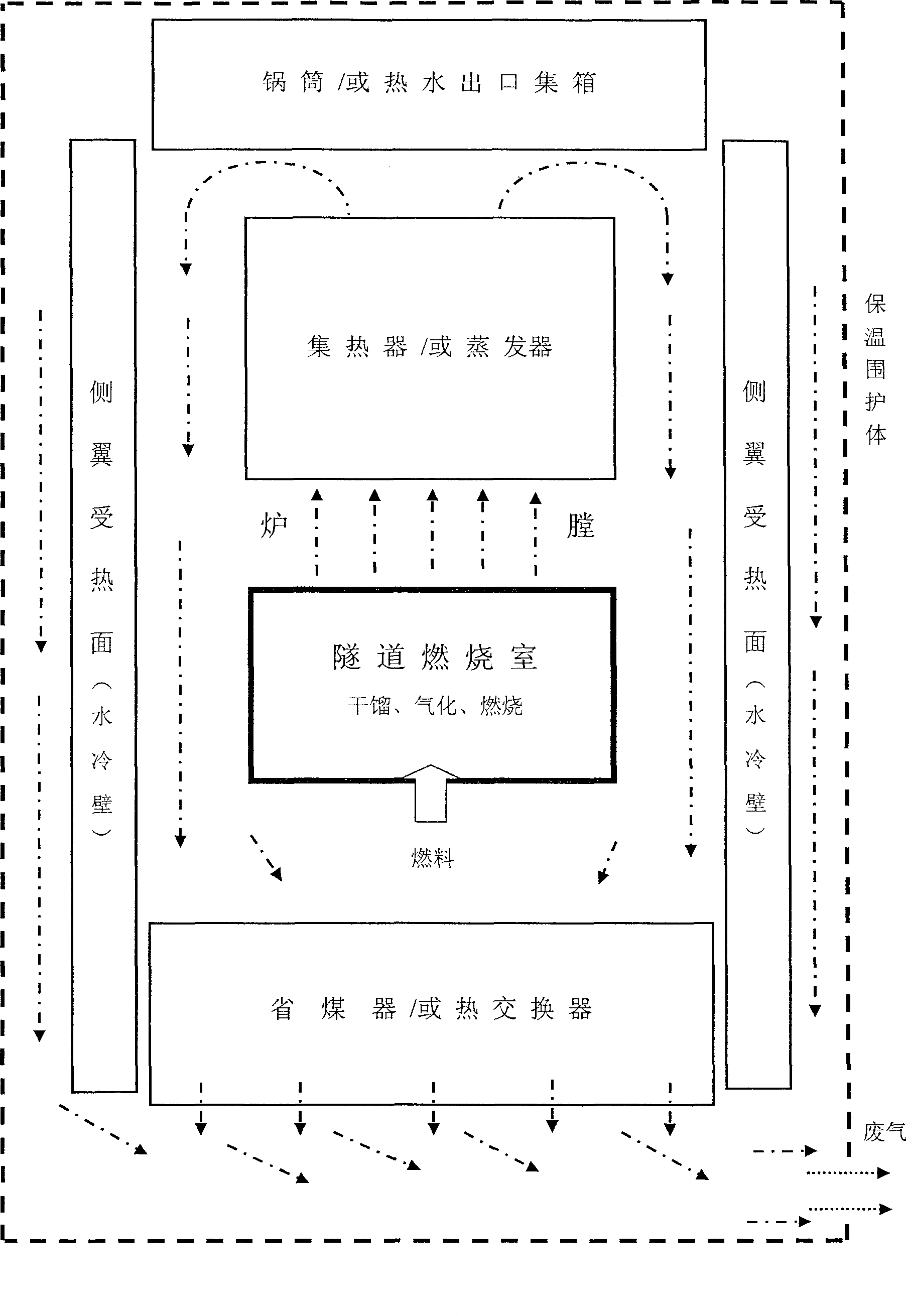

Patents

Literature

89results about How to "High efficiency requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

