Remote automatic metering system and remote automatic metering method for virgin aluminum

An automatic measurement and remote technology, applied in the direction of weighing, measuring devices, instruments, etc., can solve the problems of increasing the labor intensity of the staff and increasing the error probability of manual processing, so as to improve the accuracy and real-time performance, manage the work reasonably, Improve the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

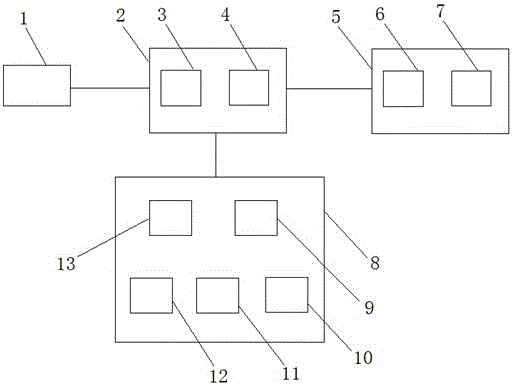

[0023] like figure 1 , the primary aluminum remote automatic metering system includes a truck scale 1, an intelligent terminal 2, a management computer 5 of a centralized control center and peripheral auxiliary equipment 8, the truck scale 1 is electrically connected to the intelligent terminal 2, and the intelligent terminal 2 is connected to the management computer 5 of the centralized control center Through the signal connection, the intelligent terminal 2 is also electrically connected with the peripheral auxiliary equipment 8; the intelligent terminal 2 includes a storage module 3 and a control module 4, and the centralized control center management computer 5 includes a memory 6 and a processor 7; The device 8 includes an infrared separation device 9 , a barrier machine 10 , an indicator light 11 , a camera 12 and an information display screen 13 . The truck scale 1 is a conventional truck weighing device.

[0024] The intelligent terminal is responsible for the collect...

Embodiment 2

[0032] With the metering system of embodiment 1.

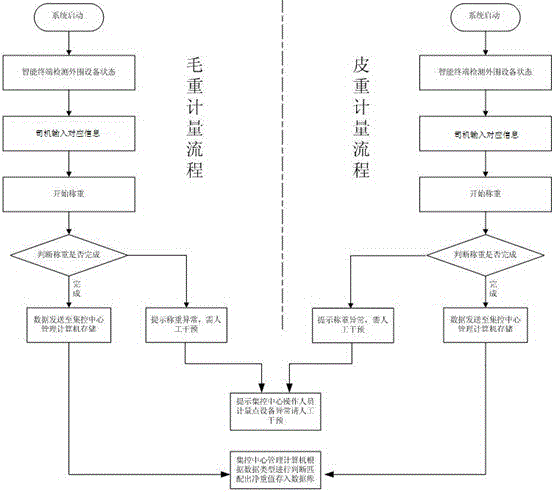

[0033] When the above-mentioned primary aluminum remote automatic metering system works, it goes through the following steps:

[0034] A. Preset the gross weight column and tare weight column on the smart terminal 2, and confirm that each device in the system is normal;

[0035] B. Load the raw aluminum produced in the electrolysis workshop to the truck scale 1 with the aluminum tapping truck, and the driver gets off the vehicle and enters the corresponding information on the smart terminal, including the shift number, the aluminum packaging package number, the number one of the electrolysis workshop, and the electrolytic tank No. 104-105-106, No. 1 of the aluminum exporter and the time at 12:35 am on July 1, 2015, the smart terminal 2 reads the weighing data of the truck scale 1, 18556kg, and records it in step A. The smart terminal 2 presets In the gross weight column of , it is judged as completed;

[0036] C. After step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com