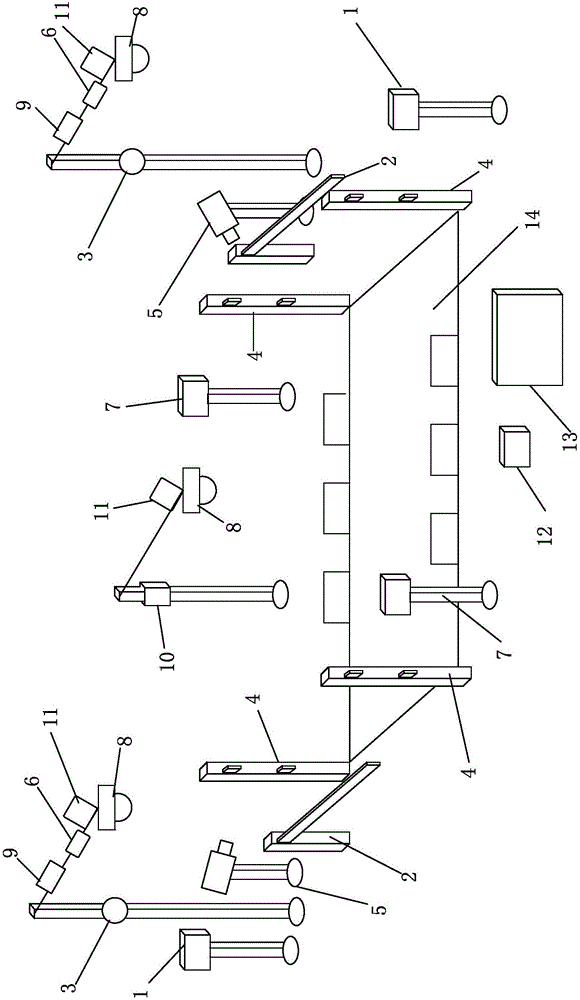

The invention provides an intelligent brick unloading machine. The intelligent brick unloading machine comprises a pair of travelling cranes, a rotating mechanism, a clamp, a shaping mechanism and a brick-holding vehicle, wherein the travelling crane is used for longitudinally travelling to fetch bricks and can randomly move in the horizontal position of a guide rail above a kiln vehicle; the rotating mechanism is used for fetching bricks from brick stacks placed in different positions and is arranged on the travelling crane; the clamp is used for fetching the bricks in a lifting mode and is connected with an electric hoist of the rotating mechanism through a steel wire rope; the shaping mechanism is used for placing the bricks tidily again after the bricks are fetched from the kiln vehicle and is positioned under the clamp; and the brick-holding vehicle is used for conveying the shaped brick stacks from a shaping platform. The intelligent brick unloading machine has the advantages of high automation degree, high using safety, high yield, high generality, simple structure, convenience for maintenance and the like.

Owner:WUHAN UNIV OF TECH +1

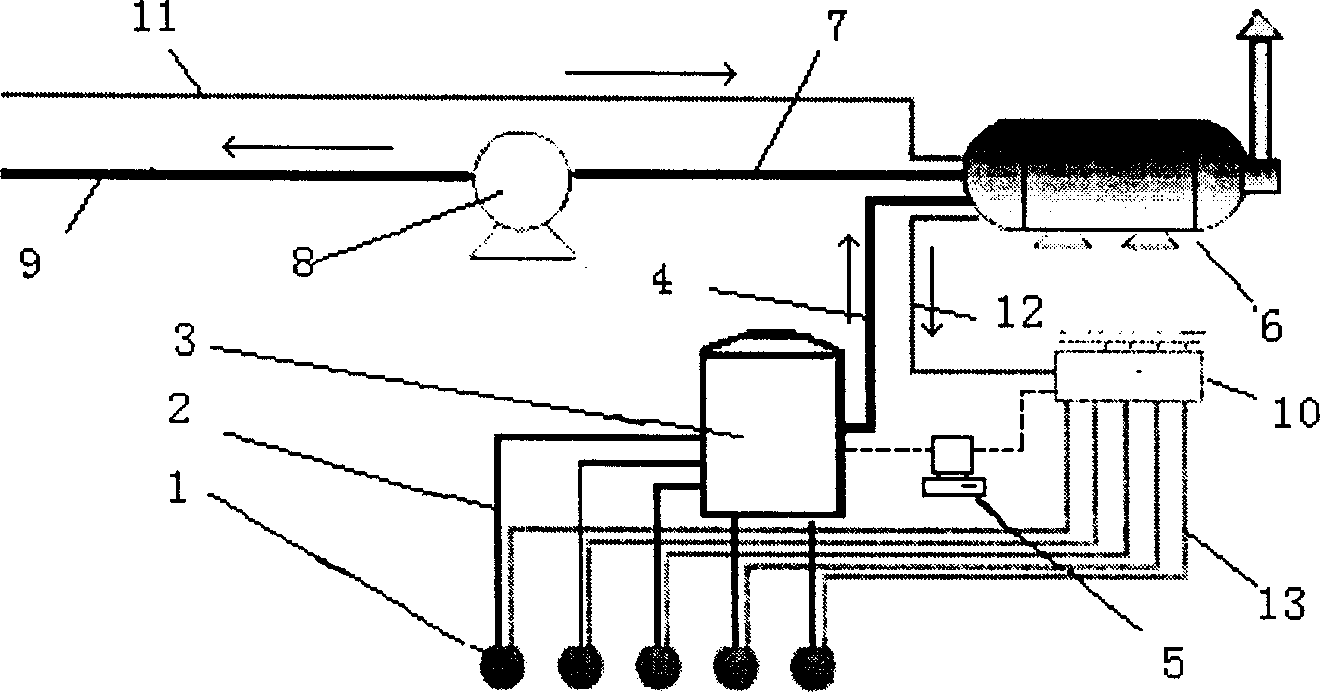

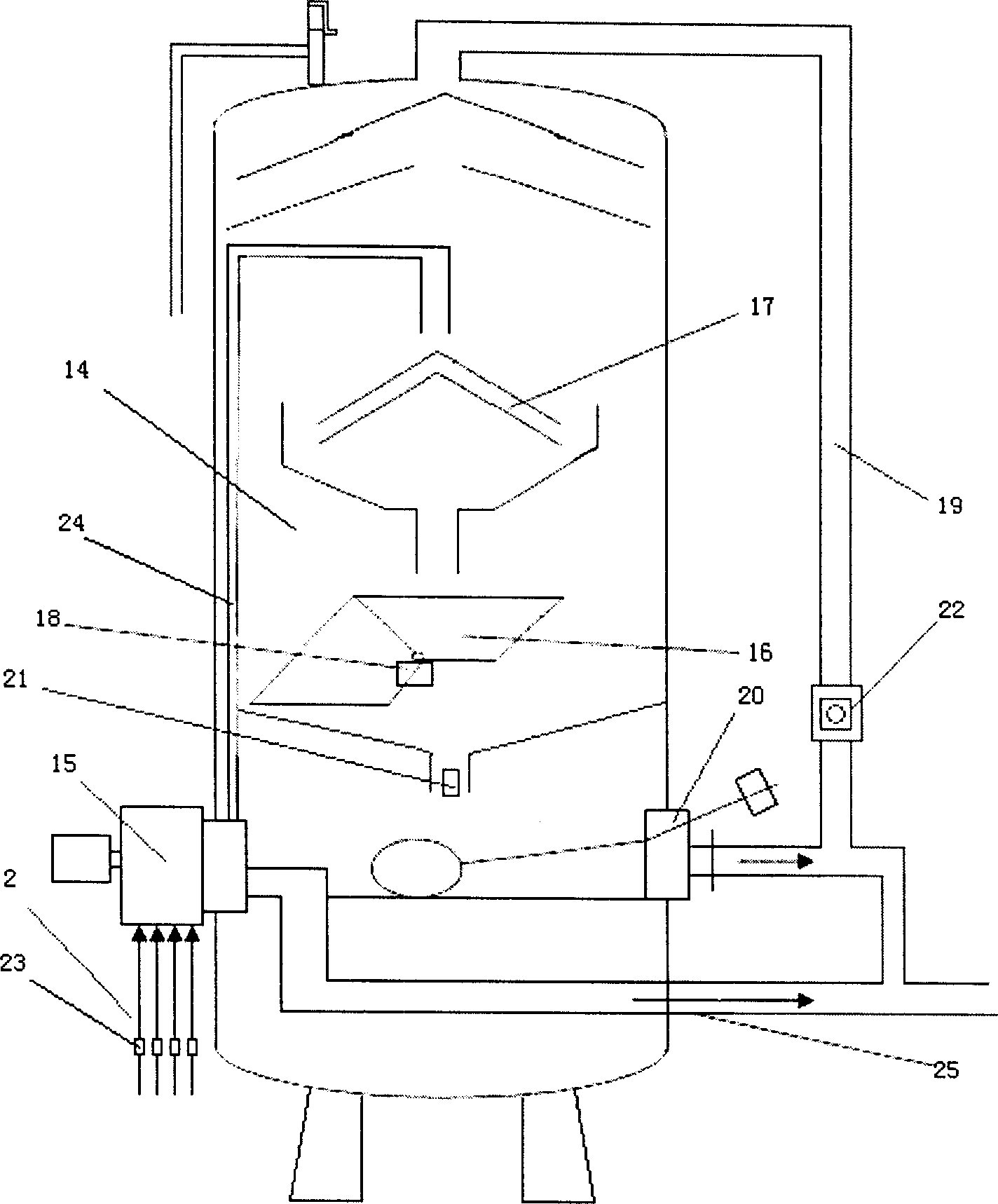

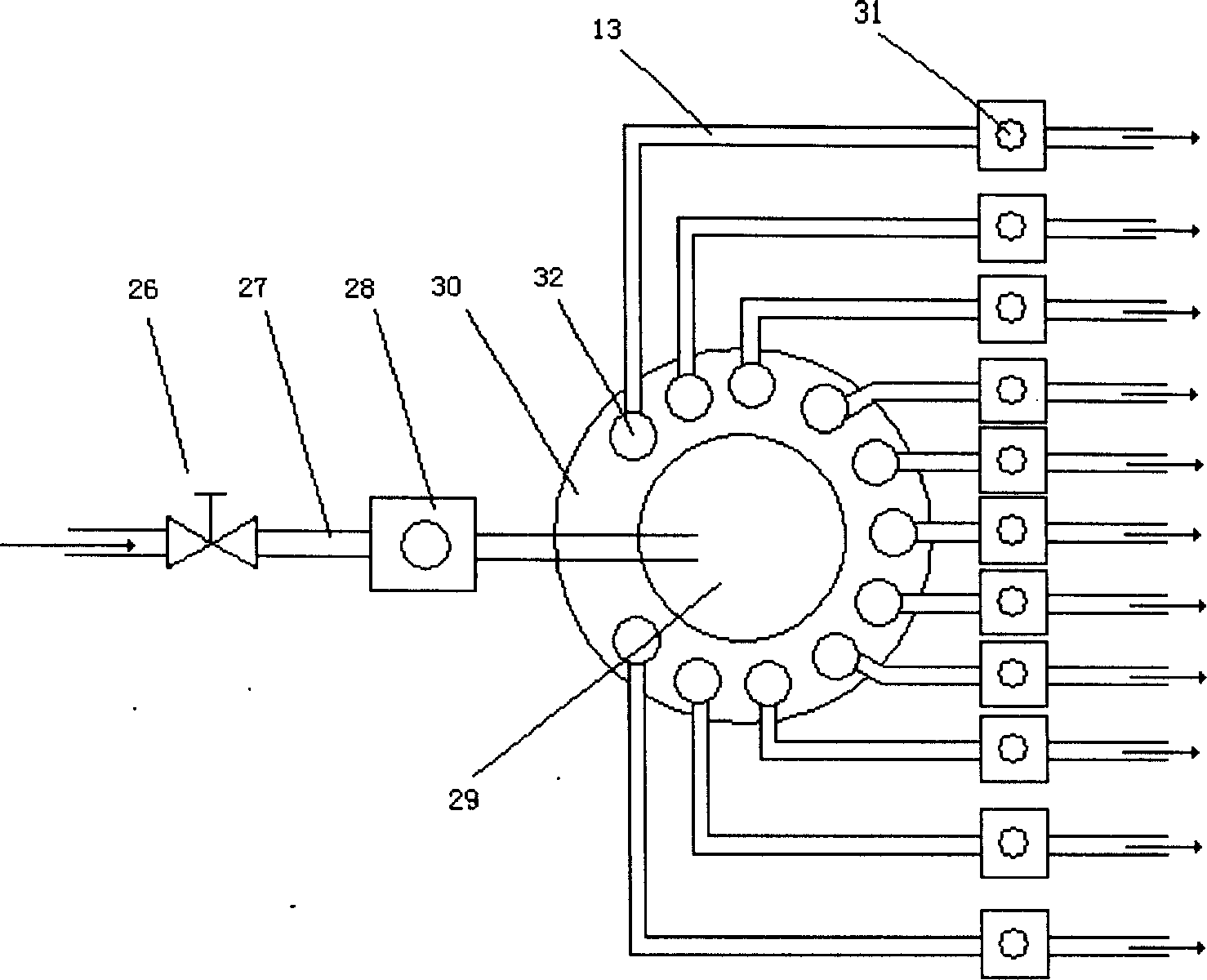

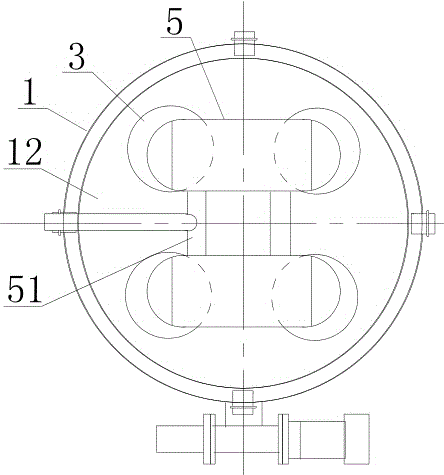

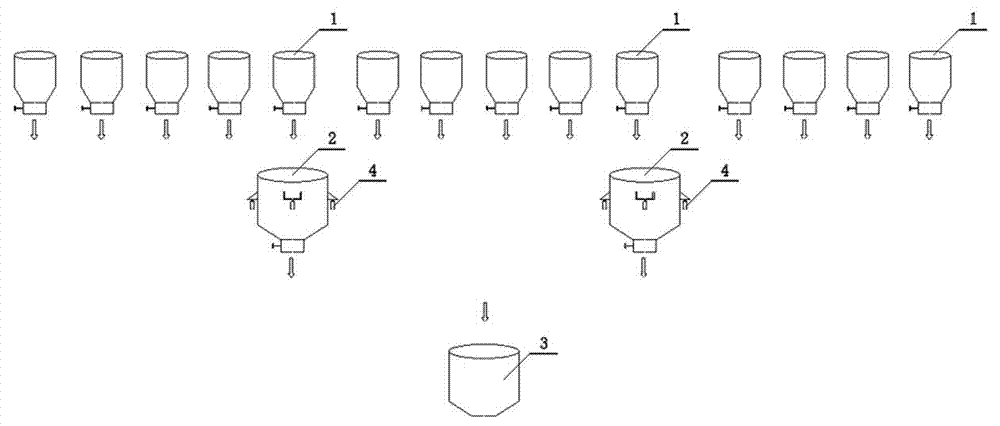

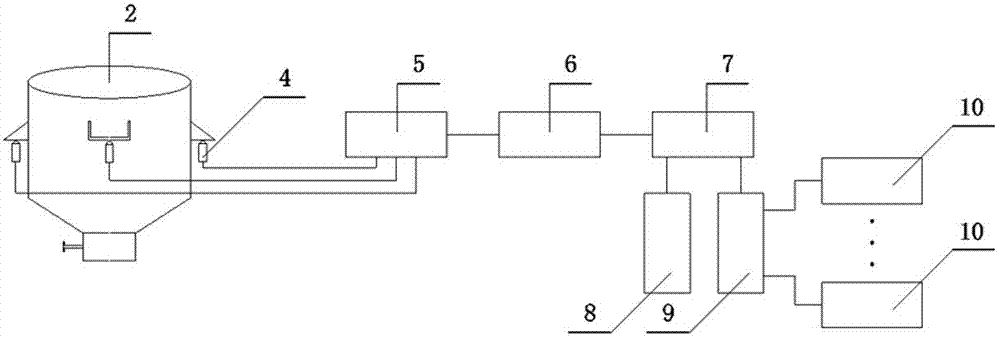

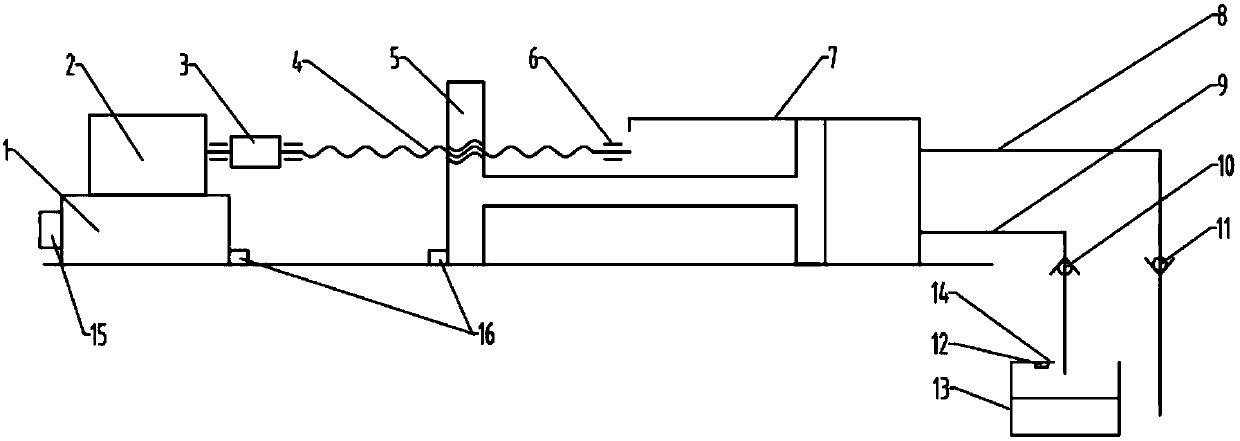

Overground gathering and transporting system for petroleum exploitation and method thereof

InactiveCN1828009ARealize automatic dosingImplement gas-liquid direct transmissionSurveyFluid removalPetroleumOil well

The invention relates to an oil exploitation ground transmission system and relative method, belonging to the oil exploitation technique. Said invention can measure the oil well, add liquid into oil well, heat the oil well and mixed transmit the oil gas. And said invention comprises four parts as aforementioned functions. Wherein, the oil well measuring part uses a liquid automatic measurer, which comprises a skip measurer, an automatic oil well switcher and a transmission tube. The invention uses industry computer to realize said functions, with high automatic degree, high practicability, and unmanned management.

Owner:岳玉全 +1

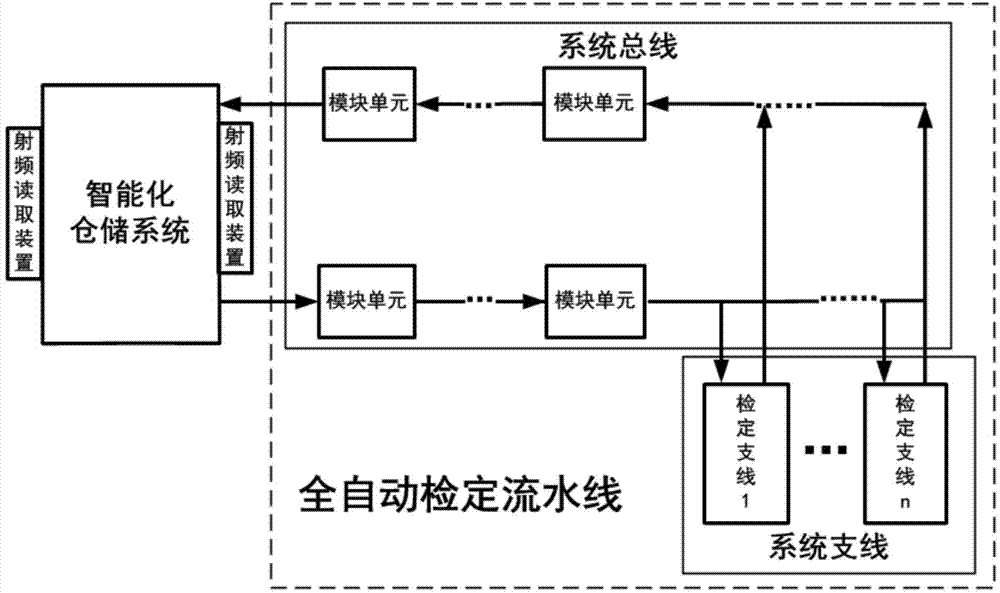

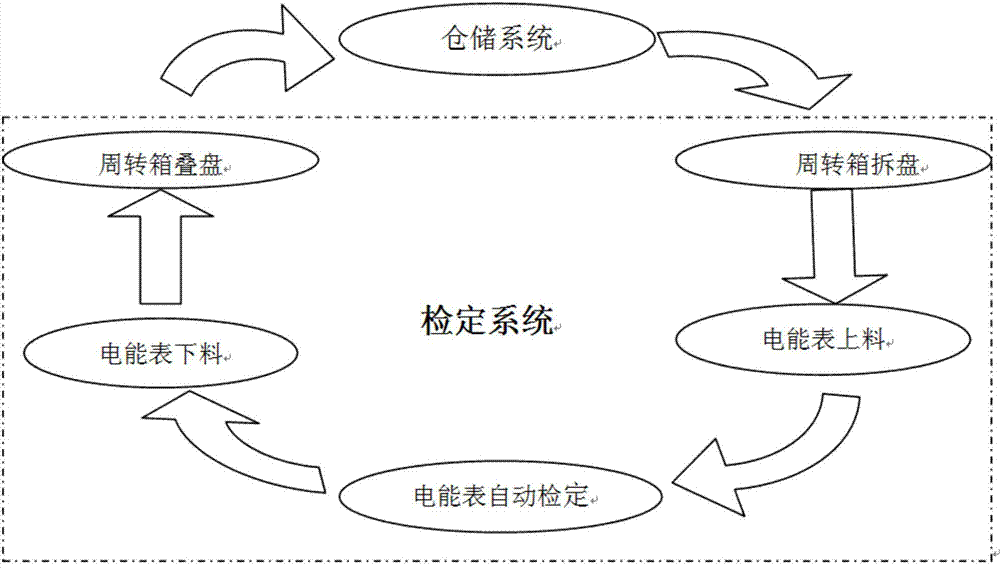

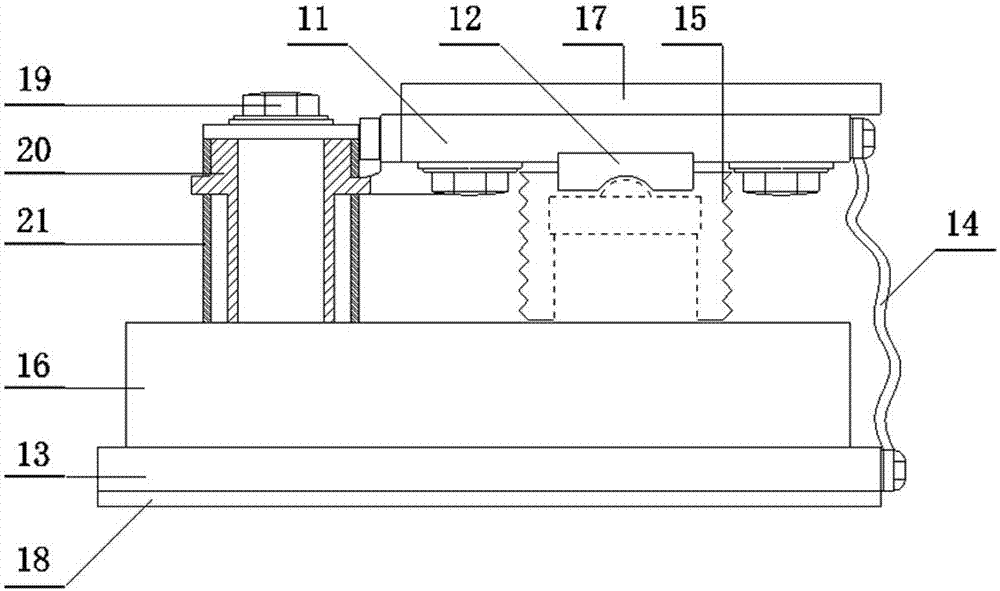

Automated operating device for storage and verification of electric energy meter of electric power system and operating method thereof

ActiveCN103489092AOptimizationImprove management toolsSensing record carriersLogisticsModularityRadio frequency

The invention discloses an automated operating device for storage and verification of an electric energy meter of an electric power system and an operating method thereof. The automated operating device comprises an intelligent warehousing system, an RFID (radio frequency identification) property recognition system and a full-automatic verification assembly line, wherein the intelligent warehousing system comprises a high level three-dimensional good shelf and a physical distribution transport system, the RFID property recognition system comprises a radio frequency chip arranged on the electric energy meter to be verified and a radio frequency read device arranged in the intelligent warehousing system, the full-automatic verification assembly line comprises a system bus and a system branch line, the system bus is combined by modularized units which are connected with each other in series, and the system branch line comprises a plurality of verification branch lines which are connected in parallel. The automated operating device for storage and verification of the electric energy meter of the electric power system and the operating method have the advantages of realizing automated storage and verification of the newly purchased electric energy meter from the process of warehousing and verification to the process of delivery, and improving intelligent management level in metering storage and verifying production.

