Industrial by-product gypsum reduction equipment

An industrial by-product gypsum and equipment technology, applied in the field of gypsum production equipment, can solve the problems of difficult temperature control, affecting the production efficiency and output of hemihydrate gypsum, and the temperature at the end far away from the flame-breathing furnace is low, so as to improve production efficiency, Improve air tightness and improve conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

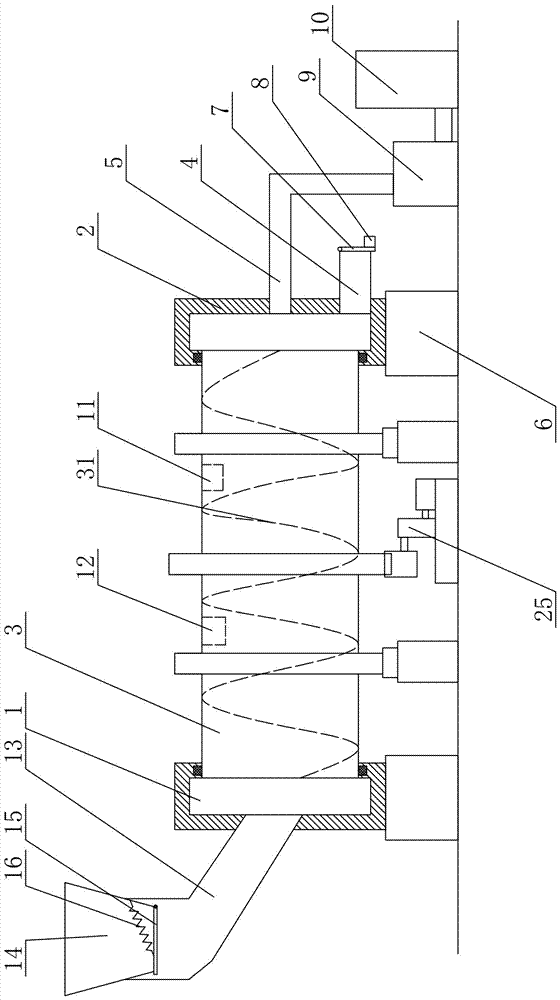

[0024] Such as figure 1As shown, a kind of industrial by-product gypsum reduction equipment, the reduction equipment is applied to the industrial by-product gypsum reduction method, the industrial by-product gypsum reduction method is as follows: anhydrous gypsum and hemihydrate gypsum are transported into the closed drum of the reduction equipment 3, at the same time transport water vapor into the airtight drum 3, under the pressure of 20~50kPa, mix anhydrite, hemihydrate gypsum and water vapor in the airtight drum 3 evenly, use the moisture and water of the hemihydrate gypsum Steam reduces anhydrite to hemihydrate gypsum. The reduction equipment includes a kiln head 1, a kiln tail 2, a drum 3, a feeding device, a discharge port 4, a rear air intake pipe 5, a power transmission device 25 and a supporting device 6. The supporting device 6 mentioned above supports the kiln head 1 and the kiln tail 2, the power transmission device 25 drives the drum 3 to rotate relative to the k...

