Method for accurately metering oil input of oil field united station

A metering method and technology of oil intake, applied in directions such as pressure measurement and display of liquid level indicators, can solve the problems of large measurement errors and high labor intensity, and achieve the effect of high precision and automatic inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

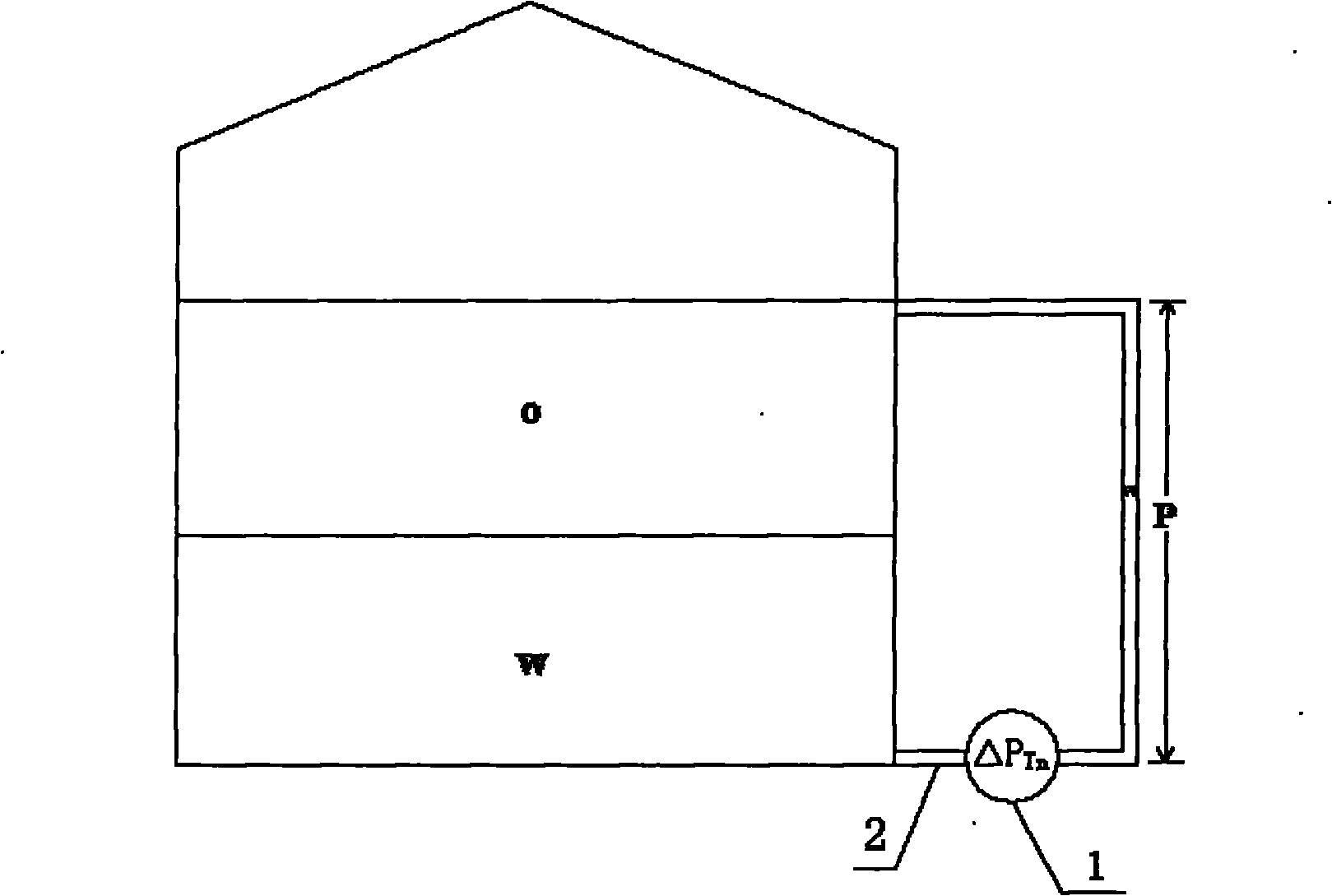

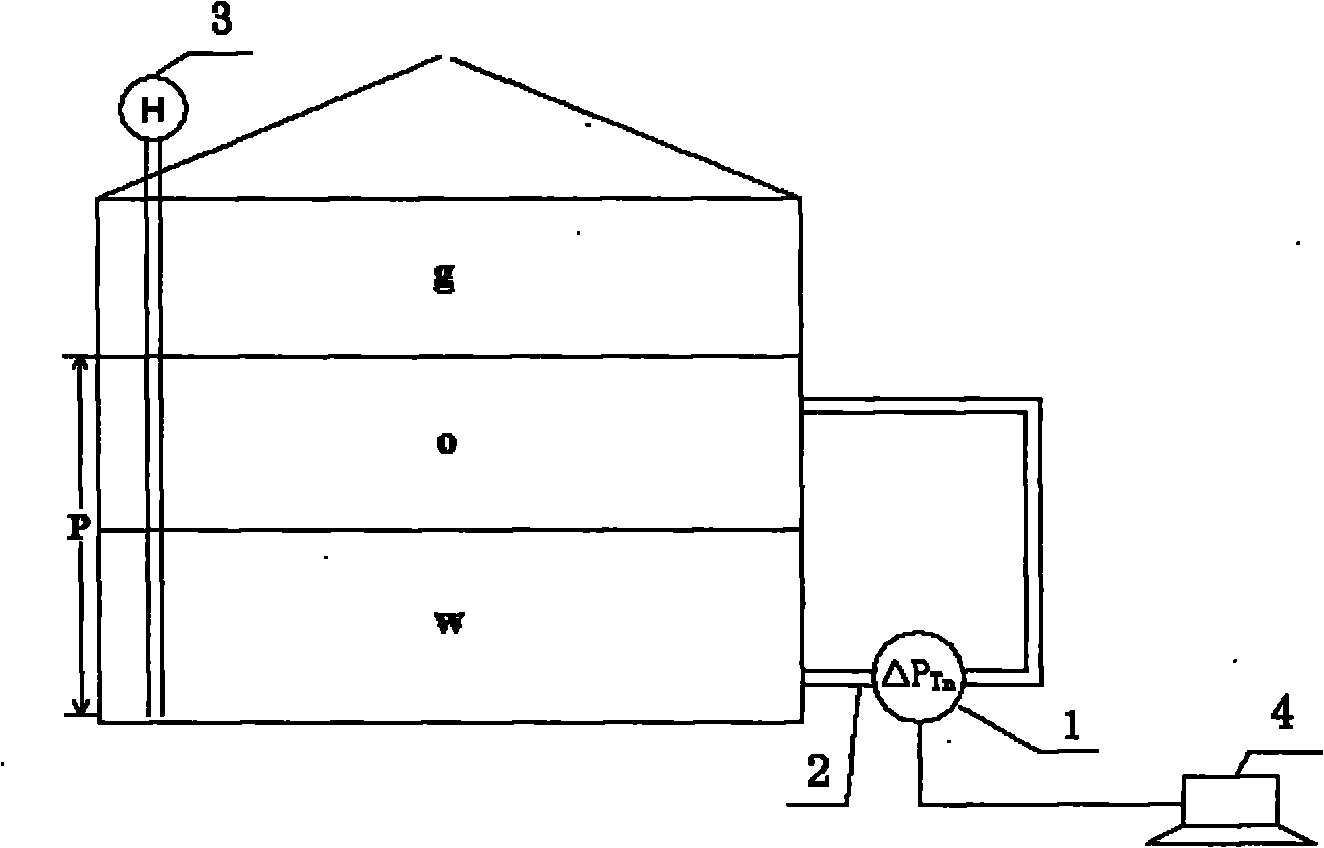

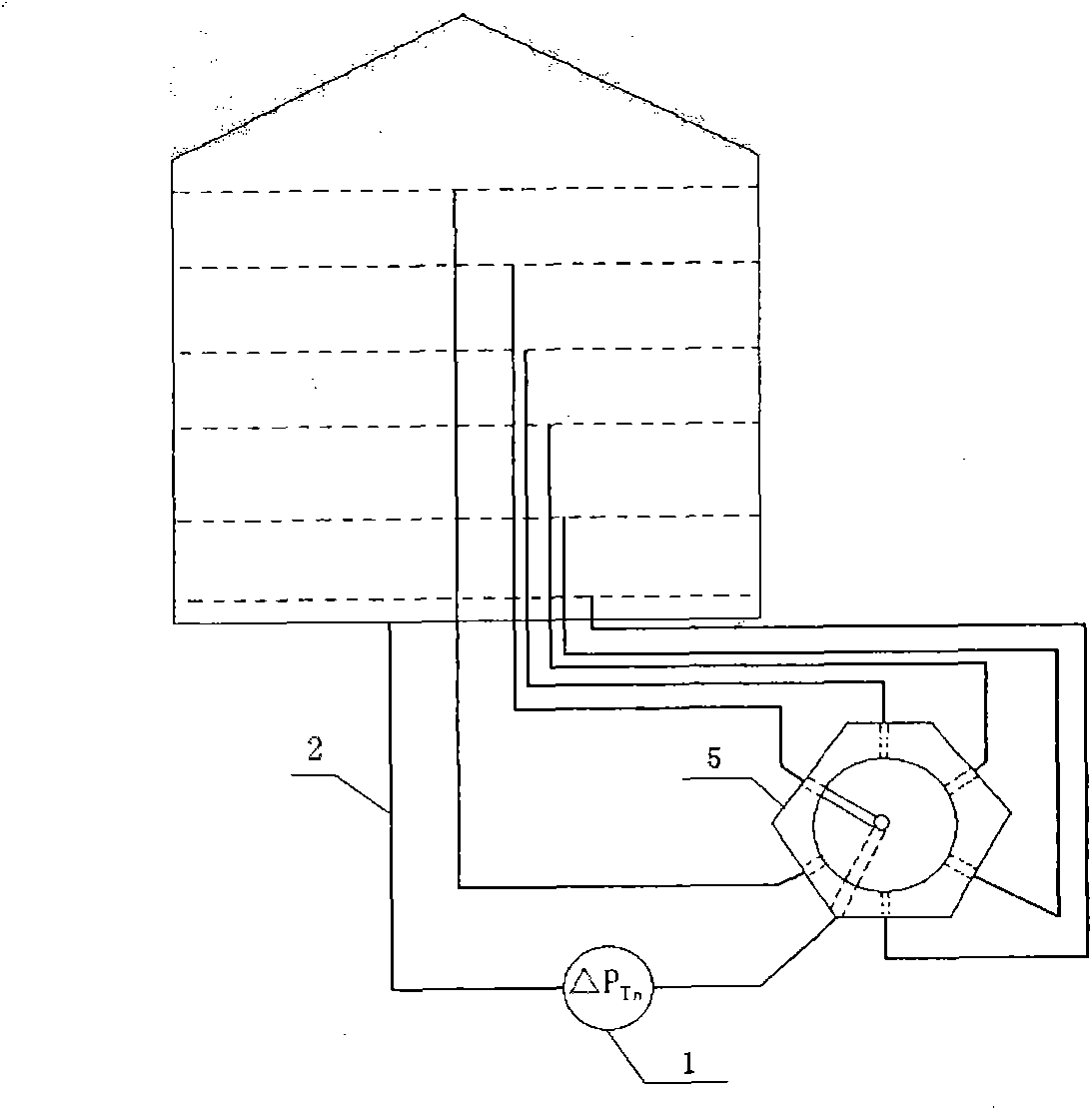

[0025] The high-precision measurement method of the oil inlet of the oilfield joint station is to use the pressure difference method, and use the pressure guide tube installed outside or inside the tank to keep the same temperature as the settling tank; the top of the pressure guide tube is at the same height as the liquid level in the tank, and the pressure guide tube The bottom is connected to the bottom of the tank and installed with a differential pressure sensor (P Tn ), taking all the clean oil and all the water in the whole oil tank as two wholes, assuming that the liquid level is constant, excluding the total amount of oil and water in the settling tank, only measuring the change of clean oil in the settling tank, using the first day of measurement The differential pressure of the differential pressure sensor and the liquid level of the settling tank, using the formula:

[0026] P 1 =ΔP T1 +H 油 · γ 油 +H 水 · γ 水

[0027] P 1 : pressure in the pilot string; ΔP T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com