Liquid alkali-free accelerator for improving cohesiveness of sprayed concrete and preparation method thereof

A technology of shotcrete and accelerator, which is applied in the field of concrete admixtures and can solve problems such as the inability to effectively reduce the rebound rate of shotcrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

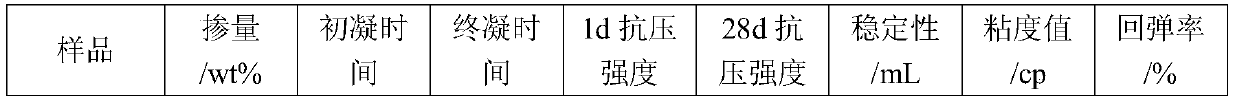

Examples

Embodiment 1

[0055] The preparation of the liquid alkali-free quick-setting agent that improves the cohesiveness of sprayed concrete comprises the following steps:

[0056] (1) Mix 20g of modified attapulgite and 80g of water, heat to 75°C, and disperse in a disperser with a linear speed of 10m / s. The high-speed dispersion time exceeds 30min. After 2h of reaction, a pre-dispersion solution is obtained A;

[0057] (2) Add 20g of industrial aluminum hydroxide to 50g of 50% dilute sulfuric acid, slowly add 30g of water, heat to 45°C, and react for 1h to obtain mixed solution B;

[0058] (3) 50g of industrial aluminum sulfate octadecahydrate, 3g of triethanolamine, 3g of oxalic acid and 44g of water were mixed and heated to 80°C, and reacted for 2 hours to obtain a mixed solution C;

[0059] (4) Add 20g of mixed solution B to 75g of mixed solution C, heat to 70-75°C, react for 1h, then add 5g of pre-dispersed solution A dropwise to mixed solution B and mixed solution C reactant at a speed of ...

Embodiment 2

[0061] The preparation of the liquid alkali-free quick-setting agent that improves the cohesiveness of sprayed concrete comprises the following steps:

[0062] (1) Mix 25g of modified attapulgite and 75g of water, heat to 75°C, and disperse in a disperser with a linear speed of 15m / s. The high-speed dispersion time exceeds 30min. After 2.5h of reaction, a pre-dispersion is obtained Solution A;

[0063] (2) Add 20g of industrial aluminum hydroxide to 50g of 50% dilute sulfuric acid, slowly add 30g of water, heat to 45°C, and react for 1h to obtain mixed solution B;

[0064] (3) 55g of industrial aluminum sulfate octadecahydrate, 6g of triethanolamine, 3g of oxalic acid, 2g of acetic acid and 34g of water were mixed and heated to 80°C, and reacted for 2 hours to obtain a mixed solution C;

[0065] (4) Add 20g of mixed solution B to 72g of mixed solution C, heat to 70-75°C, react for 1h, then add 8g of pre-dispersed solution A dropwise to mixed solution B and mixed solution C re...

Embodiment 3

[0067] The preparation of the liquid alkali-free quick-setting agent for improving the cohesiveness of sprayed concrete comprises the following steps:

[0068] (1) Mix 15g of modified attapulgite and 85g of water, heat to 75°C, and disperse in a disperser with a linear speed of 10m / s. The high-speed dispersion time exceeds 30min. After 2h of reaction, a pre-dispersion solution is obtained A;

[0069] (2) Add 25g of industrial aluminum hydroxide to 60g of 50% dilute sulfuric acid, slowly add 25g of water, heat to 45°C, and react for 2.0h to obtain mixed solution B;

[0070] (3) Mix 60g of industrial aluminum sulfate octadecahydrate, 5g of triisopropanolamine, 5g of oxalic acid and 30g of water and heat to 85°C, react for 3 hours to obtain mixed solution C;

[0071] (4) Add 20g of mixed solution B to 75g of mixed solution C, heat to 70-75°C, react for 1h, then add 5g of pre-dispersed solution A dropwise to mixed solution B and mixed solution C reactant at a speed of 10mL / min I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com