Intelligent brick unloading machine

An intelligent brick unloading machine and brick stacking technology, which is applied in the stacking of objects, destacking, transportation and packaging of objects, etc. It can achieve the effect of good versatility, flexible and continuous action, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The intelligent brick unloading machine provided by the present invention optimizes performance on the basis of mechanical design, automatic control, computer technology and other theories, realizes the mechanical integration of brick unloading, shaping, and transfer; realizes the mechanical operation after kiln brick production The process of manual operation; the actual application of automatic measurement of bricks instead of manual measurement.

[0039] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but is not limited to the content described below.

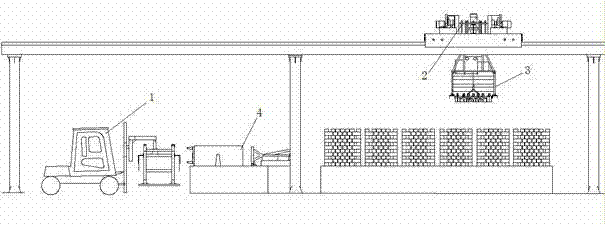

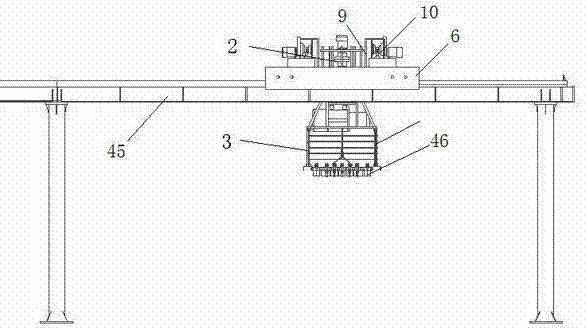

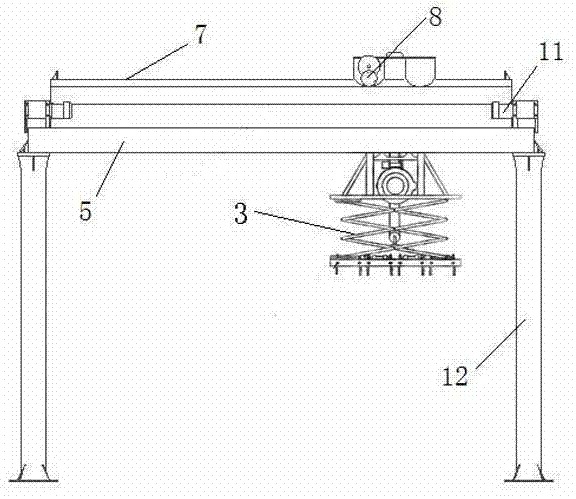

[0040] The intelligent brick unloading machine provided by the invention has a structure such as Figure 1 to Figure 5 As shown, it includes a pair of cranes 45 that can travel longitudinally to take bricks, a lifting and clamping mechanism 3 that can take bricks, a rotating mechanism 2 that can take bricks from piles of bricks in different placement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com