An unattended centralized measuring automatic control device

A technology of automatic control device and metering controller, applied in the direction of measuring device, weighing indicating device, weighing, etc., can solve problems such as affecting the smoothness of logistics, waste of human resources, interfering with normal production and business order of enterprises, and achieving perfection The effect of remote metering management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

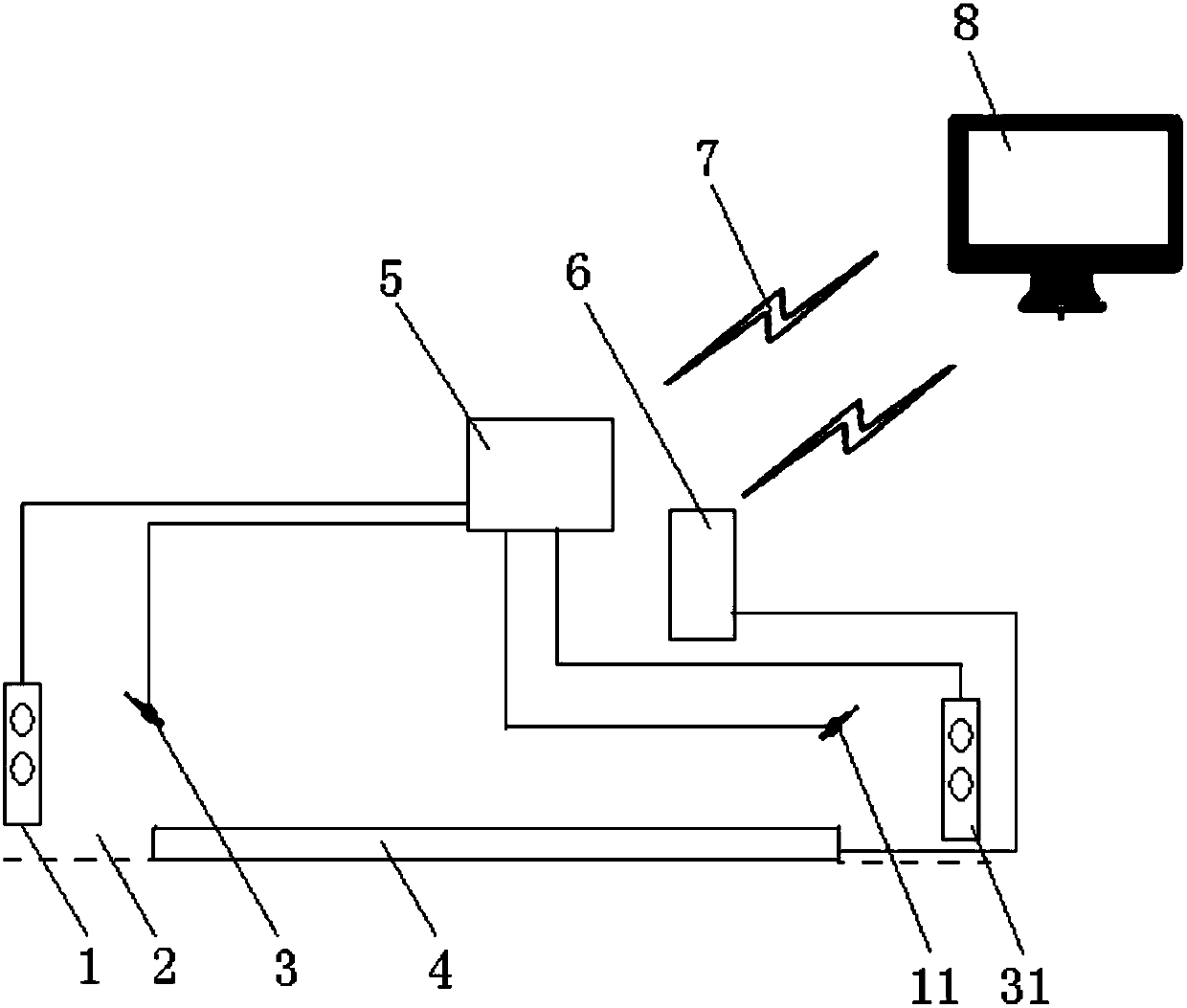

[0018] The unattended centralized metering automatic control device provided by the present invention includes a metering scale 4 installed on the metering site, traffic lights 1 and 11 respectively arranged at the entrance and exit of the metering channel 2, and respectively arranged at the front and rear ends of the weighing platform of the metering scale 4 Infrared injectors 3, 31, wherein: weighing scale 4 is electrically connected with transmitter 6, transmitter 6 is connected with server 8 signal through network 7, traffic lights 1, 11, infrared injectors 3, 31 are installed in the metering The on-site metering controller 5 is electrically connected, and the metering controller 5 is connected to the server 8 through a network signal;