Owner:STATE GRID CORP OF CHINA +1

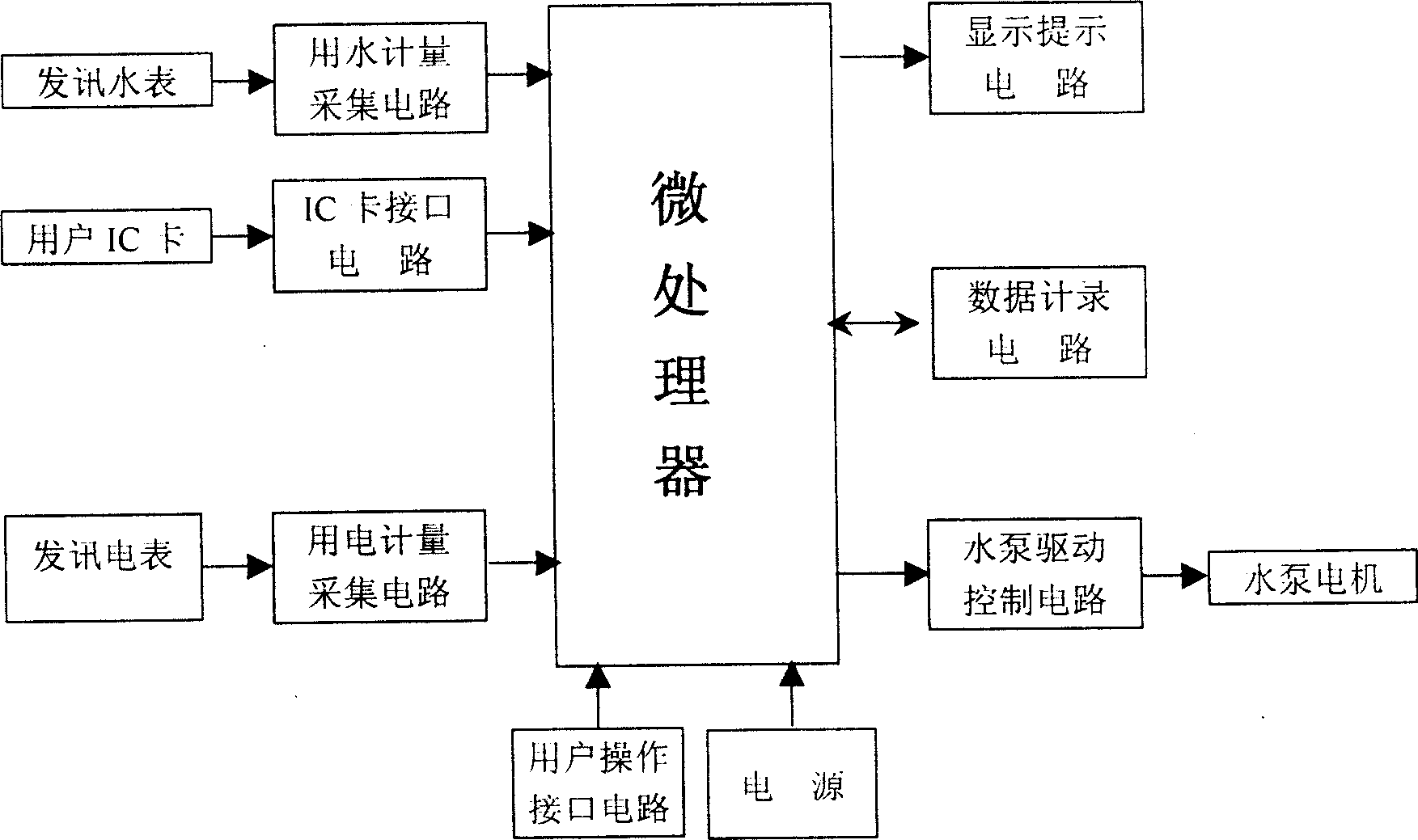

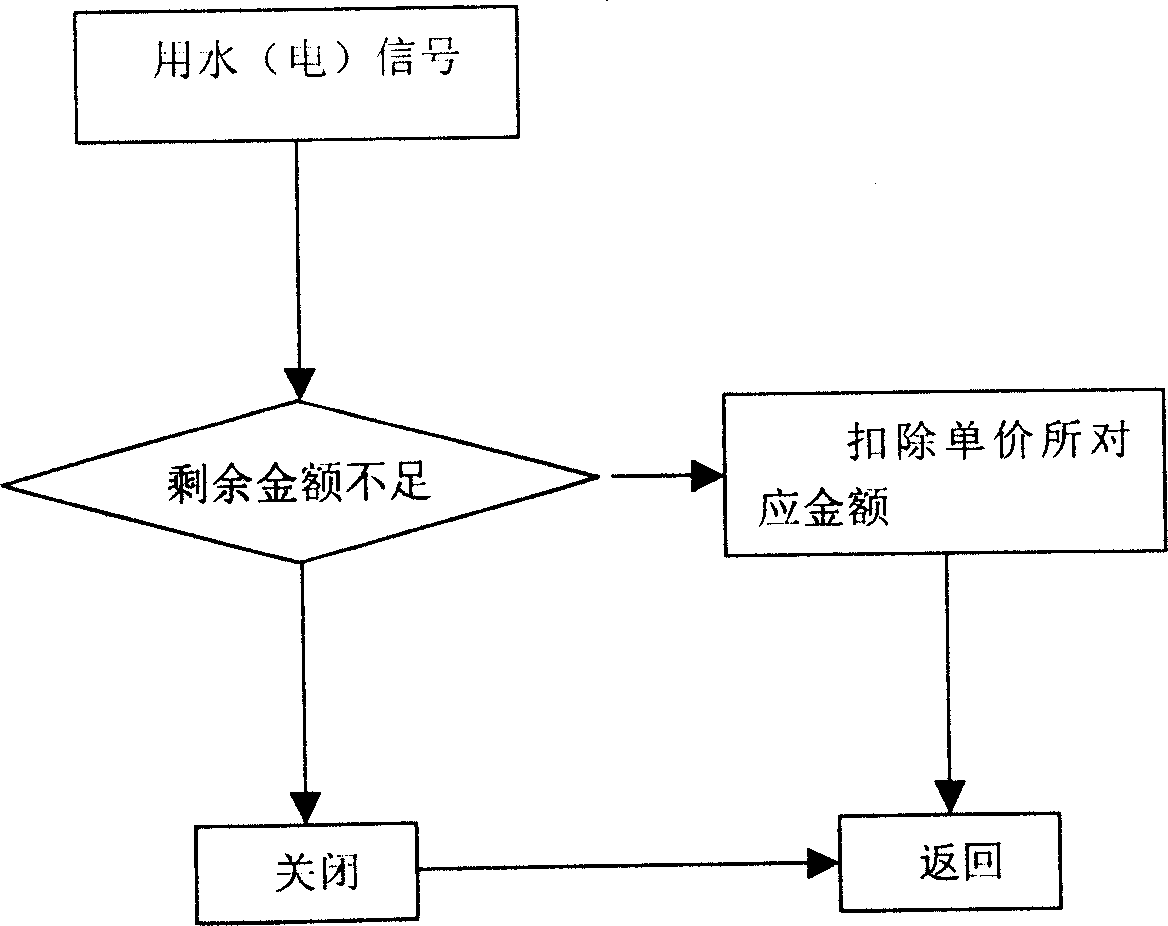

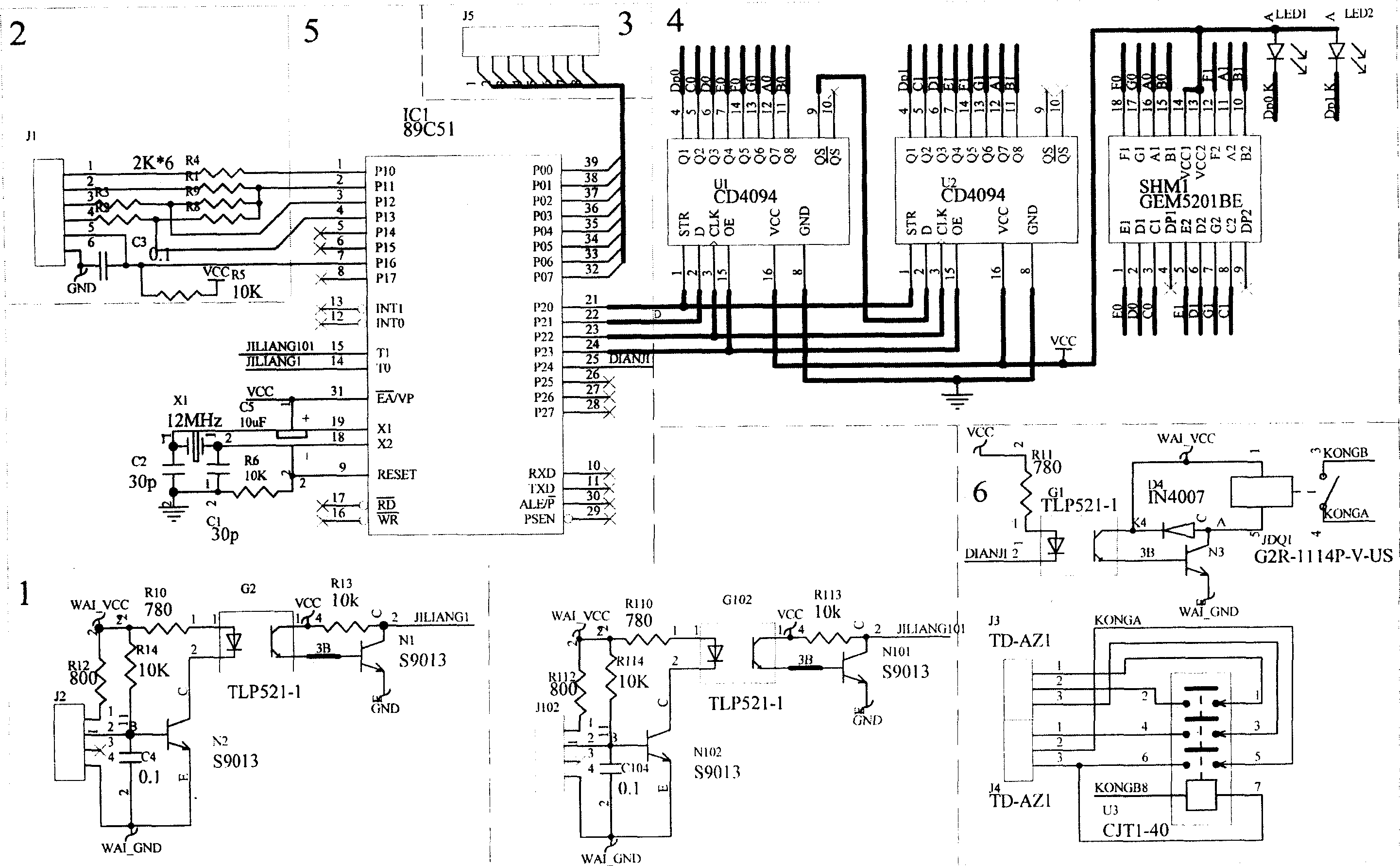

Water fetching control system for water-electric combined control prepaying IC card of motor-pumping well

InactiveCN1716323ARealize automatic meteringConserve waterApparatus for hiring articlesCoded identity card or credit card actuationControl systemElectric machinery

The present invention belongs to the field of control technology, and solves the technological problem of water fetching control system including metering the water amount and power consumption of motor pumping well and pre-paying with IC card. The control process includes the following steps: inserting the IC card; starting the controller via the user operation interface circuit; the controller reading the information in the card and starting water pump; the controller deducting the water consumption and power consumption money; shutting off the motor of the water pump to finishing water fetching; and the controller writing the residual money into the IC card. The water fetching control system includes water pump, power meter, microprocessor, water amount collecting circuit, IC card interface circuit, electric power metering sample circuit and water pump driving control circuit.

Owner:河北省水利科学研究院

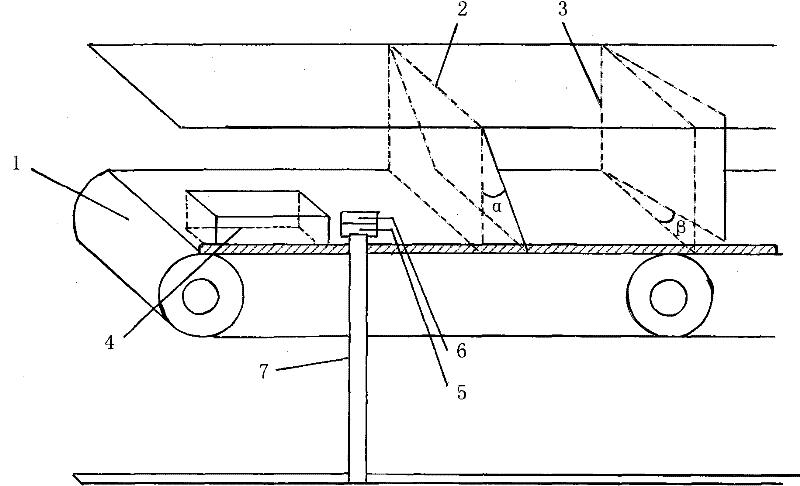

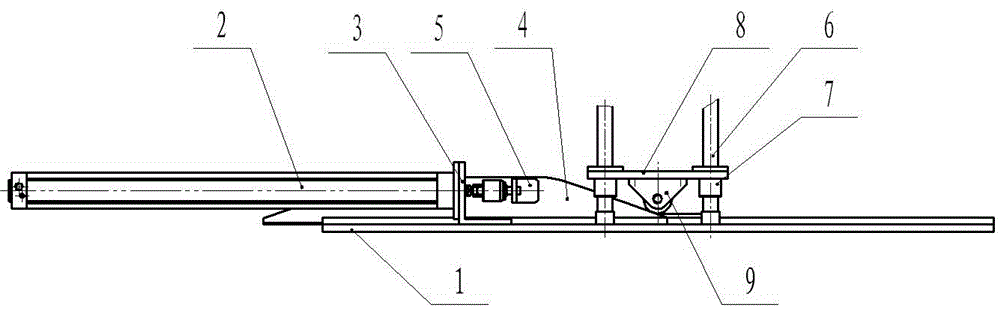

Method for automatically counting volume of wood with rectangular sectional area

InactiveCN102162719AReflect fairnessThe measurement method is simpleUsing optical meansReducerEngineering

The invention relates to a method for automatically counting the volume of a wood with a rectangular sectional area. The wood with the rectangular sectional area moves forward at a constant speed on a conveying device; photoelectric switches fixed on the left and the right of the conveying device are used for measuring the length of the wood with the rectangular sectional area; the wood with the rectangular sectional area pushes baffles which are arranged in the horizontal direction and the vertical direction so as to produce angles alpha and beta in the horizontal direction and the vertical direction respectively; the angles produced by the baffles are amplified by a speed reducer in a signal way and transmitted to an absolute encoder; the absolute encoder transforms an angular displacement into a linear displacement, and transmits a width signal and a height signal to an upper computer; and the width signal and the height signal are processed by the upper computer according to a volume formula V=X*Y*Z so as to display the volume of the wood. By adoption of the method for automatically counting the volume of the wood with the rectangular sectional area, the counting method is simple, finished automatically, and high in speed and precision; moreover , labors and resources are saved, the speed and the precision of measurement are increased, the accuracy and the objectivity of automatically counting the volume of the wood with the rectangular sectional area are guaranteed, and the transaction fairness between a wood supplier and a manufacturer is embodied. By application of the method, the manual measurement intensity is reduced, and the accuracy and the objectivity of measurement can be improved.