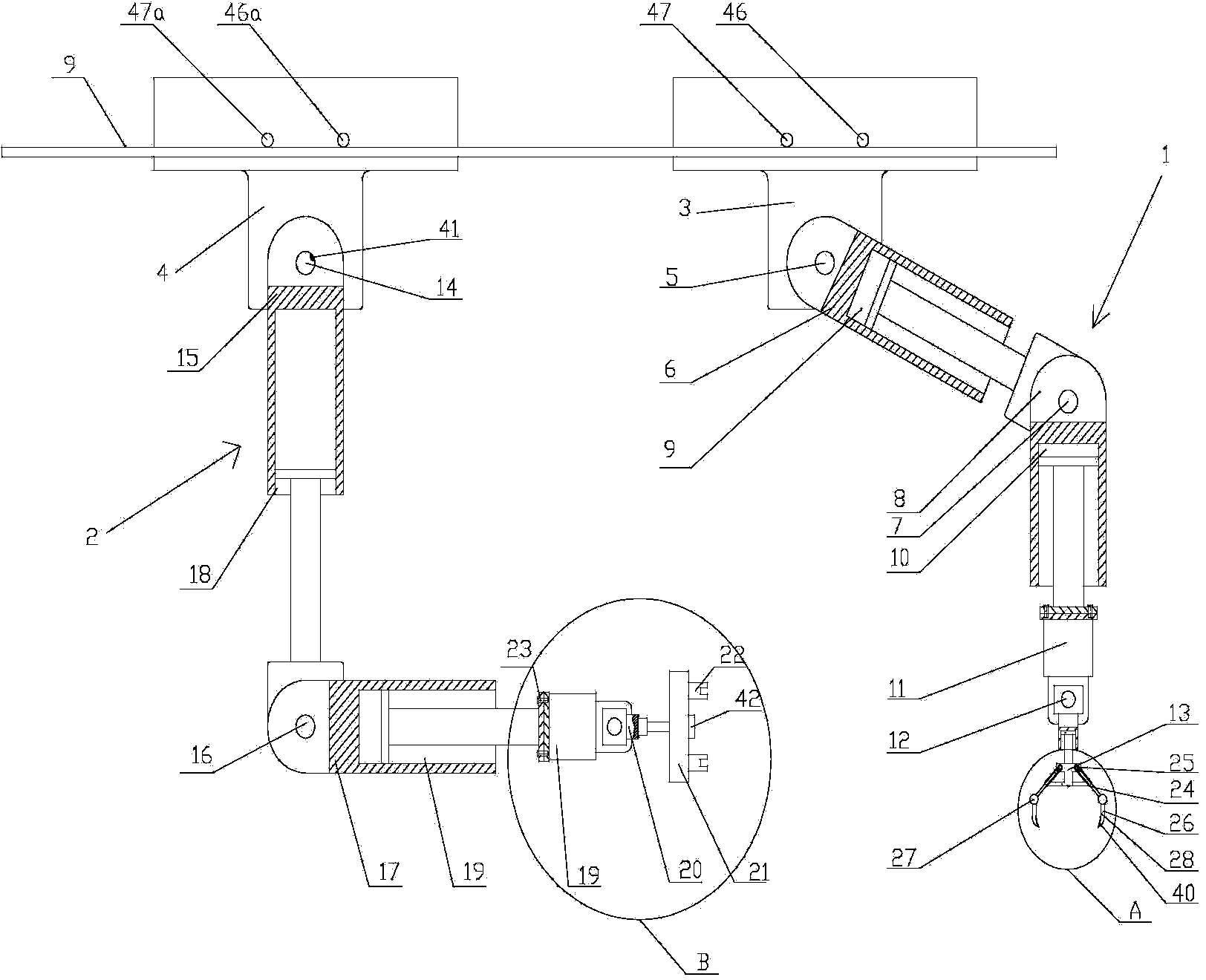

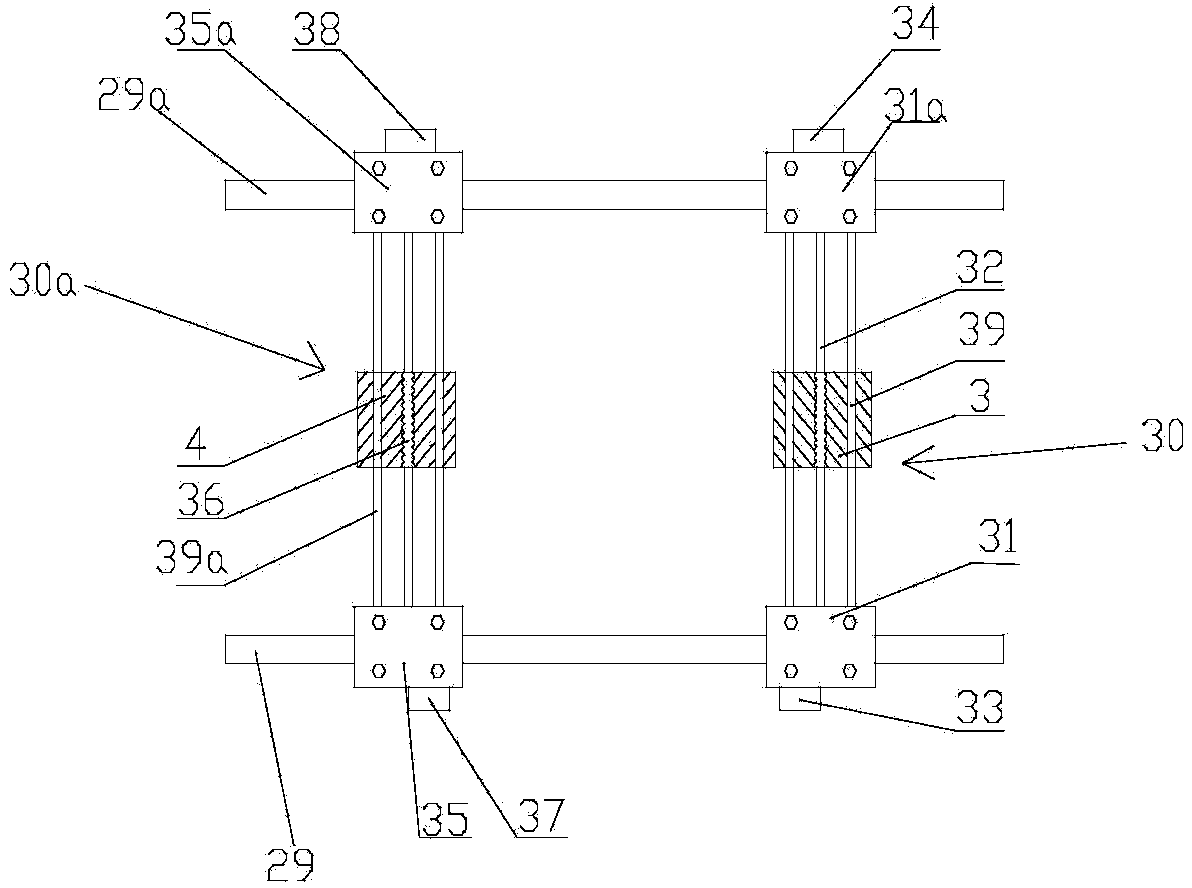

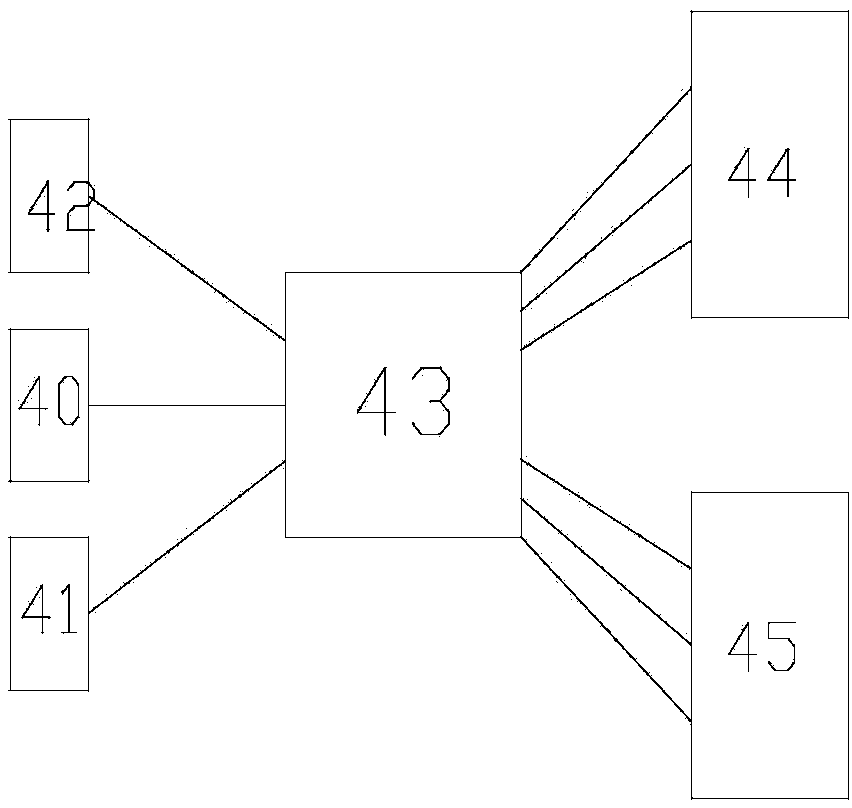

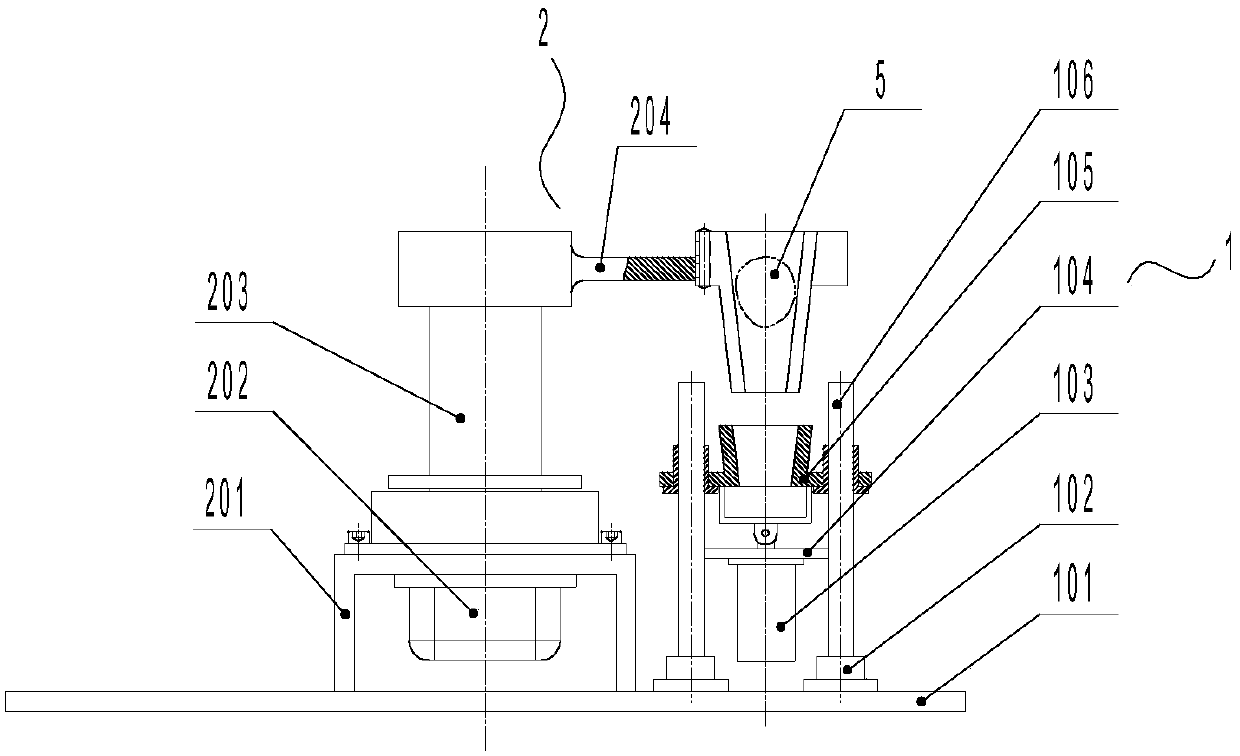

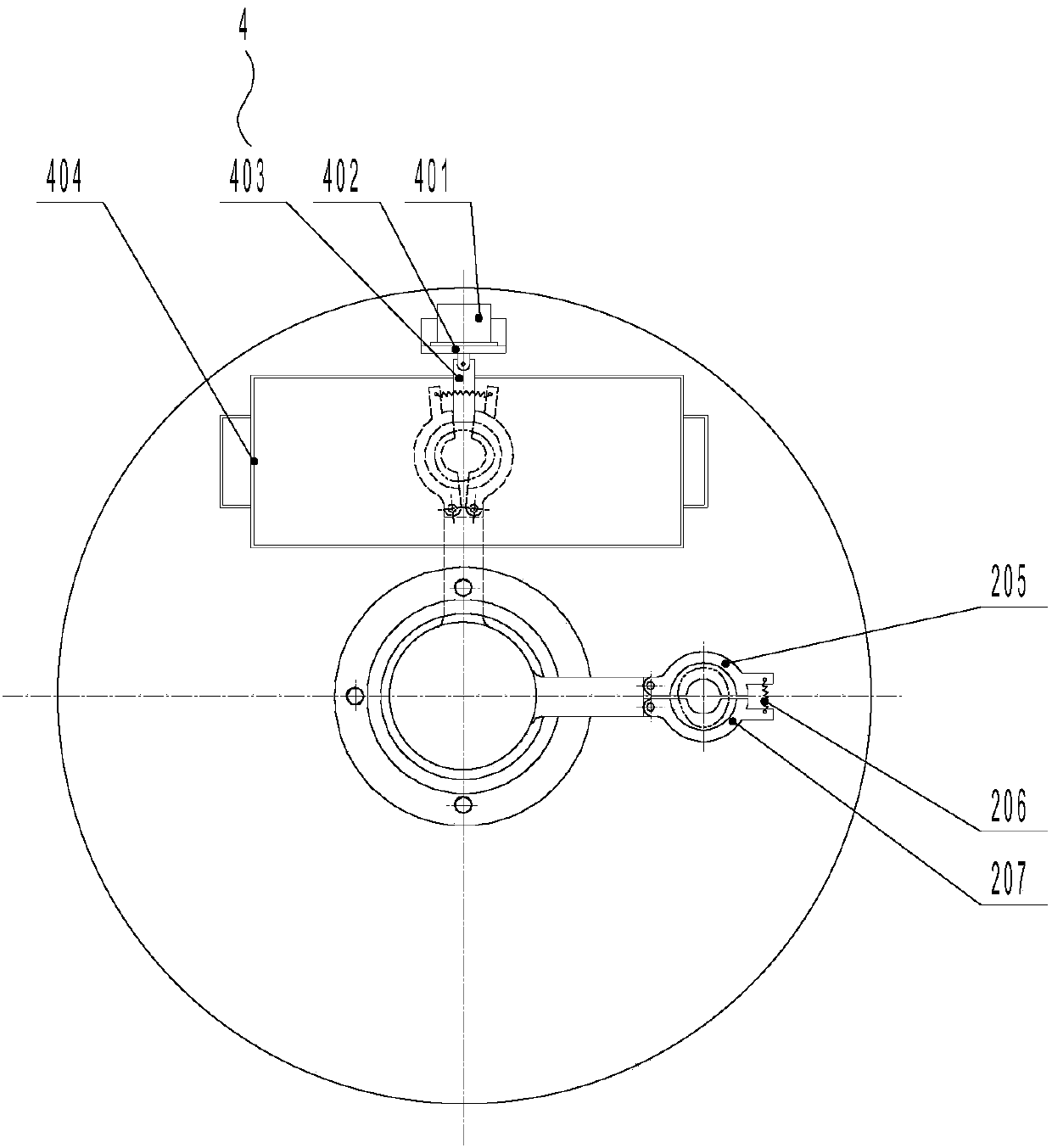

Heavy-load precise double-arm manipulator with arms cooperating with each other in space

InactiveCN103722549AGuaranteed accuracy requirementsIncrease contact areaProgramme-controlled manipulatorHigh surfaceEngineering

The invention discloses a heavy-load precise double-arm manipulator with arms cooperating with each other in a space. The manipulator comprises a linkage guide rail assembly, the load-bearing mechanical arm used for bearing weights and the assistant positioning mechanical arm used for guaranteeing workpiece positioning precision. Because the load-bearing