Physical method and equipment producing skinned walnut kernel

A physical method, walnut kernel technology, applied in food science, shelling, pod removal, etc., can solve the problems of wasting resources, affecting product quality, and low peeling rate, and achieve the effect of no loss of nutritional value and nutritional components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

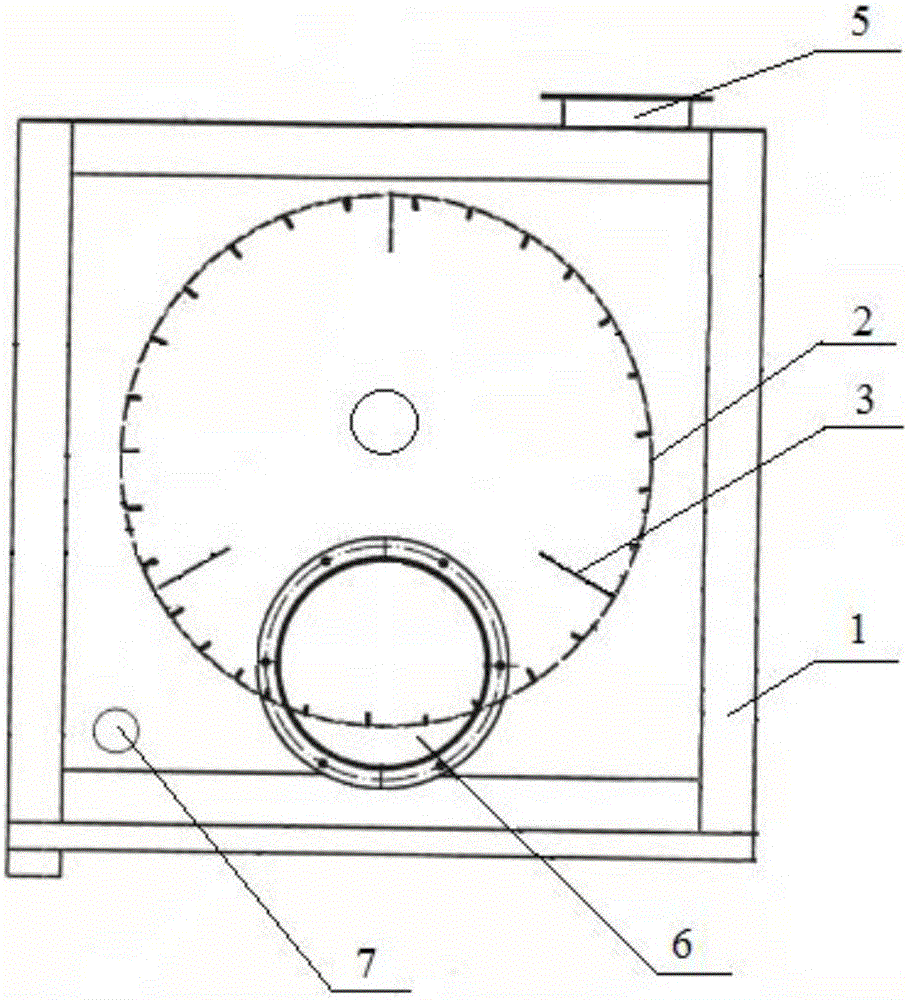

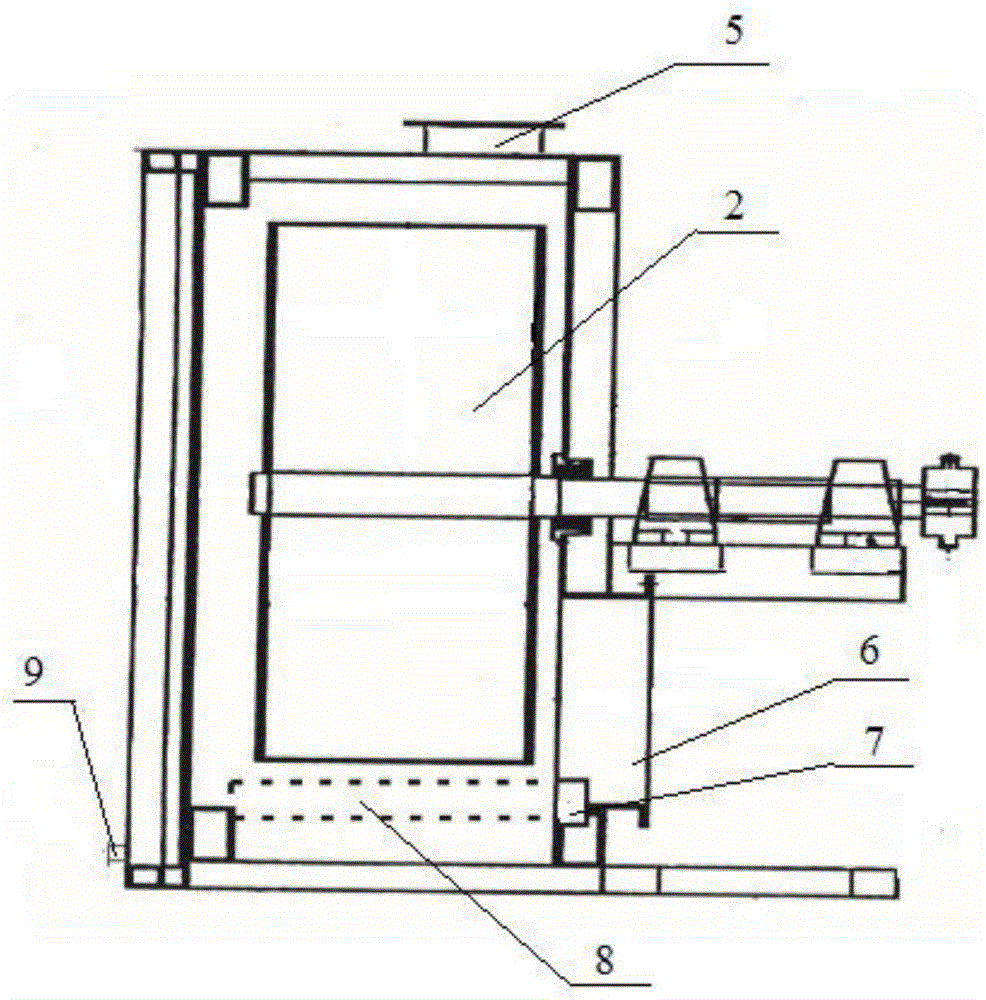

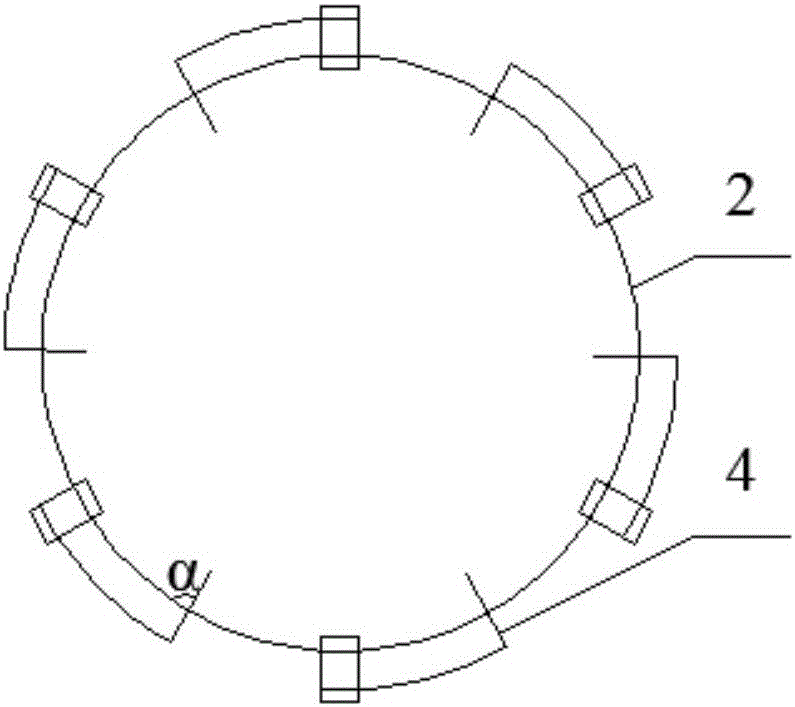

Method used

Image

Examples

Embodiment 1

[0043] The well-developed walnut kernels, which have a harvest period of no more than one year, are put into the first-stage drum oven for drying, and the hot air with a temperature of 90°C is introduced, and the rotating speed of the drum is controlled at 10r / min. After 15 minutes, it will be rotated and dried. Make walnut kernels undergo physical changes, create a small space between pure walnut kernels and underwear, and the underwear will become brittle. Due to the rotation, the walnut kernels will rub against each other, causing some of the dry and brittle walnut kernel underwear to fall off, and the walnut kernel underwear can fall up to 25%-40%, in an environment where the temperature is not lower than 50°C, use hot air to separate the underwear from the walnut kernels with part of the underwear to obtain the walnut kernels after preliminary treatment; put the walnut kernels after preliminary separation into In the second-stage drum oven, start the oven at a speed of 10r...

Embodiment 2