Owner:KUNMING UNIV OF SCI & TECH

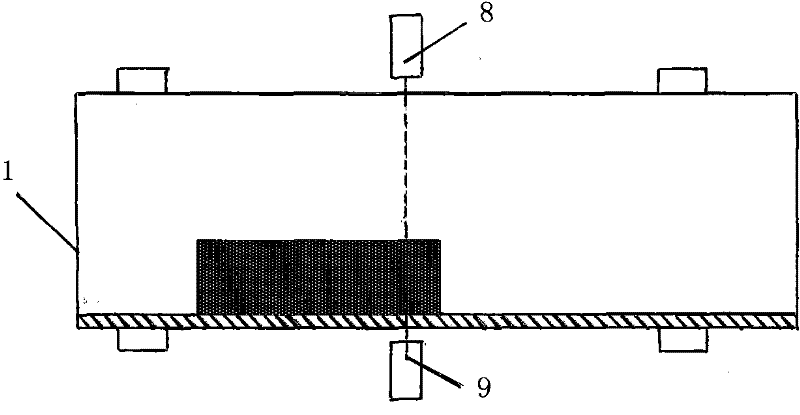

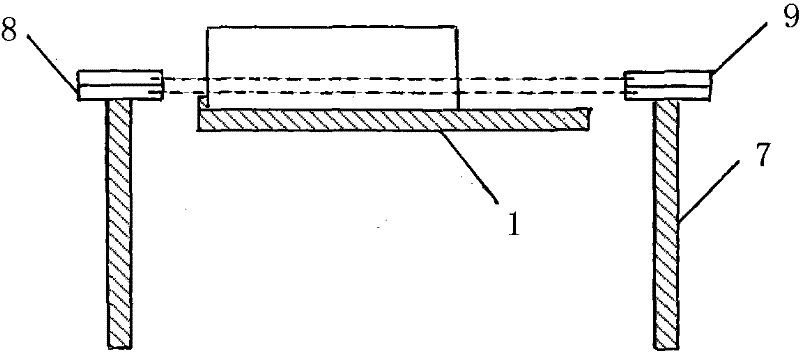

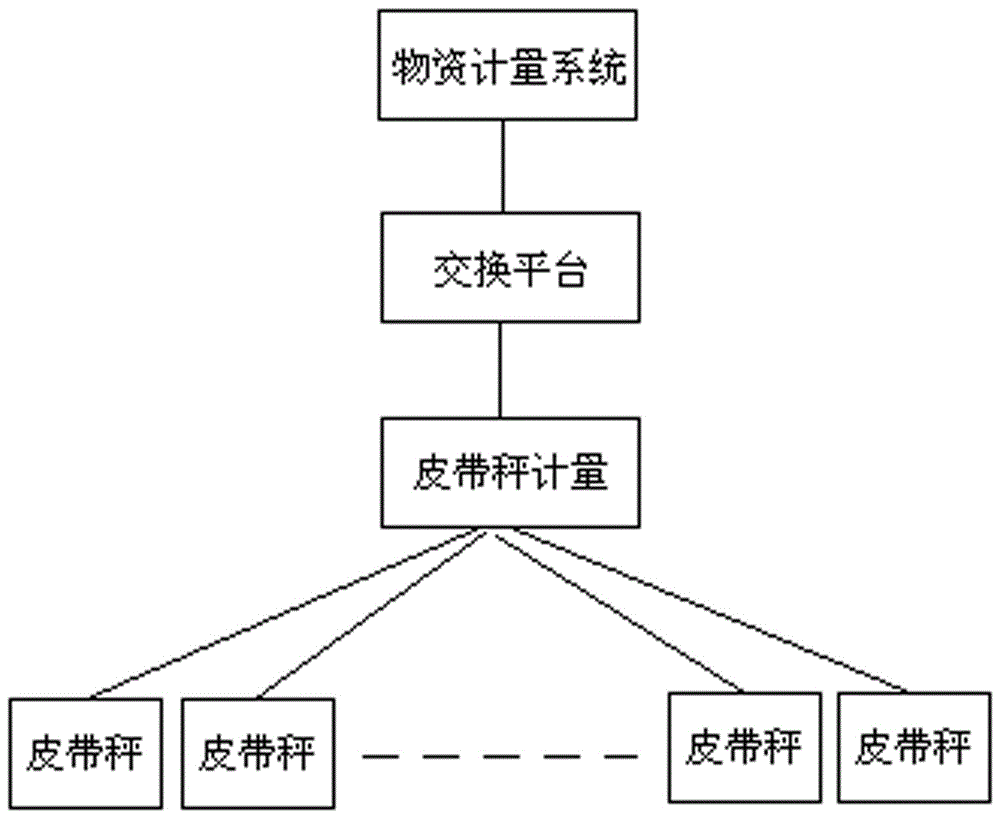

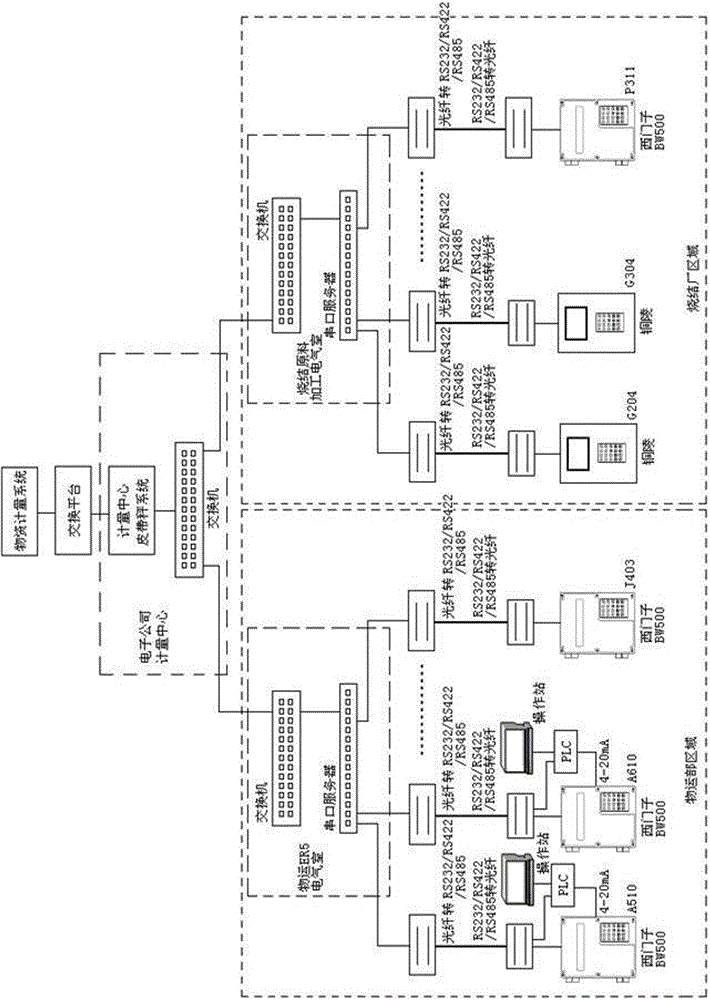

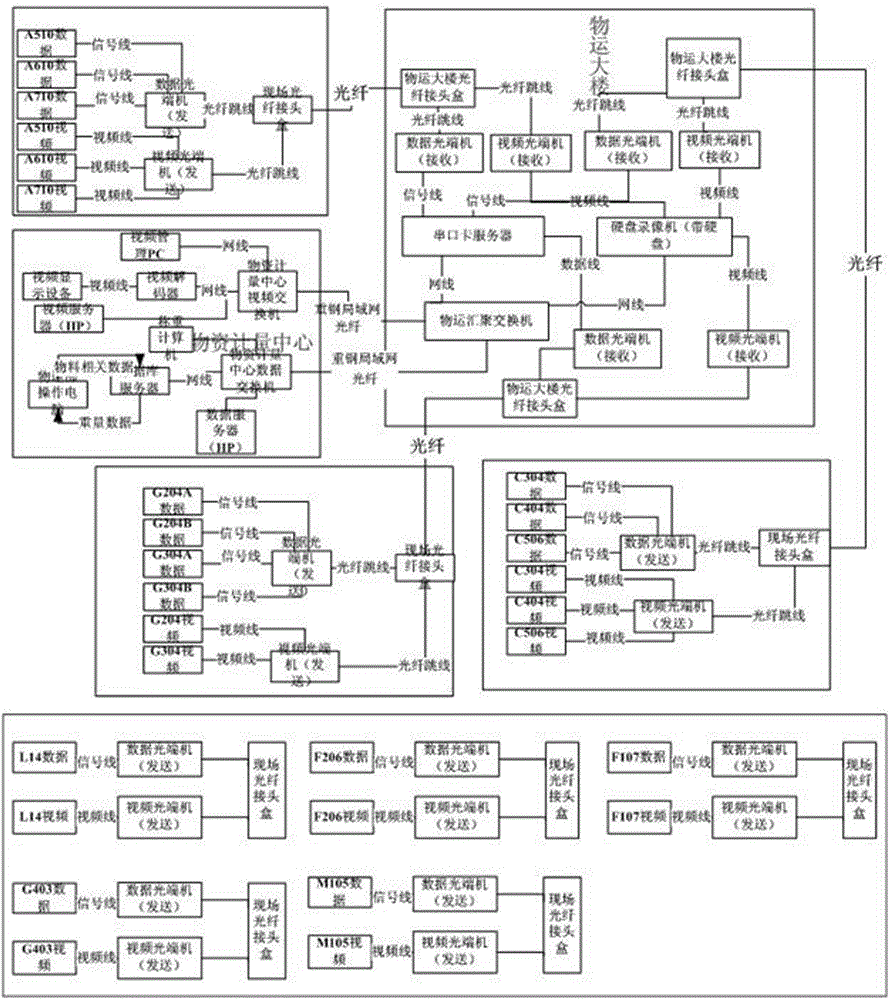

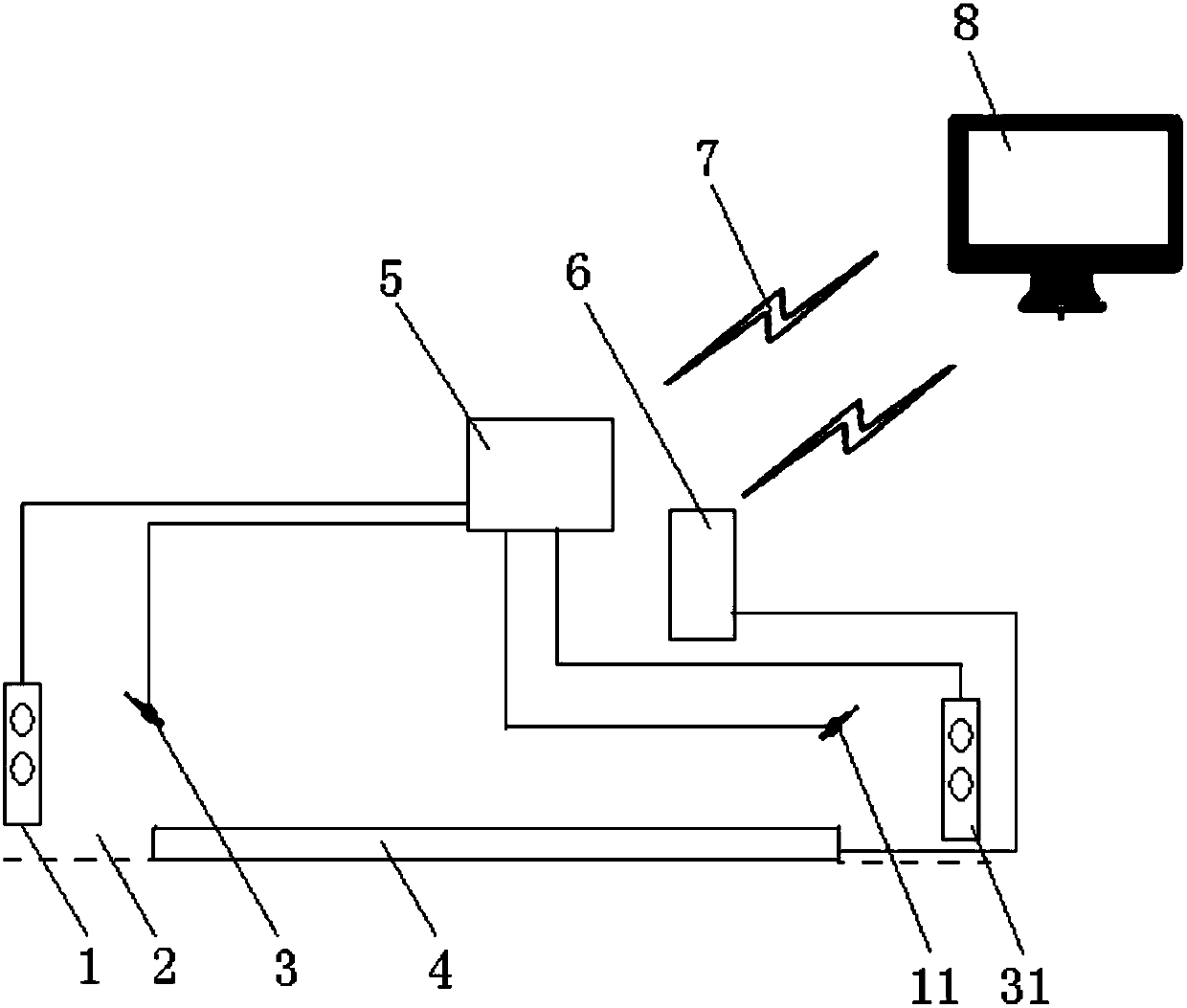

Long-distance concentrated automatic metering system and method adopting belt weighers in large region

ActiveCN106352959AMake up for deficienciesGuaranteed accuracyWeighing apparatus for continuous material flowTotal factory controlAcquisition timeComputer science

The invention relates to a long-distance concentrated automatic metering system and method adopting belt weighers in a large region. The long-distance concentrated automatic metering system comprises a serial server, a metering computer and multiple belt weighers, wherein a weighing meter of each belt weigher is connected with the serial server through optical fibers, the serial server is connected with the metering computer through the network, the metering computer, the serial server and the weighing meters of the belt weighers constitute an RS-485 bus control network, the metering computer is used for reading instantaneous weight, cumulative weight and belt operating speed of each weighing meter according to a set acquisition time point, calculating weight data of materials transported by the belt weighers in a corresponding time period and issuing a command signal to be transmitted to the weighing meter of each belt weigher through the serial server, and long-distance monitoring for the belt weighers is realized. According to the system and the method, the metering data is accurate, unified management for the multiple metering belt weighers in the large region is realized, the data is uploaded and shared in time, and an anti-cheating function of weighing equipment is realized in terms of hardware of the system.

Owner:CHONGQING IRON & STEEL GRP ELECTRONIC CO LTD

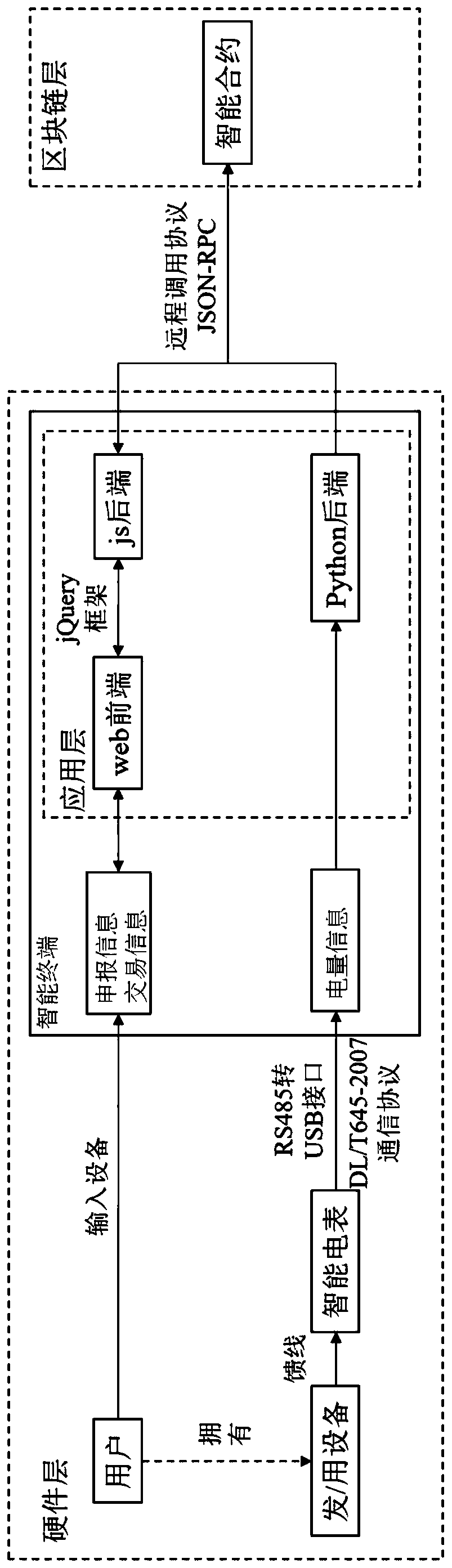

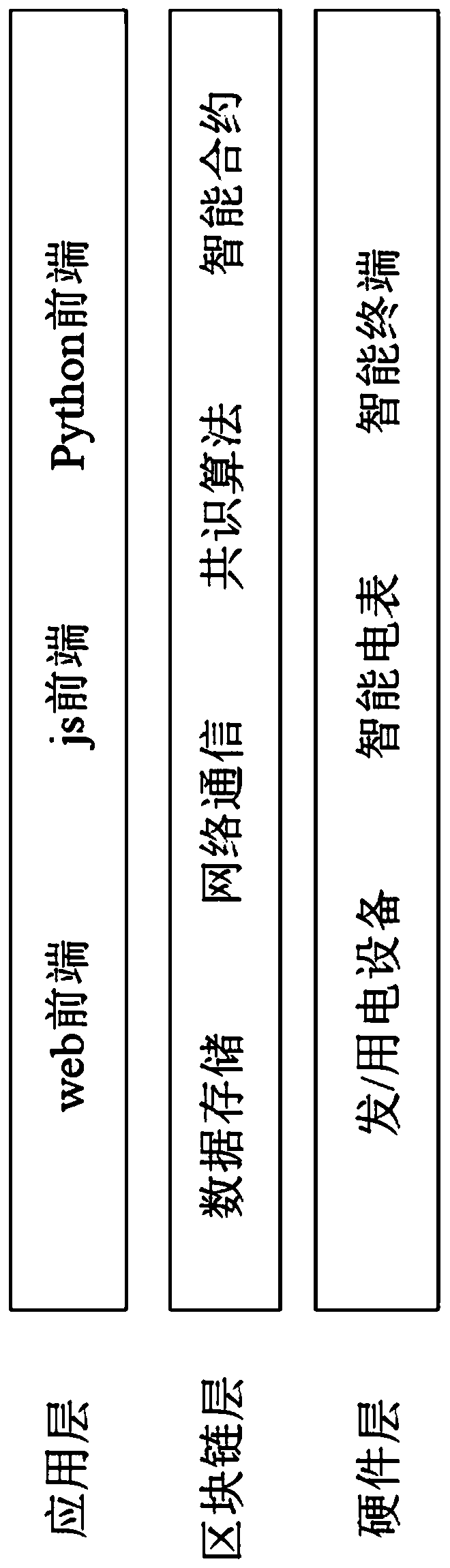

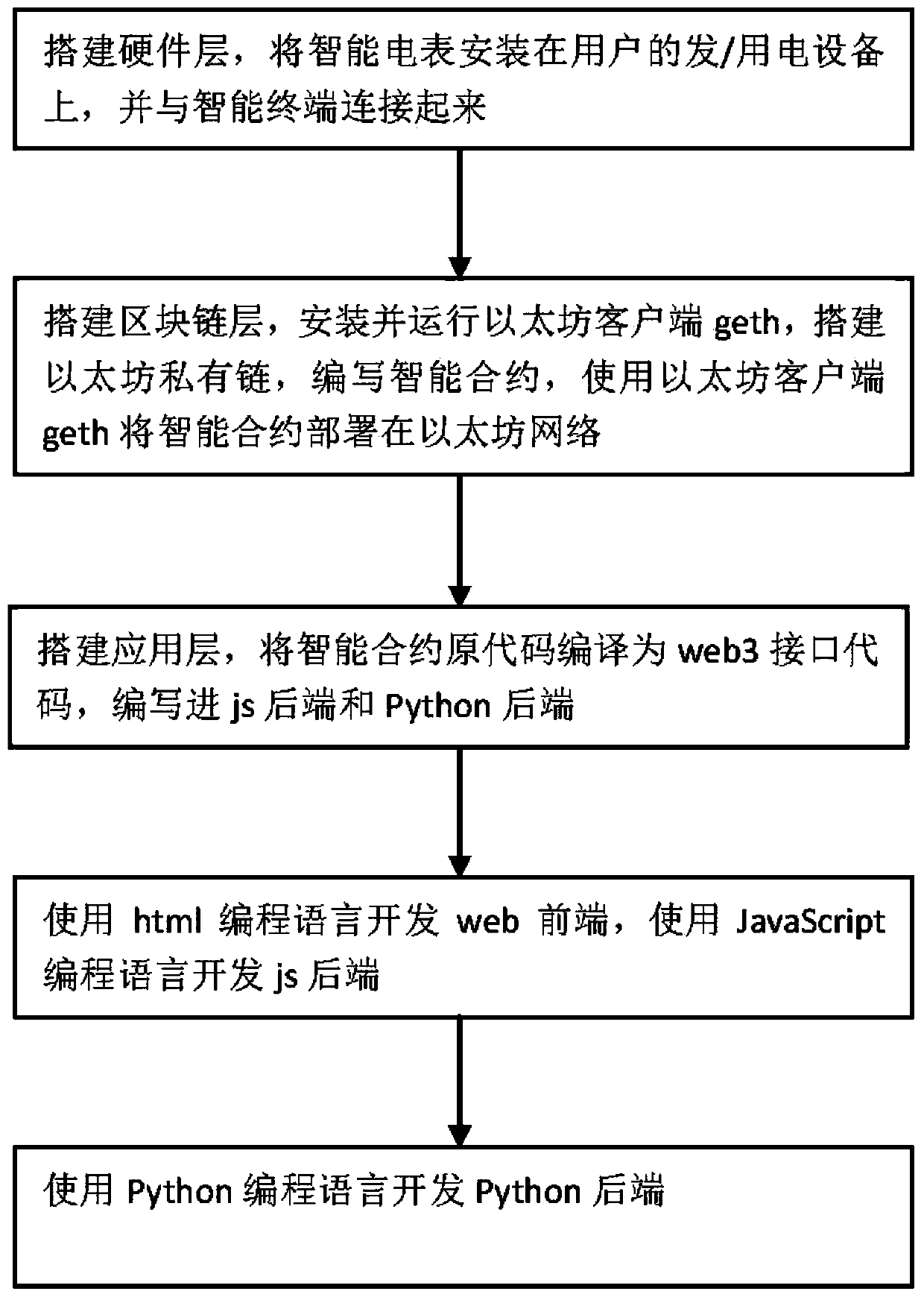

Distributed energy transaction communication platform based on block chain technology, a communication method and a construction method of the communication platform

PendingCN109872251AReduce communication response timeEfficient allocationFinanceSystems intergating technologiesCommunication ResponseEngineering

The invention relates to a distributed energy transaction communication platform based on block chain technology, a communication method and a construction method of the communication platform. The communication platform comprises three layers, a hardware layer, an application layer and a block chain layer, the hardware layer comprises power generation / utilization equipment of a user; Intelligentelectric meter and intelligent terminal, the block chain layer comprises an intelligent contract; wherein the intelligent contract is a digital transaction rule; the application layer is composed of aweb front end; the js rear end and the Python rear end form a distributed application; wherein the web front end is used for realizing mutual communication of the hardware layer, the application layer and the block chain layer, the web front end is used for receiving declaration information and transaction information input by a user, the js rear end remotely calls an intelligent contract, the declaration information and the transaction information are input, and the Python rear end remotely calls the intelligent contract and inputs electric quantity information. According to the technical scheme of the invention, communication transmission of producer information in the distributed energy transaction market is realized, the effect of multi-information fusion communication is achieved, the communication response time is shortened, and efficient distribution and reasonable utilization of energy are realized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