mechanical arm and the assistant positioning mechanical arm can cooperate with each other in the space, it is guaranteed that the whole manipulator structure has high load bearing capacity and also has high positioning precision, the problem of contradiction between the load bearing capacity and precision of existing manipulators is solved, and the requirements for clamping of workpieces with different shapes, high surface precision, high efficiency and high safety performance are met.

Owner:CHONGQING JIAOTONG UNIVERSITY

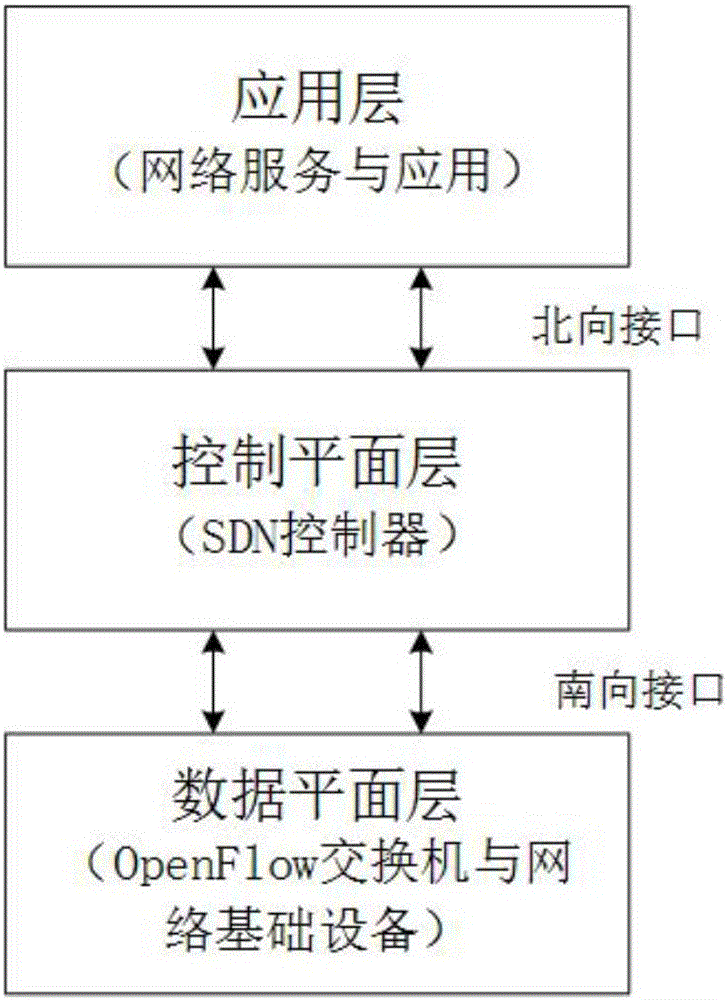

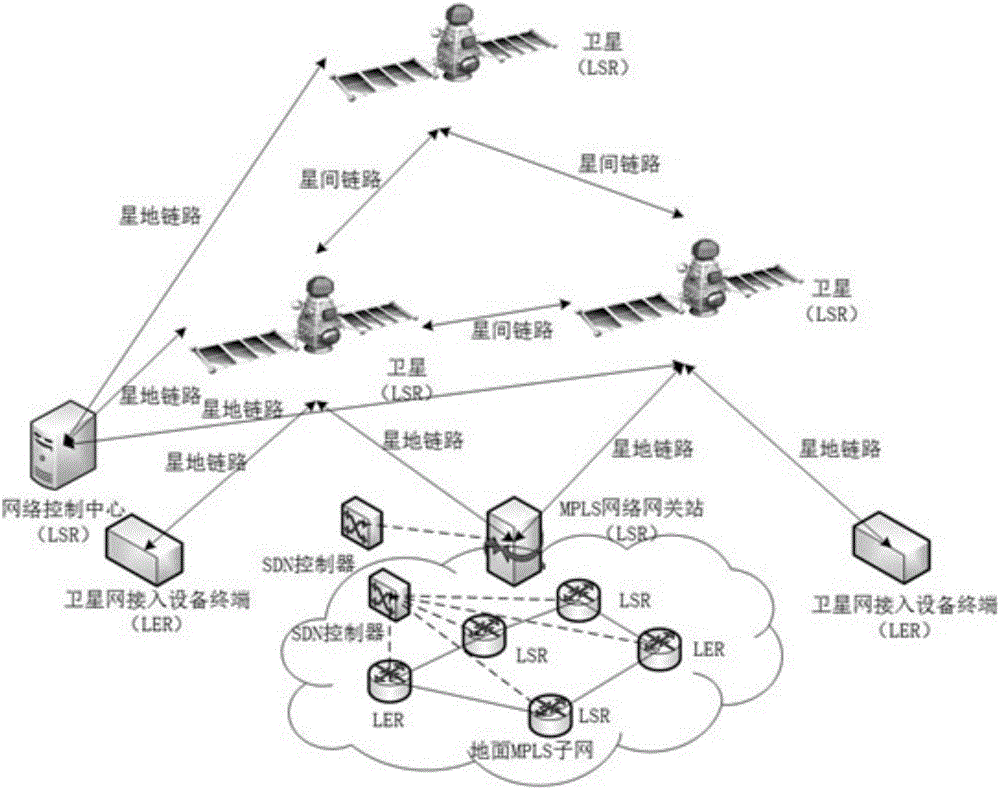

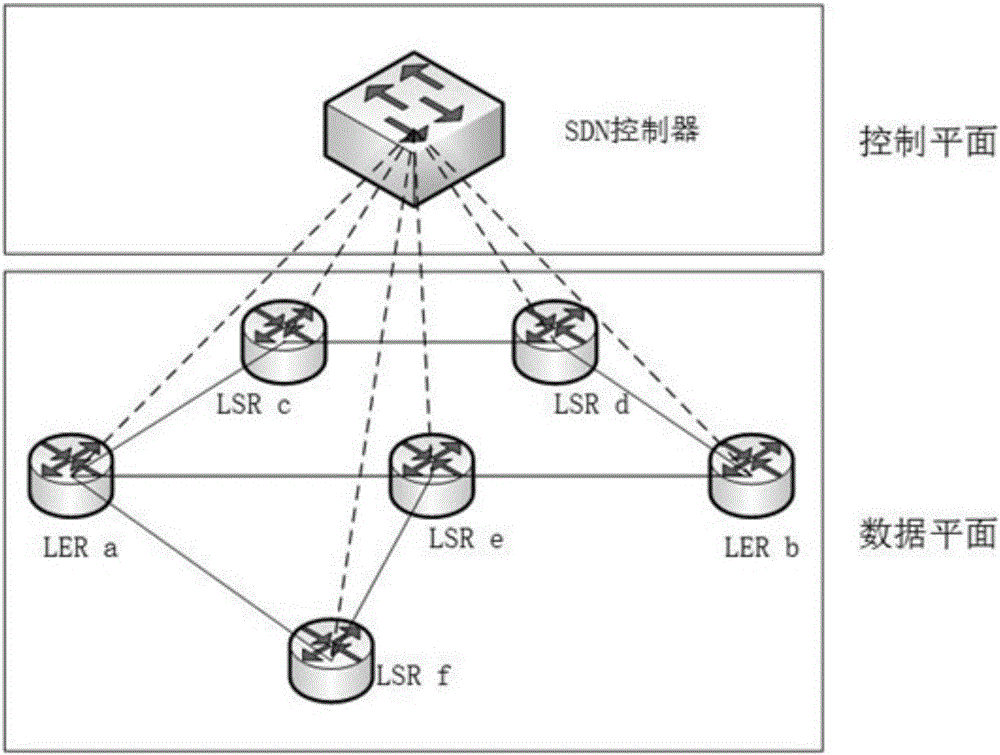

Satellite MPLS (multi-protocol label switching) network flow rate balancing method based on SDN (software defined network) controller

