Waste tire cracking furnace

A waste tire and cracking furnace technology, which is applied in the preparation of liquid hydrocarbon mixtures, fibrous fillers, petroleum industry, etc., can solve the problems of potential safety hazards, high production costs, low processing capacity, etc., and achieve low production costs and processing capacity. The effect of large, processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0031] The embodiment of the present invention provides a waste tire pyrolysis furnace to solve the intermittent operation of waste tire loading and crude carbon black out of the pyrolysis equipment in the prior art; further, this type of furnace has high energy consumption, serious pollution, and potential safety hazards. The labor intensity is high, the production capacity is low, and the production cost is high.

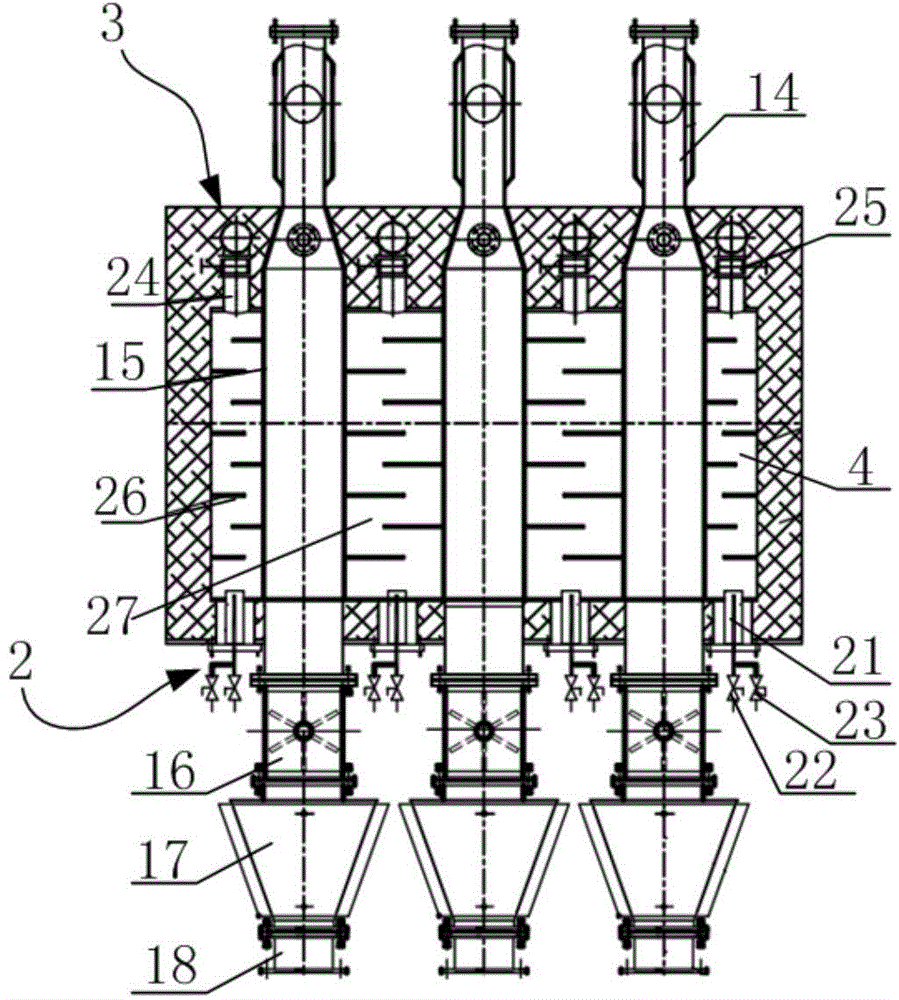

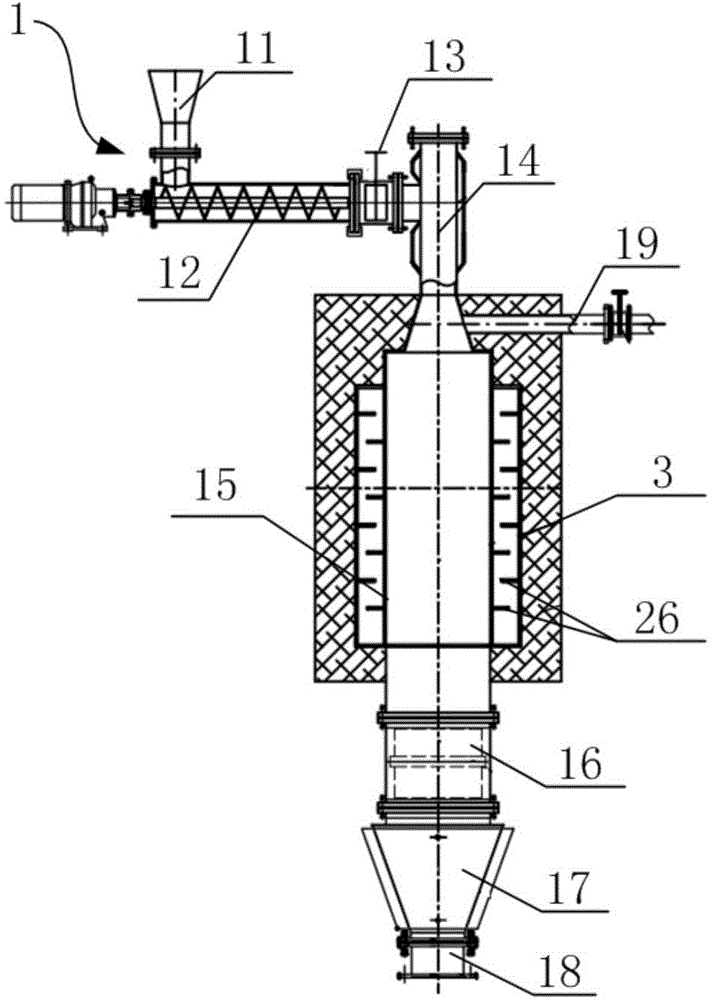

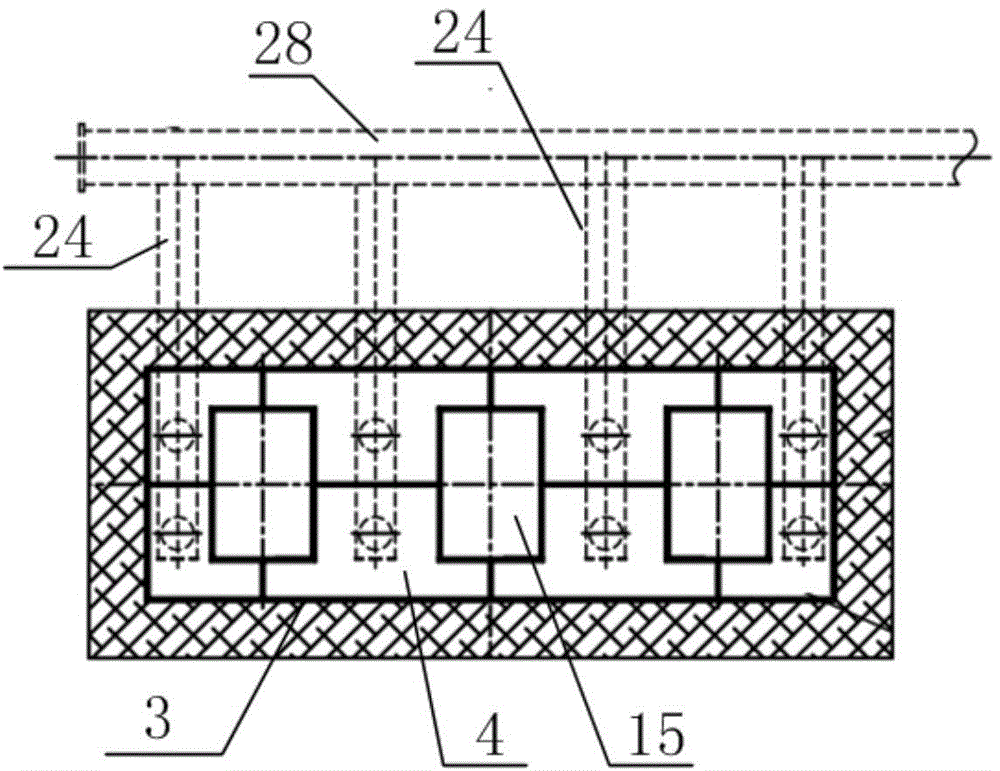

[0032] The technical solutions in the embodiments of the present invention are to solve the above-mentioned technical problems, and the general idea is as follows: figure 1 Shown is a schematic diagram of a tangent section of a waste tire pyrolysis furnace according to an embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com