Synchronous pre-support and anchorage device for follow-up heading machines

A technology of pre-support and roadheader, applied in the installation of bolts, pillars/supports, mining equipment, etc., can solve the problems of low work efficiency, insufficient support effect, low safety, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

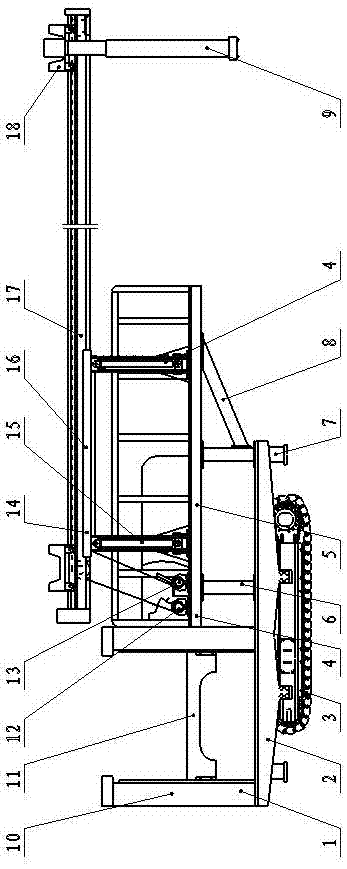

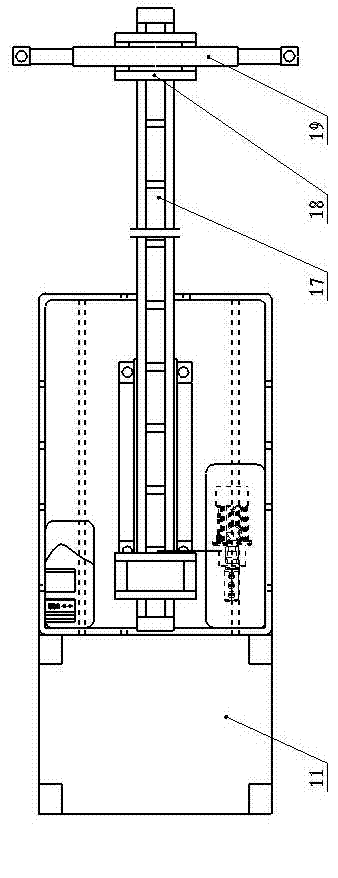

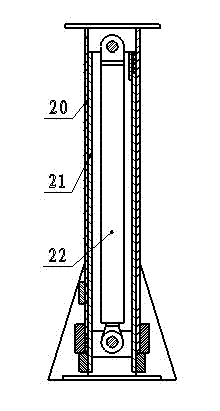

[0023] Such as figure 1 , figure 2 , image 3 As shown, the device for synchronous pre-support and anchor protection following the roadheader includes a lifting anchor protection platform 1, a frame 2, a running mechanism 3, a pre-support platform 4, a lifting frame 14 and a beam transport guide rail 17, and the frame 2 is fixedly installed on the On two walking mechanisms 3 with symmetrical arrangement and the same structure, the lifting anchor platform 1 and the pre-support platform 4 are fixed on the frame 2, the lifting frame 14 is arranged on the pre-supporting platform 4, and the beam transport guide rail 17 is installed on the lifting frame 14 superior;

[0024] The structure of the lifting anchor protection platform 1 is as follows: the lifting plate 11 is installed on four guide columns 10 through pulleys and wire ropes, and the four guide columns 10 are fixed on the frame 2;

[0025] The structure of the pre-support platform 4 is: the installation panel 5 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com