Equipment and method for improving card sliver quality by single-row nozzle mobile electrospinning method

An electrospinning method and electrospinning technology are applied in the field of textile equipment to provide a low-cost, high-efficiency improvement of sliver quality. Good electrostatic effect and the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

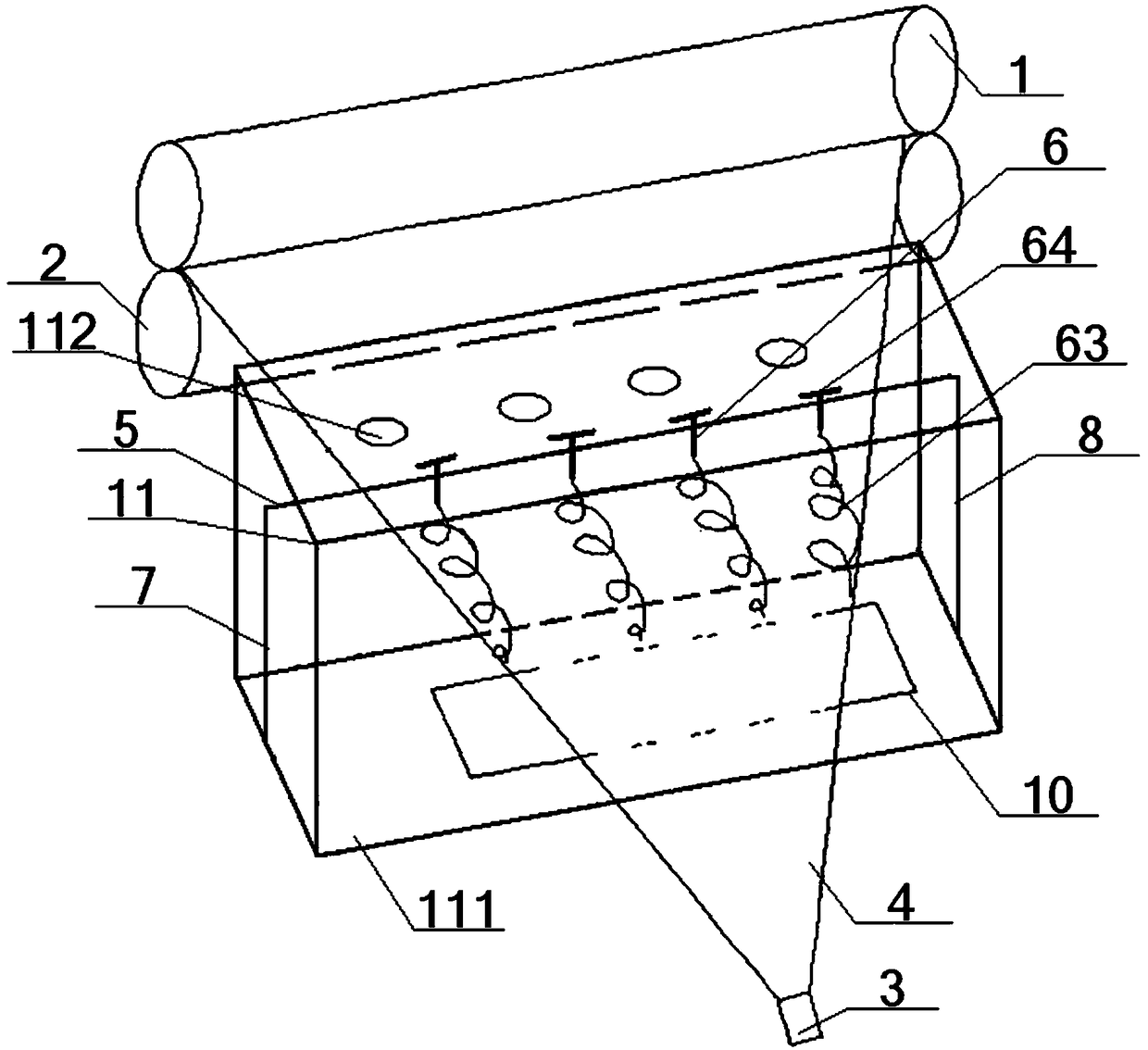

[0071] see figure 1 - Figure 7 , a device for improving the quality of raw sliver by a single-row nozzle mobile electrospinning method, including an upper roller 1, a lower roller 2, a bell mouth 3 and a cotton net 4, and the upper roller 1 and the lower roller 2 are facing up and down in parallel Set, one side of the cotton web 4 penetrates from the gap before the upper roll 1 and the lower roll 2, the other side of the cotton web 4 passes through the bell mouth 3, and the cotton web 4 is located on the upper roll 1, the lower roll 2 and the The parts between the bell mouths 3 exist in a triangular shape;

