Method for preparing calcium sulfate composite fertilizer by using solid waste titanium gypsum

A solid waste, titanium gypsum technology, applied in calcium fertilizers, ammonium orthophosphate fertilizers, alkaline orthophosphate fertilizers, etc., can solve the problems of secondary dust, occupation of large land, and large economic burden of titanium dioxide enterprises. Achieve the effect of benefiting heat absorption and warming, reducing surface crusting, good moisturizing and stomata

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

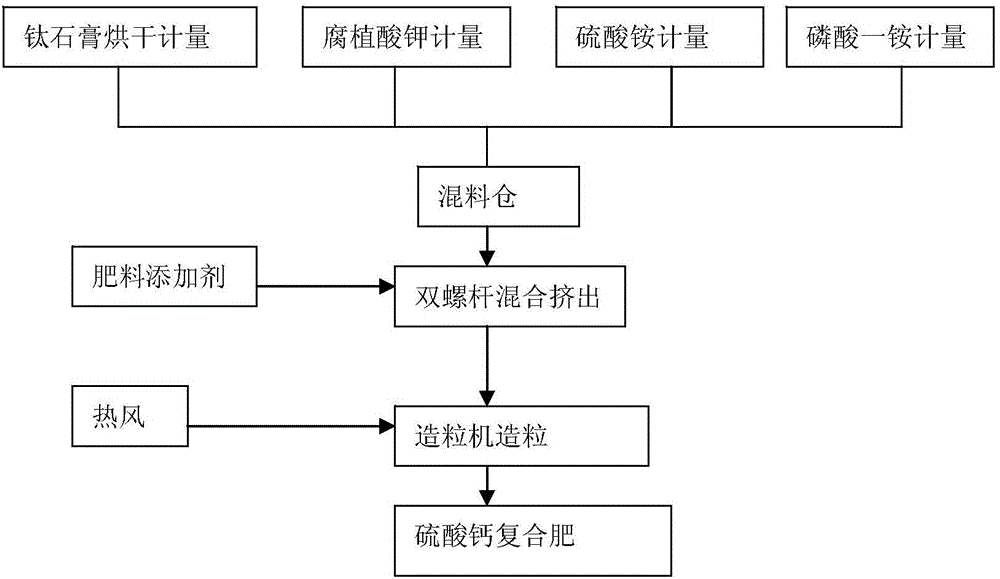

Method used

Image

Examples

Embodiment 1

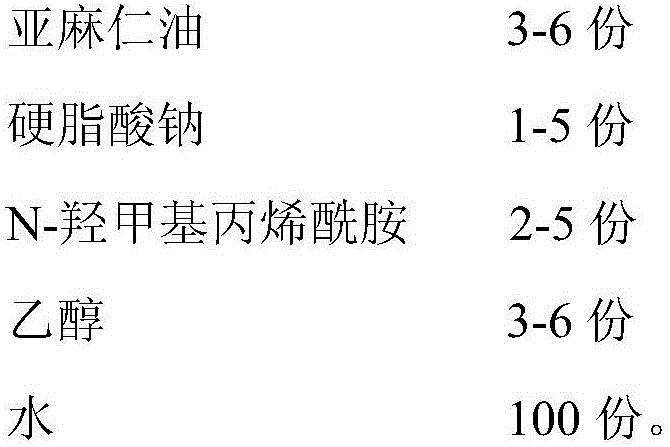

[0026] (1) Preparation of fertilizer additives: Add 3 g of linseed oil, 1 g of sodium stearate, 2 g of N-methylolacrylamide, and 3 g of ethanol into 100 g of water, and stir for 60 minutes for later use.

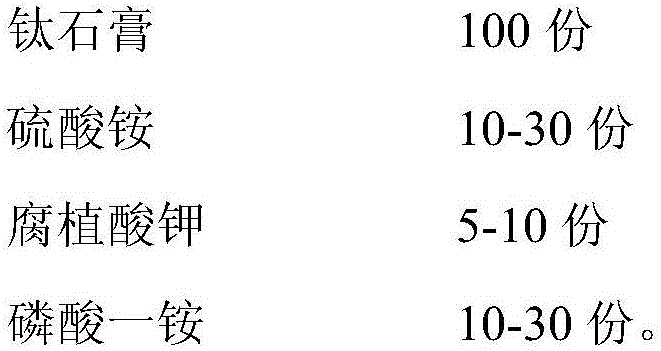

[0027] (2) Add 100g of titanium gypsum, 10g of ammonium sulfate, 5g of potassium humate, and 10g of monoammonium phosphate into the mixing chamber for material mixing. The mixing chamber adopts triple-helix stirring. After stirring for 30 minutes, it is mixed and extruded by twin-screw. 3% fertilizer additives are added to the front section of the twin-screw extruder (calculated based on the mass of the material in the mixing chamber), and the material extruded by the twin-screw extruder enters the granulator for granulation, and the particle size is required to be controlled at 2mm. Bao, which is calcium sulfate compound fertilizer, can be used as fertilization for the bottom layer of farmland pears.

Embodiment 2

[0029] (1) Preparation of fertilizer additives: Add 4 g of linseed oil, 2 g of sodium stearate, 3 g of N-methylolacrylamide, and 4 g of ethanol into 100 g of water, and stir for 60 minutes for later use.

[0030] (2) Add 100g of titanium gypsum, 20g of ammonium sulfate, 6g of potassium humate, and 20g of monoammonium phosphate into the mixing chamber for material mixing. The mixing chamber adopts triple-helix stirring. After stirring for 30 minutes, it is mixed and extruded by twin-screw. 4% fertilizer additives are added to the front section of the twin-screw extruder (calculated based on the mass of the material in the mixing bin), and the material extruded by the twin-screw extruder enters the granulator for granulation, and the particle size is required to be controlled at 3mm. Bao, which is calcium sulfate compound fertilizer, can be used as fertilization for the bottom layer of farmland pears.

Embodiment 3

[0032] (1) Preparation of fertilizer additives: Add 5 g of linseed oil, 3 g of sodium stearate, 4 g of N-methylolacrylamide, and 5 g of ethanol into 100 g of water, and stir for 60 minutes for later use.

[0033] (2) Add 100g of titanium gypsum, 30g of ammonium sulfate, 9g of potassium humate, and 30g of monoammonium phosphate into the mixing chamber for material mixing. The mixing chamber adopts triple-helix stirring. After stirring for 30 minutes, it is mixed and extruded by twin-screw. Add 6% fertilizer additives to the front section of the twin-screw extruder (calculated based on the material quality in the mixing bin), and the material extruded by the twin-screw extruder enters the granulator for granulation, and the particle size is required to be controlled at 5mm. Bao, which is calcium sulfate compound fertilizer, can be used as fertilization for the bottom layer of farmland pears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com