Method for metering and managing grey cloth of grey cloth winding package vehicle

A management method and blank loading technology, which is applied in the dyeing and finishing industry, can solve the problems of vehicle-mounted gray fabric record length deviation, etc., and achieve the effect of solving easy pollution and improving management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

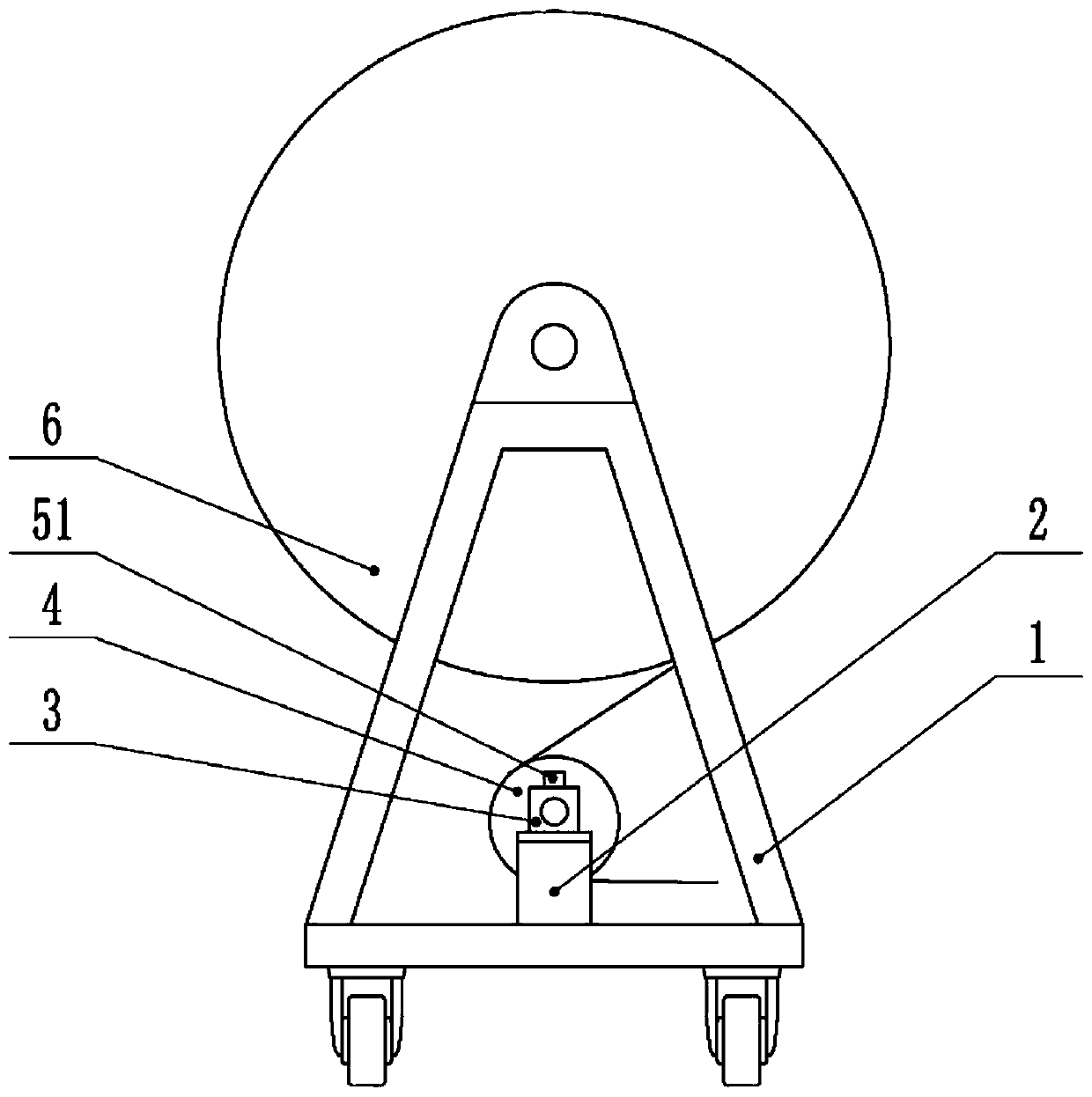

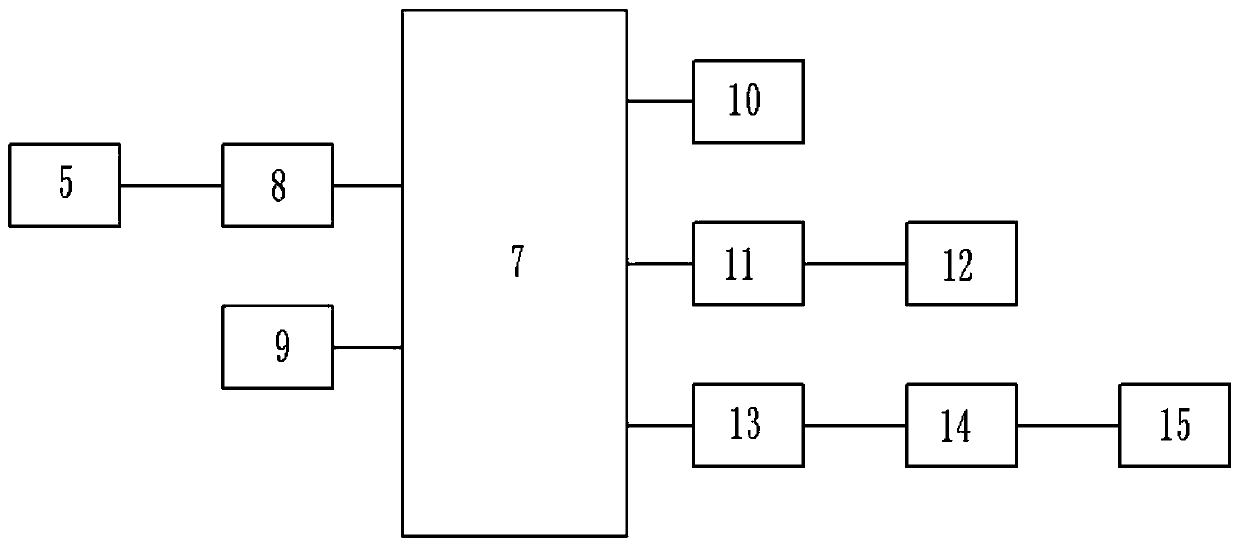

[0027] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is a gray cloth measurement and management method of a packaged gray cloth car, which adopts a packaged gray cloth car, and the packaged gray cloth car is equipped with an information management system.