[0048] Put the well-developed walnut kernels, which have a harvest period of no more than one year, into a first-stage drum oven for drying, and pass in hot air at a temperature of 80°C, and control the drum speed at 20r / min. After 13 minutes, they will be rotated and dried. Make walnut kernels undergo physical changes, create a small space between pure walnut kernels and underwear, and the underwear will become brittle. Due to the rotation, the walnut kernels will rub against each other, causing some of the dry and brittle walnut kernel underwear to fall off, and the walnut kernel underwear can fall up to 25%-40%, in an environment where the temperature is not lower than 50°C, blow with hot air, separate the underwear from the walnut kernels with some underwear, and obtain the walnut kernels after preliminary treatment; put the walnut kernels after preliminary treatment into In the second-stage drum oven, start the oven at a speed of 20r / min and add saturated steam. After the ...

Embodiment 3

[0052] Put the well-developed walnut kernels, which have a harvest period of no more than one year, into a first-stage drum oven for drying, and pass hot air at a temperature of 70°C, control the drum speed at 30r / min, and rotate and dry after 12 minutes. Make walnut kernels undergo physical changes, create a small space between pure walnut kernels and underwear, and the underwear will become brittle. Due to the rotation, the walnut kernels will rub against each other, causing some of the dry and brittle walnut kernel underwear to fall off, and the walnut kernel underwear can fall up to 25%-40%, in an environment where the temperature is not lower than 50°C, blow with hot air, separate the underwear from the walnut kernels with some underwear, and obtain the walnut kernels after preliminary treatment; put the walnut kernels after preliminary treatment into Two-stage drum oven, start at 30r / min, add saturated steam, after the inner skin on the walnut kernel absorbs moisture, sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com