Green preparation method and application of lignin-based hydrogel

A lignin-based, hydrogel technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as human injury and environmental hazards, achieve easy operation, reduce environmental pollution problems, steam depressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

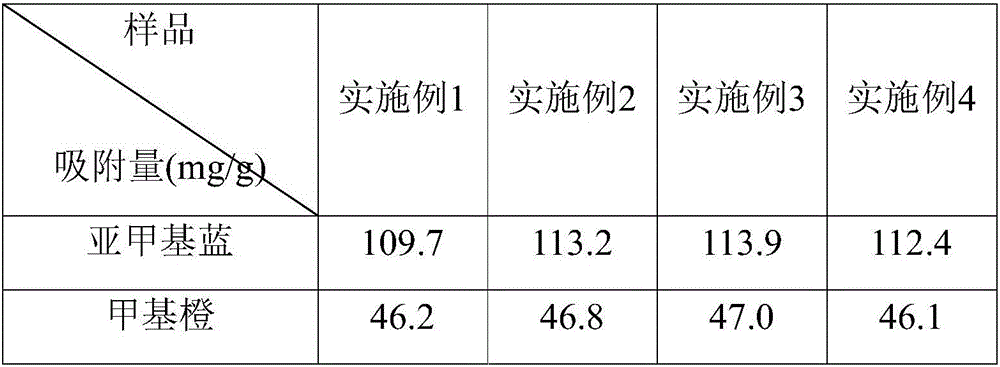

Embodiment 1

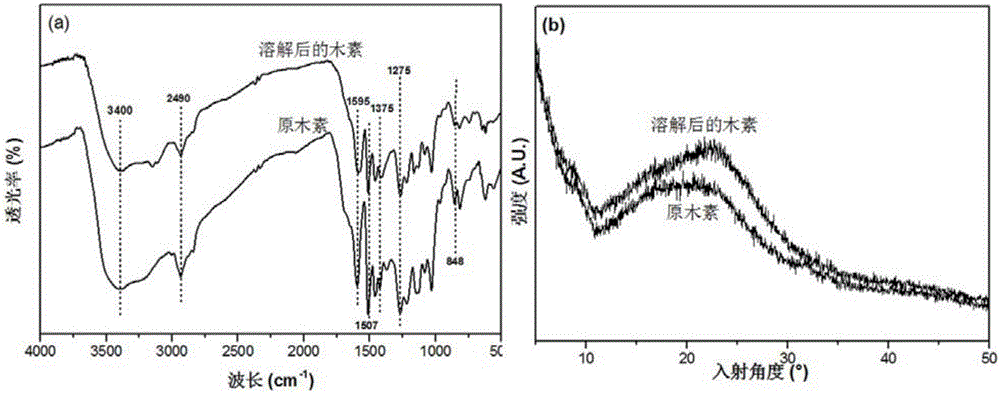

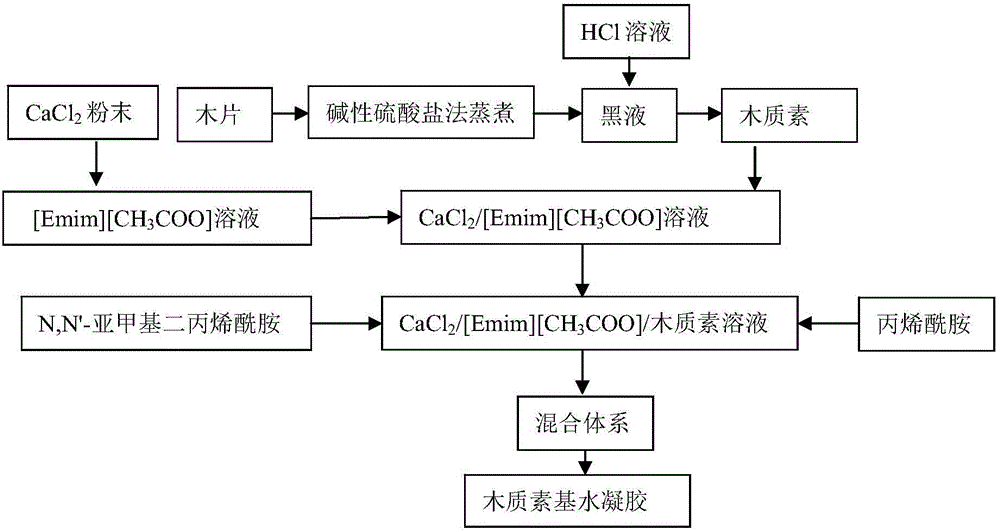

[0031] A kind of green preparation method of lignin-based hydrogel, the technological process is as follows figure 2 , including the following steps:

[0032] Weigh 5.0g 1-ethyl-3-methylimidazole acetate ([Emim][CH 3 COO]), at 80°C, magnetically stirred for 5min at a speed of 700r / min, adding 0.1g of CaCl 2 Powder (200 mesh), continue to stir for 15min to ensure that CaCl 2 The powder is completely dissolved in 1-ethyl-3-methylimidazole acetate solution, then add 0.1g lignin, stir for 10min, add 1.5g acrylamide and 0.10g N,N'-methylenebisacrylamide, Join 7.77×10 -2 After stirring for 15 minutes, quickly transfer the reaction system to a glass test tube, and react at 75°C for 1.5 hours under the protection of nitrogen or carbon dioxide gas. After the reaction, the hydrogel was taken out and soaked in 2000mL deionized water for 24 hours to remove impurities that did not participate in the reaction and 1-ethyl-3-methylimidazole acetate to obtain a pure lignin-based hydrogel....

Embodiment 2

[0035] A green preparation method of lignin-based hydrogel, comprising the following steps:

[0036] Weigh 5.0g 1-ethyl-3-methylimidazole acetate ([Emim][CH 3 COO]), at 80°C, magnetically stirred for 5min at a speed of 720r / min, adding 0.11g CaCl 2 Powder (300 mesh), continue to stir for 15min to ensure that CaCl 2 The powder is completely dissolved in 1-ethyl-3-methylimidazole acetate solution, then add 0.2g lignin, stir for 10min, add 1.7g acrylamide and 0.10g N,N'-methylenebisacrylamide, join 8.88×10 -2 After stirring for 15 minutes, the reaction system was quickly transferred to a glass test tube, and reacted at 80°C for 1.3 hours under the protection of nitrogen or carbon dioxide gas. After the reaction, the hydrogel was taken out and soaked in 2000mL deionized water for 24 hours to remove impurities that did not participate in the reaction and 1-ethyl-3-methylimidazole acetate to obtain a pure lignin-based hydrogel.

[0037] The lignin described in Example 2 is prepa...

Embodiment 3

[0039] A green preparation method of lignin-based hydrogel, comprising the following steps:

[0040] Weigh 5.0g 1-ethyl-3-methylimidazole acetate ([Emim][CH 3 COO]), at 80°C, magnetically stirred for 5min at a speed of 730r / min, added 0.12g CaCl 2 Powder (400 mesh), continue to stir for 15min to ensure that CaCl 2 The powder was completely dissolved in 1-ethyl-3-methylimidazole acetate solution, then 0.3g lignin was added, stirred for 10min, 2.0g acrylamide and 0.15g N,N'-methylenebisacrylamide were added, Join 9.99×10 -2 After stirring for 15 minutes, quickly transfer the reaction system to a glass test tube, and react at 85°C for 1.2 hours under the protection of nitrogen or carbon dioxide gas. After the reaction, the hydrogel was taken out and soaked in 2000mL deionized water for 24 hours to remove impurities that did not participate in the reaction and 1-ethyl-3-methylimidazole acetate to obtain a pure lignin-based hydrogel.

[0041] The lignin described in Example 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com