ActiveCN106789658AImprove service qualityImprove instabilityRadio transmissionData switching networksResource utilizationMulti protocol

The invention discloses a satellite MPLS (multi-protocol label switching) network flow rate balancing method based on an SDN (software defined network) controller. An SDN controller is put on a network edge; the control plane of network equipment is separated from the data plane; the functions of the control plane are concentrated onto a special controller, so that the equipment complexity in the network is reduced. The data plane and the control plane are decoupled, and an SDN obtains great flexibility, so that the network has the characteristics of high expandability, easy maintenance, programmable performance and open performance. According to the method, the SDN controller peripherally collects network topology and network state information from a router / interchanger in a data plane through an OpenFlow protocol of a southbound interface; through calculation, the available bandwidth condition of each link is obtained, so that whether the path jam occurs or not is judged; whether the flow rate dispatching is needed or not is judged; the goal of collecting and analyzing the whole network flow rate distribution condition in real time is achieved; the link flow rate is reasonably deployed, so that the flexible control of the network flow rate is realized; in addition, the bandwidth resource utilization rate can be better improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

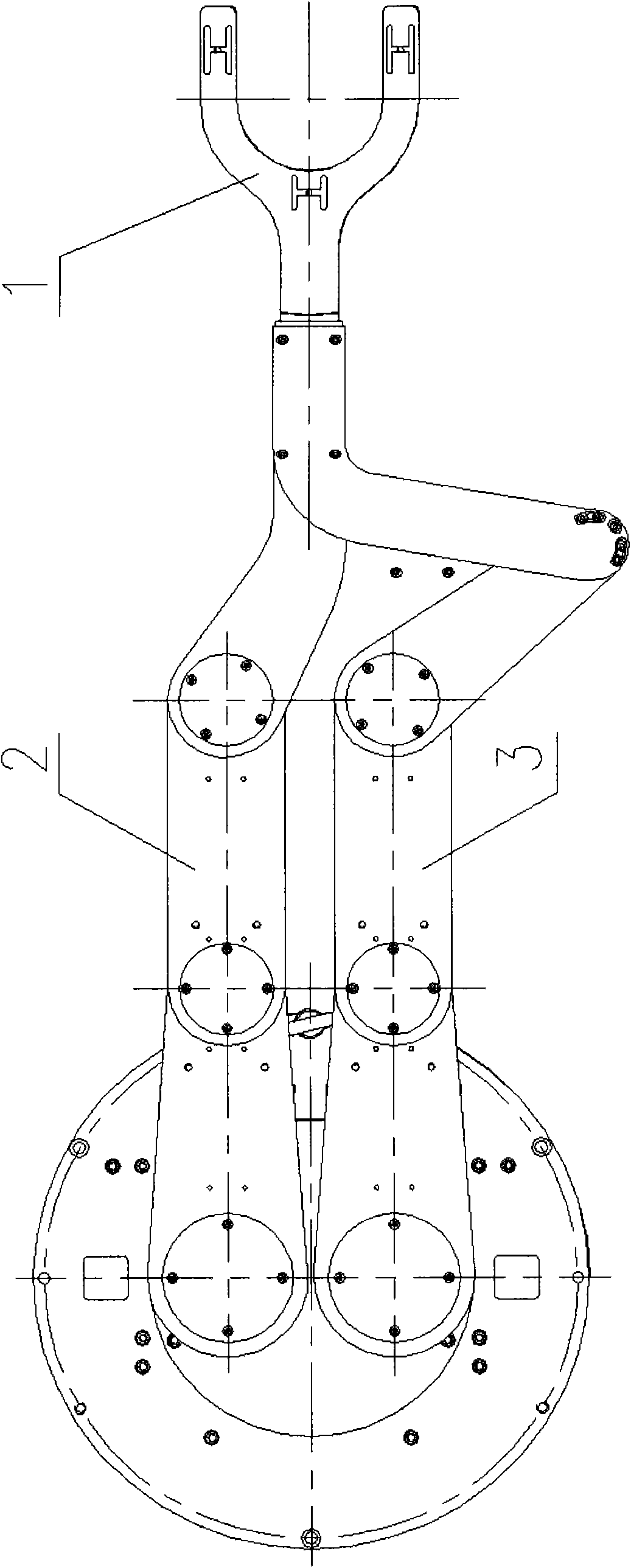

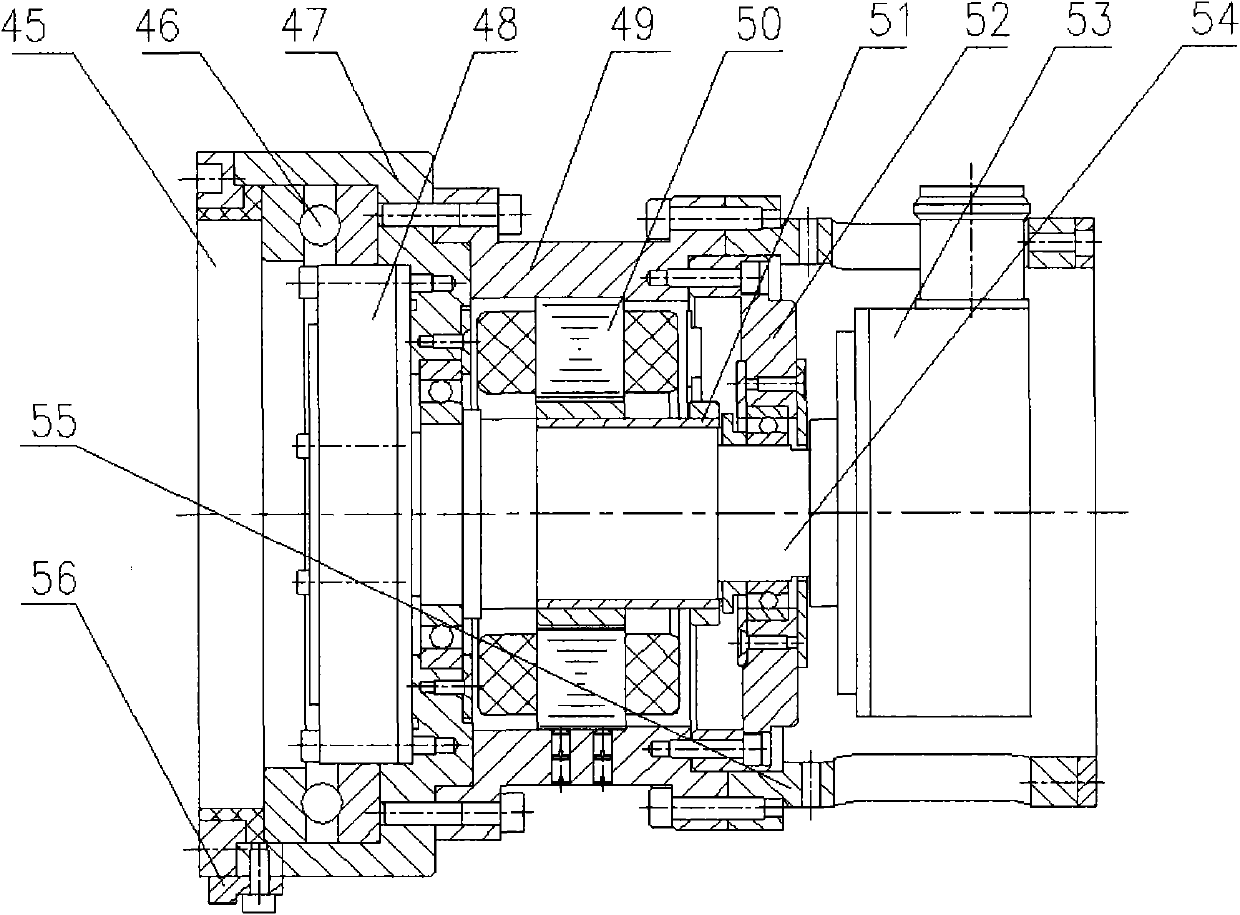

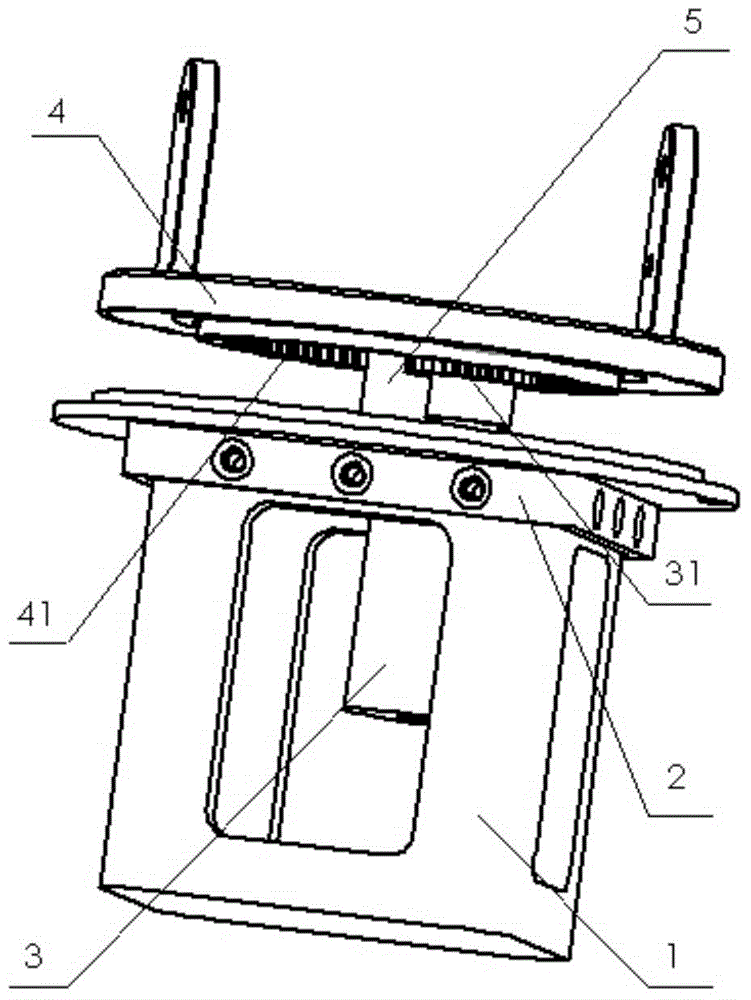

Double-arm transmission robot applied to high-cleanliness environment

InactiveCN101908497AHigh efficiency requirementsMeet cleanliness requirementsProgramme-controlled manipulatorConveyor partsSpatial structureMechanical engineering

