Novel preparation method of Fe-MOF (ferrous-metal oxide framework) catalyst and application thereof in desulfurizing field

A catalyst, a new type of technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of short reaction time, decreased product quality, limited application, etc. To achieve the effect of simple preparation and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

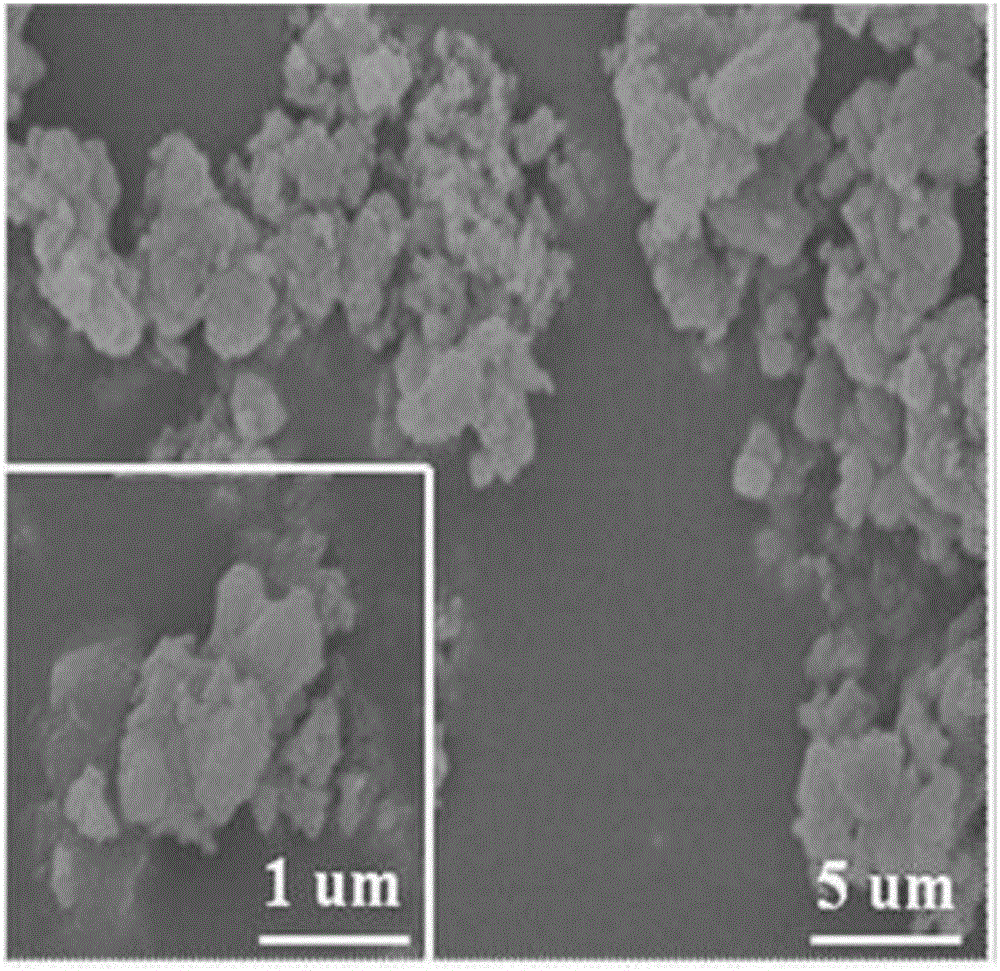

[0030] A kind of preparation of FeBTC catalyst, concrete steps are:

[0031] 240mL ethanol solution with a volume fraction of 66.7%, 1.75g organic ligand H 3 Add BTC and 2g of supporting electrolyte TBAP into the beaker, ultrasonicate for 10min, and the ultrasonic power is 100W, so that it is dispersed and dissolved evenly, and the electrolyte solution is made;

[0032] Metal Fe rod (purity is 99.98%) is used as anode, adopts copper rod as cathode, described anode, cathode and electrolytic solution are connected into electrolytic reaction circuit, guarantees that the distance between anode and cathode is 5cm, and the circuit voltage is 30V The resulting product was washed with ethanol and water for 3 times, dried at 100°C for 24h, and then treated under static vacuum at 120°C for 12h to obtain the FeBTC catalyst.

Embodiment 2

[0034] A kind of preparation of FeBTC catalyst, concrete steps are:

[0035] 240mL of 75% ethanol aqueous solution, 1.75g organic ligand H 3 Add BTC and 2g of supporting electrolyte TBAP into the beaker, ultrasonicate for 10min, and the ultrasonic power is 100W, so that it is dispersed and dissolved evenly, and the electrolyte solution is made;

[0036] Metal Fe rod (purity is 99.98%) is used as anode, adopts copper rod as cathode, described anode, cathode and electrolytic solution are connected into electrolytic reaction circuit, guarantees that the distance between anode and cathode is 5cm, and the circuit voltage is 30V The resulting product was washed with ethanol and water for 3 times, dried at 100°C for 24h, and then treated under static vacuum at 120°C for 12h to obtain the FeBTC catalyst.

Embodiment 3

[0038] A kind of preparation of FeBTC catalyst, concrete steps are:

[0039] 240mL of 80% ethanol aqueous solution, 1.75g organic ligand H 3 Add BTC and 2g of supporting electrolyte TBAP into the beaker, ultrasonicate for 10min, and the ultrasonic power is 100W, so that it is dispersed and dissolved evenly, and the electrolyte solution is made;

[0040] Metal Fe rod (purity is 99.98%) is used as anode, adopts copper rod as cathode, described anode, cathode and electrolytic solution are connected into electrolytic reaction circuit, guarantees that the distance between anode and cathode is 5cm, and the circuit voltage is 30V The resulting product was washed with ethanol and water for 3 times, dried at 100°C for 24h, and then treated under static vacuum at 120°C for 12h to obtain the FeBTC catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com