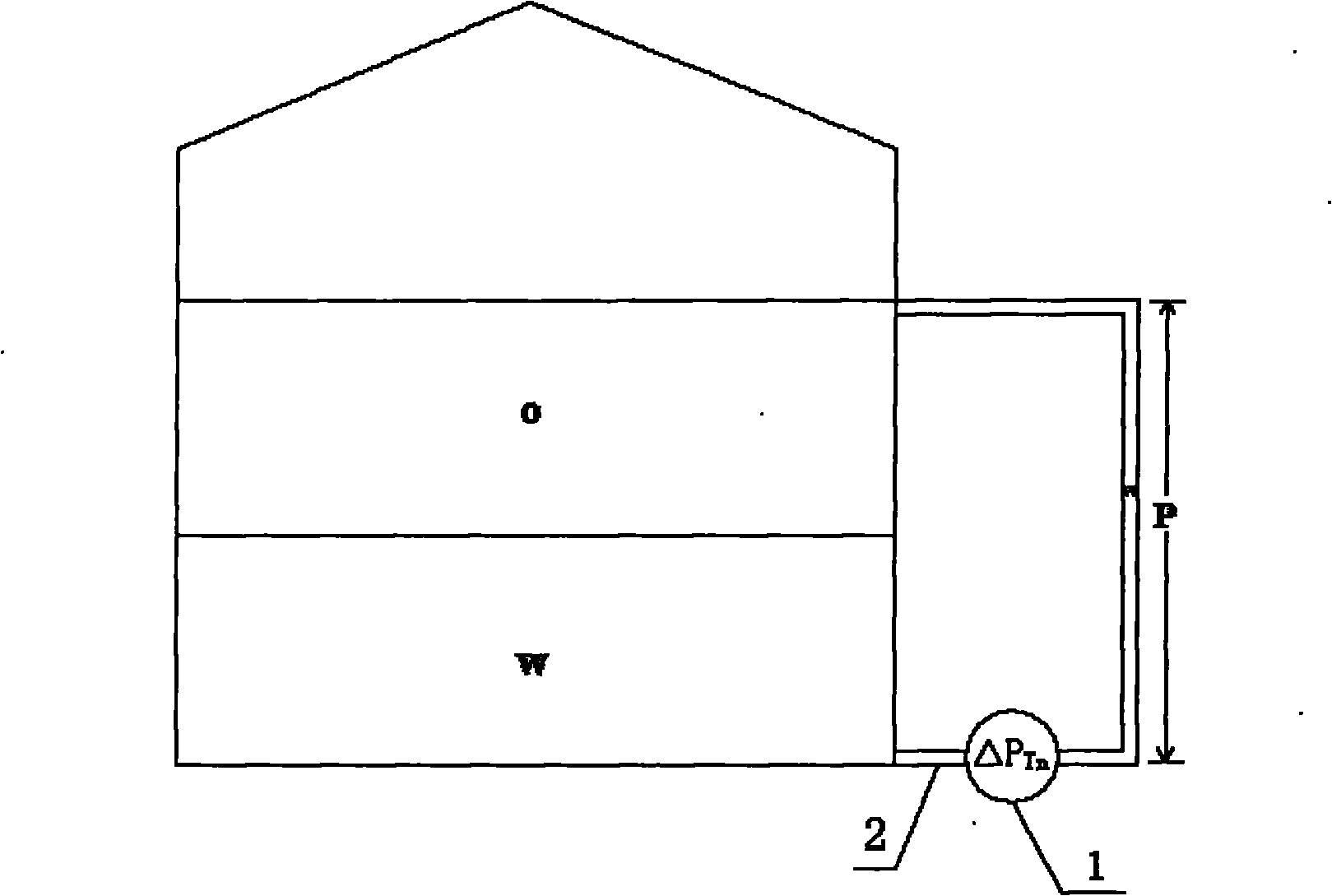

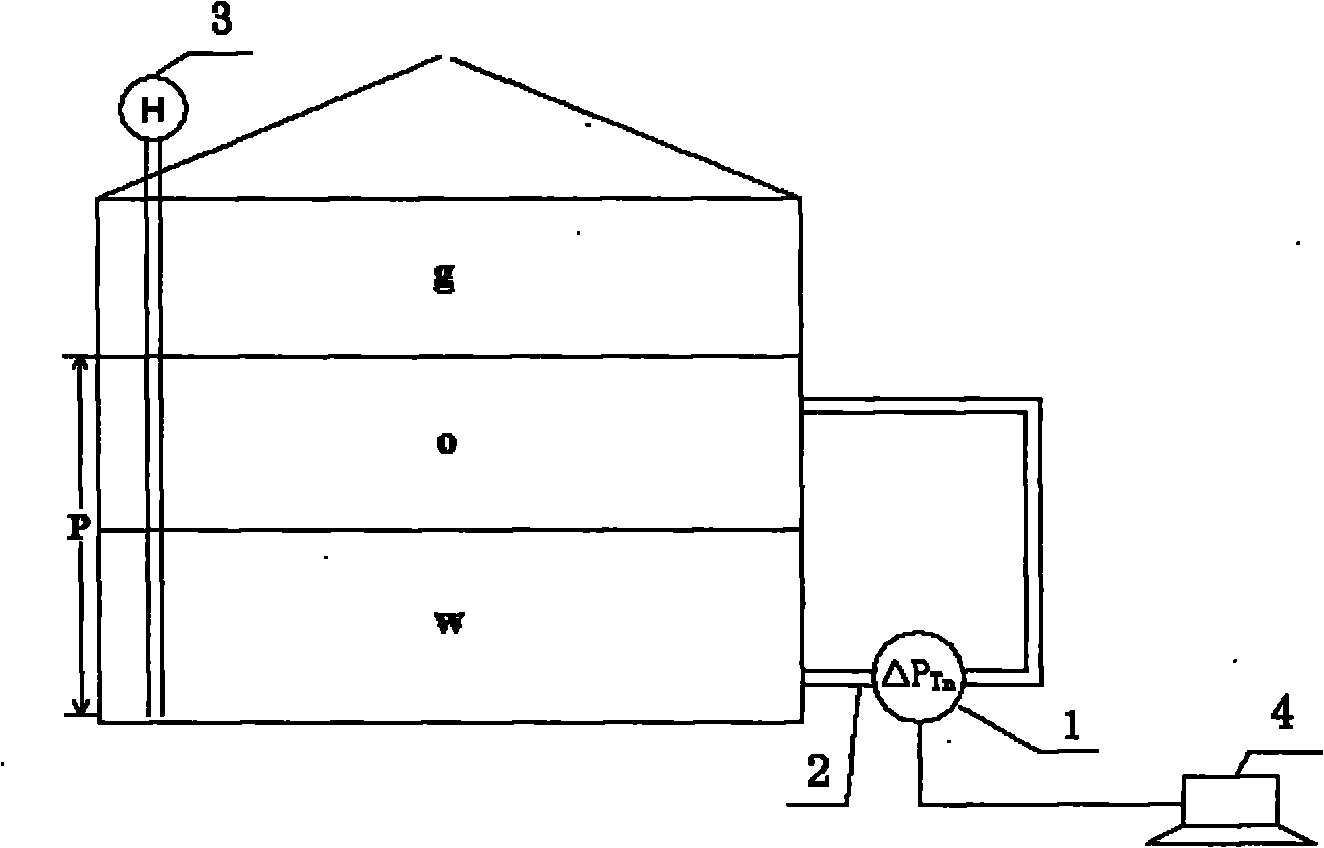

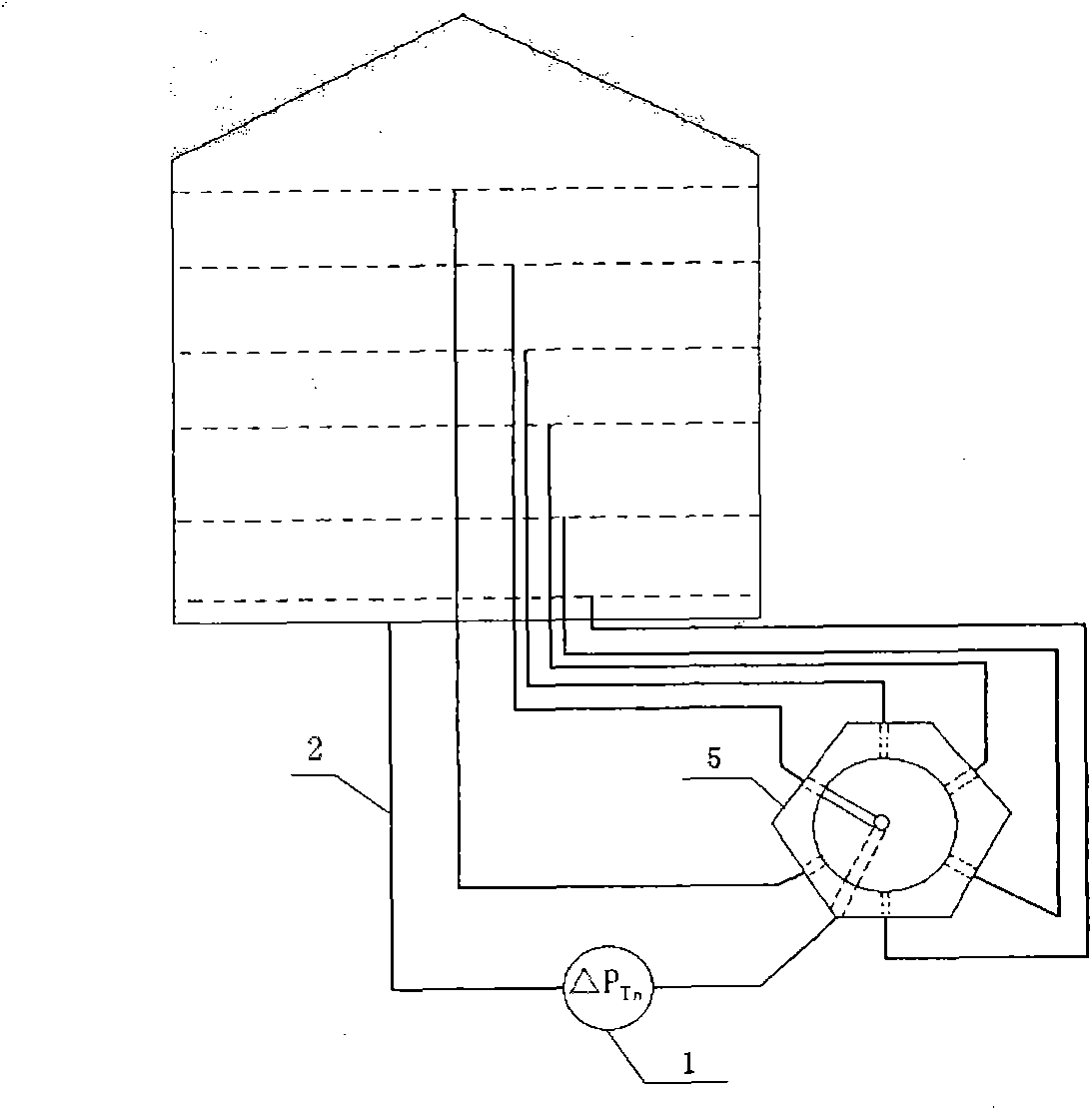

Method for accurately metering oil input of oil field united station

InactiveCN101852637AHigh precisionAutomatic inventory heightLevel indicators by pressure measurementDifferential pressureBuffer tank

The invention discloses a method for accurately metering oil input of an oil field united station, which is used for the metering of crude oil of the oil field united station. In the method, a differential pressure method is adopted, the temperature of a pressure pipe is kept equal to that of a sedimentation tank by arranging the pressure pipe inside and outside the tank, and all absolute oil and all water in an entire oil tank are considered as two wholes; a liquid level is supposed to be constant, only the variation of the absolute oil in the sedimentation tank is measured by using a dehydrator differential pressure metering device without measurement of the total amount of oil and water in the sedimentation tank. The method consists of a sedimentation tank differential pressure metering method, a buffer tank differential pressure metering method and a dehydrator differential pressure metering method or consists of a sedimentation tank differential pressure method, a buffer tank differential pressure method and a dehydrator differential pressure method and is implemented through a sedimentation tank differential pressure method device, a buffer tank differential pressure method device and a dehydrator differential pressure method device. The device consists of a differential pressure sensor, a pressure pipe, a liquid level meter, a computer, a multidirectional pressure valve, a multidirectional pressure valve seat and a multidirectional pressure valve faucet, wherein the differential pressure sensor is connected with the pressure pipe through a screw thread; the multidirectional pressure valve is connected with the pressure pipe through a screw thread; and the multidirectional pressure valve seat is in tolerance fit with the multidirectional pressure valve faucet. The method solves the problems of high labor intensity and big metering error existing in a conventional method and can be widely applied to crude oil metering operation of the oil field united station.

Owner:张殿华

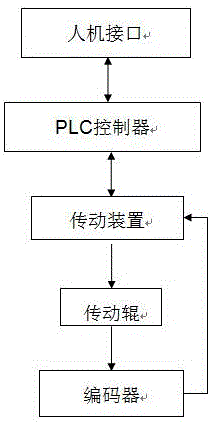

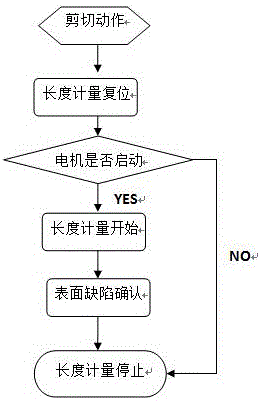

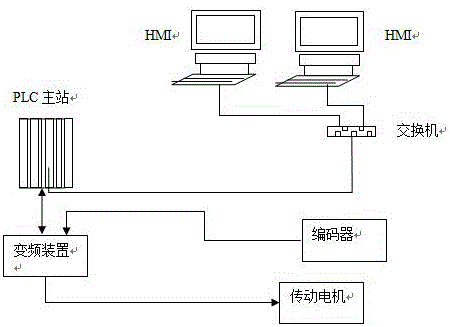

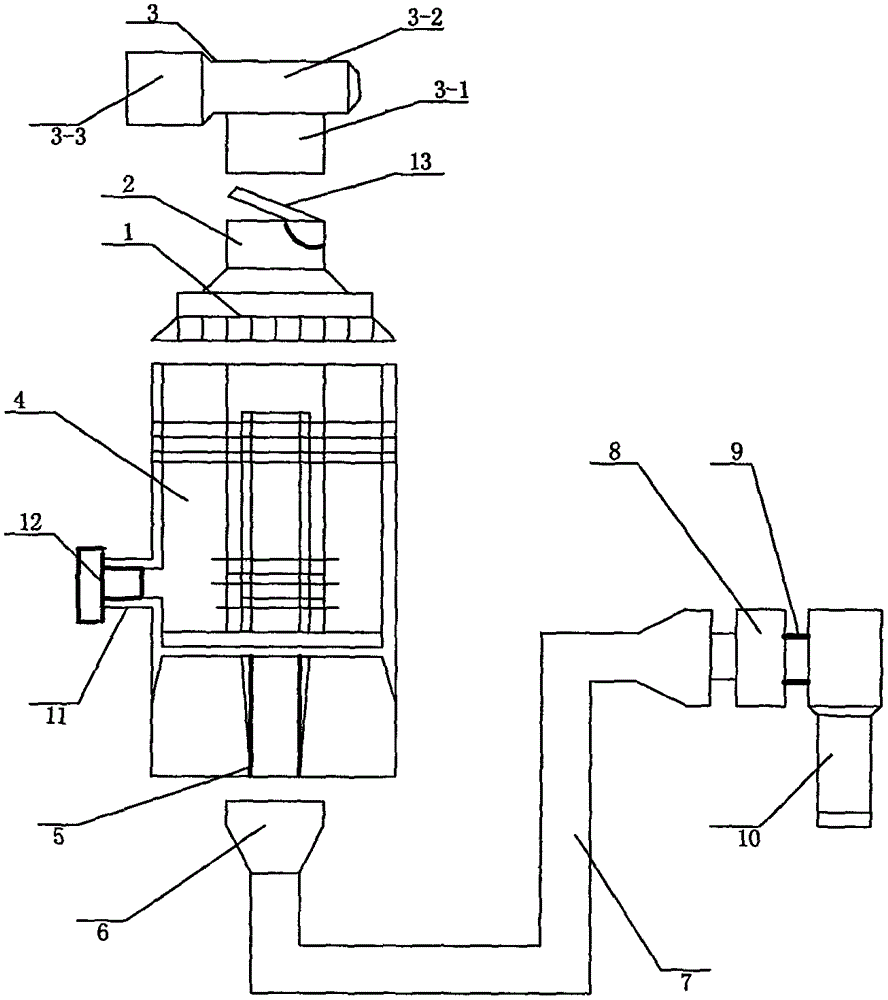

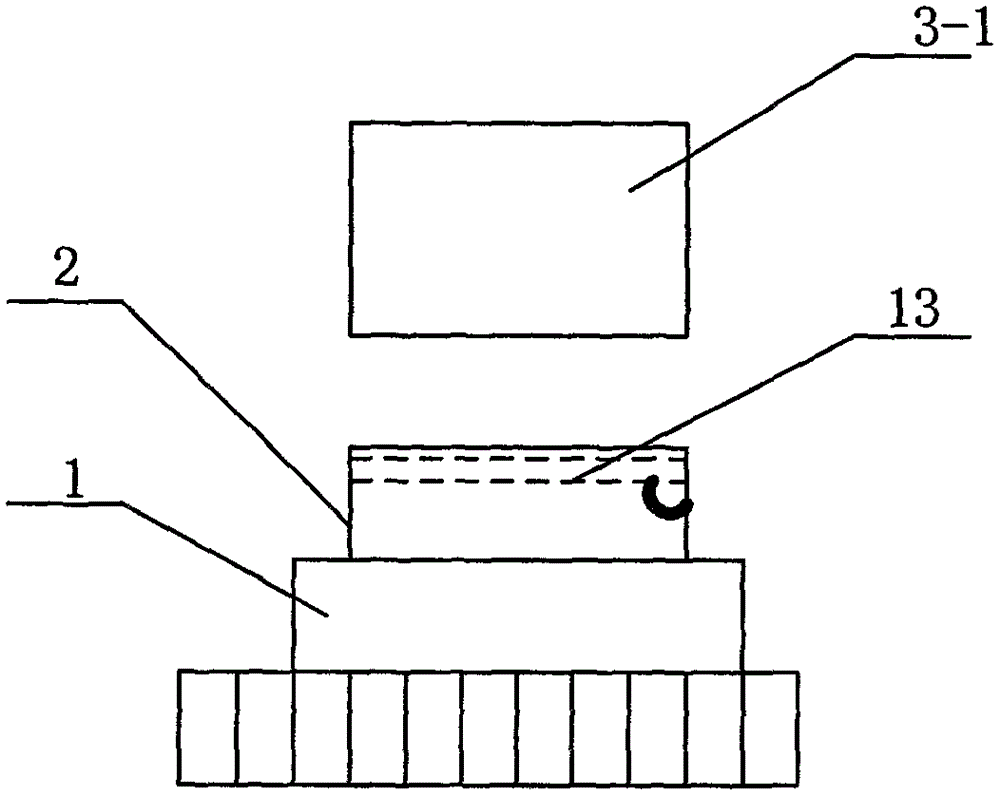

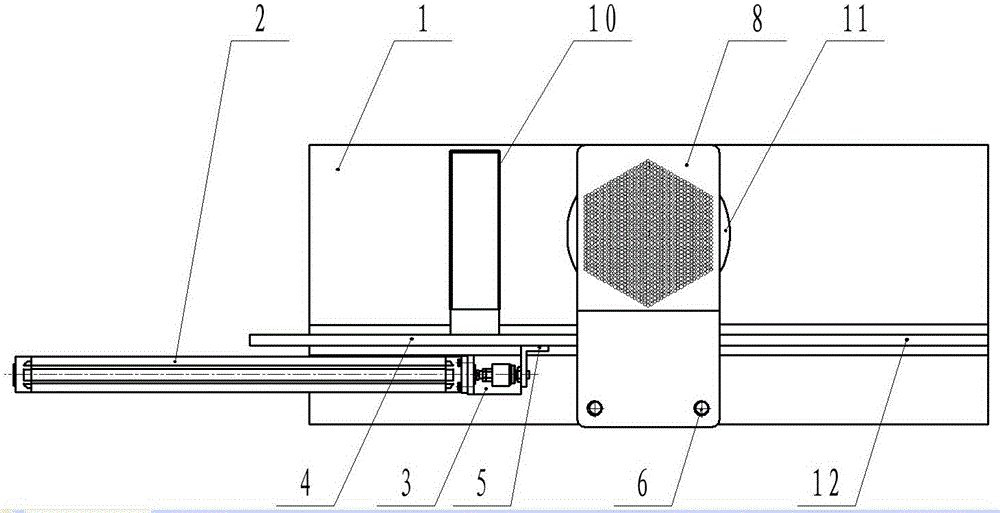

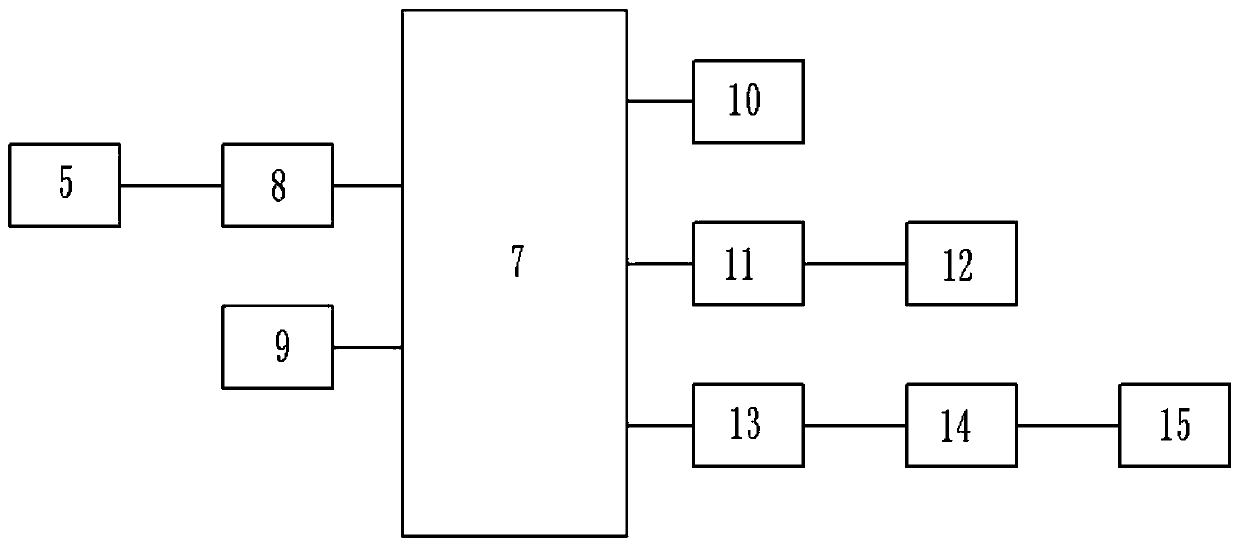

Novel length measuring system

ActiveCN106311766ARealize automatic meteringMeasuring devicesMetal rolling arrangementsHuman–machine interfaceVisual inspection

The invention discloses a novel length measuring system. The novel length measuring system is characterized by comprising a coder detection unit, a transmission unit, a PLC control unit and a human-machine interface HMI, wherein the coder detection unit measures the transmission length of a to-be-detected object strip plate, the transmission unit is arranged between the PLC control unit and the human-machine interface HMI, and the coder detection unit is mainly composed of a coder which is mounted at the shaft end of a main motor, and synchronously rotates with the main motor. The system can automatically measure the length of the strip plate and locate the strip plate in quality inspection. When a hot rolled strip plate which is annealed and acid-pickled is conveyed and transported to a quality inspection table, if a quality inspection person finds surface defects or other quality problems, the quality inspection person will press down a stop button and confirm the surface quality problems, and meanwhile, a PLC system calculates the length distance from the surface defect part to the head of the strip plate and the length distance is stored and displayed in an industrial personnel computer.

Owner:PANYU ZHUJIANG STEEL PIPE LIANYUNGANG

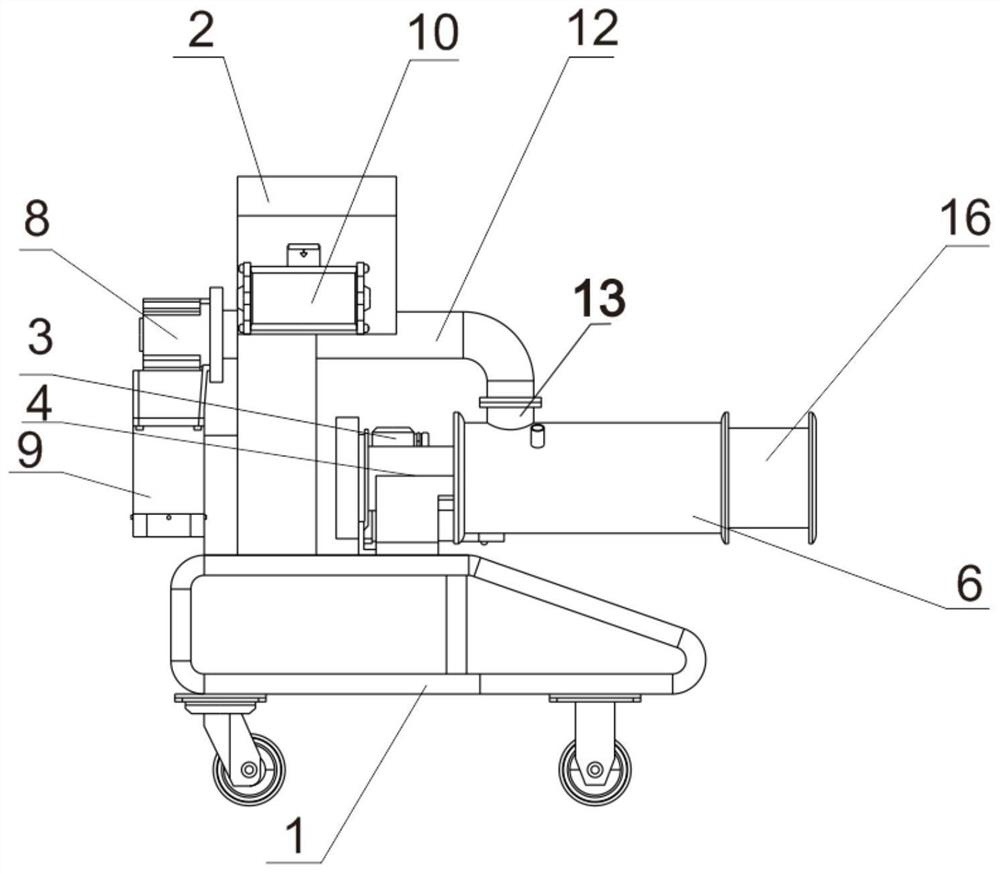

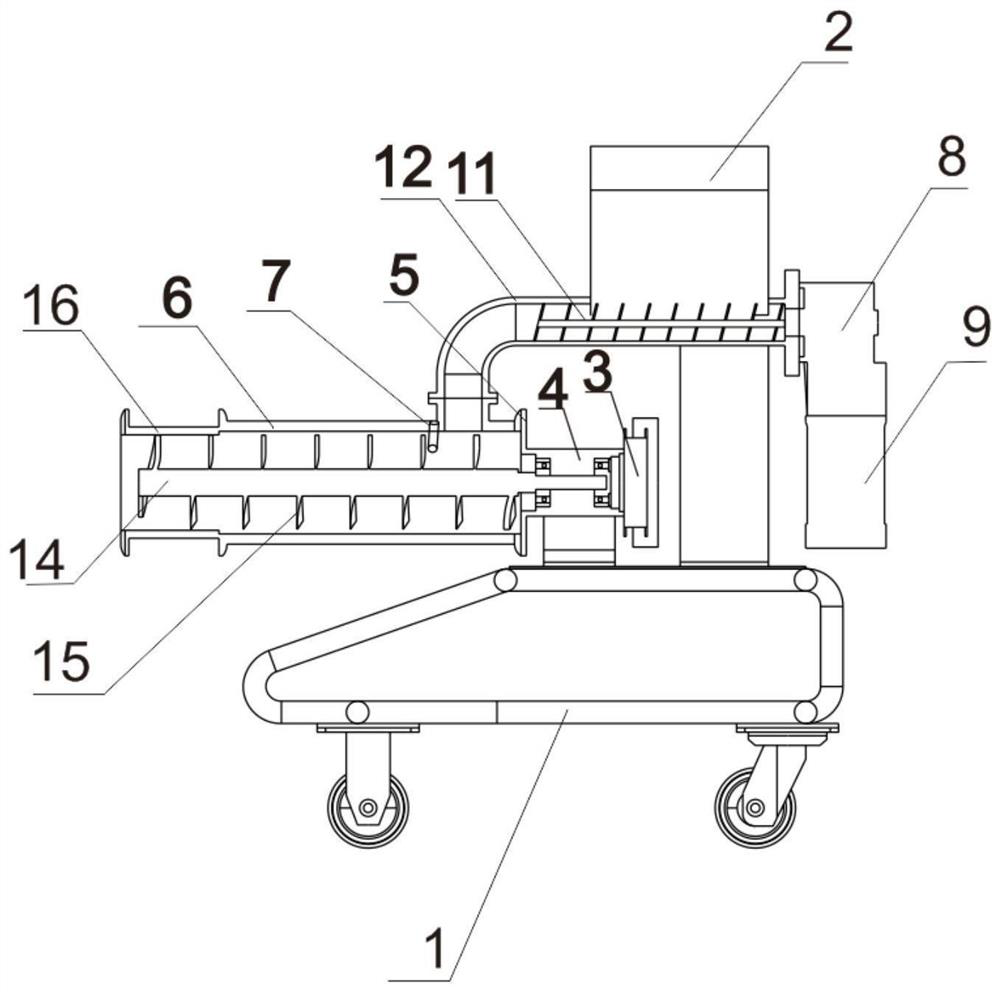

Intelligent atomizing device of breathing machine

InactiveCN105457136ANo Interfering Oxygen ConcentrationNo Interference Tidal VolumeRespiratorsMedical devicesTidal volumeEngineering