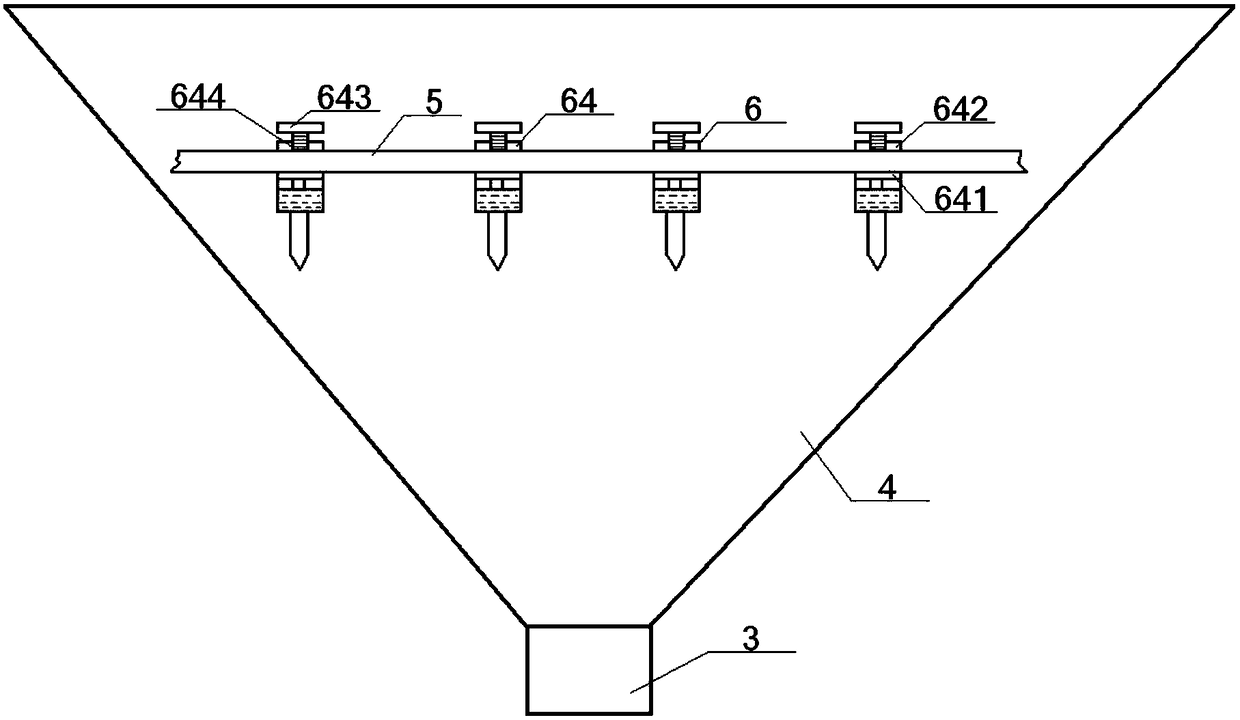

[0072] The top of the electrospinning nozzle 6 is provided with an insulating nozzle connection device 64, the nozzle connection device 64 includes a cavity part 641, a solid part 642, a bolt 643 and a through hole 644, and the bottom of the cavity part 641 is connected to the The top of the electrospinning nozzle 6 is connected, the top of the cavity part 641 is connec...

Embodiment 2

[0076] Basic content is the same as embodiment 1, the difference is:

[0077] The middle part of the horizontal fixed rod 5 is located directly above the cotton web 4, and the two ends of the horizontal fixed rod 5 extend to the outside of the cotton web 4, and a plurality of electrospinning nozzles 6 are arranged on the middle part of the horizontal fixed rod 5. The two ends of the fixed rod 5 are connected with the No. 1 vertical adjustment device 7 and the No. 2 vertical adjustment device 8 respectively, and a vertical adjustment device 7 and a No. 2 vertical adjustment device 8 are respectively provided with a Vertical moving device 9; the outside of the horizontal fixed rod 5, the No. 1 vertical adjusting device 7, the No. 2 vertical adjusting device 8, and the longitudinal moving device 9 are covered with the same outer cover 11 (transparent shield), and the outer cover 11 It is a closed structure with one-way opening, the bottom of the outer cover 11 is provided with an...

