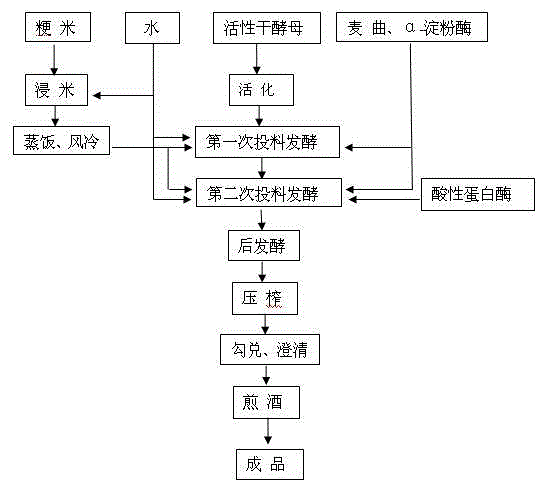

Manufacturing technology of japonica rice wine

A production process and technology for adding rice wine, applied in the field of production technology of rice wine with rice, can solve problems such as mashed paste foam and the like, and achieve the effects of preventing rancidity, preventing yeast senescence, and avoiding bacterial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The production process of japonica rice and rice wine in this embodiment 1 includes the following steps:

[0028] (1) Soaking rice: After 10,000kg of japonica rice is screened and removed, it is soaked for two days. The amount of soaked rice per day is 5000kg. The water surface is 10 cm above the rice layer. Soak for 6 hours and drain;

[0029] (2) Steamed rice and cooling: Steamed rice requires no white heart inside, loose and not sticky, cooked but not rotten, and uniform. The steamed rice is quickly blasted to the required temperature, so that the product temperature is 27°C;

[0030] (3) The first fermentation: activate 8kg of active dry yeast, and then mix rice (5000kg of japonica rice), 5000kg of water, 550kg of raw wheat koji, 300kg of cooked wheat koji, 300g of 35000U α-amylase and activated active dry yeast. Even, the product temperature is controlled at 27℃ after dropping the can, and the rake can be started 9 hours after the can, and the rake will be opened every 4...

Embodiment 2

[0036] The production process of japonica rice and rice wine in this embodiment 2 includes the following steps:

[0037] (1) Soaking rice: After 10,000kg of japonica rice has been screened and removed, it is soaked for two days. The amount of soaked rice per day is 5000kg. The water surface is 6 cm above the rice layer. Soak for 4 hours and drain;

[0038] (2) Steamed rice and cooling: Steamed rice requires no white heart inside, loose and not sticky, cooked but not rotten, and uniform. The steamed rice is quickly blasted to the required temperature, so that the product temperature is 25°C;

[0039] (3) The first feeding fermentation: activate 7kg of active dry yeast, then mix rice (5000kg of japonica rice), 4500kg of water, 500kg of raw wheat koji, 250kg of cooked wheat koji, 500g of 35000U α-amylase and activated active dry yeast. Even, the product temperature is controlled at 25°C after dropping the can, and the rake can be started 7 hours after dropping, and the rake will be ope...

Embodiment 3

[0045] The production process of japonica rice and rice wine in this embodiment 3 includes the following steps:

[0046] (1) Soaking rice: After 10,000kg of japonica rice is screened and removed, it is soaked for two days. The amount of soaked rice per day is 5000kg. The water surface is 8 cm above the rice layer. Soak for 5 hours and drain;

[0047] (2) Steamed rice and cooling: Steamed rice requires no white heart inside, loose and not mushy, cooked but not rotten and uniform. The steamed rice is quickly blasted to the required temperature, so that the product temperature is 26°C;

[0048] (3) The first fermentation: 7.5kg of active dry yeast is activated, then rice (5000kg of japonica rice), 4750kg of water, 525kg of raw wheat koji, 275kg of cooked wheat koji, 400g of 35000U α-amylase and activated active dry yeast Mix evenly, control the product temperature at 26°C after dropping the can, start the rake 8 hours after dropping, and open the rake every 3.5 hours later, control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com