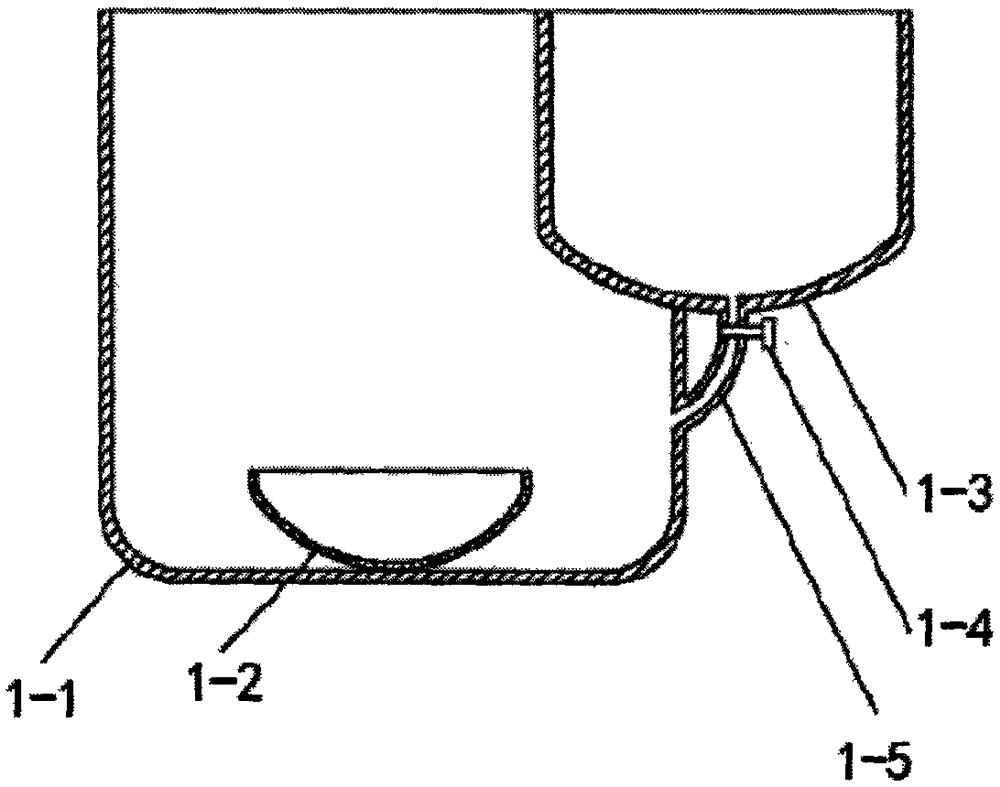

The invention discloses an intelligent atomizing device of a breathing machine. An atomizer is spirally installed at the upper end of a volume cup. An upper end cover is installed on the top of the atomizer. A one-way valve is arranged on the upper end cover and sleeved with a connecting pipe. A discharge port is formed in the side wall of the volume cup. A rubber plug is arranged in the discharge port. A gas inlet port is formed in the lower end of the volume cup and sleeved with a connecting port. The connecting port is connected with a gas flow controller through a guide pipe. The gas flow controller is connected with the port of the breathing machine through a flow division port. Gas flow power used by the atomizing device comes from the breathing machine, flow speed is stable, flow is more precise compared with the prior art, the oxygen concentration and tidal volume of the breathing machine during treatment are not influenced, the safety of patients is ensured, and it can be ensured that medical work and nursing work are smoothly conducted; in the medicine addition process, by means of the discharge port in the outer side of the volume cup, the upper cover of the atomizer does not need to be opened, and ventilation continuity can be ensured.

Owner:李振翮

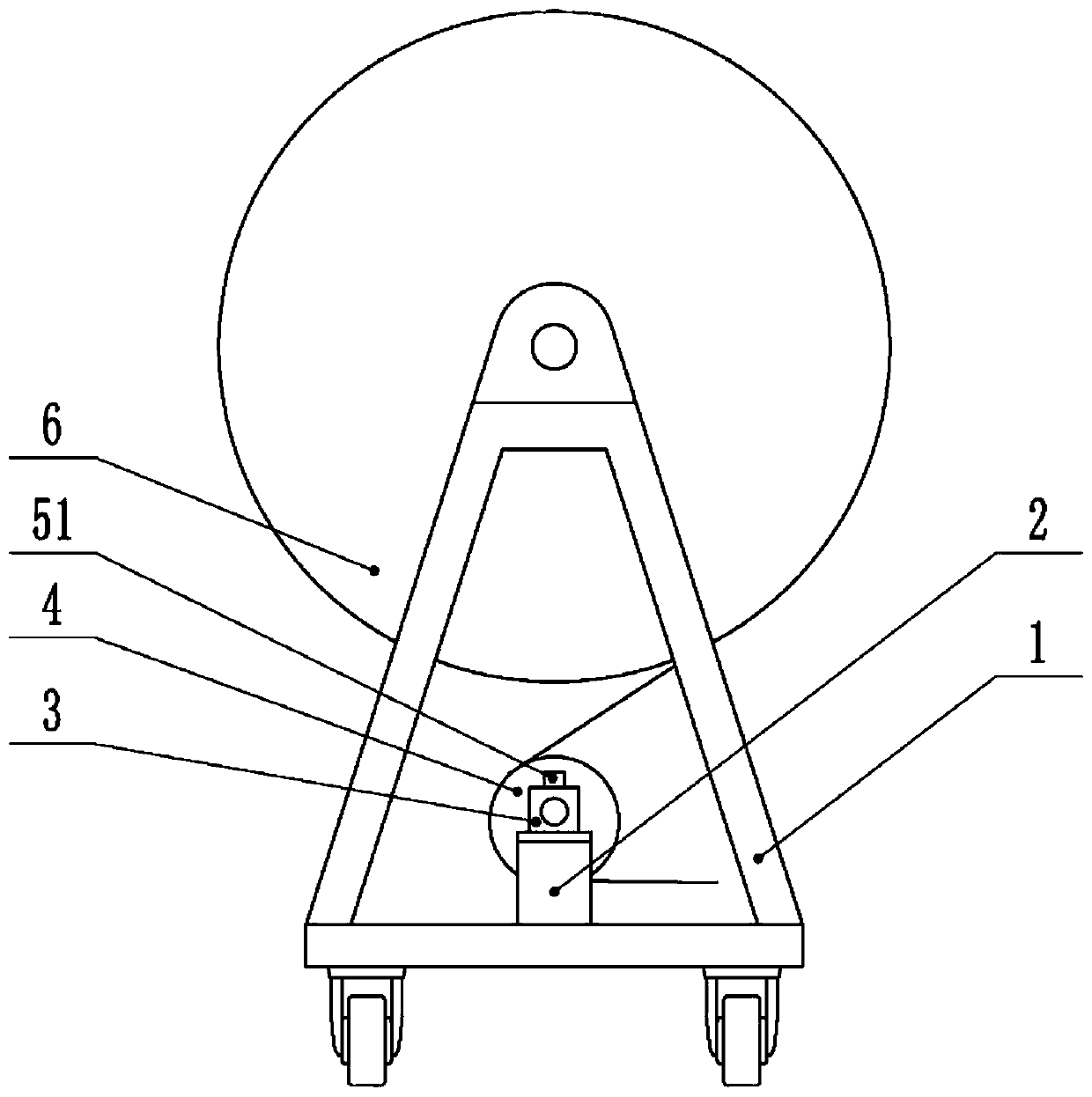

Automatic steel wire winding device

ActiveCN107150075AAvoid breakingRealize automatic meteringMetal working apparatusStopped workEngineering

Owner:SHANGHAI HEKE EQUIP MFG

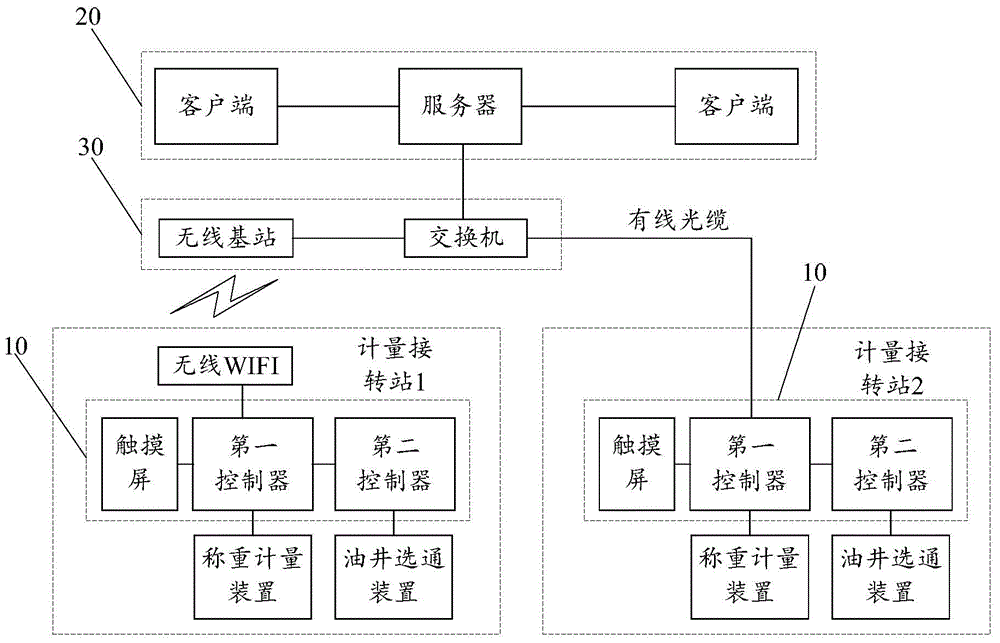

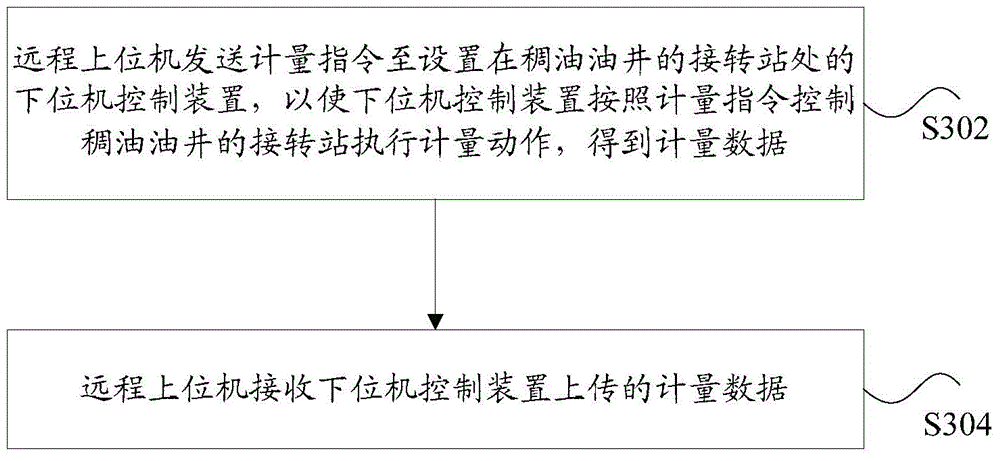

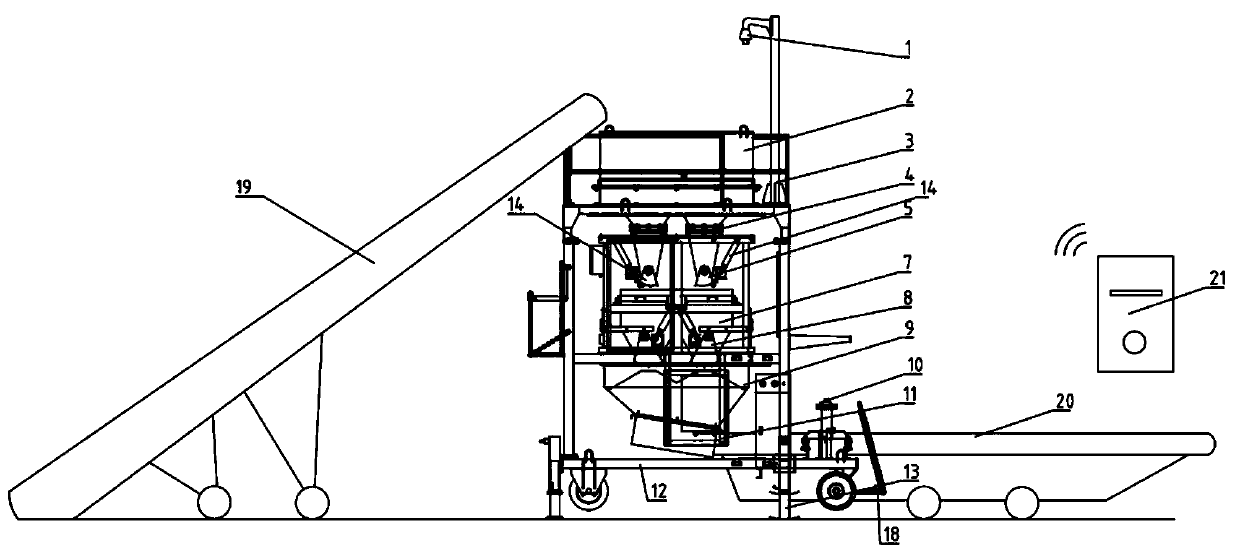

Heavy oil metering system and method

InactiveCN105716700ARealize automatic meteringReduce labor intensityWeighing apparatus for materials with special property/formWired communicationOil well

The invention discloses a heavy oil metering system and a method. The heavy oil metering system comprises a lower computer control device, and a remote upper computer. The lower computer control device is arranged at a transfer station of a heavy oil well for receiving a metering order and controlling the transfer station to execute the metering operation according to the metering order to obtain the metering data; the remote upper computer is connected to the lower computer control device through a wired communication mode and / or a wireless communication mode for transmitting the metering order to the lower computer control device and receiving the metering data. The heavy oil metering system solves the problem that the heavy oil data metering work in the prior art is low in efficiency, and reduces the labor intensity of the staff and improves the working efficiency.

Owner:PETROCHINA CO LTD

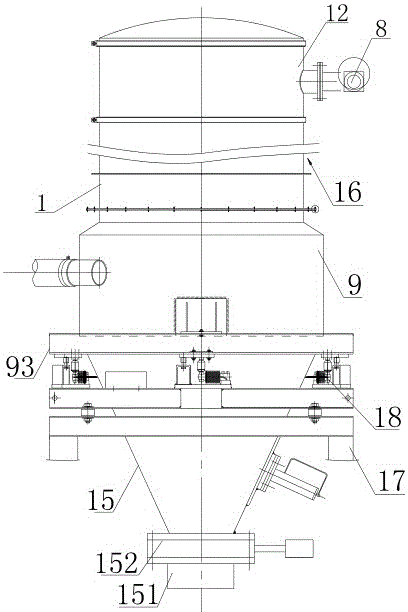

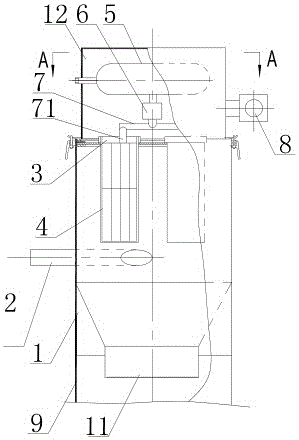

Bulk grain metering weighing system

InactiveCN110174163AImprove management efficiencyRealize automatic controlConveyorsWeighing apparatus for materials with special property/formManagement efficiencyInput/output

The invention discloses a bulk grain metering weighing system. The system comprises an input belt conveyor, a weighing system, a computer server, an output belt conveyor and a video monitoring device;the input belt conveyor conveys the grain to a weighing system, the weighing system is wirelessly connected with the computer server and transmits the weighing data to the computer server; the weighing system outputs the weighed grain through the output belt conveyor; and the video monitoring device is arranged on the weighing system. The combination of the discontinuous accumulative weighing metering and grain conveying of the grain warehouse-inputting and outputting is realized, the grain warehouse input-output transporting, warehouse changing and weighing problems are solved, the quantitative warehouse inputting-outputting, quantitative loading, automatic metering and like functions are realized, and then the data is uploaded to the computer server, the classification group querying and management can be performed on the data, and the management efficiency is improved.

Owner:JINAN JINZHONG ELECTRONICS SCALE

Automatic weighing type main material discharging device

The invention discloses an automatic weighing type main material discharging device. The automatic weighing type main material discharging device comprises a material collecting bin. The bottom of the material collecting bin is fixedly connected with a material collecting hopper. A discharging port is formed in the bottom of the material collecting hopper and provided with a discharging valve capable of controlling opening and closing of the discharging port. A vacuum feeder is arranged on the top of the material collecting bin and can convey main materials in a main material storage tank into the material collecting bin. The material collecting bin is arranged on the rack in a supporting manner, and at least two weighing sensors are arranged between the material collecting bin and the rack. The automatic weighing type main material discharging device has the beneficial effects that the vacuum feeder is utilized for conducting feeding on the material collecting bin, and the whole process is efficient, fast and free of raise dust; after feeding in the material collecting bin is over, the weighing sensors can transmit mass signals of the main materials in the material collecting bin outwards to a controller, and therefore automatic metering of the mass of the main materials in the material collecting bin is achieved; and by means of the metering manner, accuracy can be improved, the metering efficiency is also greatly improved, and therefore the plastic profile or pipe extrusion production efficiency is improved in an assisting manner.

Owner:张家港市繁昌机械有限公司

Converter steelmaking iron alloy smelting feeding weighing data collecting and monitoring system

ActiveCN103792922AEnsure effectivenessGuaranteed accuracyEnergy industryTotal factory controlSteelmakingInteraction interface

The invention discloses a converter steelmaking iron alloy smelting feeding weighing data collecting and monitoring system. The weighing data collecting and monitoring system comprises three weighting sensors which are arranged on the same horizontal plane on the outer portion of an iron alloy weighing hopper trolley and are arranged respectively through cylindrical pressing head mechanisms. The weighting sensors are connected with a secondary weighing instrument and a programmable logic controller in sequence, the programmable logic controller is connected with an industrial exchanger through the Ethernet, the industrial exchanger is respectively connected with a human-computer interaction interface and an ERP server, and the ERP server is connected with a plurality of clients. The converter steelmaking iron alloy smelting feeding weighing data collecting and monitoring system is accurate in data collecting, objective in recording, capable of conducting displaying in real time, capable of transmitting collected monitoring data into a production cost management system of a steel plant and capable of conducting data secondary development and utilization.

Owner:WUKUN STEEL

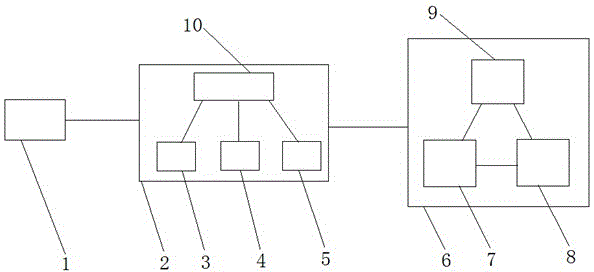

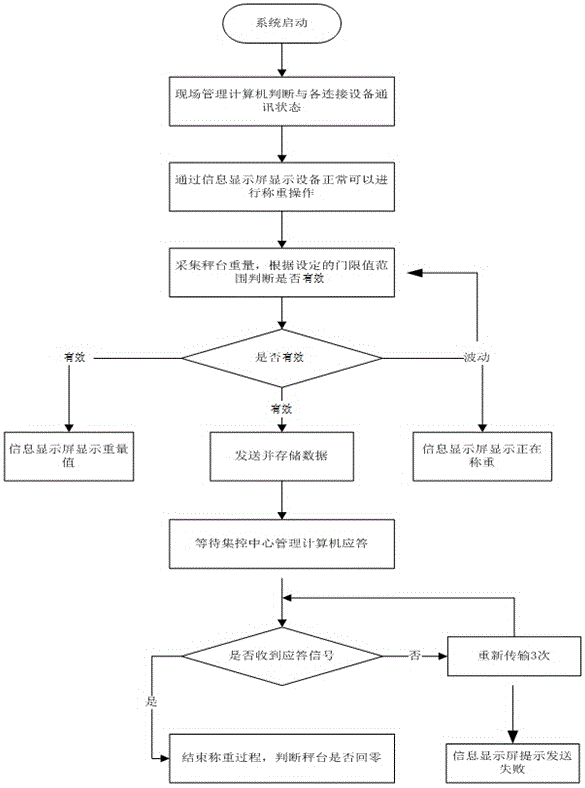

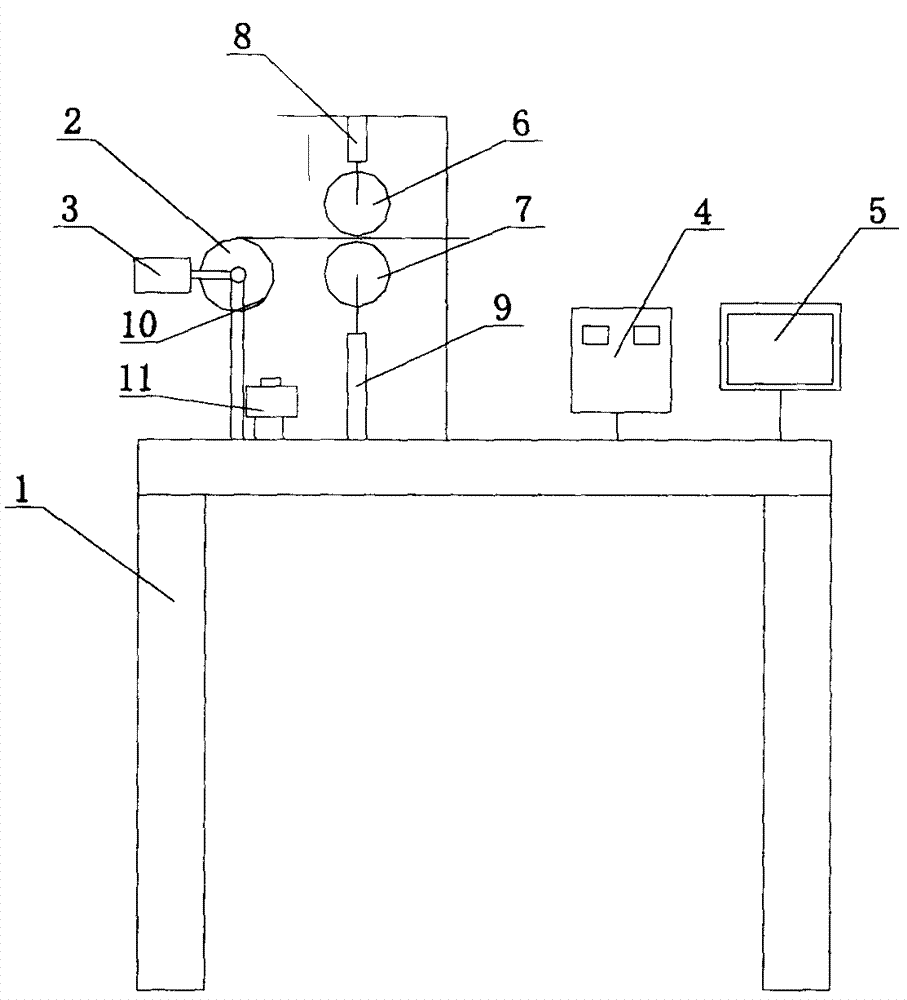

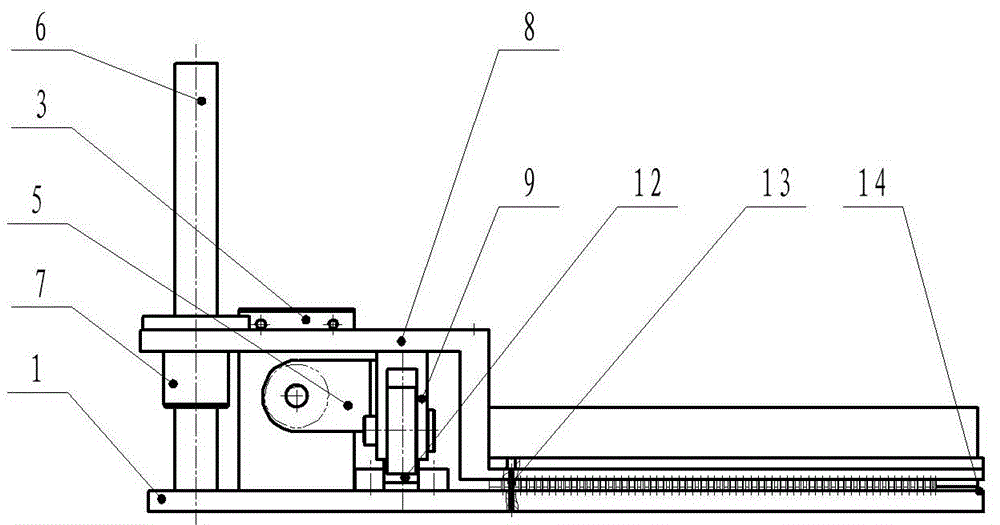

Remote automatic metering system for finished aluminum ingots and method thereof

InactiveCN105092005ARealize automatic meteringReduce labor intensitySpecial purpose weighing apparatusWork periodIngot

The invention discloses a remote automatic metering system for finished aluminum ingots and a method thereof. The remote automatic metering system for the finished aluminum ingots comprises a digital buffer electronic platform scale, a field management computer and a centralized control center management computer. The digital buffer electronic platform scale is electrically connected with the field management computer. The field management computer is in signal connection with the centralized control center management computer. The field management computer is composed of an information display screen, a state indicating lamp, a storage module and a field management module. The centralized control center management computer is composed of a monitoring image camera, a memory and a processing module; wherein the monitoring image camera, the memory and the processing module are interconnected. The remote automatic metering system for the finished aluminum ingots and the method have advantages of realizing automatic metering for the finished aluminum ingots in aluminum electrolysis, realizing no requirement for tedious and repeated operations such as data statistics, calculation and checking manually, greatly reducing labor intensity of workers, greatly improving labor productivity, greatly reducing error probability in a metering process, ensuring good continuous operation of the system, greatly simplifying a working flow, and reducing working time.

