Equipment and method for improving sliver quality by guiding electrospinning with support plate

A technology of electrospinning and electrospinning liquid, which is applied in the direction of electrospinning, textiles and papermaking, filament/thread forming, etc. It can solve the problems of static electricity affecting the quality of raw sliver, and achieve the solution of static electricity and strong environmental protection , Good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

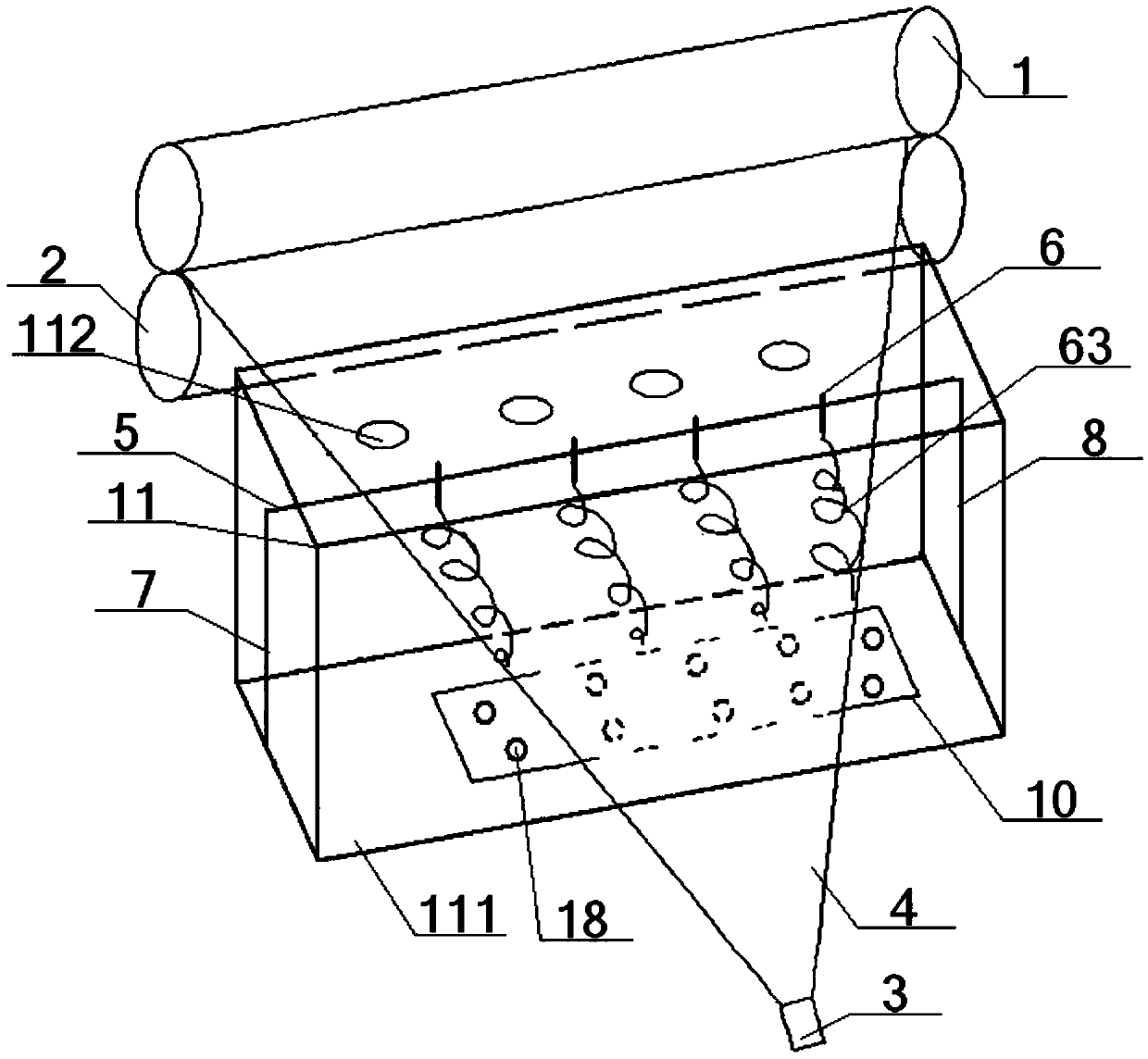

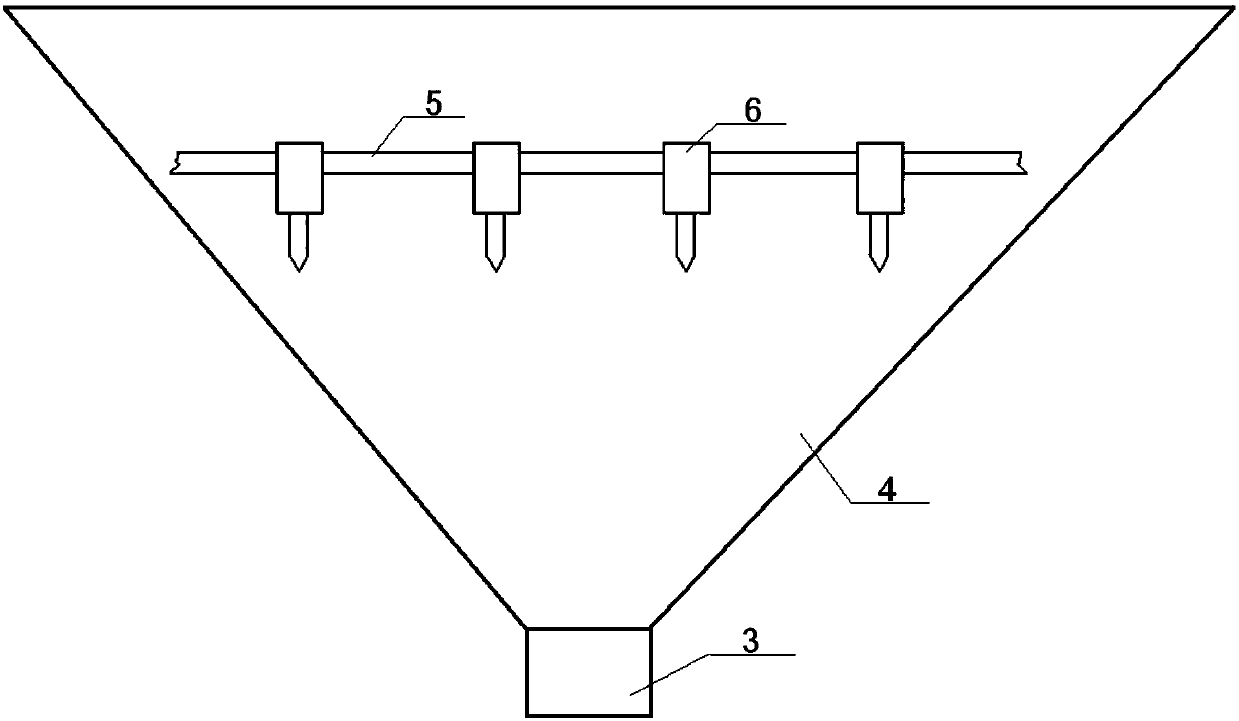

[0071] see figure 1 - Figure 8 , a device for improving the quality of raw sliver by guiding electrospinning with a support plate, comprising an upper roller 1, a lower roller 2, a bell mouth 3 and a cotton net 4, and the upper roller 1 and the lower roller 2 are arranged in parallel up and down One side of the cotton web 4 penetrates from the gap before the upper roll 1 and the lower roll 2, and the other side of the cotton web 4 passes through the bell mouth 3, and the cotton web 4 is located between the upper roll 1, the lower roll 2 and the horn. The part between mouth 3 exists in a triangular shape;

[0072] The top of described cotton web 4 is suspended with the transverse fixing bar 5 parallel with upper roller 1, lower roller 2, and this transverse fixing bar 5 is provided with a plurality of electrospinning nozzles 6, and the casing of described electrospinning nozzles 6 With high-voltage power supply 62 electrified, the inner chamber of electrospinning nozzle 6 is...

Embodiment 2

[0076] Basic content is the same as embodiment 1, the difference is:

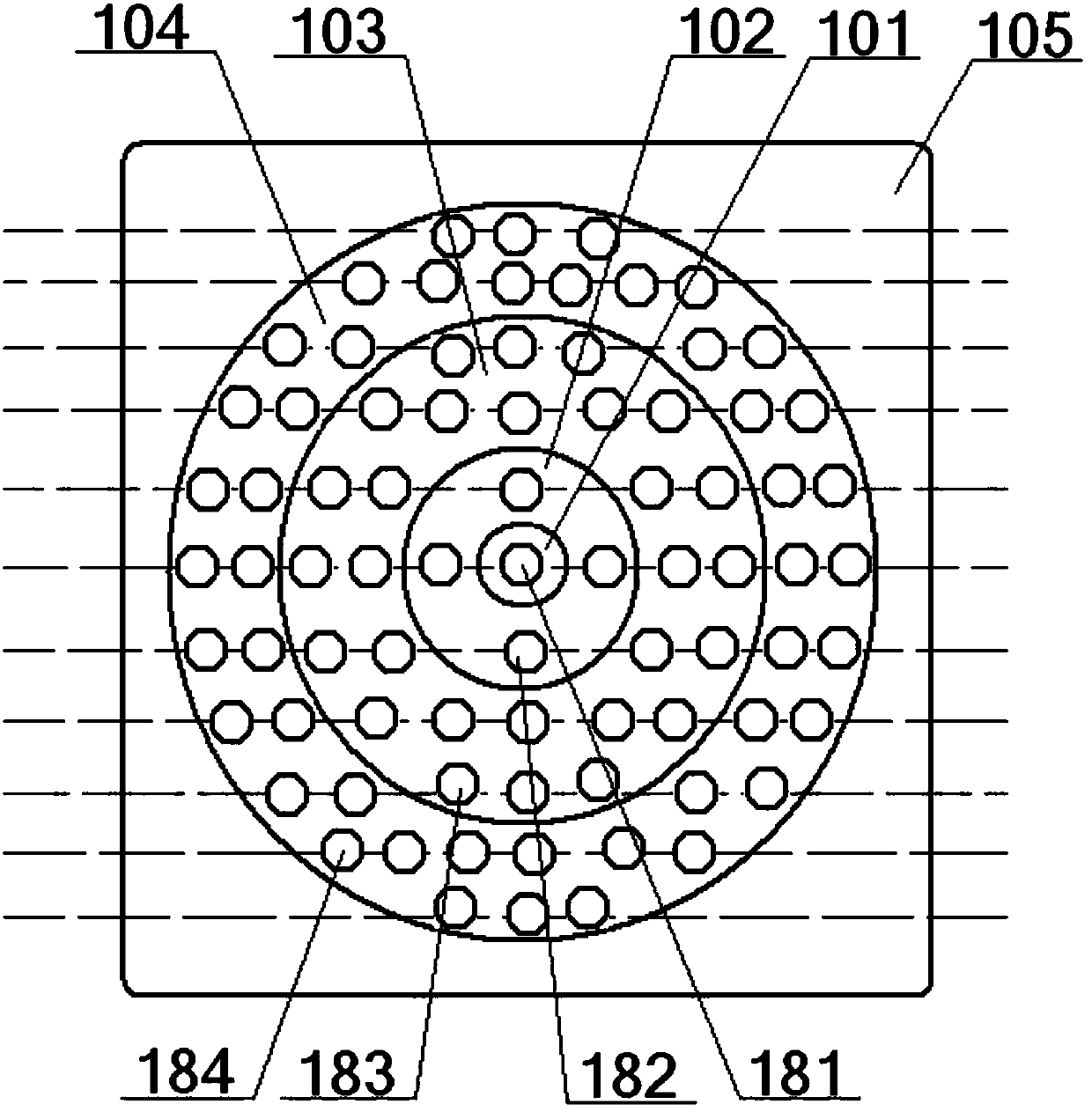

[0077] The guide air holes 18 include No. 1 guide air hole 181, No. 2 guide air hole 182, No. 3 guide air hole 183 and No. 4 guide air hole 184; Concentric No. 1 rotating annulus 101, No. 2 rotating annulus 102, No. 3 rotating annulus 103, and No. 4 rotating annulus 104. The center of the No. 1 rotating annulus 101 is provided with a No. 1 guide air hole 181, and No. 1 rotating ring surface 102 is provided with a plurality of No. 2 guide air holes 182, No. 3 rotating ring surface 103 is provided with a plurality of No. 3 guiding air holes 183, and No. 4 rotating ring surface 104 is provided with a plurality of No. 4 guiding air holes. hole 184; the No. 2 guide air hole 182 is evenly arranged in the same circle on the No. 2 rotating annulus 102, and the No. 3 guiding air hole 183 is evenly arranged in two concentric circles on the No. 3 rotating annulus 103, The No. 4 air guide holes 184 are evenly arranged...

Embodiment 3

[0079] Basic content is the same as embodiment 1, the difference is:

[0080] The middle part of the horizontal fixed rod 5 is located directly above the cotton web 4, and the two ends of the horizontal fixed rod 5 extend to the outside of the cotton web 4, and a plurality of electrospinning nozzles 6 are arranged on the middle part of the horizontal fixed rod 5. The two ends of the fixed rod 5 are connected with the No. 1 vertical adjustment device 7 and the No. 2 vertical adjustment device 8 respectively, and a vertical adjustment device 7 and a No. 2 vertical adjustment device 8 are respectively provided with a Vertical moving device 9; the outside of the horizontal fixed rod 5, the No. 1 vertical adjusting device 7, the No. 2 vertical adjusting device 8, and the longitudinal moving device 9 are covered with the same outer cover 11 (transparent shield), and the outer cover 11 It is a closed structure with one-way opening, the bottom of the outer cover 11 is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com