Egg yolk-phytosterol-polysaccharide composite emulsion gel and preparation method thereof

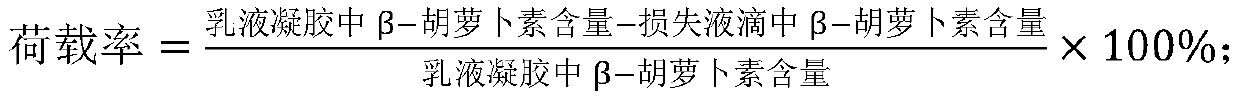

An emulsion gel and phytosterol technology, applied in food science and other directions, can solve the problems of reduced oil loading capacity, phase separation, increased loss of emulsion gel droplets, etc., to avoid the reduction of production efficiency and the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

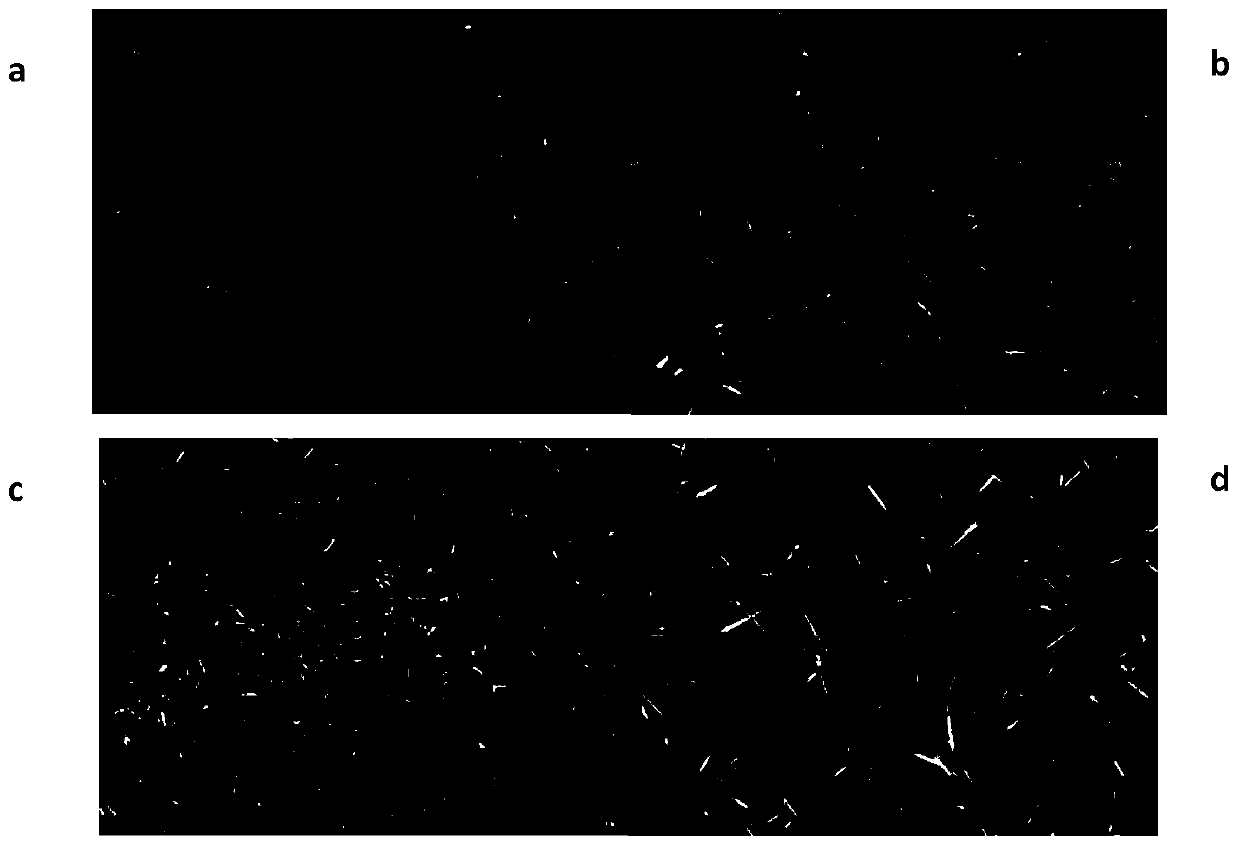

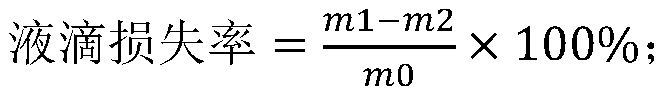

Image

Examples

Embodiment 1

[0049] (1) Separation of egg yolk: after the eggs are washed and dried, use an egg separator to separate and obtain the egg yolk;

[0050] (2) Preparation of egg yolk and polysaccharide compound emulsion:

[0051] Egg yolk and other components are mixed according to the following parts by weight: 3 parts of egg yolk, 6 parts of phytosterol (β-sitosterol), 0.4 part of gellan gum, 40 parts of walnut oil, 0.1 part of phosphate (sodium pyrophosphate 0.05, six 0.05 part of sodium metaphosphate), 0.05 part of sodium bicarbonate, 0.1 part of edible salt, 50 parts of water, and 0.1 part of white sugar; min, the homogenization time is 15 minutes;

[0052] (3) Formation of egg yolk-polysaccharide composite emulsion gel: heat the emulsion in step (2) at 95°C for 10 minutes to cool down to form a gel, then stir with a scraper stirrer and then homogenize for a short time with a rotor of 0.5 min, forming a semi-solid emulsion-filled gel, that is, an emulsion gel.

Embodiment 2

[0054] (1) Separation of egg yolk: after the eggs are washed and dried, use an egg separator to separate and obtain the egg yolk;

[0055] (2) Preparation of egg yolk and polysaccharide compound emulsion:

[0056] Egg yolk and other components are mixed according to the following parts by weight: 5 parts of egg yolk, 8 parts of phytosterol (6 parts of β-sitosterol+2 parts of campesterol), 1 part of polysaccharide (0.9 part of carrageenan+0.1 part of guar gum), 60 parts of perilla oil, 0.2 parts of sodium tripolyphosphate, 0.1 part of sodium bicarbonate, 0.5 parts of edible salt, 25 parts of water, and 5 parts of white sugar; after mixing, mix and emulsify in a high-shear mixing emulsifier, with a scraper stirring speed of 30r / min, homogenization speed 3200r / min, homogenization time 10 minutes;

[0057] (3) Formation of egg yolk-polysaccharide composite emulsion gel: heat the emulsion in step (2) at 75°C for 15 minutes to cool to form a gel, then stir with a scraper stirrer a...

Embodiment 3

[0059] (1) Separation of egg yolk: after the eggs are washed and dried, use an egg separator to separate and obtain the egg yolk;

[0060] (2) Preparation of egg yolk and polysaccharide compound emulsion:

[0061] Egg yolk and other components are mixed according to the following parts by weight: 7 parts of egg yolk, 12 parts of phytosterol (2.8 parts of β-sitosterol+1.2 parts of campesterol+0.8 part of brassicasterol+1.2 parts of stigmasterol), 0.5 part of polysaccharide ( 0.45 parts of carrageenan, 0.03 parts of xanthan gum, 0.02 parts of locust bean gum), 70 parts of DHA algae oil, 0.3 parts of sodium hexametaphosphate, 0.1 part of sodium carbonate, 0.1 part of edible salt, 10 parts of water, 8 parts of sugar; the above ingredients Mix and emulsify in a high-shear mixing emulsifier, with a scraper stirring speed of 30r / min, a homogenizing speed of 3200r / min, and a homogenizing time of 10 minutes.

[0062] (3) Formation of egg yolk-polysaccharide composite emulsion gel: hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com