The invention relates to a double-arm transmission robot applied to a clean environment, which is used for the transmission and high-precision positioning placement of a large-diameter semiconductor silicon wafer in a high-cleanliness environment. The double-arm transmission robot is in the structural form of R-theta type and has the working principle of a space structure based on a cylindrical coordinate system and the characteristic of independent control of all motion shafts. The double-arm transmission robot mainly comprises an R-axis left arm mechanism, an R-axis right arm mechanism, a T-axis rotating mechanism, a Z-axis lifting mechanism, and the like and seals the pollution of a drive mechanism on an external environment by adopting a special seal device so as to be suitable for the high-cleanliness production environment requirement.

Owner:HARBIN INST OF TECH

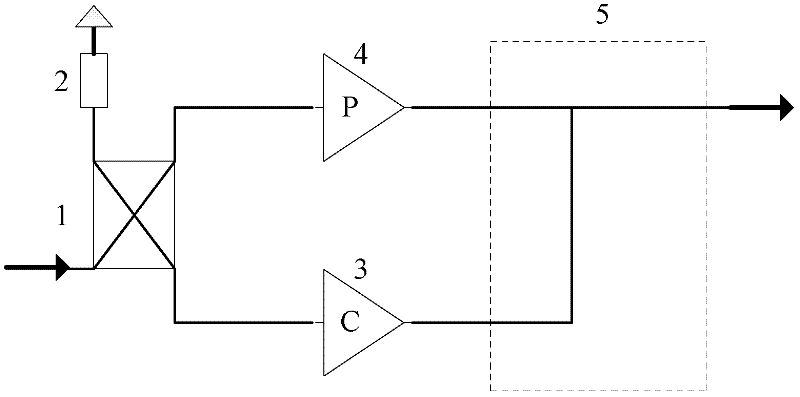

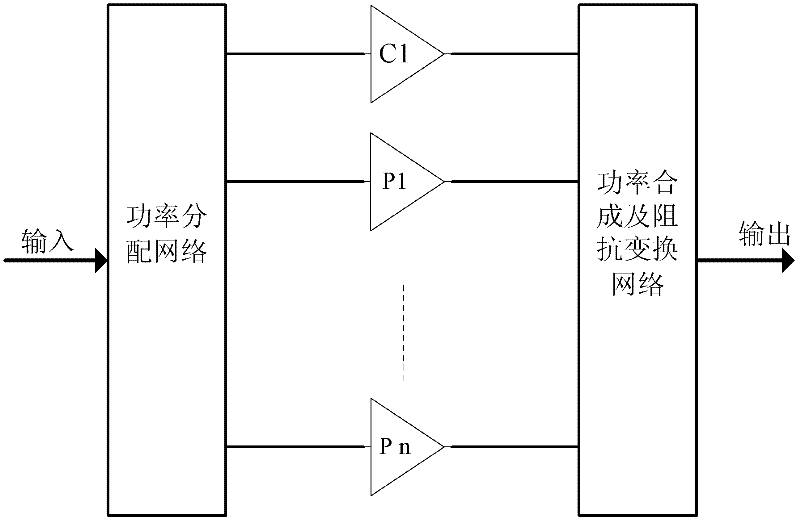

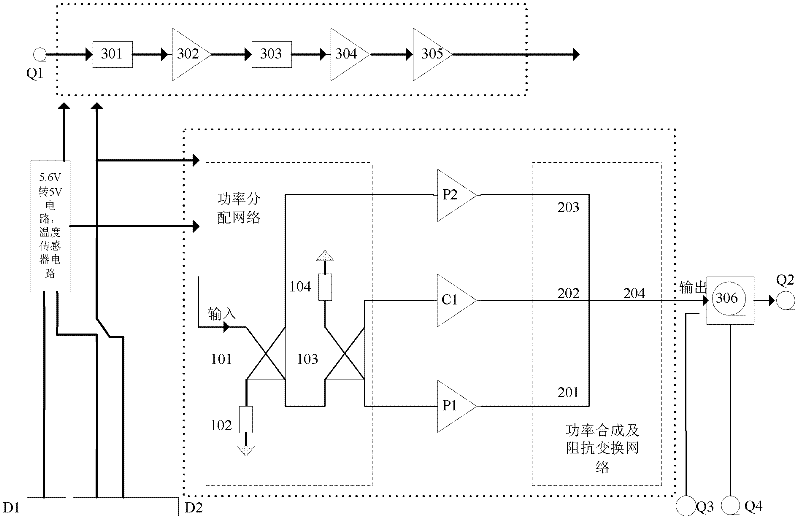

Multi-way asymmetrical Doherty amplifier

InactiveCN102545788APeak-to-average ratioHigh efficiency requirementsAmplifier modifications to raise efficiencyAudio power amplifierPeak value

The invention provides a multi-way asymmetrical Doherty amplifier, which comprises a multi-way power splitting network circuit, a carrier amplifier, at least two peak amplifiers and an output power combination and impedance conversion network circuit. An input end of the carrier amplifier and input ends of the peak amplifiers are respectively connected with the multi-way power splitting network circuit, and an output end of the carrier amplifier and output ends of the peak amplifiers are respectively connected with the output power combination and impedance conversion network circuit. In the peak amplifiers, the power of the first peak amplifier is 0.7-1.3 times of that of the carrier amplifier, and the power of the other peak amplifiers is doubled gradually with the doubling coefficient ranging from 1.5 to 2.5. When GSM (global system for mobile communication) multi-carrier signals with the peak-to-mean ratio of 7dB are output while the circuit of a three-way asymmetrical Doherty amplifier returns by 7dB, the efficiency can be over 56%, and higher peak-to-mean ratio and efficiency requirements can be met along with increase of the stage number of the peak amplifiers.