Embodiment 2

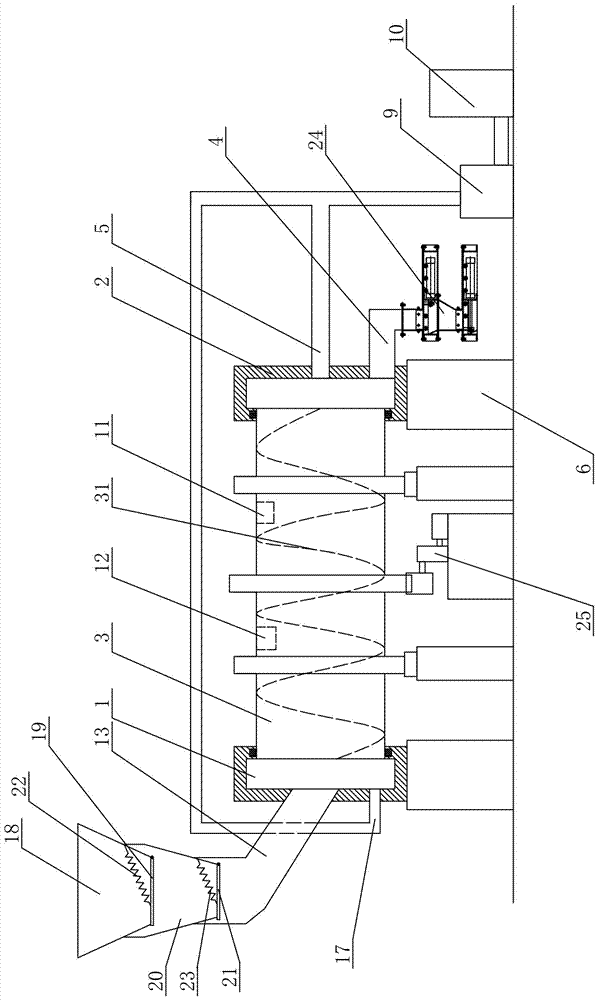

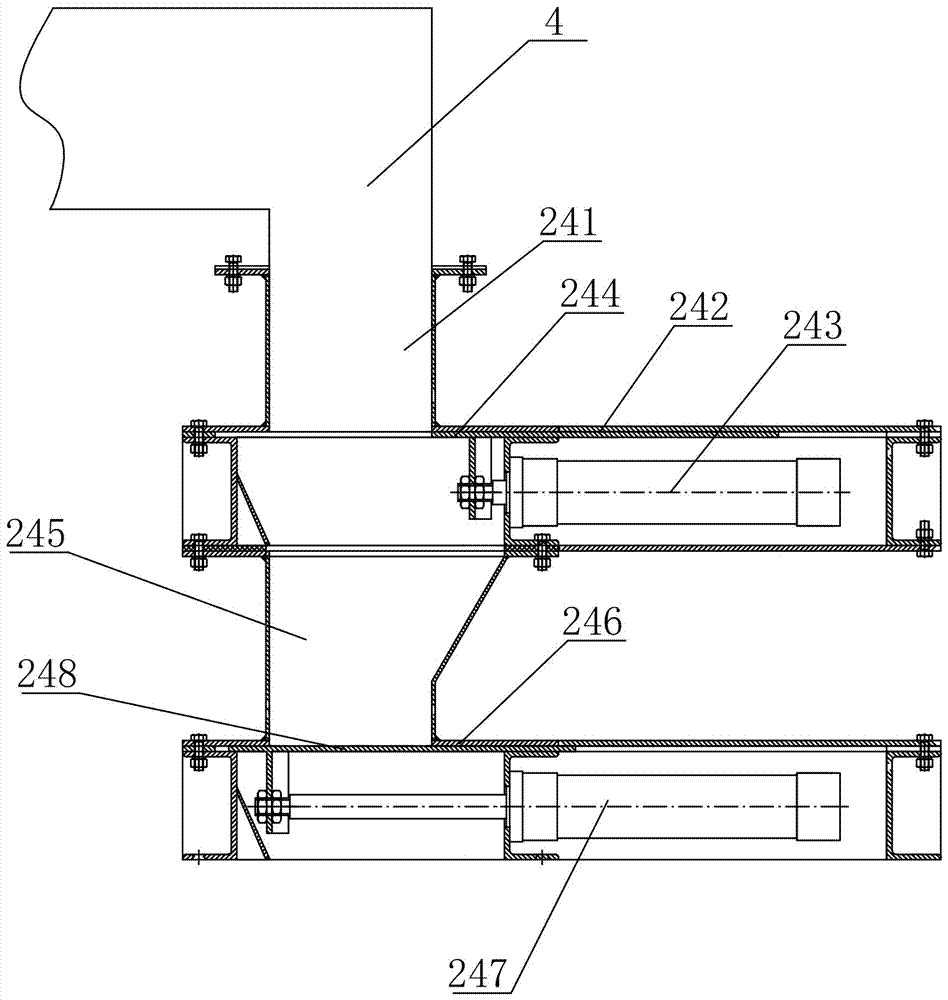

[0031] Such as figure 2 , image 3 As shown, the first embodiment is repeated, with the following differences: the kiln head 1 is provided with a head inlet pipe 17, and the head inlet pipe 17 is connected to the steam delivery pump 9 through a pipeline. The feeding device includes an upper hopper 18, an upper pressure door 19, a lower hopper 20, a lower pressure door 21 and a feeding pipe 13. The upper end of the upper hopper 18 is opened to connect the hemihydrate gypsum outlet and the anhydrous gypsum outlet of the gypsum dryer. , the lower part of the upper hopper 18 is fixedly connected to the upper part of the lower hopper 20, the lower opening of the upper hopper 18 is located in the lower hopper 20, and an upper pressure door 19 is arranged on the lower opening of the upper hopper 18, and one end of the upper pressure door 19 is hinged with the upper hopper 18, and the upper pressure door 19 is hinged to the upper hopper 18. The other end of the pressure door 19 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com