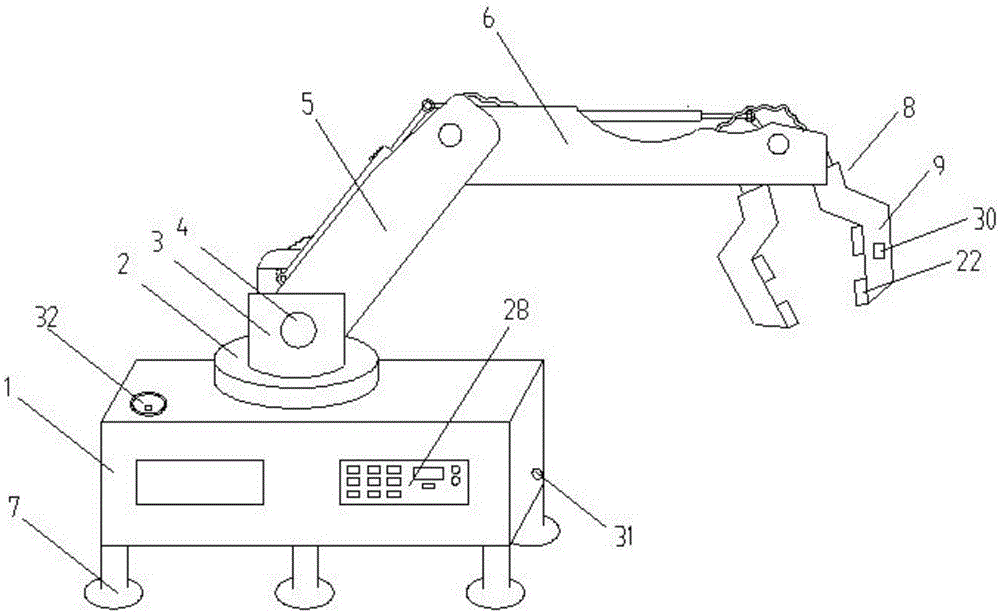

Hydraulic manipulator

A manipulator, hydraulic technology, applied in the field of manipulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

