Long-distance concentrated automatic metering system and method adopting belt weighers in large region

An automatic measurement and belt scale technology, applied in weighing, measuring devices, weighing auxiliary equipment, etc., can solve problems such as unfavorable production, large gap in weight data, and impact on cost accounting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

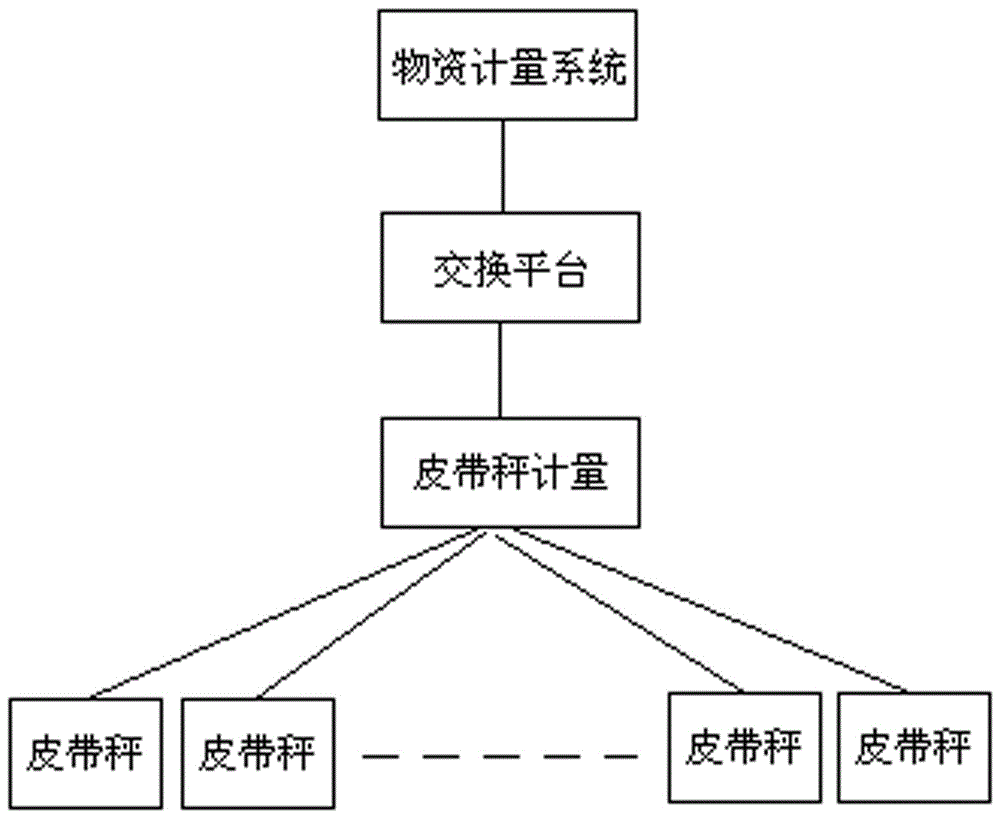

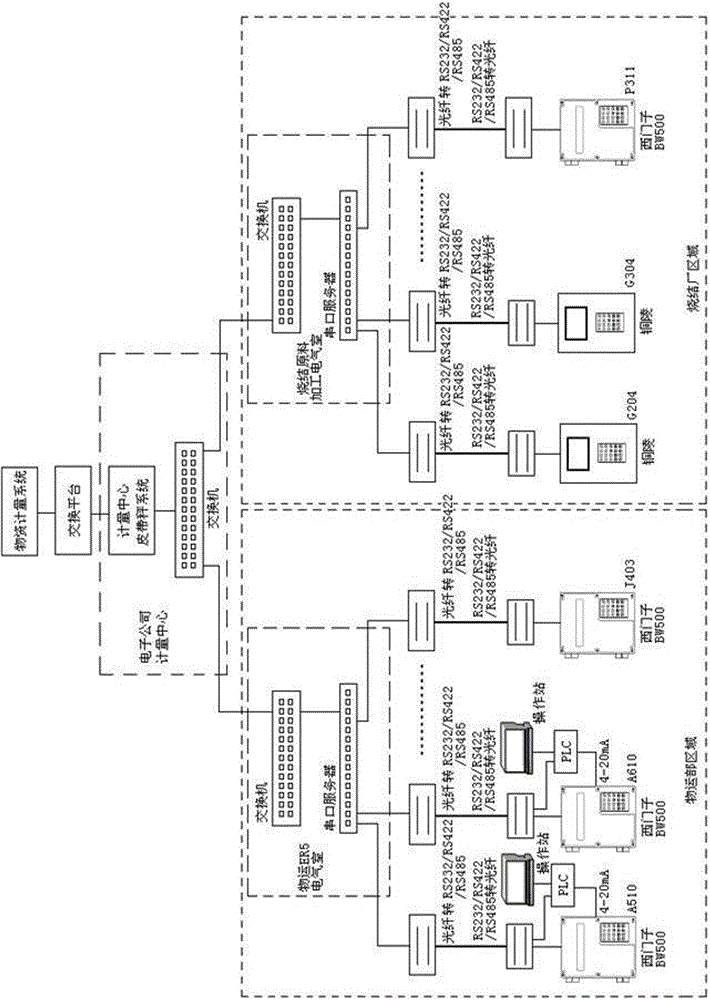

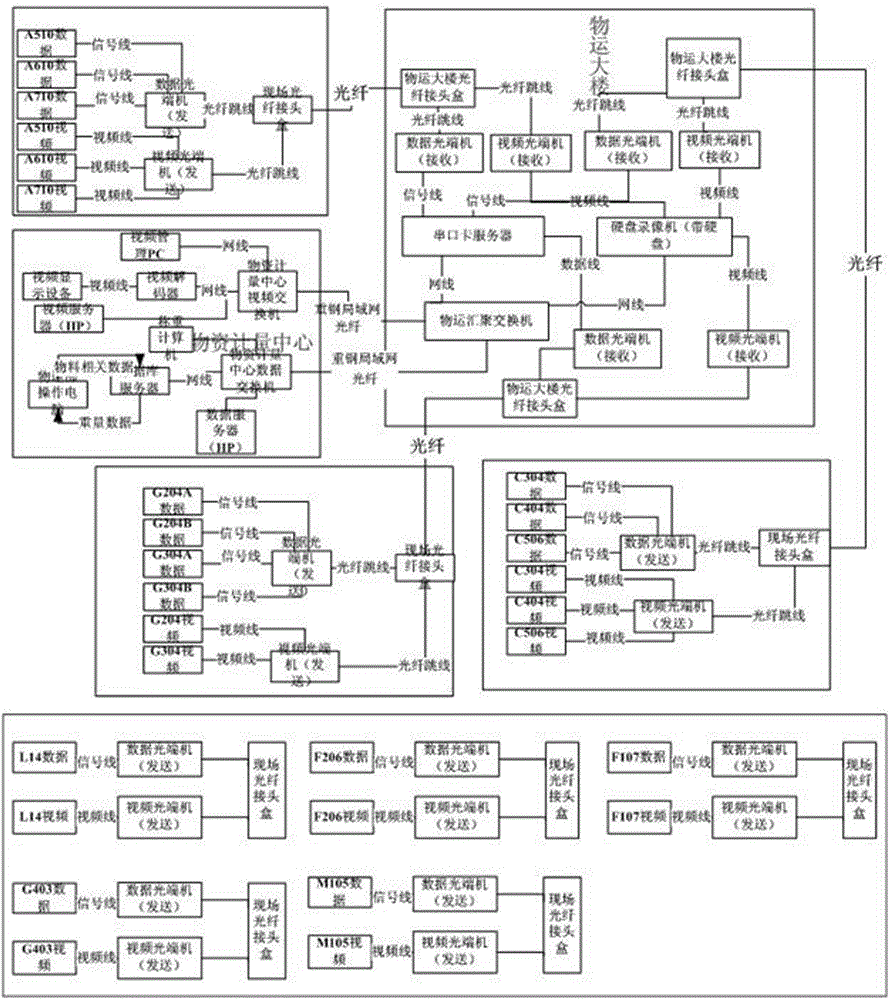

[0030] see Figure 1 to Figure 3 , this embodiment discloses a remote centralized automatic metering system for belt scales in a large area, including a serial port server, a metering computer, and multiple belt scales, the weighing instruments of each belt scale are connected to the serial port server through optical fibers, and the serial port server Connect with metering computer through network, the weighing instrument of described metering computer, serial port server, each belt scale forms RS-485 bus control network, and described metering computer is used for reading the data in weighing instrument according to the collection time point of setting. Instantaneous weight, cumulative weight, and belt running speed are used to calculate the weight data of belt scales transporting materials within the corresponding period of time. The metering computer is used to issue command signals to the weighing instruments of each belt scale through the serial port server, so as to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com