Thin film type infrared-radar beam synthesizer

A radar beam and beam synthesizing technology is applied in the field of infrared-radar beam synthesizers, which can solve the problems of affecting test accuracy, large radar waves, and the inability of beam synthesizers to move with the simulator, and achieves high infrared reflectivity and radar waves. The effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

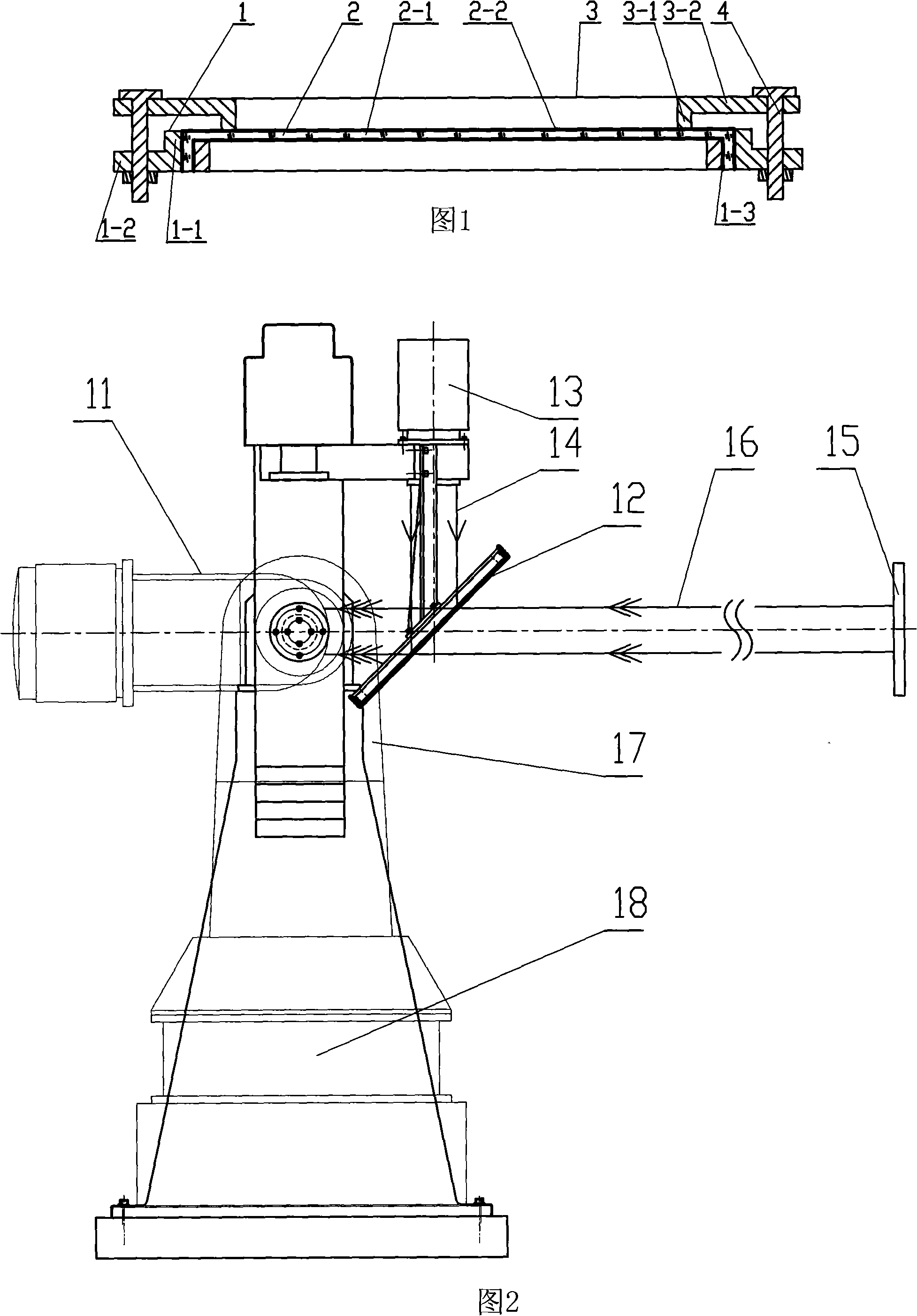

[0008] Specific Embodiment 1: This embodiment is described in conjunction with FIG. 1. The thin-film infrared-radar beam combiner described in this embodiment is composed of a fixed adjustment mechanism and a beam synthesis film 2, and the beam synthesis film 2 is fixed on the fixed adjustment mechanism. superior.

