Converter steelmaking iron alloy smelting feeding weighing data collecting and monitoring system

A converter steelmaking and data acquisition technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of signal interference, inability to carry out cost, data acquisition, etc., to eliminate external signal interference, Eliminate the effects of low accuracy and not easy winding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any transformation made based on the present invention falls within the scope of protection of the present invention.

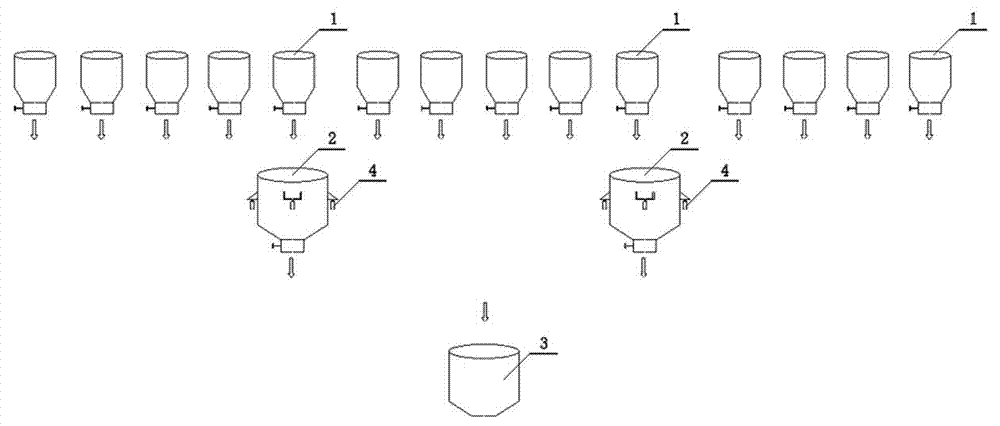

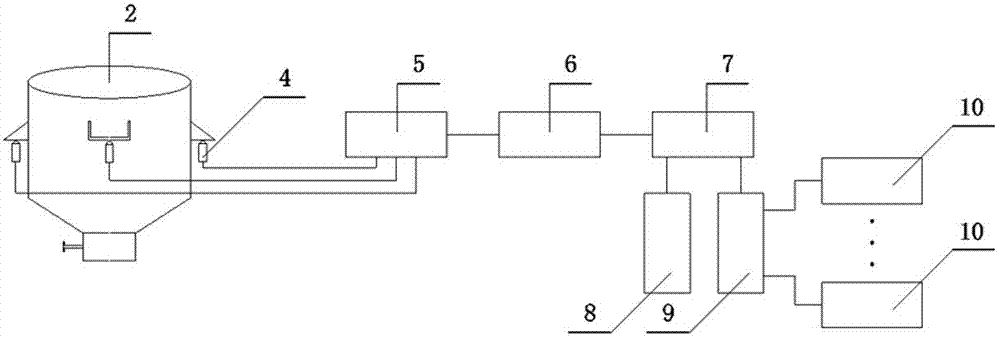

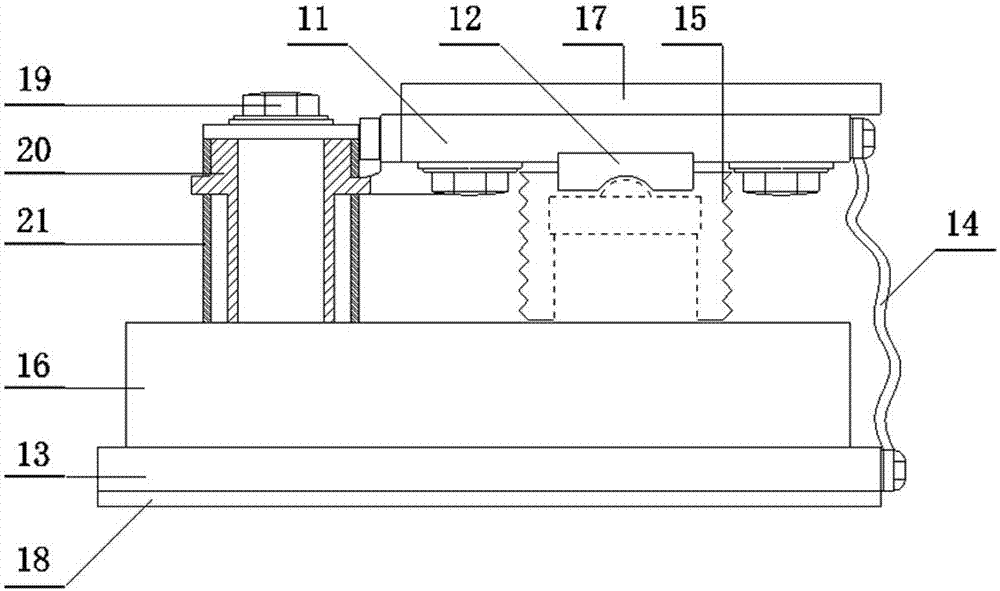

[0017] Such as figure 1 As shown, the equipment involved in the converter steelmaking alloy feeding process mainly includes ferroalloy high-level feeding bin 1, ferroalloy weighing bucket car 2, and steelmaking converter 3. Each tank of molten steel sent from steelmaking converter 3, due to the difference in composition and The types and quantities of ferroalloy materials that need to be added are also different depending on the steel type of the product; according to the parameters of the ingredient list, the required ferroalloy materials are unloaded from the high-level feeding bin 1 to the ferroalloy weighing bucket trolley 2 for weighing. For the actual production rhythm, in this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com