Owner:YUNNAN RUNXIN ALUMINUM

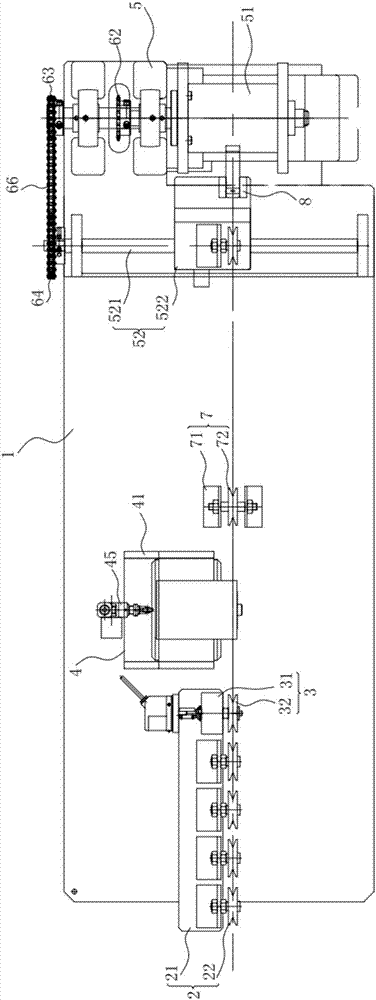

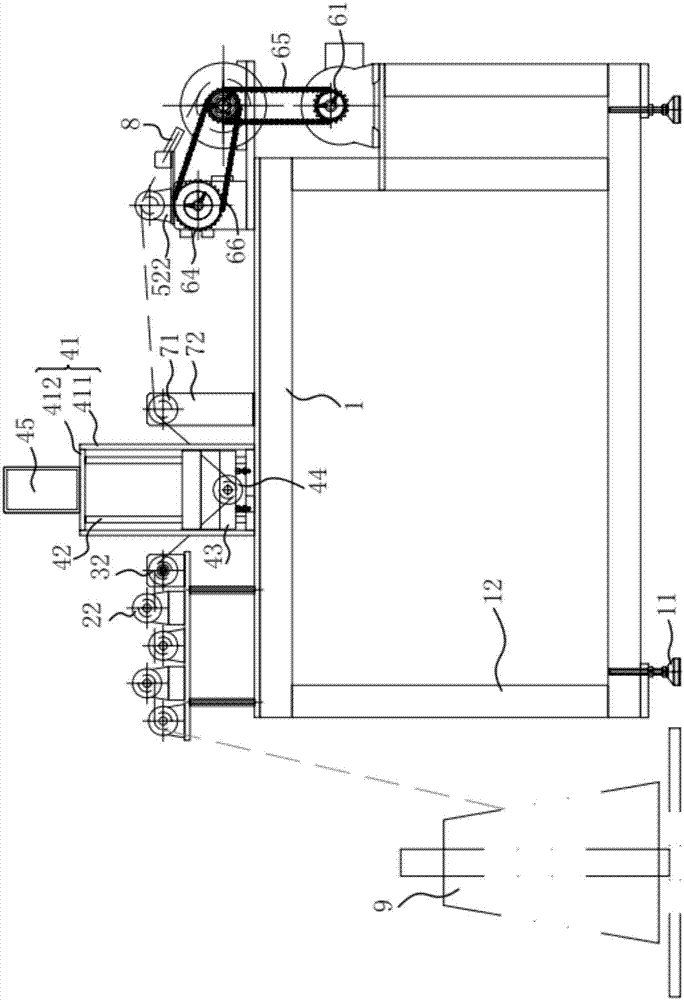

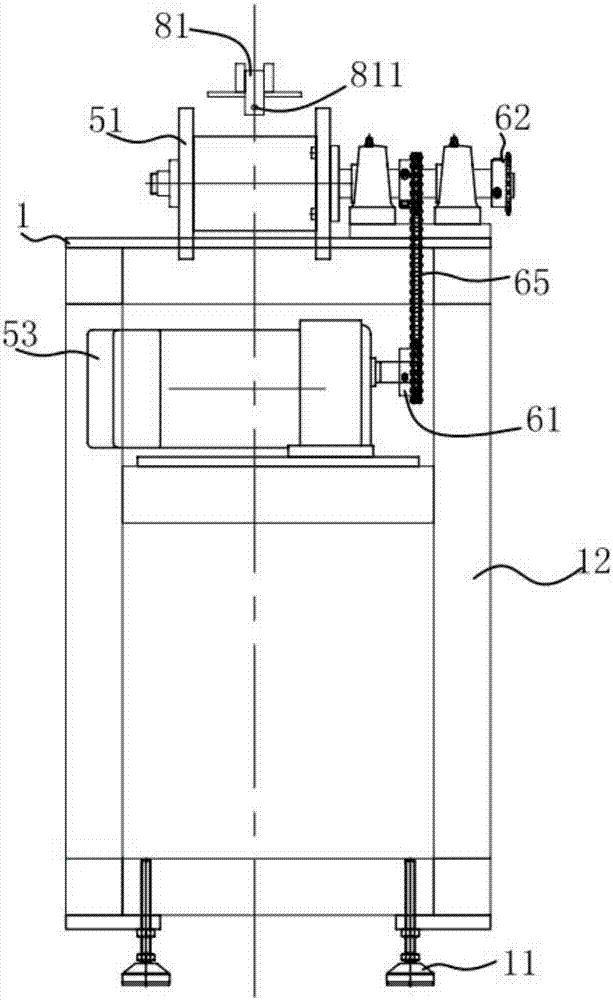

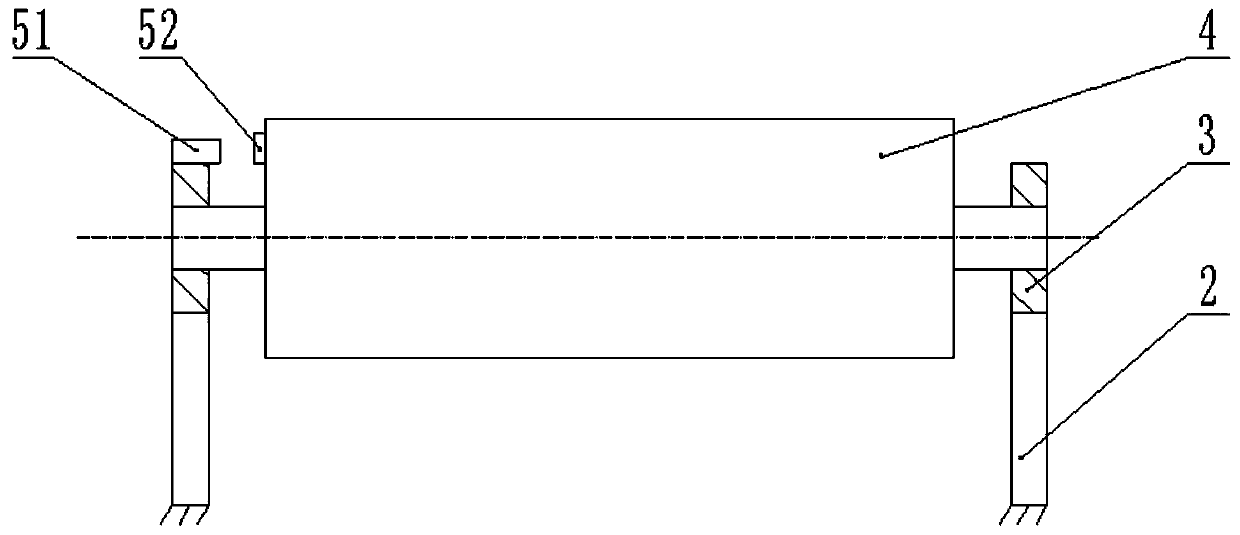

Unreeling device for manufacturing bamboo paper

InactiveCN104709750AAchieve flatnessReasonable design structureWebs handlingPaper sheetDisplay device

The invention relates to an unreeling device for manufacturing bamboo paper. The unreeling device for manufacturing the bamboo paper comprise a rack, an unreeling shaft, a driving system, a control box and an operation display, wherein the rack is used for supporting on the ground, the unreeling shaft is installed on the rack, the driving system is installed on the rack, the driving system is connected with the unreeling shaft, the control box is connected with the driving system, the operation display is connected with the driving system, an upper press roller and a lower press roller arranged opposite to the upper press roller are also installed on the rack, a gap is formed between the upper press roller and the lower press roller, an upper electronic regulator is connected between the upper press roller and the rack, a lower electronic regulator is connected between the lower press roller and the rack, and the upper electronic regulator and the lower electronic regulator are connected with the control box. The unreeling device for manufacturing the bamboo paper has the advantages that the design structure is reasonable, the automatic measuring of the unreeling amount is achieved, and the smoothness of the unreeled paper is achieved.

Owner:GUANGXI PROVINCE NANNING CITY ZHIJIANZHIFAN TECH CONSULTING

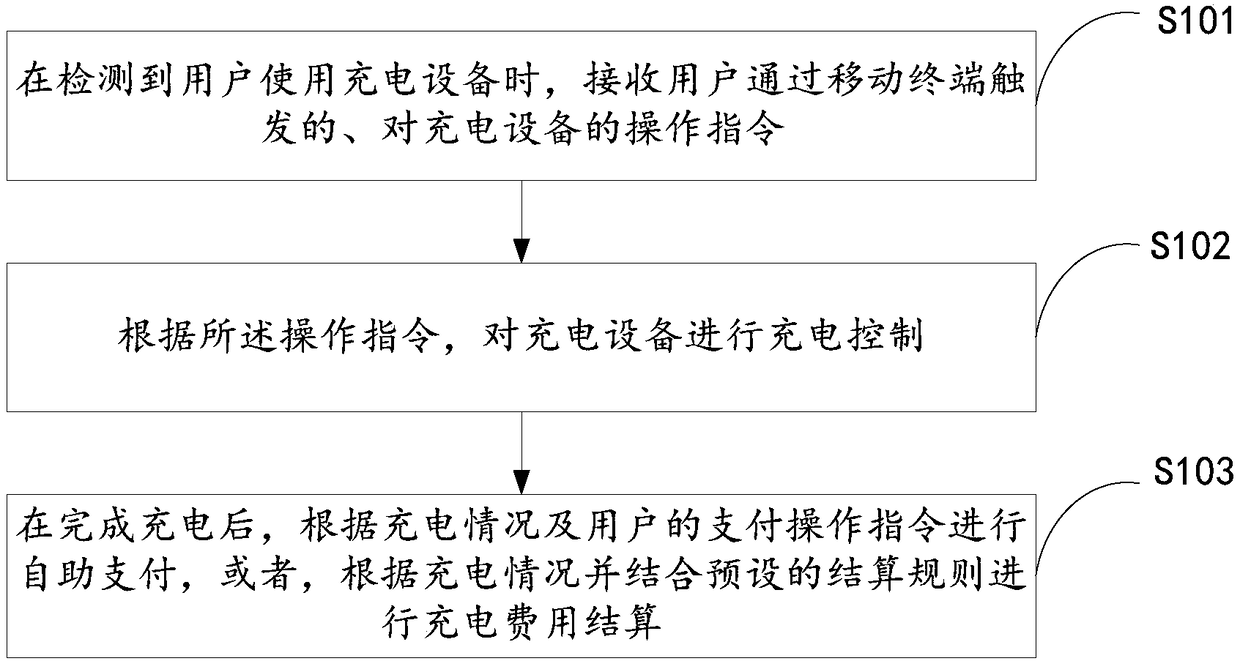

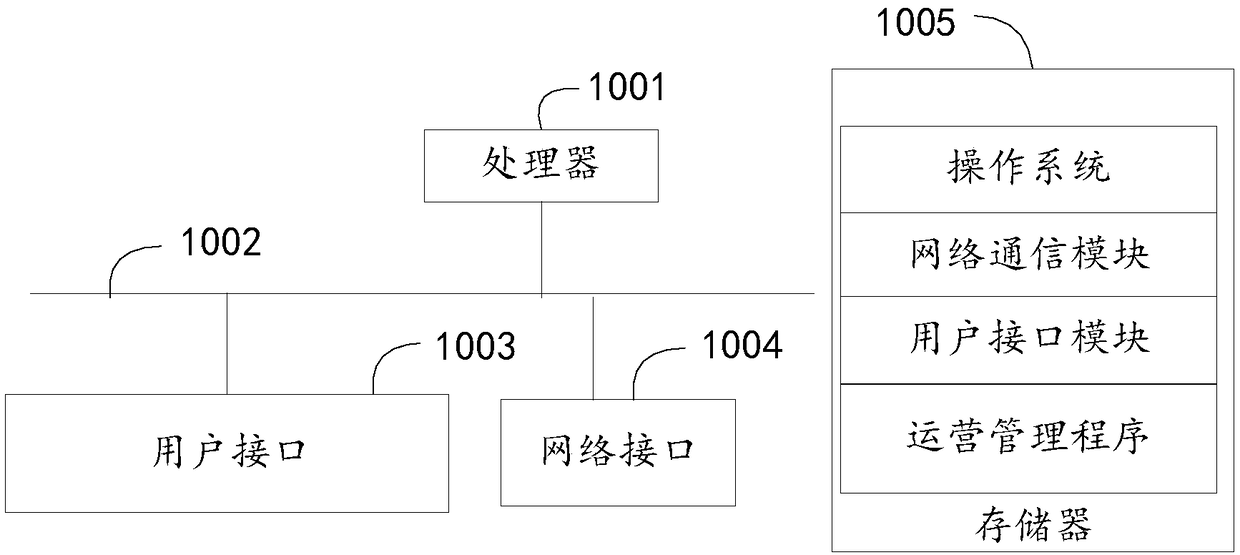

Method and system for managing operation of charging device, and storage medium

PendingCN109147193ARealize automatic meteringRealize self-service paymentApparatus for hiring articlesThird partyPayment

The invention discloses a method and system for managing operation of a charging device, and a storage medium. The method comprises the following steps: receiving an operation instruction for the charging device triggered by a user through a mobile terminal when detecting that the user uses the charging device; performing charging control on the charging device according to the operation instruction; and after the charging is completed, performing self-service payment according to the charging situation and the user's payment operation instruction, or performing charging fee settlement according to the charging situation and a preset settlement rule. The method and system for managing operation of the charging device, and the storage medium realize automatic measurement and self-service payment of the charging cost, and further make the property party and the management party immediately obtain the service fee income according to the predetermined profit sharing method through the third-party management end App and operation services provided by the third-party charging field device.

Owner:XIAN IRAIN IOT TECH SERVICES CO LTD

Metering device for mechanical light sensation combined redundant water quality monitor

PendingCN107782872AGuaranteed accuracyHigh precisionWithdrawing sample devicesTesting waterWater storageCoupling

The invention discloses a metering device for a mechanical light sensation combined redundant water quality monitor. The metering device comprises a motor, a lead screw, a piston rod, a piston cavity,an infrared range sensor, a photoelectric range sensor and a controller. The motor is connected with the lead screw through a coupler. The lead screw is connected with the piston rod through a lead screw pair. The piston rod moves leftwards and rightwards in a piston cavity. A water inlet pipe and a water outlet pipe are connected with the piston cavity. Two ends of the infrared range detector are mounted on opposite sides of the motor and the piston rod. The photoelectric range sensor is mounted above a water storage device and faces the interior of the water storage device. The controller is connected with the infrared range detector and the photoelectric range sensor electrically. The metering device has the advantages that the volume of sample water of water quality sampling can be controlled accurately, accuracy and automation in water quality sampling can be realized, and accordingly, accuracy of water quality detection results is improved.

Owner:CHINA UNIV OF MINING & TECH +1

Automatic gunpowder filling mechanism for firecrackers

The invention provides an automatic gunpowder filling mechanism for firecrackers. A power cylinder installing plate, a positioning groove and a column in the automatic gunpowder filling mechanism are fixedly installed on a table face plate. A power cylinder is fixedly installed on the power cylinder installing plate, an inclined plane block is placed in the positioning groove, and the front end of the power cylinder is connected with the inclined plane block through an installing block. A lifting plate is slidably installed on the column through a sliding bearing, the upper end of a sliding part is fixed on the bottom surface of the lifting plate, and the lower end of the sliding part is contacted with the inclined plane block. A gunpowder box is fixedly installed on the side of the inclined plane block, and a gunpowder scraping block is installed on the lower end face of the gunpowder box. A measurement plate is arranged below the lifting plate and installed on the table face plate in an embedded mode. The gunpowder scraping block is contacted with the measurement plate. The automatic gunpowder filling mechanism for the firecrackers is simple in structure and convenient to use, firecracker gunpowder can be automatically measured and filled, production safety and production efficiency are improved.

Owner:中国兵器装备集团自动化研究所有限公司

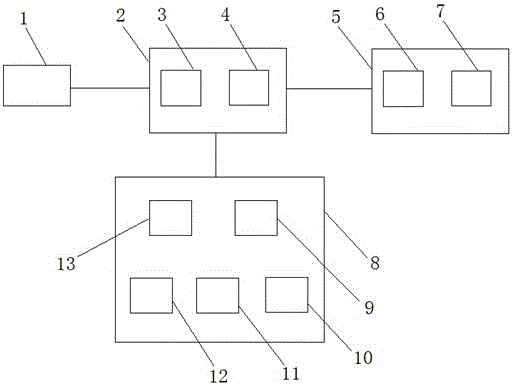

Remote automatic metering system and remote automatic metering method for virgin aluminum

InactiveCN105091999ARealize automatic meteringAchieve sharingWeighing indication devicesSpecial purpose weighing apparatusElectricityInformation resource

The invention provides a remote automatic metering system and a remote automatic metering method for virgin aluminum. The remote automatic metering system comprises an automotive balance, an intelligent terminal, a centralized control center management computer and peripheral auxiliary equipment. The automotive balance is electrically connected with the intelligent terminal. The intelligent terminal is in signal connection with the centralized control center management computer. The intelligent terminal is electrically connected with the peripheral auxiliary equipment. The intelligent terminal comprises a storage module and a control module. The centralized control center management computer comprises a memory and a processor. The intelligent terminal finishes weight data acquisition, peripheral equipment signal acquisition, weighing motion judgment and data transmission with the centralized control center management computer. The centralized control center management computer acquires metering data which are transmitted after weighing of the automotive balance and performs processing such as comparing, matching and storage on the data. The remote automatic metering system and the remote automatic metering method have advantages of realizing automatic metering for the virgin aluminum, improving accuracy and real-time property of virgin aluminum metering data, realizing sharing of virgin aluminum metering information resource, reducing stock amount, improving virgin aluminum metering efficiency, and realizing more reasonable, standard and scientific performance.

