Coal-fired boiler measuring system

A coal-fired boiler and metering device technology, which is applied in the field of coal-fired boilers, can solve problems such as waste of labor, time and energy, measurement errors, difficult calculations, etc., and achieve the effects of accurate measurement, small errors, and labor and time savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

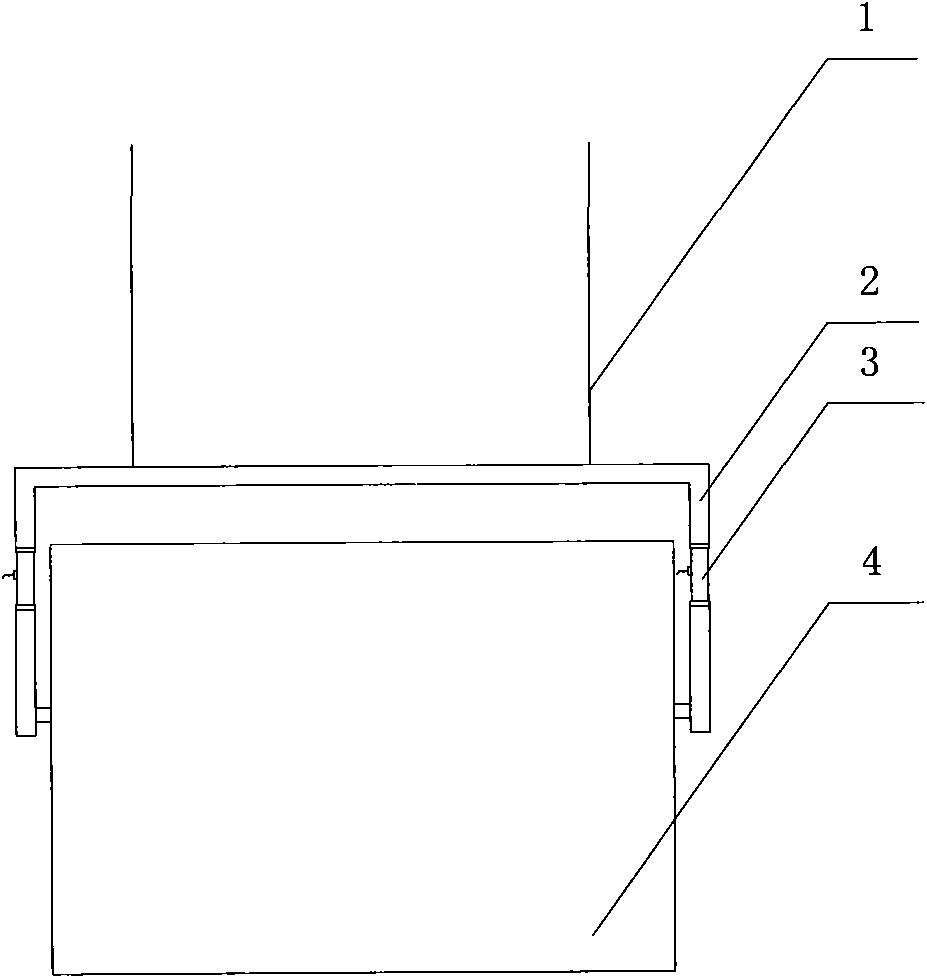

[0015] Such as figure 1 , figure 2 As shown, there is no coal-fired metering device for existing coal-fired boilers. When the weighing of the coal hopper is within 1000kg, a coal-fired boiler metering device is provided, including coal hopper 4, guide wheel 6, guide rail 7, Support rod 2, steel wire sling 1, tension sensor 3 and the control instrument connected to the tension sensor, steel wire sling 1 is connected to support rod 2, support rod 2 is hinged on coal bucket 4, and guide wheel 6 is fixedly installed on the coal hopper. The bucket 4 can slide stably along the guide rail 7, and the tension sensor 3 is connected in series with the steel wire rope 1 through a steel ring.

[0016] Weighing method: When the steel wire rope 1 lifts the coal bucket 4 and rises at a constant speed along the guide rail 7, the tension of the steel wire rope 1 is transmitted to the support rod 2 and the coal bucket 4 through the tension sensor 3. During this process, the tension sensor 3 is...

