Automatic gunpowder filling mechanism for firecrackers

An automatic and powder-charging technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as safety accidents, low production efficiency, and poor consistency of production quality, and achieve the goals of improving production efficiency, simple structure, and improving production safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

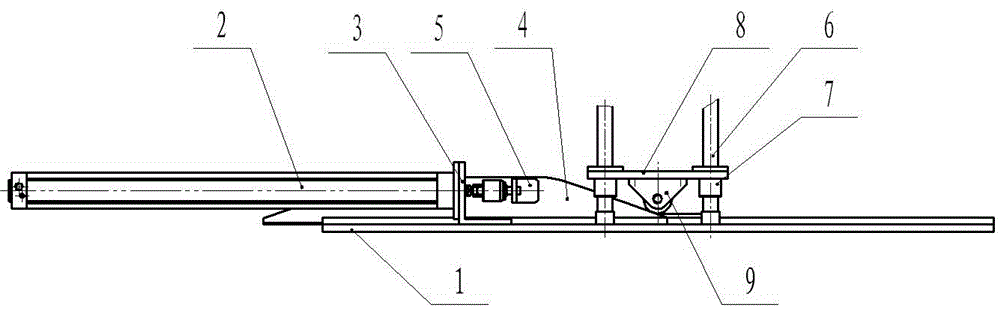

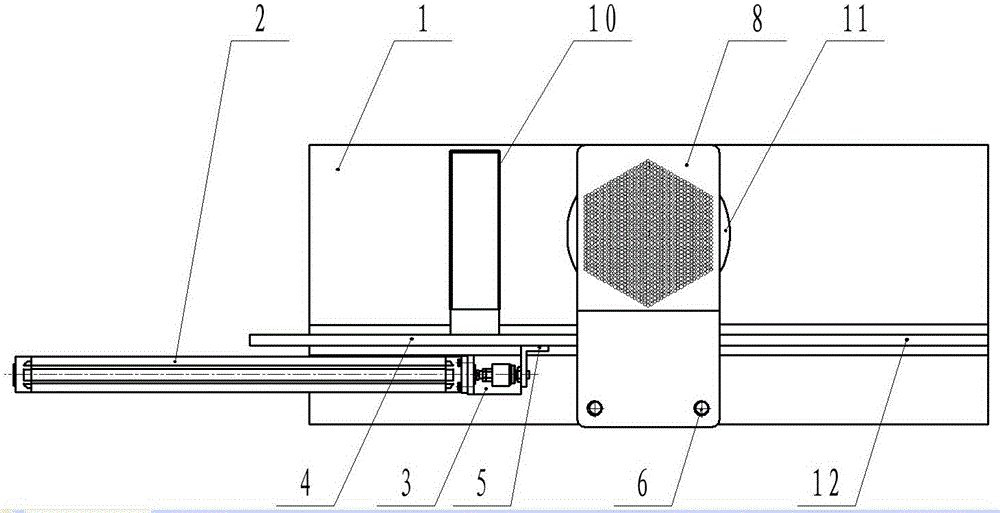

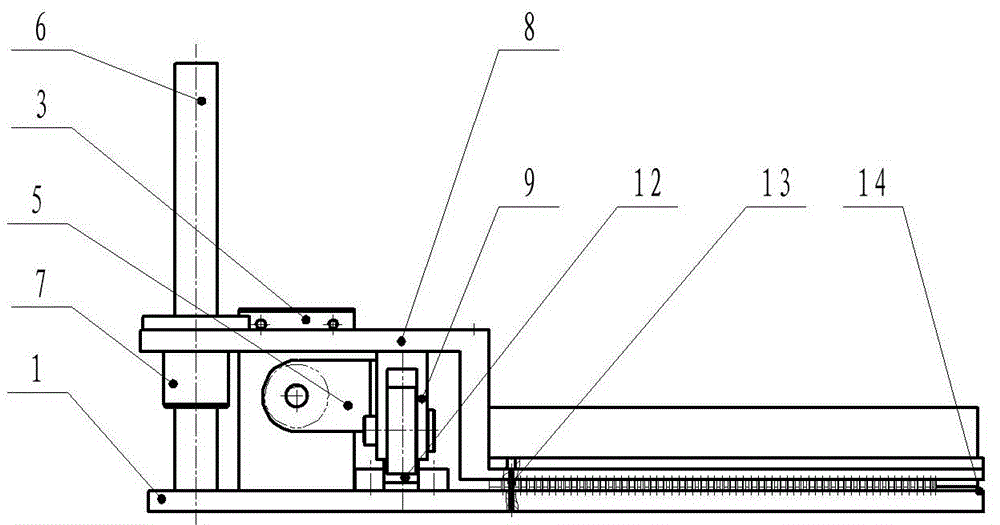

[0018] figure 1 Is the front view of the overall structure of the present invention, figure 2 Is a top view of the overall structure of the present invention, image 3 It is a side view of the overall structure of the present invention. in figure 1 ― image 3 Among them, the automatic firecracker charging mechanism of the present invention includes a table top 1, a power cylinder 2, a power cylinder mounting plate 3, an inclined plane block 4, a mounting block 5, a column 6, a sliding bearing 7, a lifting plate 8, a sliding piece 9, and a medicine box 10. Measuring plate 11, positioning groove 12, medicine punching head 13, scraping plate 14. The connection relationship is that the power cylinder mounting plate 3, the positioning groove 12, and the column 6 are fixedly installed on the table top 1. The power cylinder 2 is fixedly installed on the power cylinder mounting plate 3, the inclined plane block 4 is placed in the positioning groove 12, and the front end of the power...

Embodiment 2

[0021] The basic structure of this embodiment is the same as that of embodiment 1, except that the number of the medicine heads is 1,141.

[0022] The medicine box 10, the medicine scraping block 14, and the metering plate 11 in the present invention complete the constant volume metering of medicine under the action of the power cylinder 2 and the inclined plane block 4. Under the action of the power cylinder 2 and the inclined block 4, the punching head 13 works together with the column 6, the sliding bearing 7, the sliding member 9, and the lifting plate 8 to complete the discharge of the medicine from the hole of the metering plate 11.

[0023] The working process of the firecracker automatic charging mechanism of the present invention is that the firecracker medicine is delivered into the medicine box 10 by the medicine mixing mechanism before the work starts. After the work starts, the power cylinder 2 drives the inclined plane block 4 through the mounting block 5. Since the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com