Remote automatic metering system for finished aluminum ingots and method thereof

A technology of automatic metering and aluminum ingots, applied in weighing, measuring devices, instruments, etc., can solve the problems of increasing labor intensity, reducing labor productivity, low work efficiency, etc., to improve labor productivity, reduce labor intensity, and save work. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

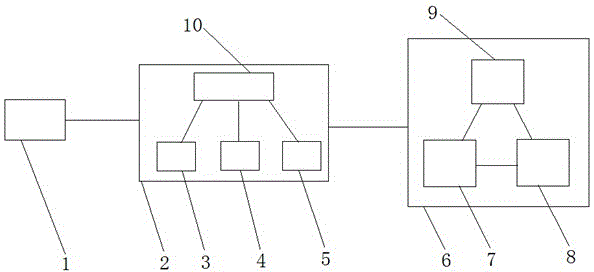

[0035] Such as figure 1 The remote automatic metering system for finished aluminum ingots includes a digital buffer electronic platform scale 1, an on-site management computer 2 and a centralized control center management computer 6, the digital buffer electronic platform scale 1 is electrically connected to the on-site management computer 2, and the on-site management computer 2 is connected to the centralized control center. Control center management computer 6 is connected by signal, and described on-site management computer 2 is made of information display screen 3, status indicator light 4, storage module 5 and on-site management module 10, and information display screen 3, status indicator light 4 and storage module 5 are respectively Connected with the on-site management module 10, the centralized control center management computer 6 is composed of a monitoring camera 9, a memory 7 and a processing module 8 connected to each other.

[0036] The digital buffer electronic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com