A permanent magnet bias bearingless switched reluctance starter/generator

A technology of switched reluctance and permanent magnet bias, applied in the shape/style/structure of magnetic circuit, magnetic circuit, synchronous machine, etc., can solve problems such as slot full rate limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

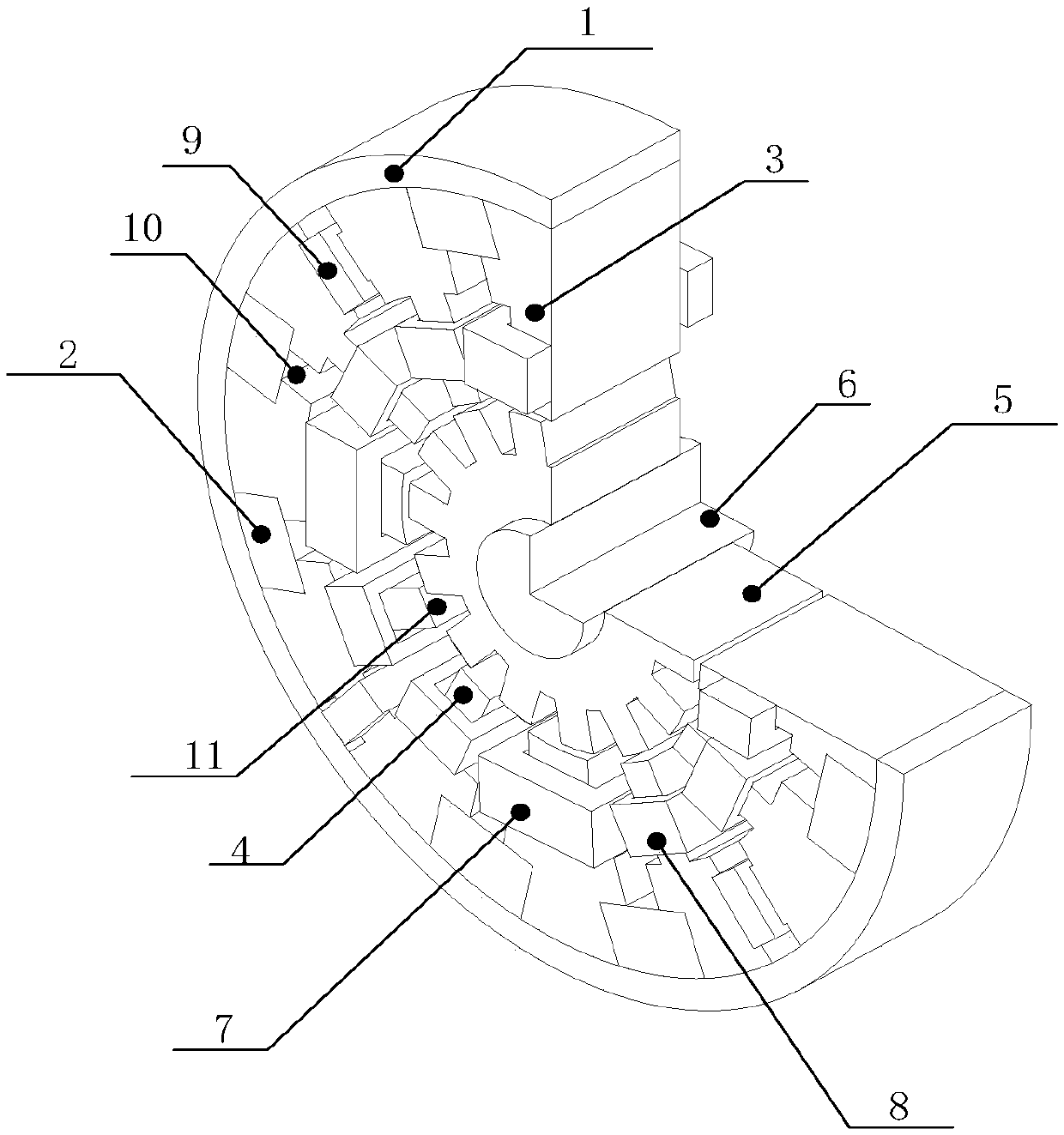

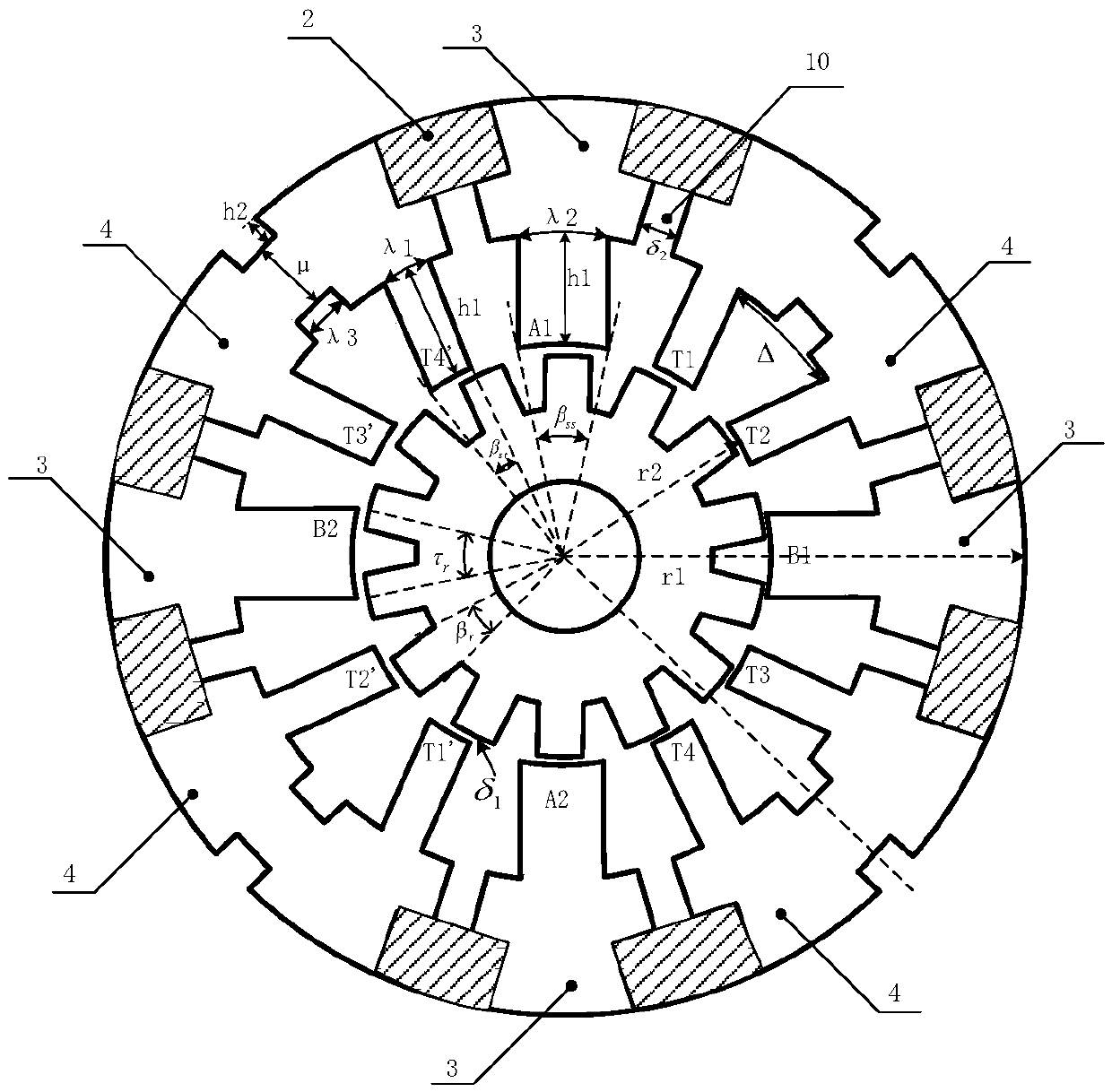

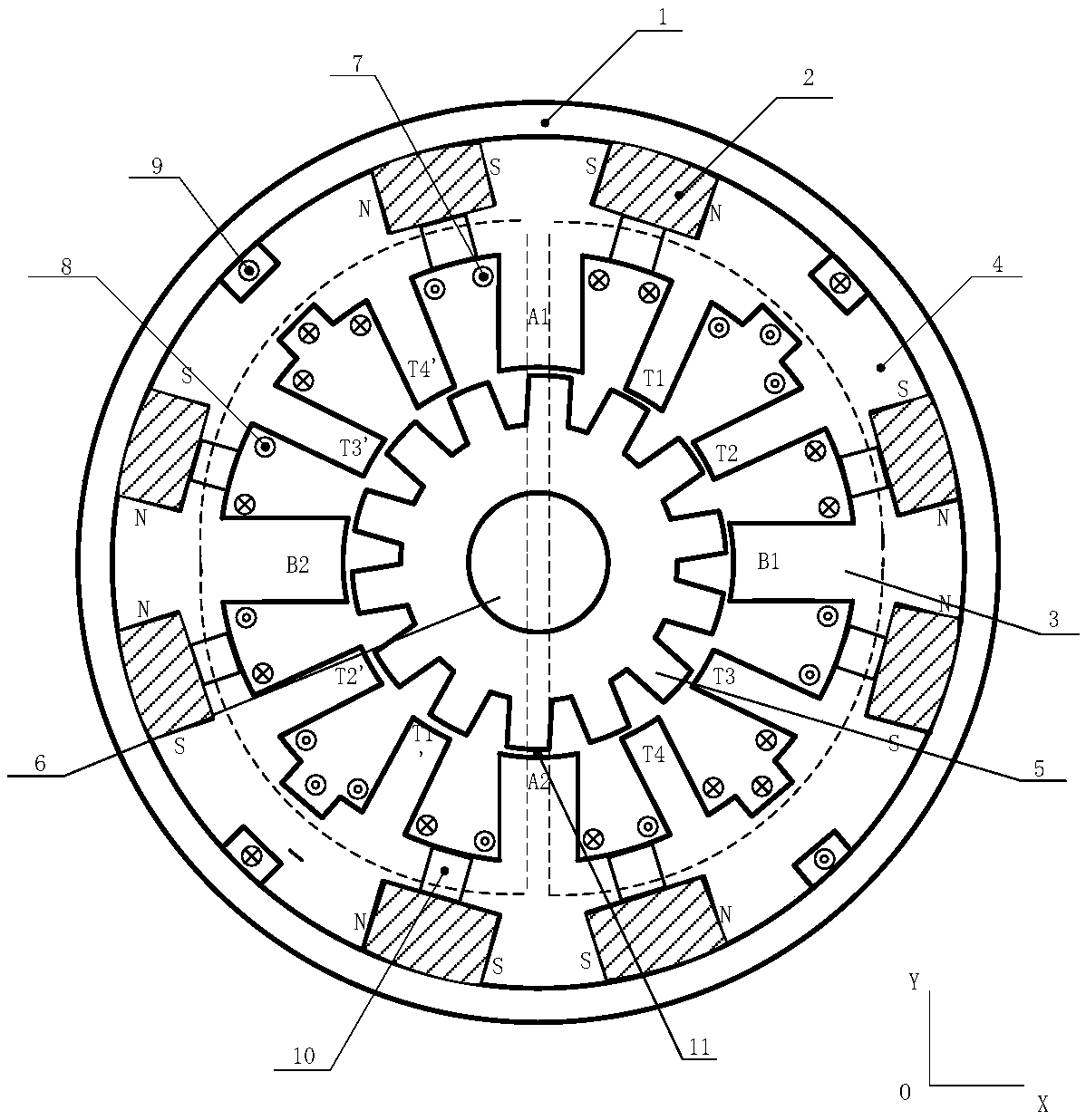

[0015] Such as figure 1 Shown is an axial cross-sectional view of a permanent magnet-biased bearingless switched reluctance starter / generator of the present invention. It consists of a stator back yoke 1, eight permanent magnets 2, four stator levitation cores 3, and four The stator torque core 4, a rotor core 5, a shaft 6, four suspension force winding coils 7, eight torque winding coils 8, and four auxiliary excitation winding coils 9. The stator levitation force core 3 is composed of four stator levitation force core teeth placed along the +x, -x, +y, -y directions, and a levitation force winding coil 7 is wound on it; the stator torque core 4 has a total of eight teeth, Evenly distributed on the circumference, and a torque winding coil 8 is wound on it. Set the outer diameter of the sub-suspension force core 3 and the stator torque core 4 to r1, the inner diameter to r2, and the arc length of the stator torque core tooth root λ 1 , Tooth height h1, polar arc β st ;The arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com