Owner:WUHAN GEWEI ELECTRONICS TECH

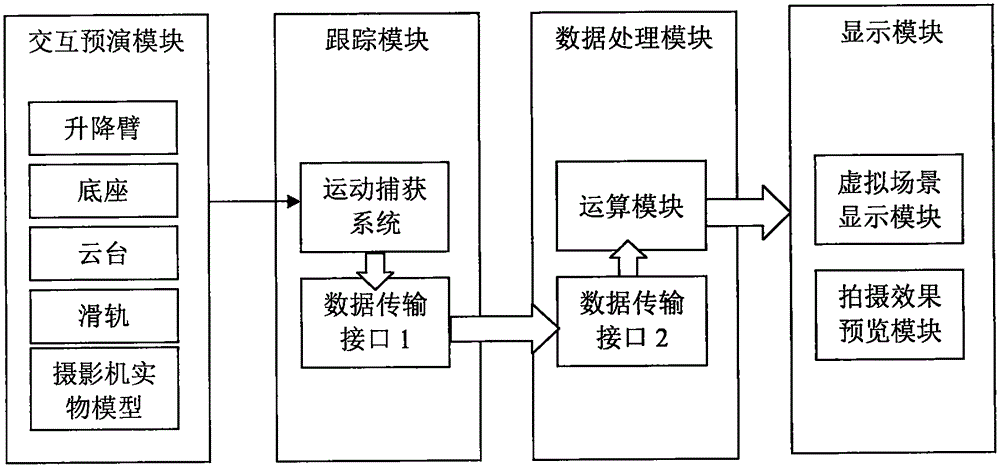

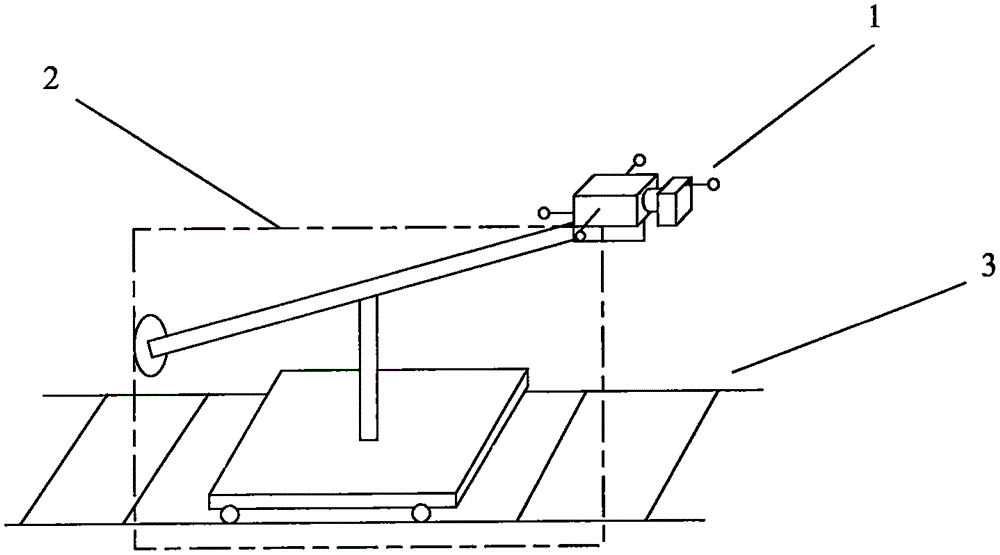

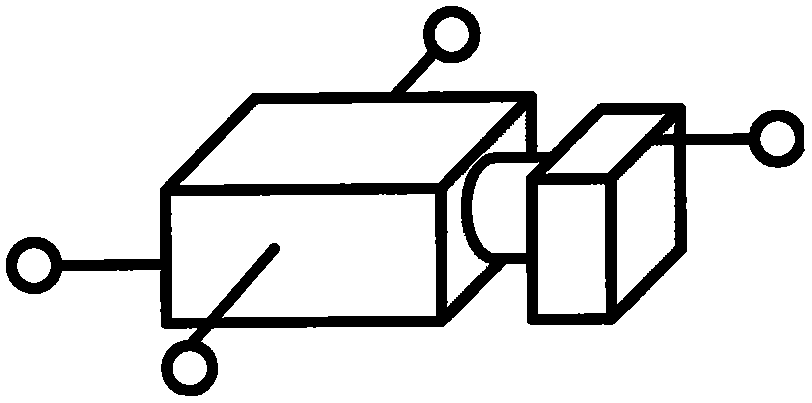

Virtual simulation method and system of camera motion control system in film shooting

InactiveCN105488457AImprove interactivityReduce shooting costsTelevision system detailsCharacter and pattern recognitionCamera controlCamera lens

The invention discloses a virtual simulation method and system of a camera motion control system in film shooting, and belongs to the technical field of camera control. The method and the system cause a film creator to more visually regulate the motion track and the picture sequence of the camera according to own operation habits and visual angles, picture planning and the like in the early stage of film shooting, utilizes three-dimensional virtual simulation to design a satisfactory lens effect for the creator, automatically calculates the parameters of the camera motion control system which plans to be adopted, and precisely controls the space coordinates of the camera lens so as to improve the interaction of the camera motion control system, save the shooting cost of the lens which uses the camera motion control system and greatly improve the digital manufacture quality and efficiency of the film.

Owner:BEIJING FILM ACAD

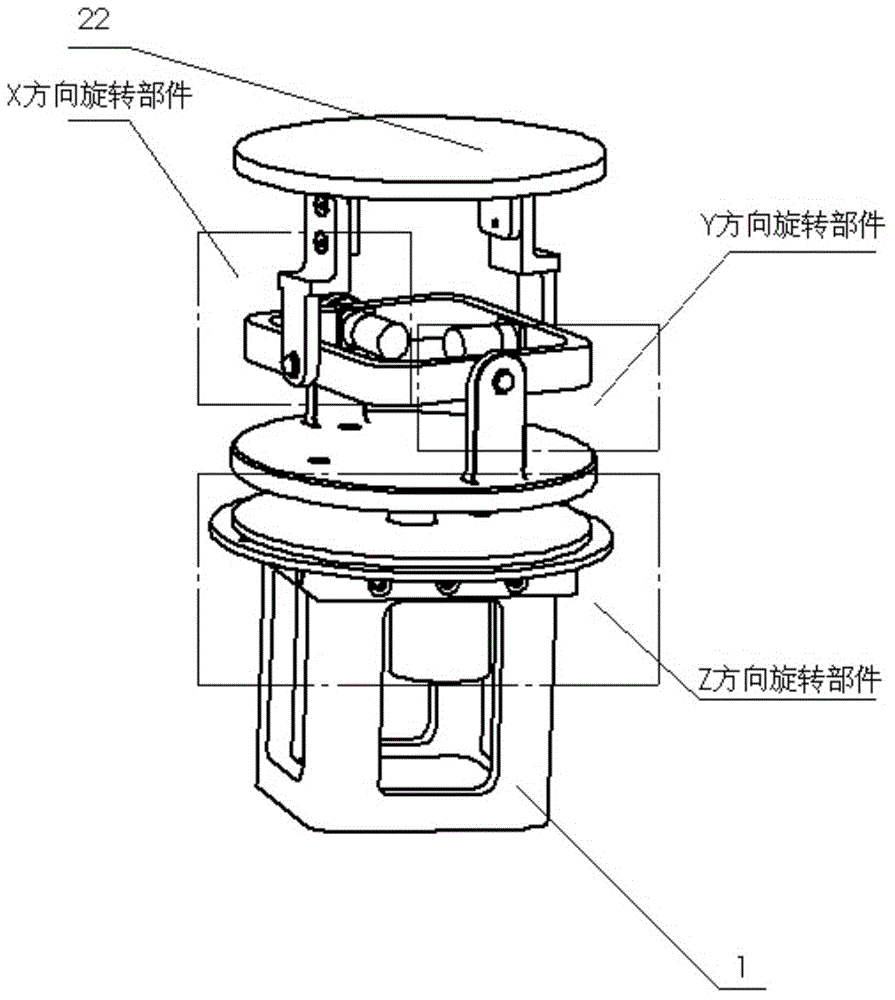

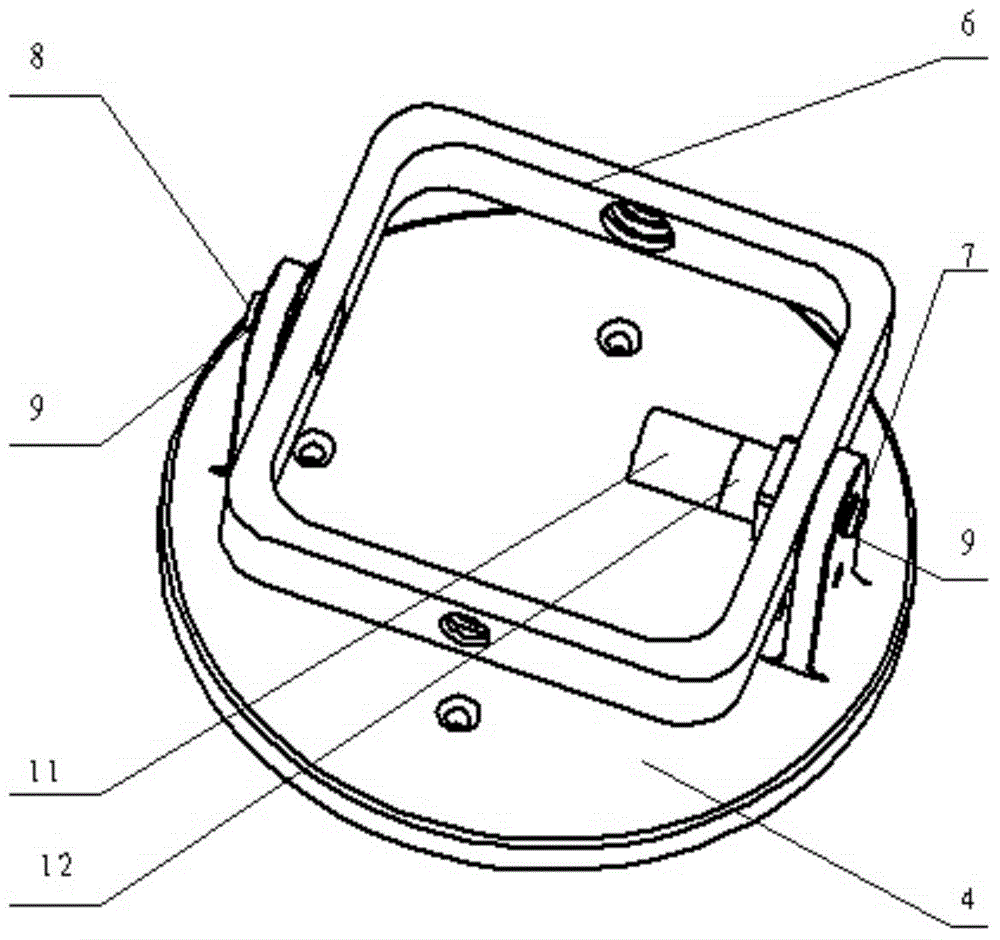

Three-degree-of-freedom rotating platform

InactiveCN104633407ASimple structureEasy to controlStands/trestlesThree degrees of freedomEngineering

