Device for promoting reaction by direct contact between blast furnace slag particles and biomass particles

A biomass particle, contact reaction technology, applied in the direction of biofuel, direct heating dry distillation, coke oven, etc., can solve the problems of different particle specific gravity, different residence time, low efficiency, etc., to solve pollution, avoid environmental pollution, easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

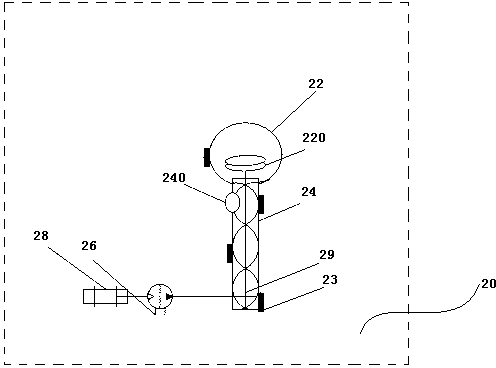

[0042] The present invention will be described in further detail below with reference to the accompanying drawings.

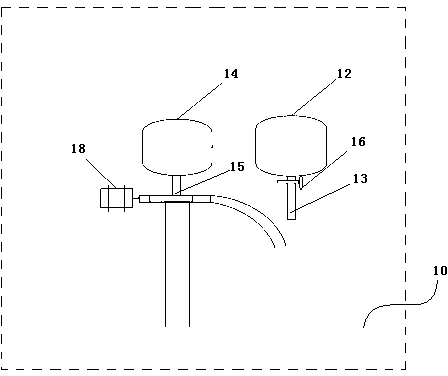

[0043] A device for direct contact reaction between blast furnace slag particles and biomass particles, mainly including a feeding device 10, a reaction device 20, a separation device 30, and a gas purification and collection device 40; the gas purification and collection device 40 includes a tar gas separation device connected in sequence at the top device 42, a carbon dioxide filter bottle 44 and a gas storage tank 46, and the top of the tar gas separator 42 communicates with the gas outlet of the reaction device 20.

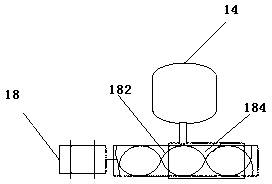

[0044] The feeding device 10 has a feeding device discharge pipe, and the feeding device 10 includes a biomass particle feeder 14, a blast furnace slag particle feeder 12 and a stepping motor 18; the biomass particle feeder 14 has a "D"-shaped biomass particle feeder Pipe 15, one end of the biomass particle feeding pipe 15 is connected with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com