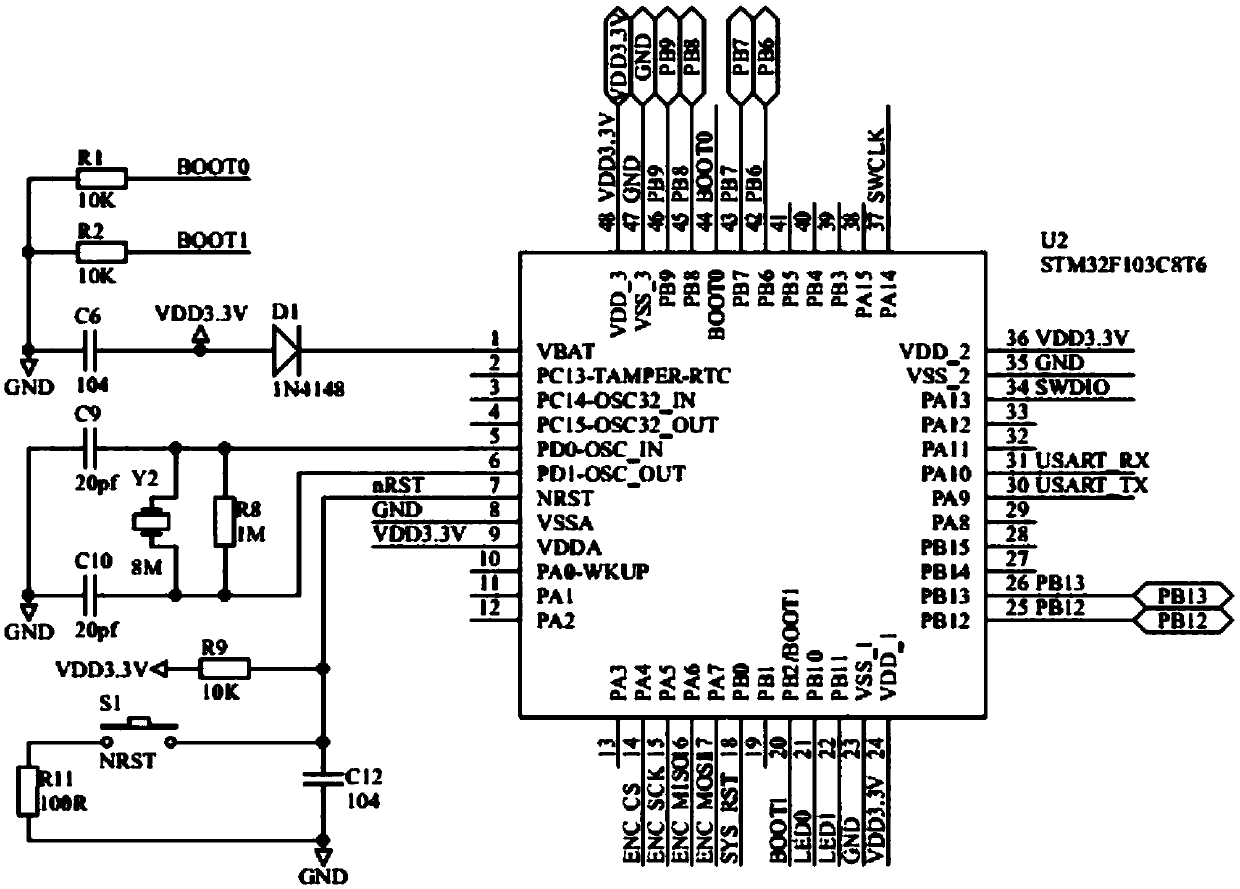

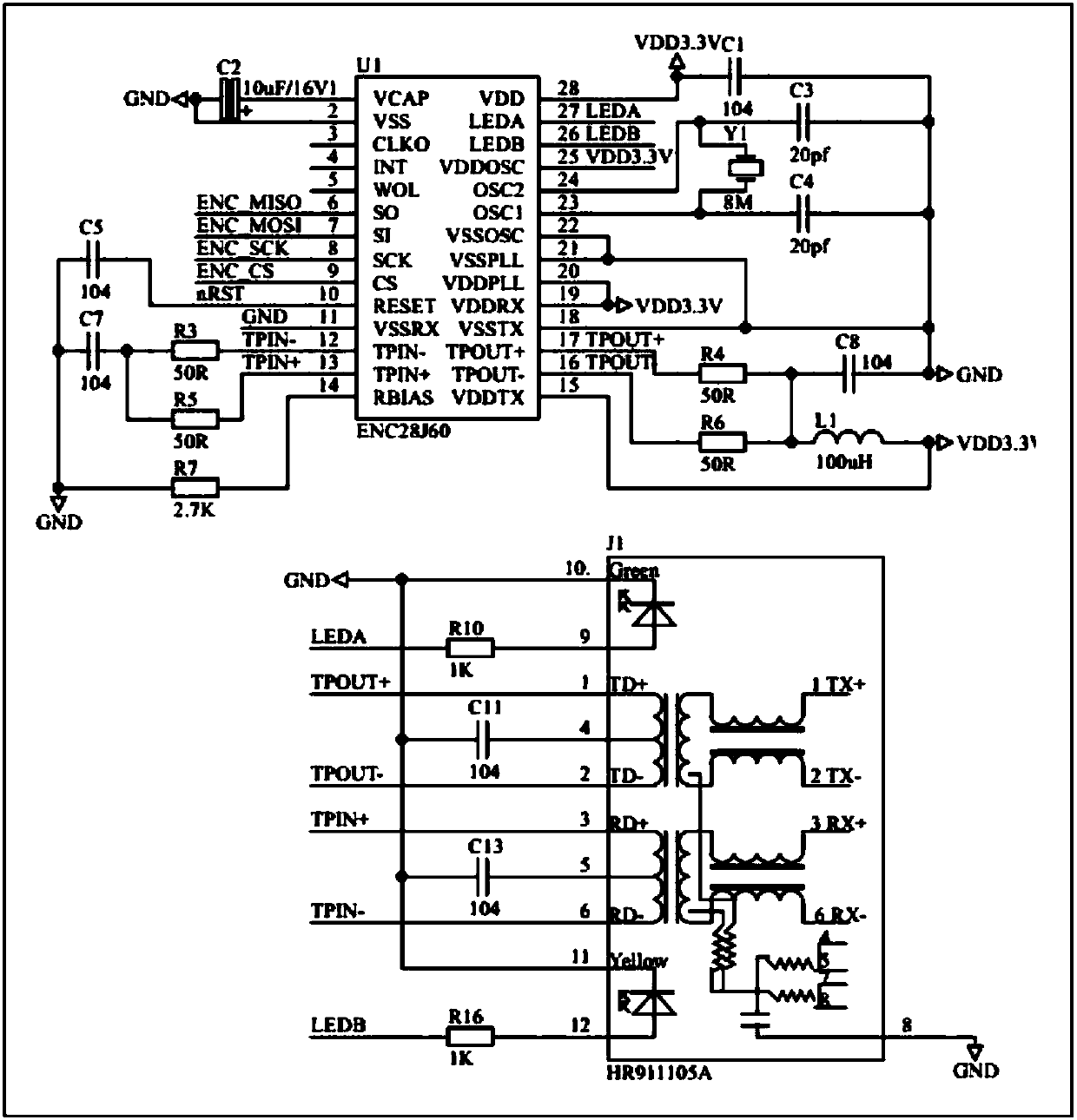

[0019] Described network 7 is Ethernet and Ethernet transceiver controller, and this Ethernet transceiver controller model is ENC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com