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

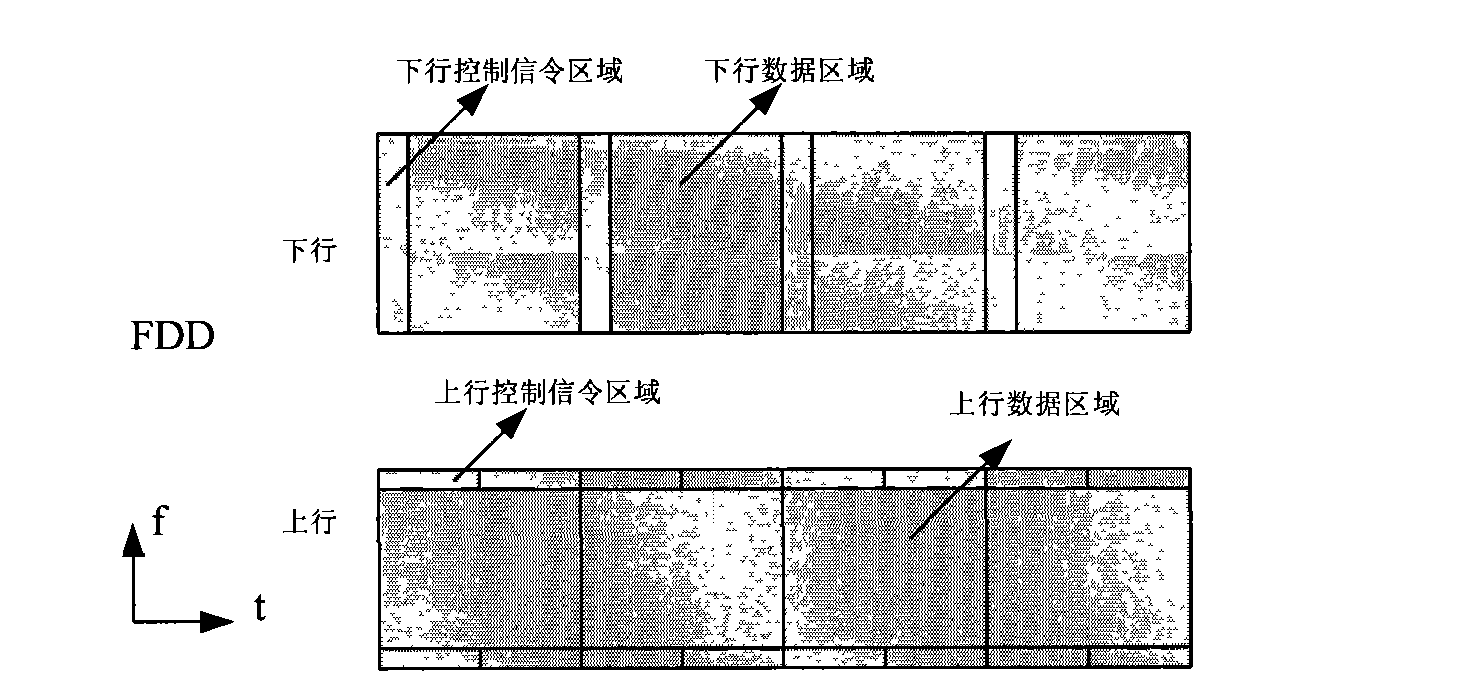

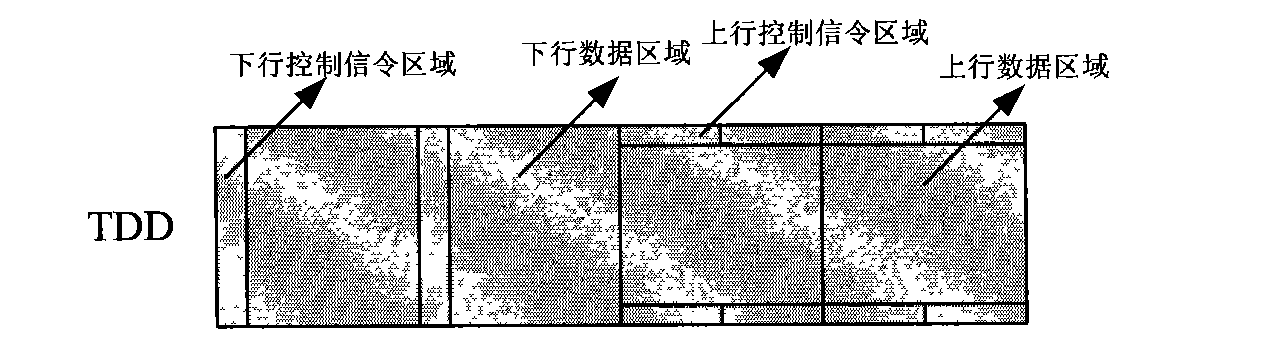

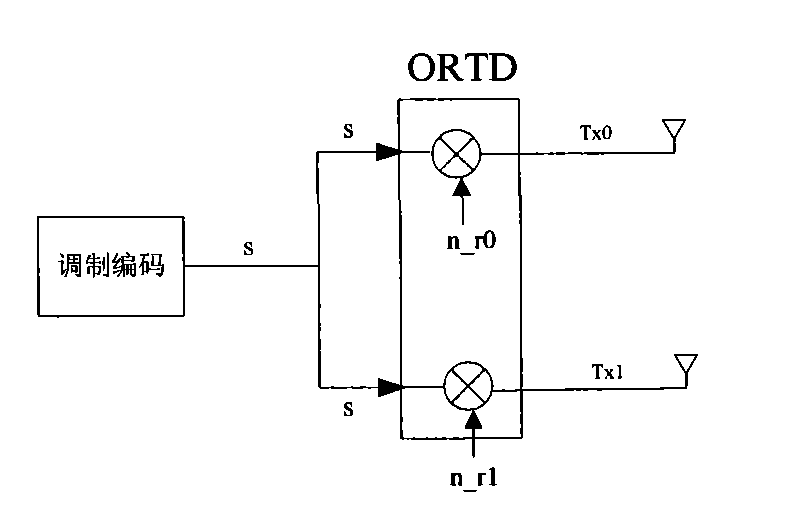

Method and device for transmitting uplink control channel

ActiveCN101989873AHigh reliability requirementsHigh efficiency requirementsSpatial transmit diversityWireless communicationTransfer modeControl channel

The embodiment of the invention provides a method for transmitting an uplink control channel. The method comprises the following steps that: a base station configures a transmission mode of the uplink control channel of user equipment (UE) through a high-level signaling; and the base station receives the uplink control channel transmitted by the UE through transmit diversity or the uplink control channel transmitted by the UE through a single-antenna port according to the transmission mode. The embodiment of the invention also provides equipment for implementing the transmission of the uplink control channel. In the technical scheme provided by the embodiment of the invention, the base station flexibly configures different modes for the UE with a plurality of transmission antennae to transmit the uplink control channel according to the operation state of the system, so that the requirements of the system on reliability and efficiency are improved, and the system performance is effectively improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