Embodiment 3

[0082] Basic content is the same as embodiment 2, the difference is:

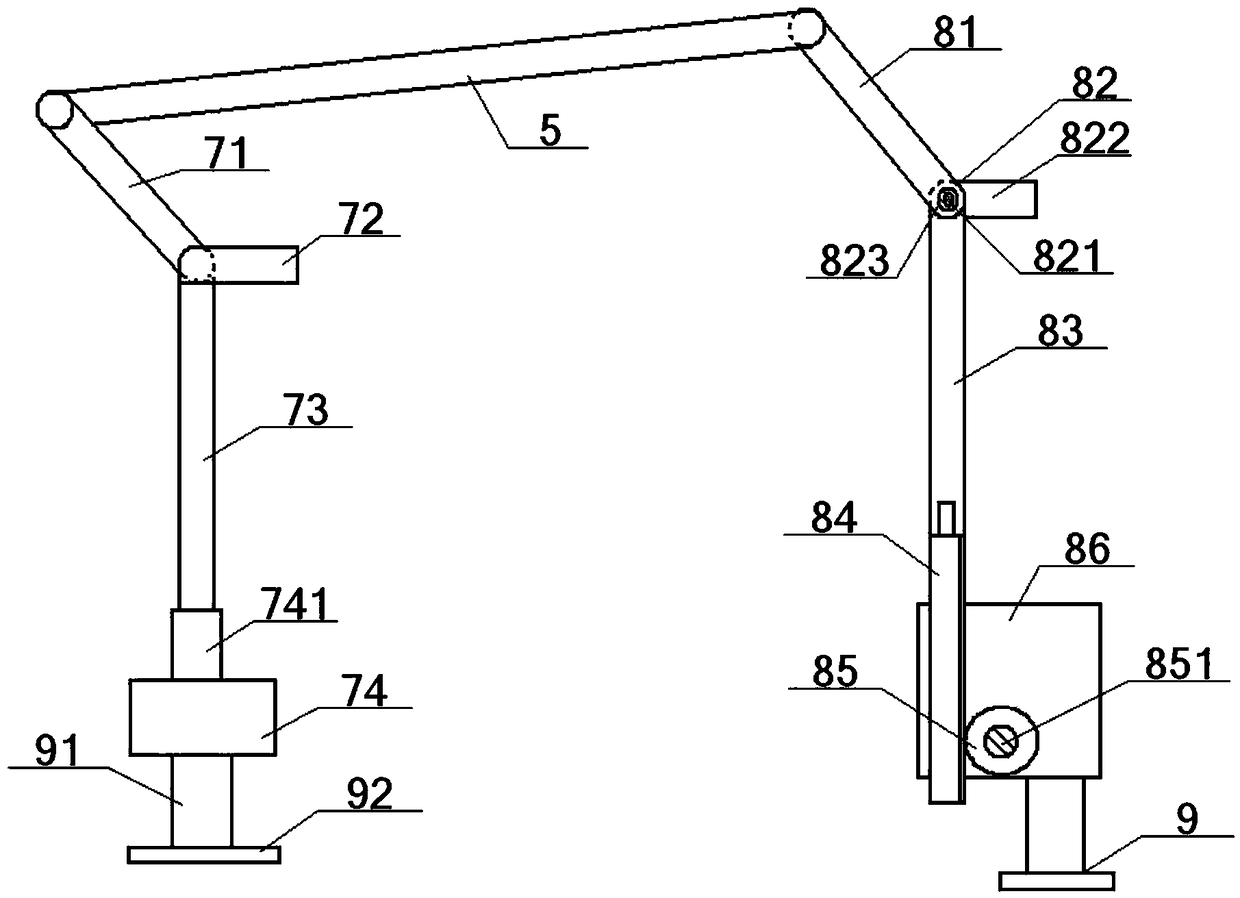

[0083] The No. 1 vertical adjustment device 7 includes a No. 1 swing arm 71, a No. 1 handle 72, a No. 1 vertical rod 73 and a No. 1 cylinder 74. The top of the No. 1 swing arm 71 is connected to the left end of the horizontal fixed rod 5 , the bottom of the No. 1 swing arm 71 is hinged with the top of the No. 1 vertical rod 73, the bottom of the No. 1 vertical rod 73 is connected with the driving rod 741 provided on the top of the No. 1 cylinder 74, and the bottom of the No. 1 cylinder 74 Connected with the longitudinal moving device 9; the No. 1 handle 72 is an L-shaped structure, including a No. 1 connecting shaft 721 and a No. 1 driving plate 722 vertically connected to each other, and the inner end of the No. 1 driving plate 722 is connected to the No. 1 connecting shaft 721 The outer ends of the No. 1 connecting shaft 721 pass through the junction of the No. 1 swing arm 71 and the No. 1 vertical bar 73...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com