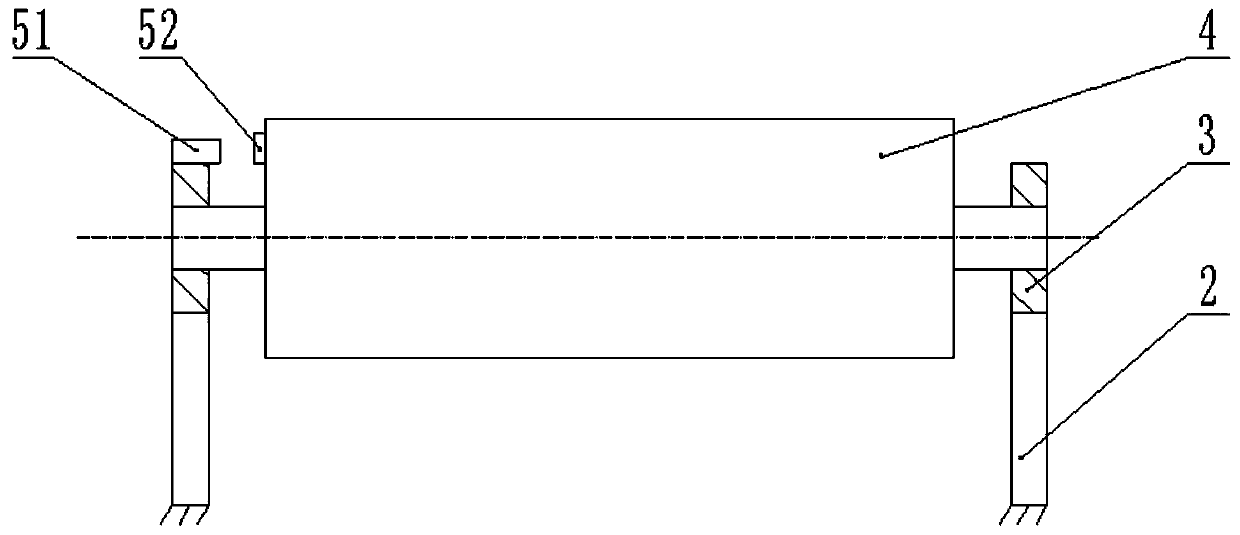

[0028] The package gray cloth car is composed of a frame 1, a bearing seat connecting plate 2, a bearing seat 3, a length counting roller 4, a magnetic switch 51 and a magnetic material 52 and the like.

[0029] A packaged fabric 6 is horizontally pivoted on the frame 1 . The bearing block connecting plate 2 is installed on the frame 1 . The bearing block 3 is installed on the bearing connecting plate 2 and connected to each other.

[0030] The length gauge roller 4 is supported on the frame 1 by a pair of bearing housings 3, and the package gray cloth 6 bypasses the length gauge roller 4 . When the package gray cloth 6 is wound or unrolled, the length gauge roller 4 is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com