Owner:YUNNAN RUNXIN ALUMINUM

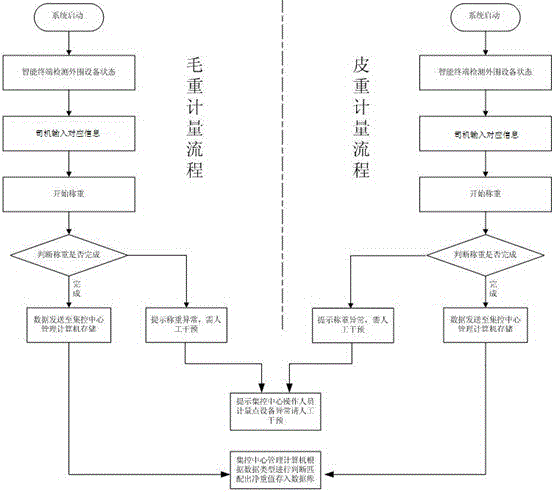

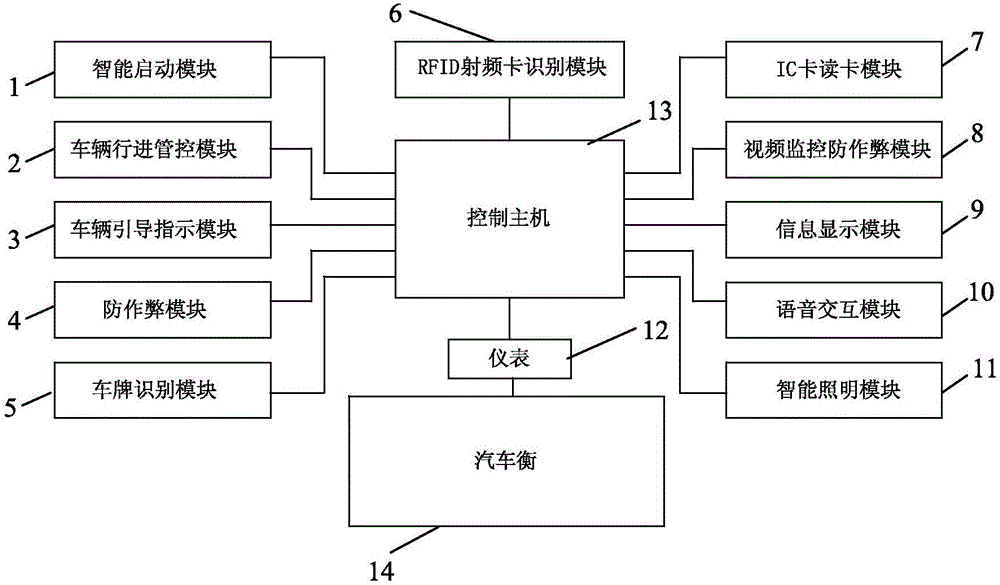

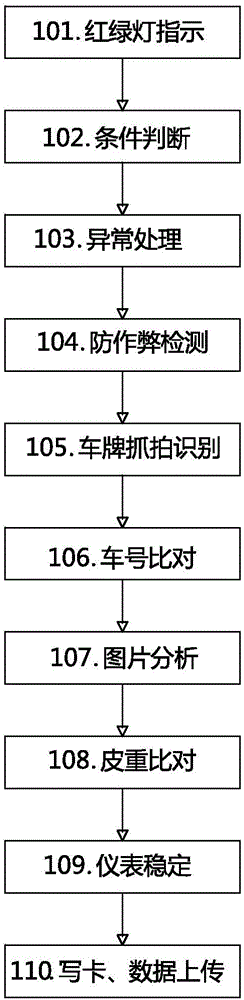

Intelligent unattended automatic metering system and metering method for warehouse entry and exit

ActiveCN103576648BAvoid failureEliminate Tare CheatingProgramme total factory controlIntelligent lightingVideo monitoring

Owner:JINAN JINZHONG ELECTRONICS SCALE +1

Cement concrete continuous stirring and discharging equipment and application thereof

PendingCN113427632ARealize automatic meteringDischarging apparatusMixing operation control apparatusStructural engineeringControl valves

The invention discloses cement concrete continuous stirring and discharging equipment and application thereof. The equipment comprises a machine body support, a powder hopper and a first power device are arranged on the machine body support, a first gearbox and a fixing plate are sequentially and fixedly connected to the first power device, a pipe barrel is detachably connected to the fixing plate, a liquid inlet is formed in the wall of the pipe barrel, a control valve is arranged on the liquid inlet, a stirring propelling device is arranged in the pipe barrel and connected with a first power device through the first gearbox, a powder propelling device is arranged at the bottom of the powder hopper, one end of the powder propelling device is detachably connected with the pipe barrel, and the other end of the powder propelling device is sequentially connected with a second gearbox and a second power device. The equipment can effectively solve the problems that existing equipment cannot achieve automatic metering and continuous discharging and is difficult to clean.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

Coal-fired boiler measuring system

The invention relates to the field of coal-fired boilers, in particular to a device for weighing and measuring a coal-fired boiler. The technical problem to be solved is to provide a coal-fired boiler measuring system which has the advantages of saving a great deal of labor, time and energy, along with convenient use and accurate measurement. The coal-fired boiler measuring system comprises a coal bucket, a support bar and a wire sling. The wire sling is connected to the support bar which is hinged on the coal bucket. The coal-fired boiler measuring system also comprises a tension sensor for weighing and a control instrument which is connected to the tension sensor. The tension sensor can be connected in series with the wire sling, or fixedly connected in series with the support bar, or arranged on a pin shaft of the support bar and the coal bucket. The coal-fired boiler provided with the measuring device has the advantages of convenient use and accurate measurement in the aspect of measuring the consumption of fire coal, and the labor, time and energy can be greatly saved simultaneously.