specific Embodiment approach 2

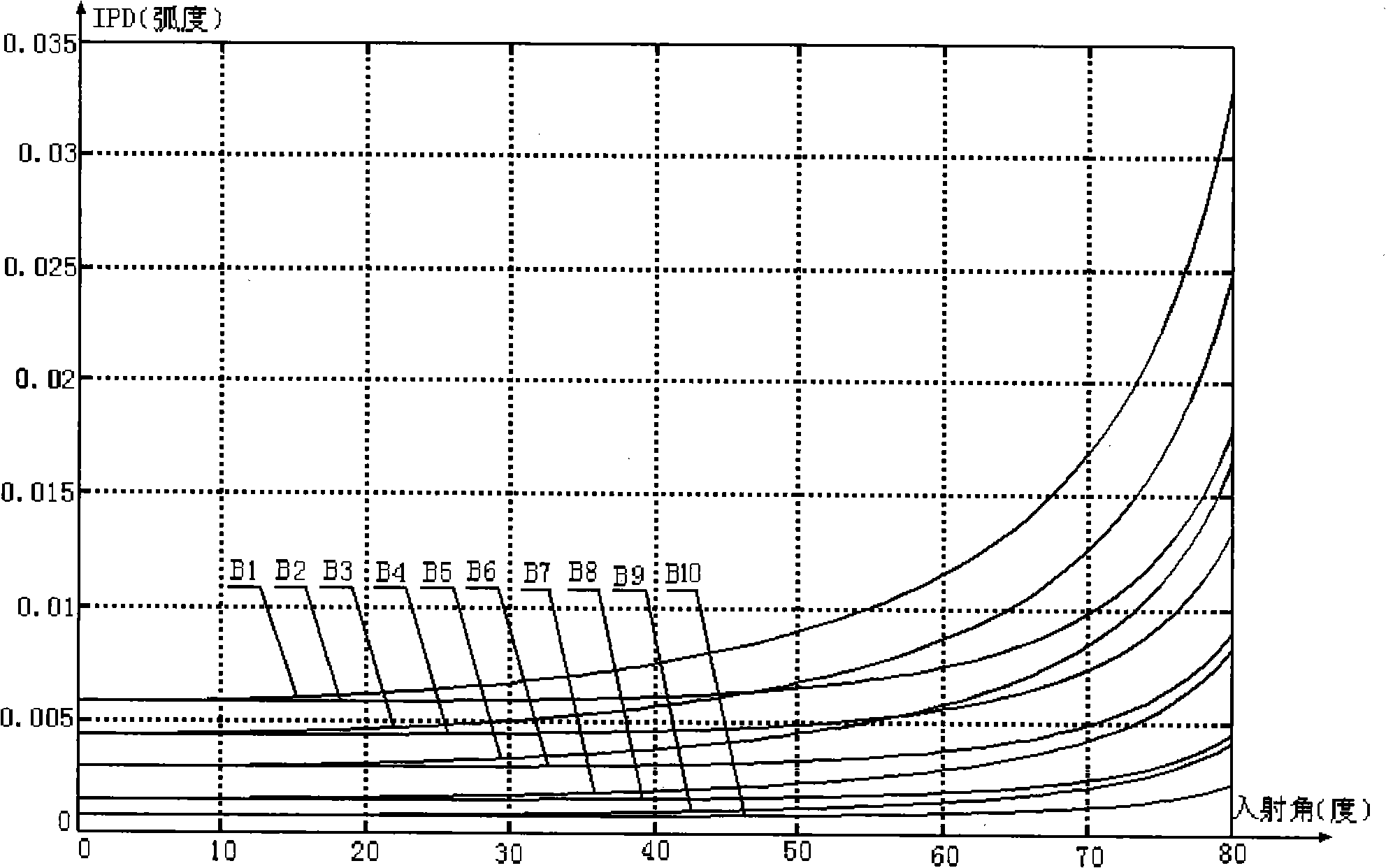

[0009] Embodiment 2: The thickness of the beamforming film 2 in this embodiment is 0.005mm-1mm. In order to reduce the IPD value and its difference in the horizontal and vertical directions, the thickness of the beamformer should be reduced as much as possible. Considering the processing technology and processing level of the non-metallic film and the comprehensive factors in the fixing process of the beamformer, the final thickness of the beamformer is selected at 0.05mm in practice. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific embodiment three: This embodiment is described in conjunction with FIG. 1. The beamforming film 2 in this embodiment is composed of a dielectric substrate 2-1 and a dielectric reflection film layer 2-2. The dielectric reflection film layer 2-2 is attached to on the outer surface of the dielectric substrate 2-1. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com