Automatized sequential reaction unit for aerobic particle sludge culture and research

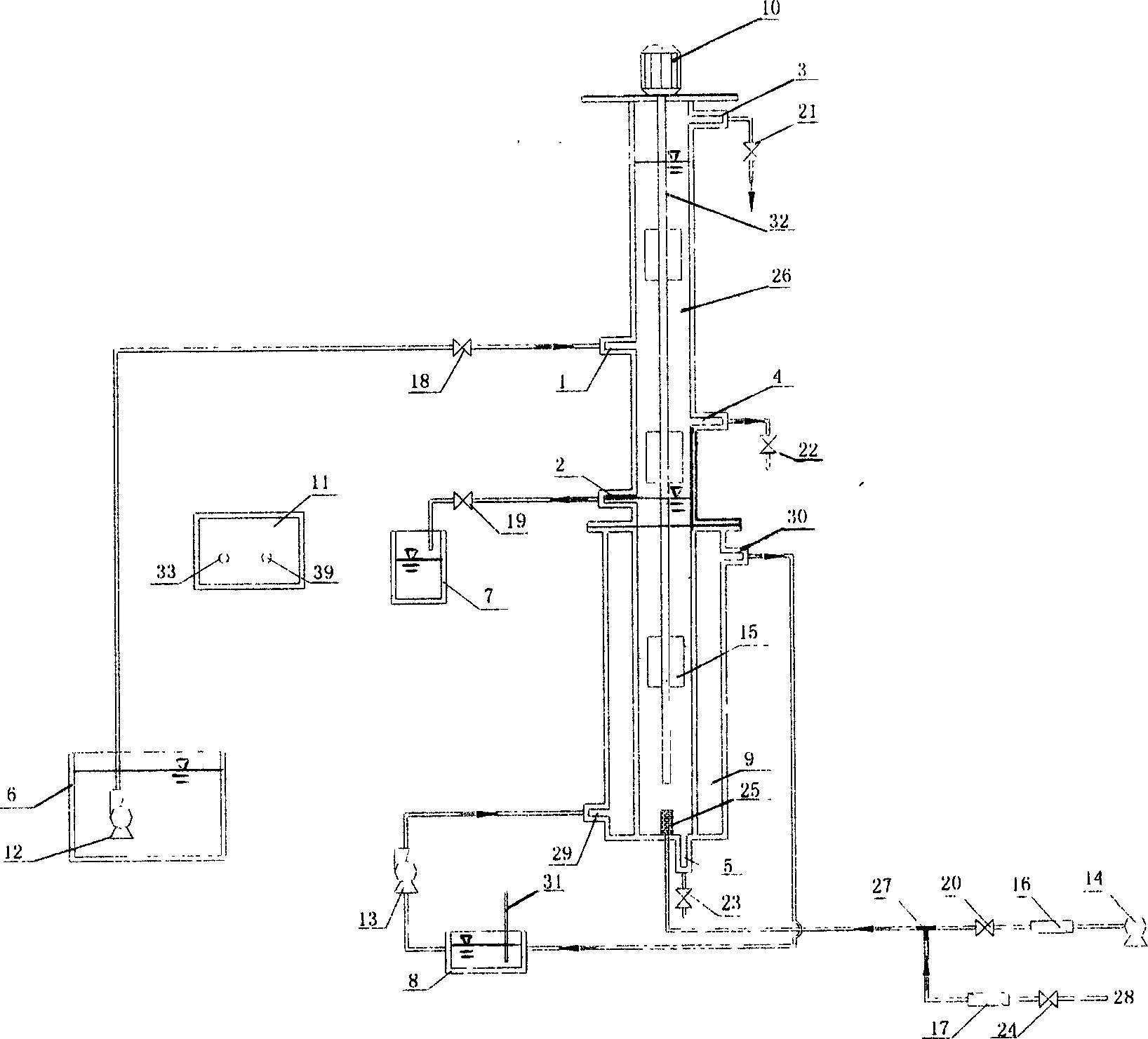

A technology of aerobic granular sludge and sequencing batch reaction, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. problems such as the influence of culture conditions, to achieve the effect of simple operation and meeting temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Simultaneous nitrification and denitrification of aerobic granular sludge

[0030] (a) Use aerobic granular sludge as inoculation sludge to maintain the mixed liquid suspended solids concentration (MLSS) in the reactor main body 26 at 6.7g / L; (b) select the operating parameters as follows: water inflow and drainage are about 3 minutes respectively and for about 5 minutes, aeration for 240 minutes, precipitation for 2 minutes, and anaerobic treatment for 30 minutes; (c) The temperature of the constant temperature water bath was set at 20°C, the aeration rate was 75L / h, and the chemical oxygen demand (COD) of the influent was maintained. Cr ) and ammonia nitrogen concentrations are 420mg / L and 30mg / L respectively, and run 3 cycles every day; (d) after the operation starts, the simulated wastewater enters the reactor main body 26 through the lifting effect of the water pump 12, and under the action of the control system, the After aeration, sedimentation, draina...

Embodiment 2

[0031] Embodiment 2: the cultivation of aerobic granular sludge

[0032] (a) Ordinary flocculent sludge is used as inoculation sludge, and the MLSS in the reactor is maintained at 2.7g / L; (b) The operating parameters are selected as follows: water inflow and drainage are about 3 minutes and 5 minutes respectively, aeration is 240 minutes, sedimentation The time is set to more than 30 minutes at the beginning, and the sedimentation time is artificially shortened gradually with the extension of the acclimatization time, and the selective cultivation of granular sludge is accelerated by reducing the sludge sedimentation time, and the anaerobic time is 30 minutes; (c) The temperature of the constant temperature water bath is set to 20 °C , the aeration rate is 75L / h, and the influent COD is maintained Cr and ammonia nitrogen concentrations are 420mg / L and 30mg / L respectively, and run 3 cycles per day; (d) after the operation starts, the simulated wastewater enters the reactor main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com