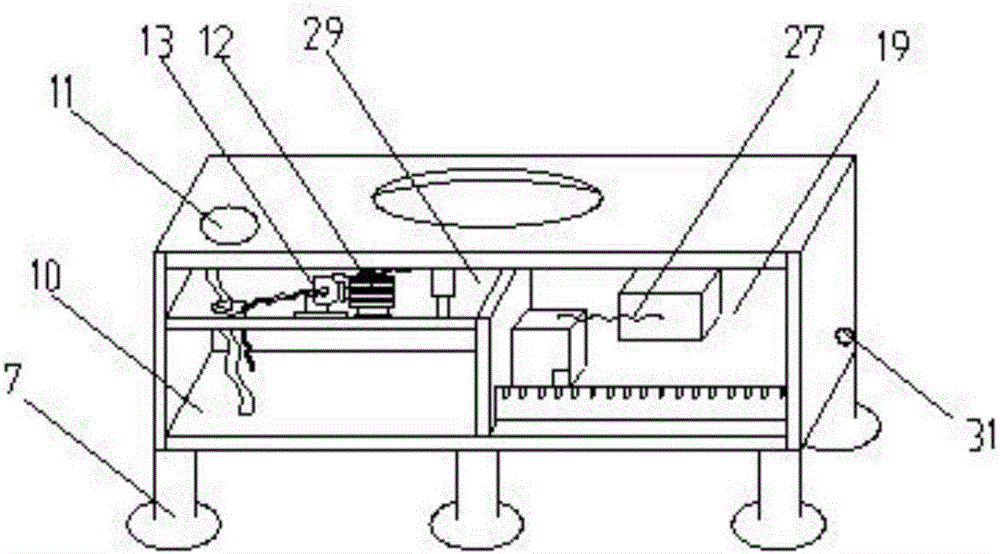

Examples

Embodiment 2

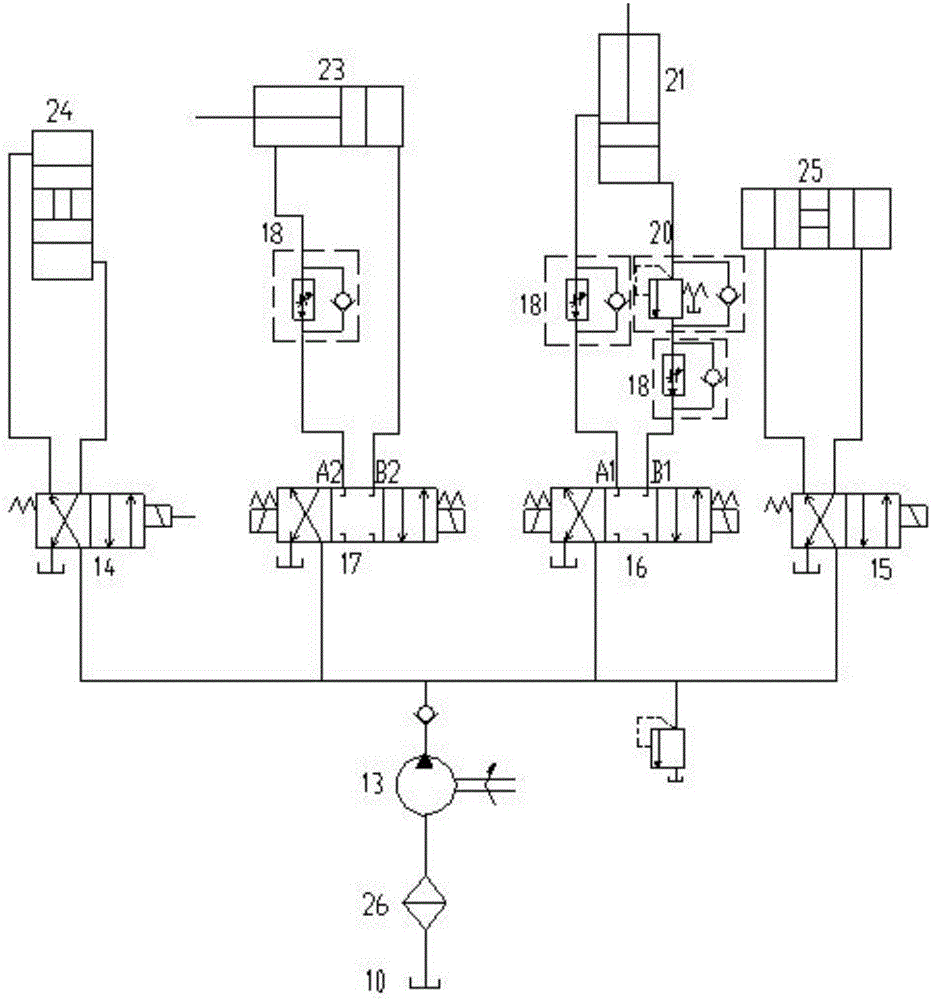

[0024]Embodiment 2: When the second three-position four-way electromagnetic reversing valve 17 is reversing to the left position, the first one-way valve inside the one-way throttle valve 18 and the adjustable throttle valve quickly feed the rodless cavity of the boom cylinder 23 quickly. Filled with oil, when the rod cavity of the boom cylinder 23 is completely filled with oil, the boom 5 rises to the highest position; when the second three-position four-way electromagnetic reversing valve 17 switches to the middle position, the first one-way valve is closed, The boom 5 is kept at the highest position, which can prevent the hydraulic manipulator from "nodding"; when the second, three-position, four-way electromagnetic reversing valve 17 is in the right position, the boom cylinder 23 has no rod cavity filled with oil, and the boom cylinder 23 has a rod The chamber pressure returns to the oil through the adjustable throttle valve. At this time, the one-way throttle valve 18 is c...

Embodiment 3

[0025] Embodiment 3: The operation mode of the two one-way throttle valves 18 connected to the first three-position four-way electromagnetic reversing valve 16 is the same as that of Embodiment 2. When the pressure in the rodless chamber of the forearm cylinder 21 reaches 1 MPa, the sequence valve will be sequenced. The valve moves to the right, and connects the oil circuit between the rodless chamber of the forearm oil cylinder 21 and the one-way throttle valve 18. At the same time, the spring chamber of the sequence valve is connected to the oil tank 10, which can ensure that the spring chamber of the sequence valve is always in a low-pressure state and prevent the sequence valve from being stuck. Simultaneously when the rodless cavity of the arm oil cylinder 21 is in a state where the pressure is lower than 1 MPa, the sequence valve closes the oil circuit between the rodless cavity of the arm cylinder 21 and the one-way throttle valve 18, and the first one-way sequence valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com