Owner:重庆大唐科技股份有限公司 +1

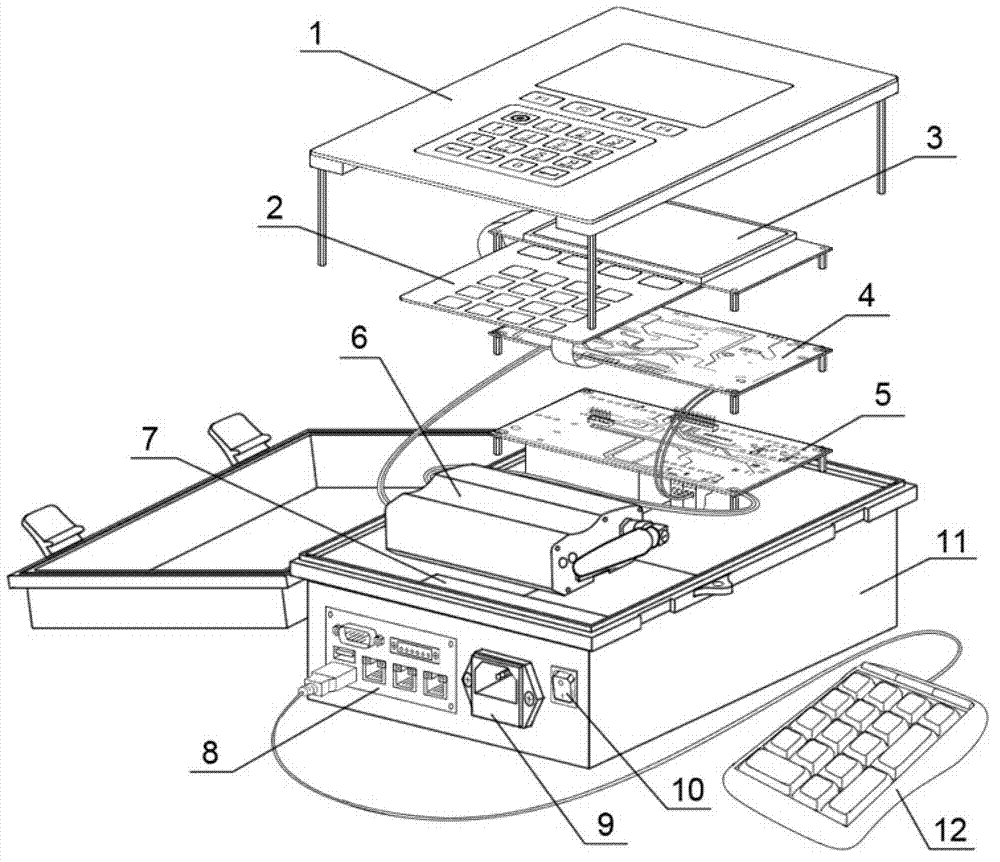

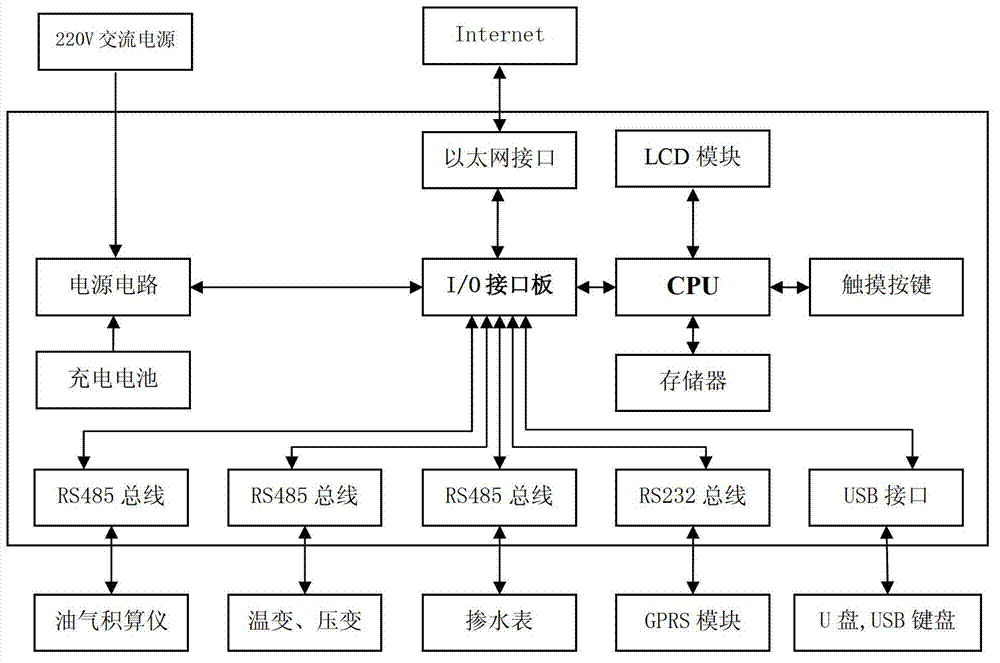

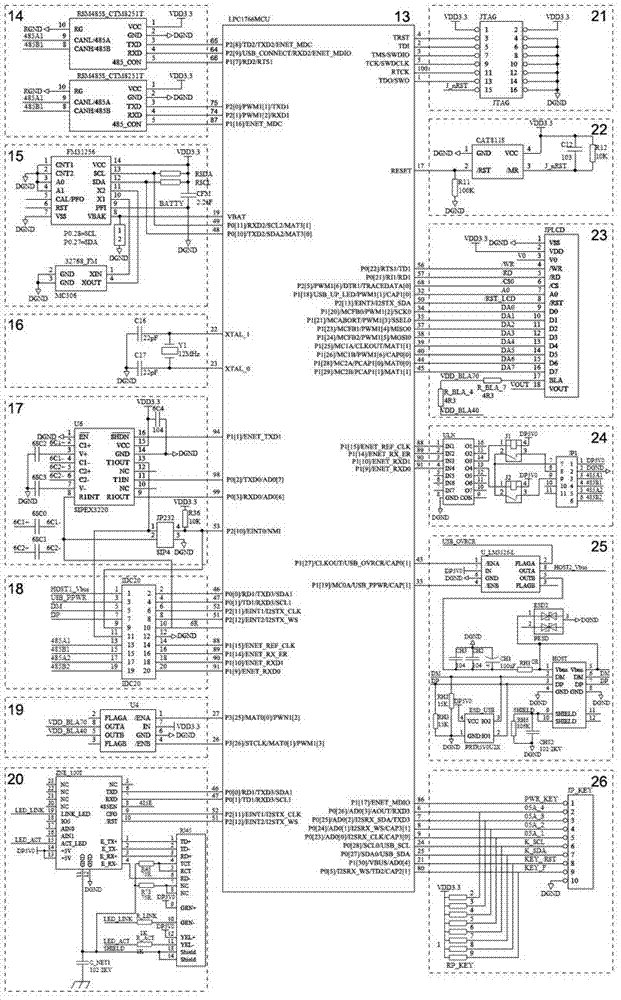

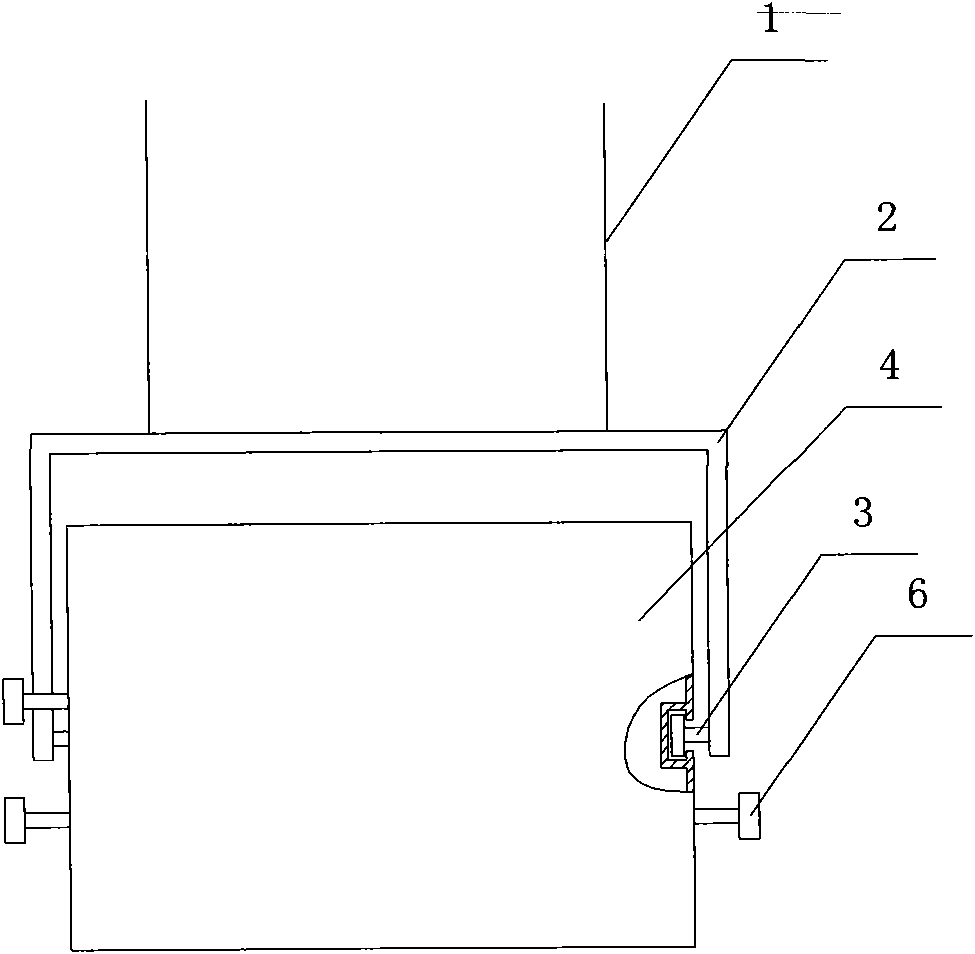

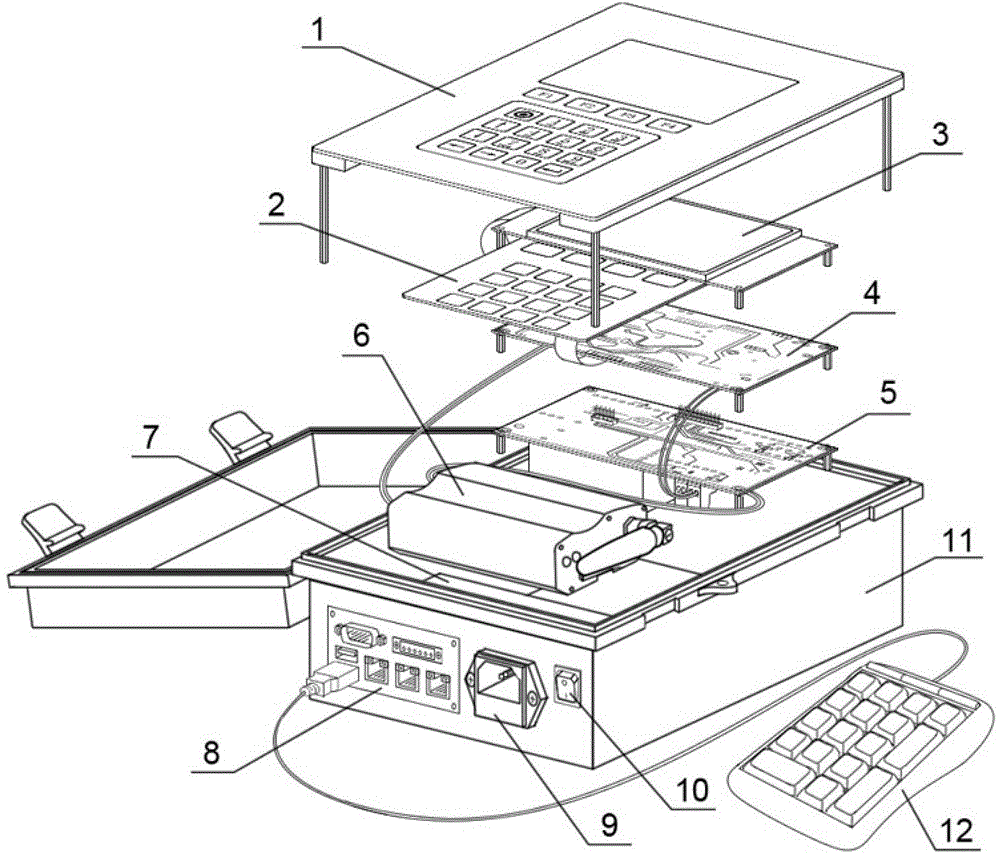

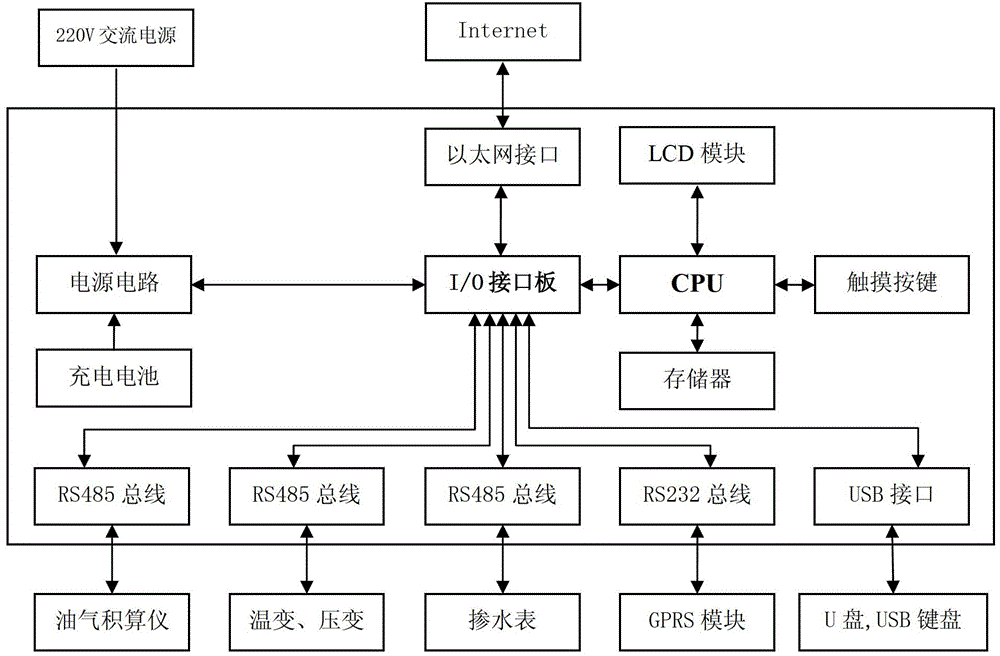

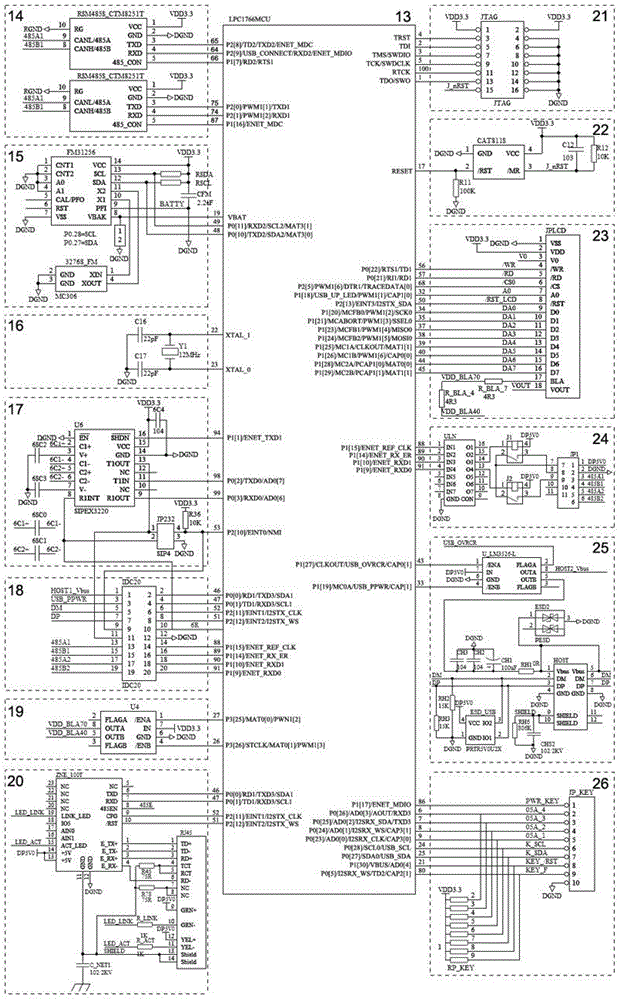

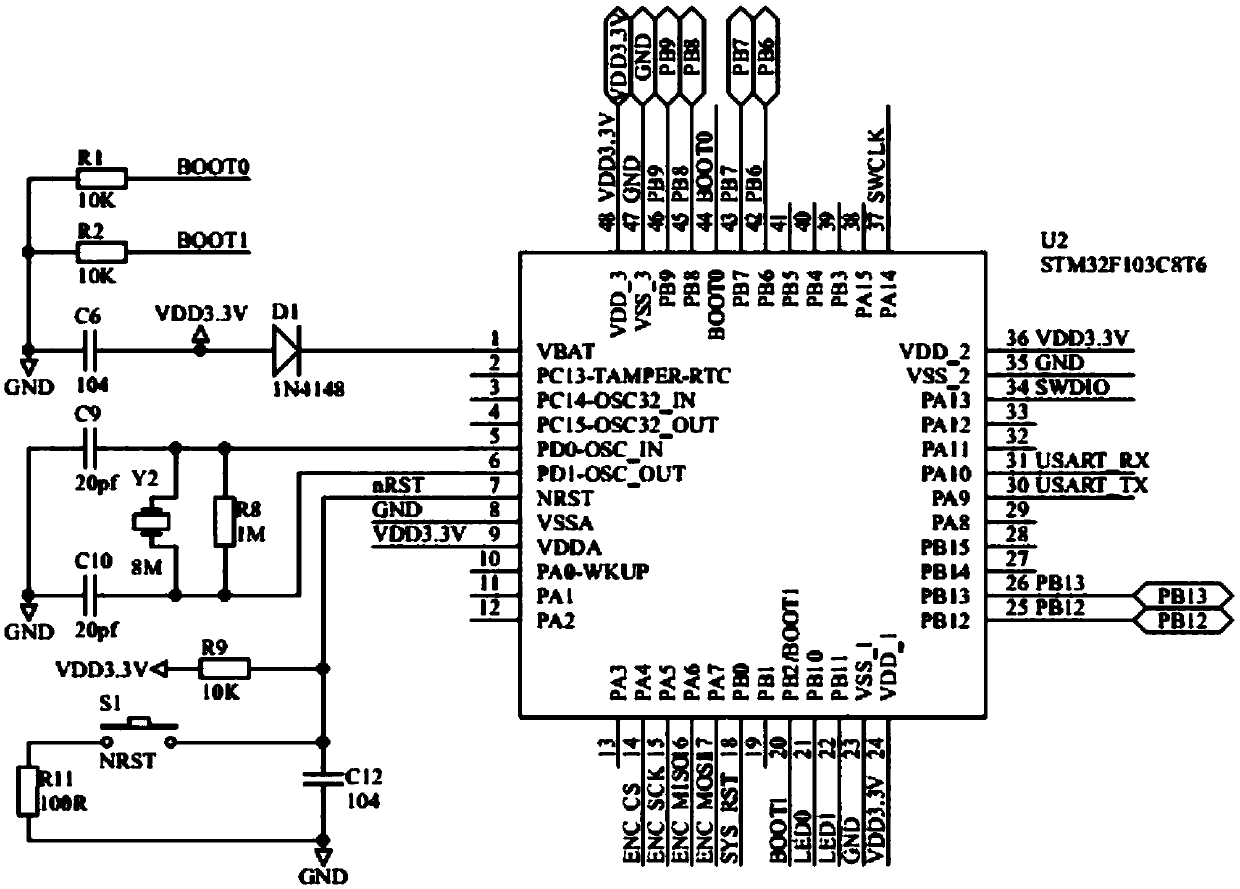

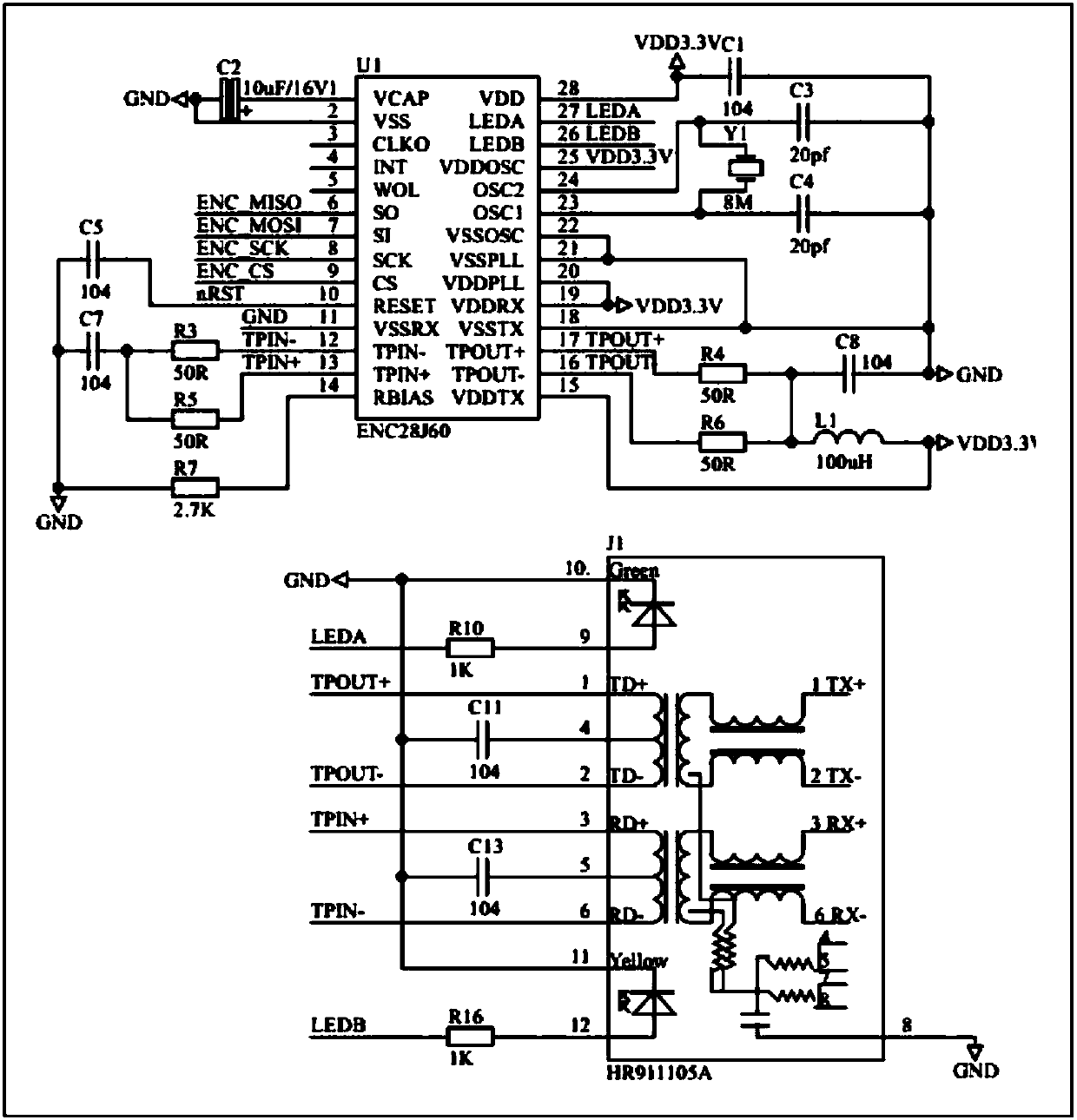

Data transmission instrument

ActiveCN102866655AReduce operator workloadAccelerateProgramme controlComputer controlData transmissionControl function

A data transmission instrument mainly solves the problem that a device special for performing oil metering control and effective data transmission in a metering room is not arranged in an oil field. The data transmission instrument is characterized in that a LPC 1766 single chip microcomputer, a FM 31256 chip, a MC 306 chip, a joint test action group (JTAG) interface circuit unit, a reset circuit adopting a CAT811S chip and a 12MHZ oscillating circuit are integrated on a main board of the data transmission instrument. An RS485 interface circuit unit, an RS232 interface circuit unit adopting a SIPEX3220 chip, an Ethernet network switching circuit unit with a ZNE_100T chip as a main chip, a relay output circuit unit adopting a ULN2003 drive chip and a universal serial bus (USB) interface circuit unit adopting a LM3526 chip are correspondingly connected onto a IDC20 socket and are connected with the LPC 1766 ARM single chip microcomputer through the IDC20 socket. The data transmission instrument can achieve an automatic oil metering control function, provides multiple data transmission modes and can improve the oil well metering accuracy and ensure the reliability of daily acquired data of oil field production.

Owner:DAQING KERUI ELECTRONICS TECH DEV

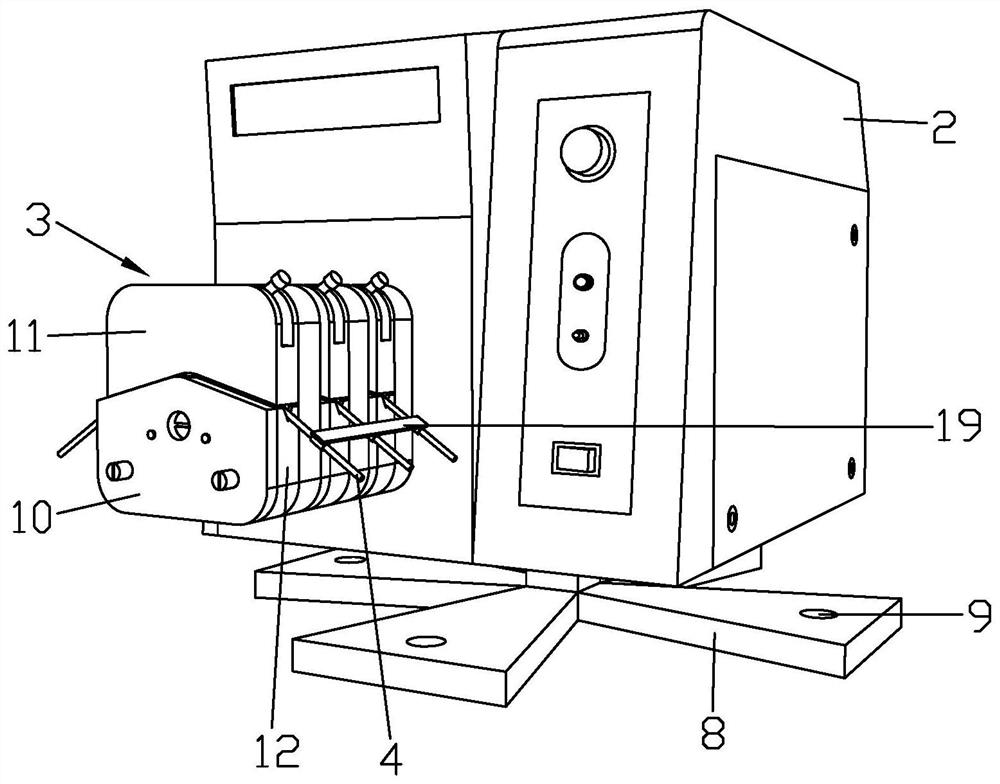

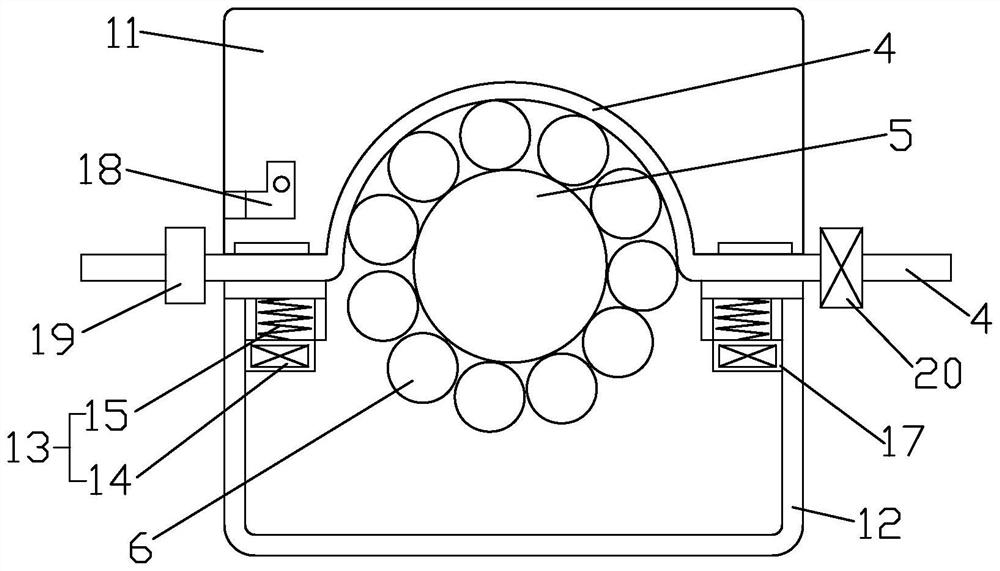

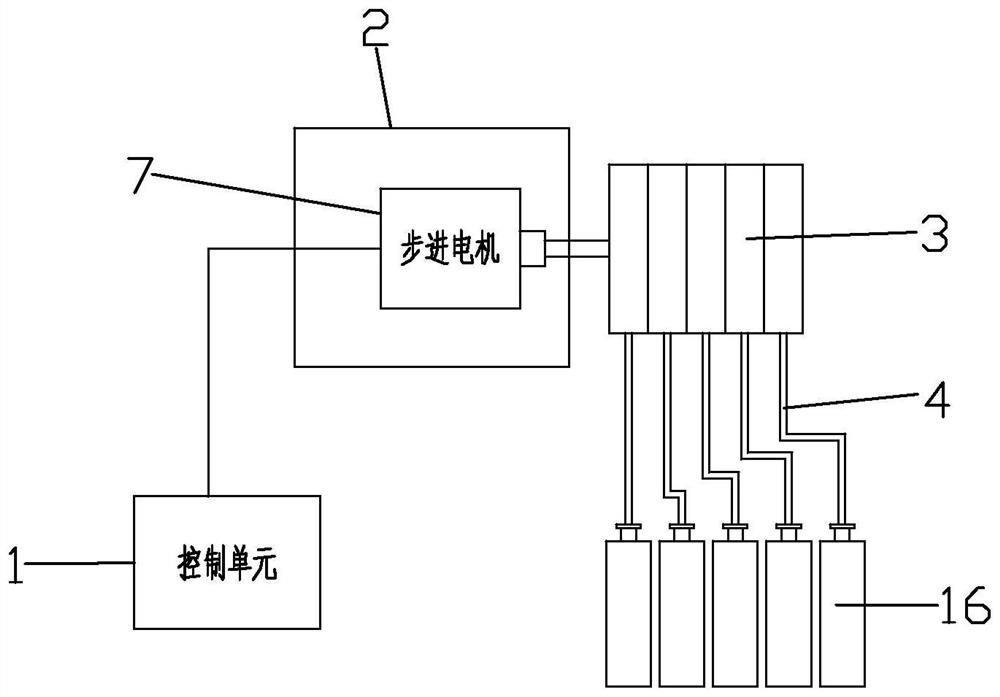

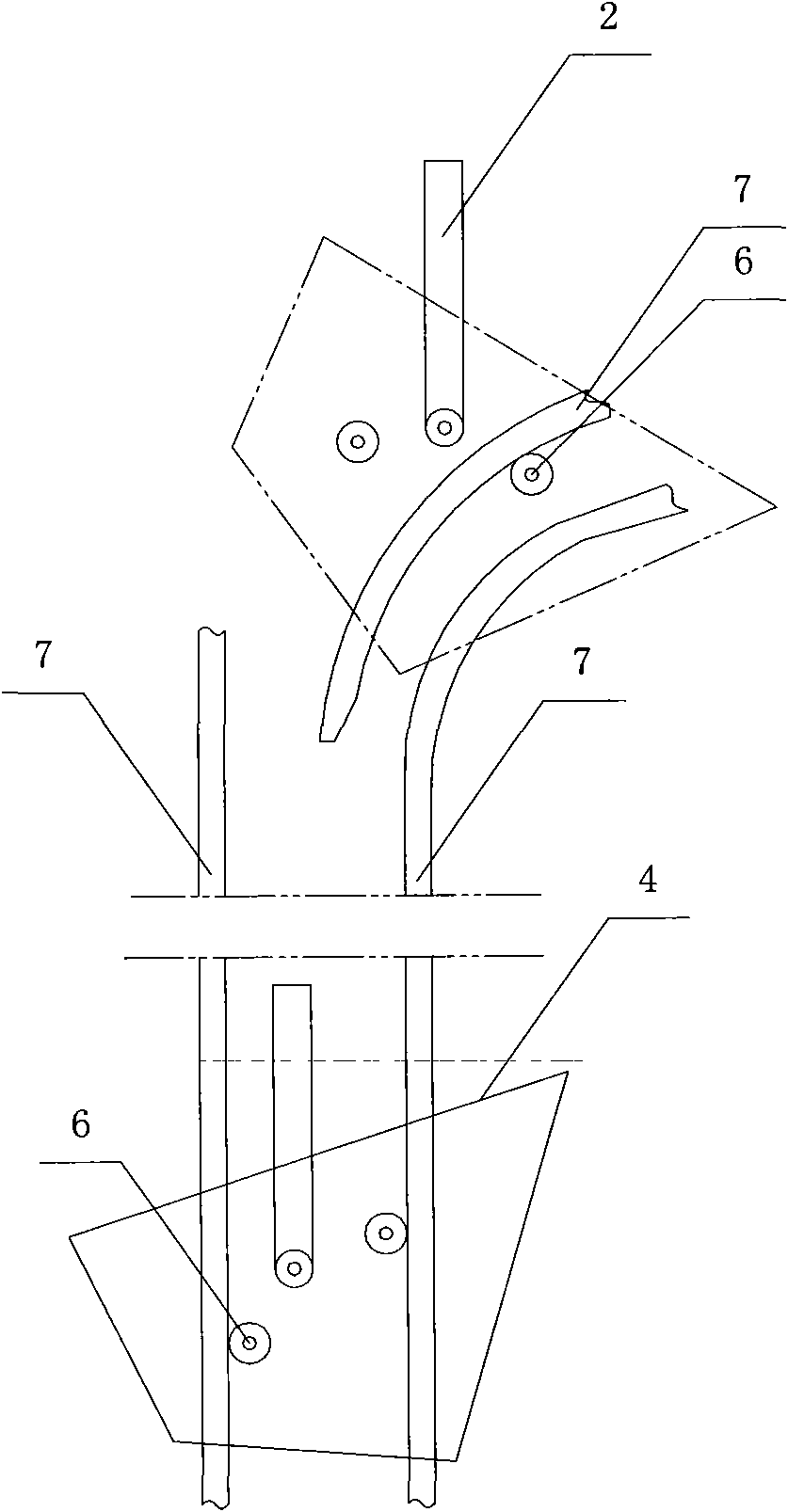

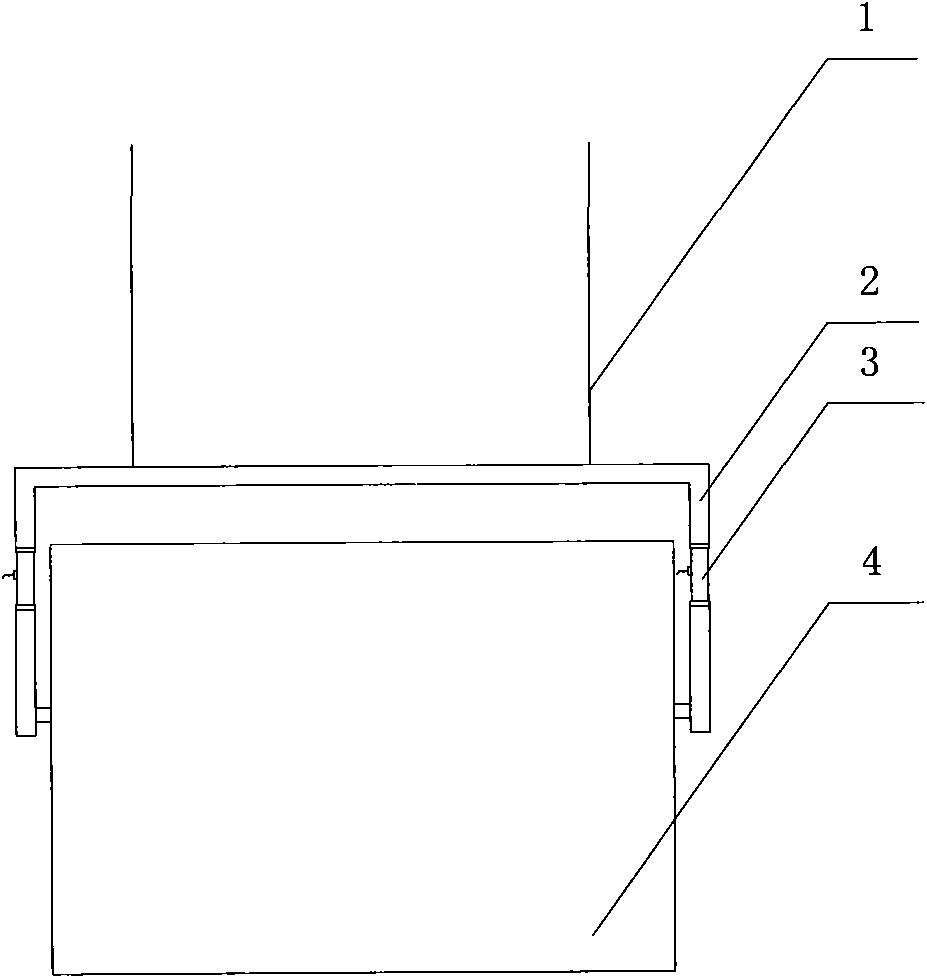

Self-control metering sampling peristaltic pump system

PendingCN114294208AHigh equipment integrationAchieve individual controlFlexible member pumpsPump controlPhysicsPeristaltic pump

According to the technical scheme, the peristaltic pump system comprises a control unit, a driving unit, a machine box and a pump head, a liquid conveying pipe and a pump shaft with idler wheels are arranged in the pump head, the pump head comprises a front shell, an upper shell and a lower shell, the lower shell is arranged on the front shell, and the lower shell is arranged on the upper shell. A linkage mechanism is arranged between the upper shell and the lower shell, the linkage mechanism is electrically connected with the control unit, the control unit controls the linkage mechanism to be opened, the upper shell is matched with the lower shell to clamp the infusion tube, the control unit controls the linkage mechanism to be closed, and the upper shell is far away from the lower shell. According to the present invention, the design is novel, each pump head can be separately controlled, the liquid inlet amount of each reagent can be separately metered, the traditional metering pipe, the traditional multi-ported valve and other devices are cancelled, such that the device integration level is high, different channels can be switched, the flexibility and the variability are provided, and the automatic metering and automatic sample introduction functions are achieved.

Owner:浙江陆恒环境科技有限公司

Coal-fired boiler measuring system

InactiveCN101782238BRealize automatic meteringEasy to useWeighing apparatus with automatic feed/dischargeEngineeringCoal fired

The invention relates to the field of coal-fired boilers, in particular to a device for weighing and measuring a coal-fired boiler. The technical problem to be solved is to provide a coal-fired boiler measuring system which has the advantages of saving a great deal of labor, time and energy, along with convenient use and accurate measurement. The coal-fired boiler measuring system comprises a coal bucket, a support bar and a wire sling. The wire sling is connected to the support bar which is hinged on the coal bucket. The coal-fired boiler measuring system also comprises a tension sensor for weighing and a control instrument which is connected to the tension sensor. The tension sensor can be connected in series with the wire sling, or fixedly connected in series with the support bar, or arranged on a pin shaft of the support bar and the coal bucket. The coal-fired boiler provided with the measuring device has the advantages of convenient use and accurate measurement in the aspect of measuring the consumption of fire coal, and the labor, time and energy can be greatly saved simultaneously.

Owner:重庆大唐科技股份有限公司 +1

Data transmission instrument

ActiveCN102866655BFully automatedAvoid missingProgramme controlComputer controlMicrocontrollerData acquisition

A data transmission instrument mainly solves the problem that a device special for performing oil metering control and effective data transmission in a metering room is not arranged in an oil field. The data transmission instrument is characterized in that a LPC 1766 single chip microcomputer, a FM 31256 chip, a MC 306 chip, a joint test action group (JTAG) interface circuit unit, a reset circuit adopting a CAT811S chip and a 12MHZ oscillating circuit are integrated on a main board of the data transmission instrument. An RS485 interface circuit unit, an RS232 interface circuit unit adopting a SIPEX3220 chip, an Ethernet network switching circuit unit with a ZNE_100T chip as a main chip, a relay output circuit unit adopting a ULN2003 drive chip and a universal serial bus (USB) interface circuit unit adopting a LM3526 chip are correspondingly connected onto a IDC20 socket and are connected with the LPC 1766 ARM single chip microcomputer through the IDC20 socket. The data transmission instrument can achieve an automatic oil metering control function, provides multiple data transmission modes and can improve the oil well metering accuracy and ensure the reliability of daily acquired data of oil field production.

Owner:DAQING KERUI ELECTRONICS TECH DEV

An unattended centralized measuring automatic control device

PendingCN107894271APrevent cheatingPerfect remote measurement managementWeighing indication devicesSpecial purpose weighing apparatusEngineering

The invention provides an unattended centralized measuring automatic control device. The device comprising a measuring balance installed on a measuring site, traffic lights arranged at an entrance andan exit of a measuring channel, and infrared detectors arranged on the front end and the rear end of a balance stand of the measuring balance. The measuring balance is electrically connected with a transmitter which is in signal connection with a server through a network; the traffic lights and the infrared detectors are electrically connected with a measuring controller installed on the measuring site; the measuring controller is in signal connection with the server via the network. The device fully integrates a motor truck scale, a rail weigher and a belt weigher in the prior art for automatic measuring and effectively prevents the problem of cheating in warehousing of materials and delivery of products from storage. By using the technologies of distributed networks, long-distance measuring data transmission, real-time capture of weighing images, traffic light control, accurate measurement of the infrared detectors and remote control, the device perfects remote measuring management,finally achieves automatic measuring and enables measuring personnel to perform unified scheduling, distribution and acceptance of measuring takes at a remote measuring center.

Owner:YUNNAN KUNGANG ELECTRONICS INFORMATION TECH CO LTD

Method for metering and managing grey cloth of grey cloth winding package vehicle

InactiveCN110606391ARealize automatic meteringImprove management efficiencyCo-operative working arrangementsElectrical/magnetic length/width measurementsInformatizationIntelligent management

The invention relates to a method for metering and managing grey cloth of a grey cloth winding package vehicle. The method adopts the grey cloth winding package vehicle, wherein the grey cloth windingpackage vehicle is equipped with an informatization management system, the system comprises a PLC controller, a touch screen, a printer and an RFID tag; the PLC controller automatically calculates the winding or unwinding length of winding packaged grey cloth according to the number of pulses generated during a magnetic switch is measured by a pulse counter; the touch screen is connected with thePLC controller, and can display working state information of a single or multiple grey cloth winding package vehicles; the printer is connected with the PLC controller through a signal transmission line; and the RFID tag is connected with the PLC controller through an antenna and a reader unit. According to the method, automatic metering of the winding or unwinding length of the grey cloth on thegrey cloth winding package vehicle can be realized, gray cloth information can be output or recorded in a RFID chip in the form of cards, two-dimensional codes and the like, so that a new method is provided for digitalization and intelligent management of a textile workshop, and the management efficiency of the textile workshop can be improved.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com