Embodiment 2

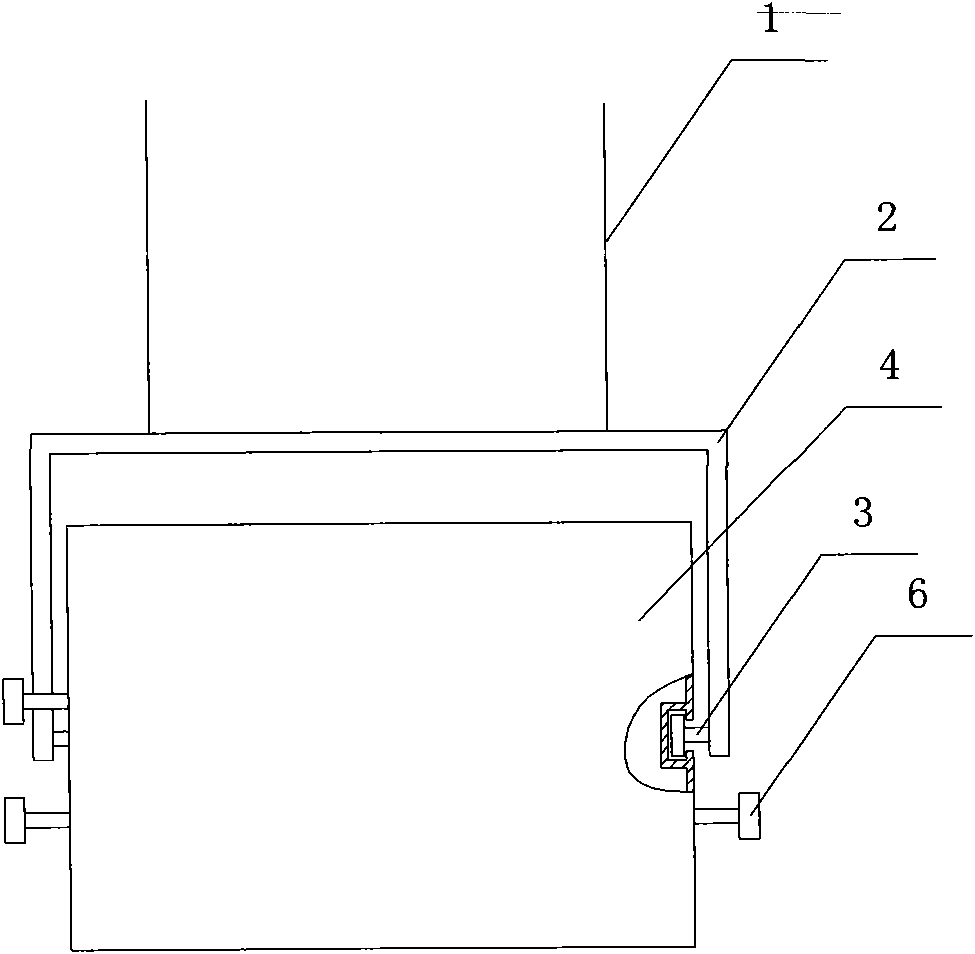

[0018] Such as image 3 As shown, in view of the existing coal-fired boiler without coal-fired metering device, when the weighing of the coal hopper is within 500kg, a coal-fired boiler metering device is provided, including coal hopper 4, support rod 2, and steel wire rope 1. The tension sensor 3 and the control instrument connected to the tension sensor, the steel wire sling 1 is connected to the support rod 2, the support rod 2 is hinged on the coal bucket 4, and the tension sensor 3 is connected in series to the steel wire sling 1 through the flange superior.

[0019] The specific weighing calculation process is the same as in Embodiment 1.

Embodiment 3

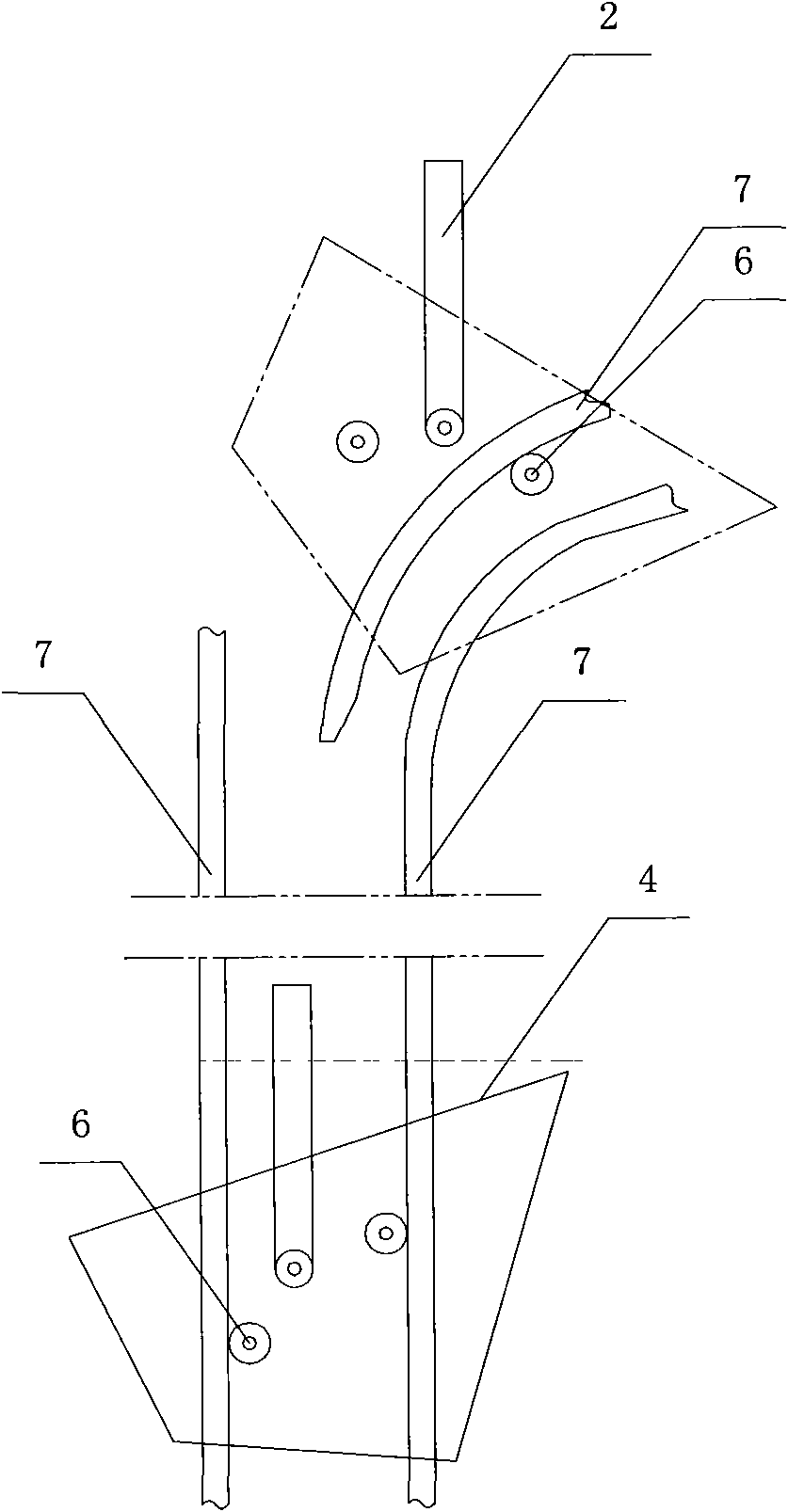

[0021] Such as figure 2 , Figure 4 As shown, there is no coal-fired metering device for existing coal-fired boilers. When the weighing conditions of the coal hoppers are complicated and changeable, a coal-fired boiler metering device is provided, including coal hoppers 4, guide wheels 6, guide rails 7, Support rod 2, steel wire sling 1, tension sensor 3 and the control instrument connected to the tension sensor, the steel wire sling 1 is connected to the support rod 2, the support rod 2 is hinged on the coal bucket 4, and the tension sensor 3 constitutes the hinged coal bucket And the axle pin of support bar, guide wheel 6 is fixedly installed on the coal bucket 4 and can slide steadily along guide rail 7.

[0022] The specific weighing calculation process is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com