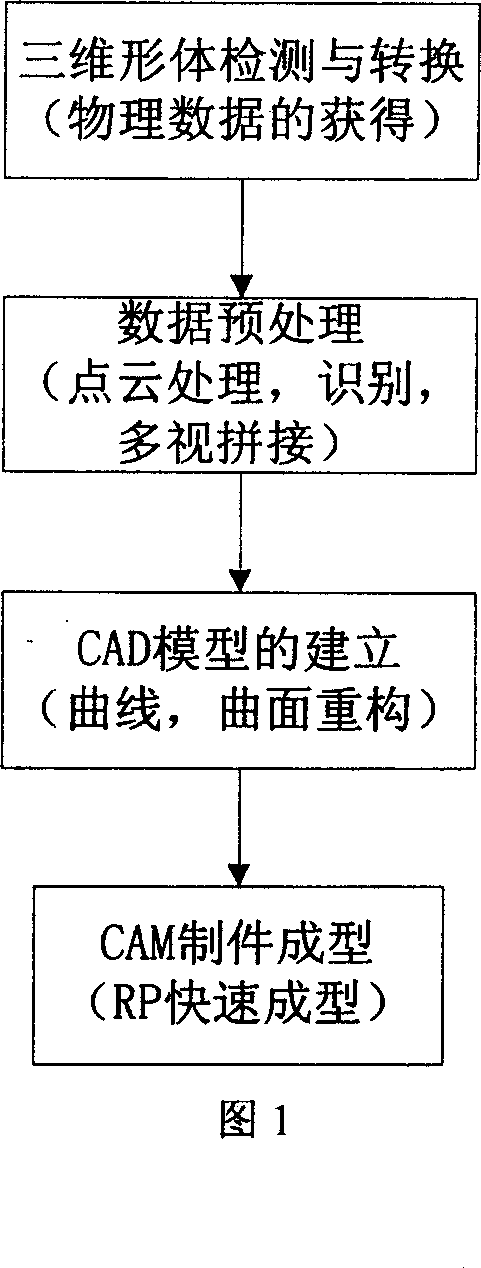

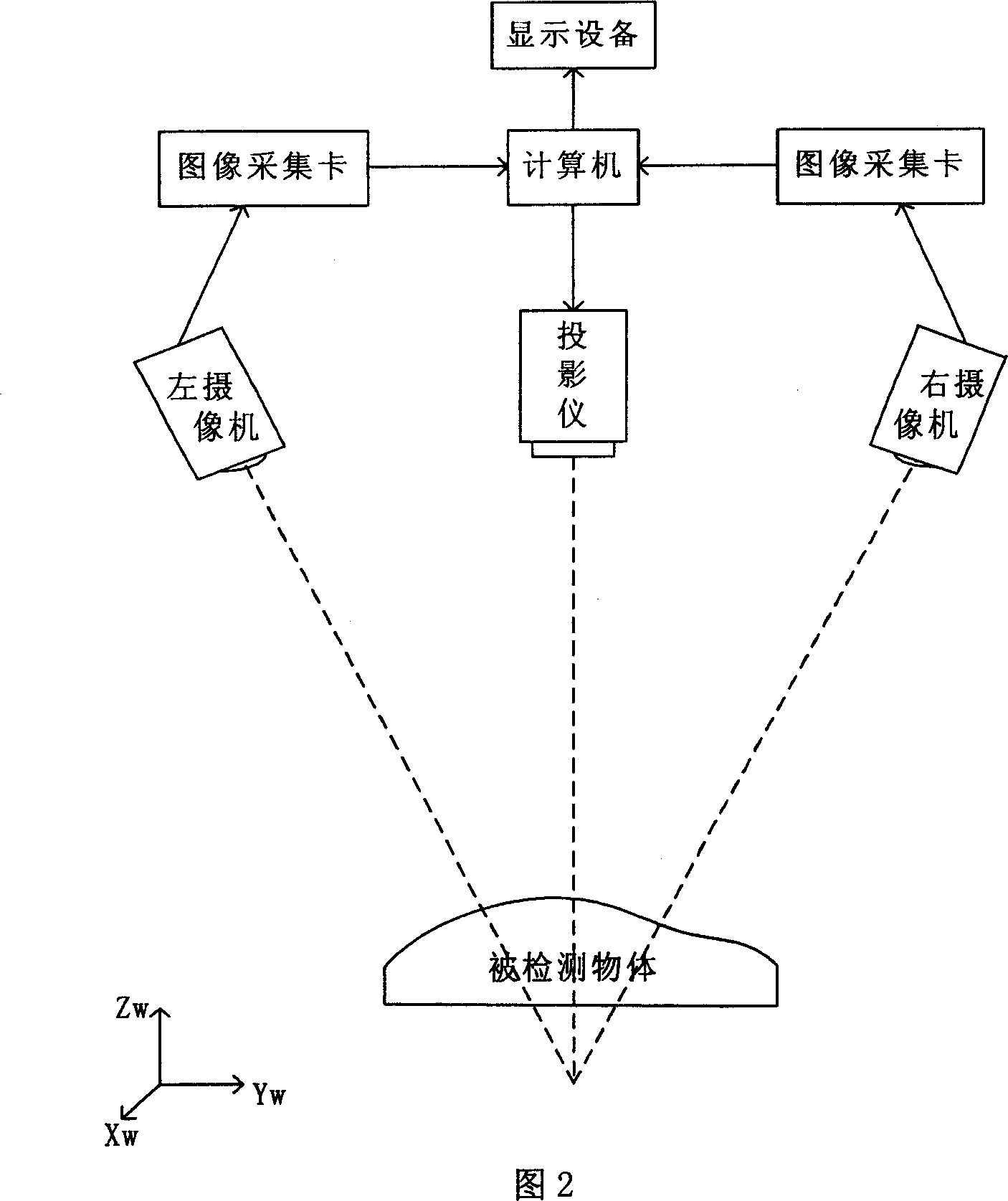

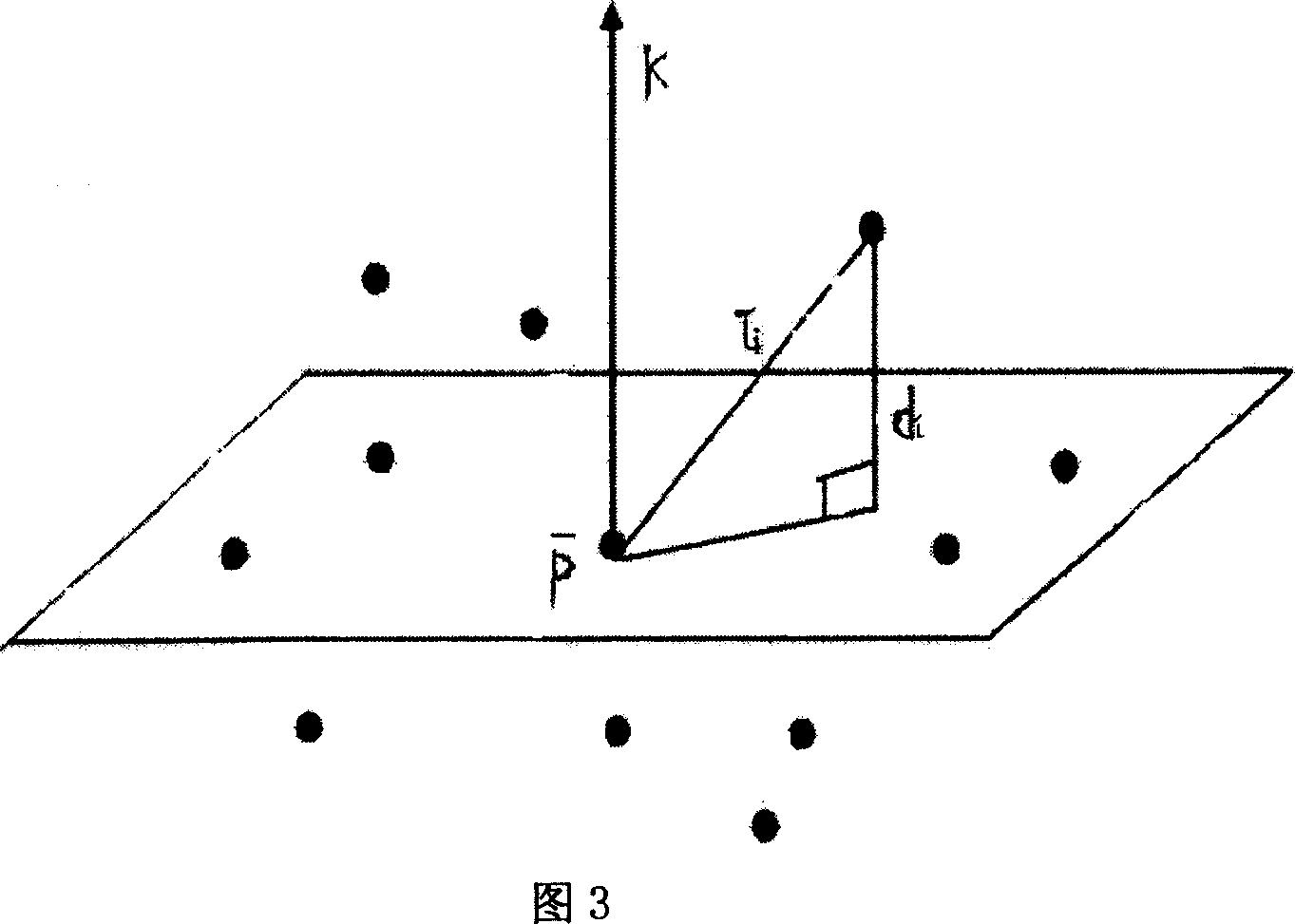

Automatic searching method for characteristic points cloud band in three-dimensional scanning system

InactiveCN1928921AAvoid the disadvantage of having to judge the direction of the normal vectorReduce time complexityImage analysisPattern recognitionPoint cloud

The automatic search method for discrete feature point cloud belt in 3D scanning system comprises: dividing the point cloud into cubic blocks every contained only one point; calculating the near one for every point to obtain its normal vector by LSM and the curvature; then, dividing whole cloud data to obtain the feature belt. This invention overcomes defect in prior art and has well effect.

Owner:SOUTHEAST UNIV

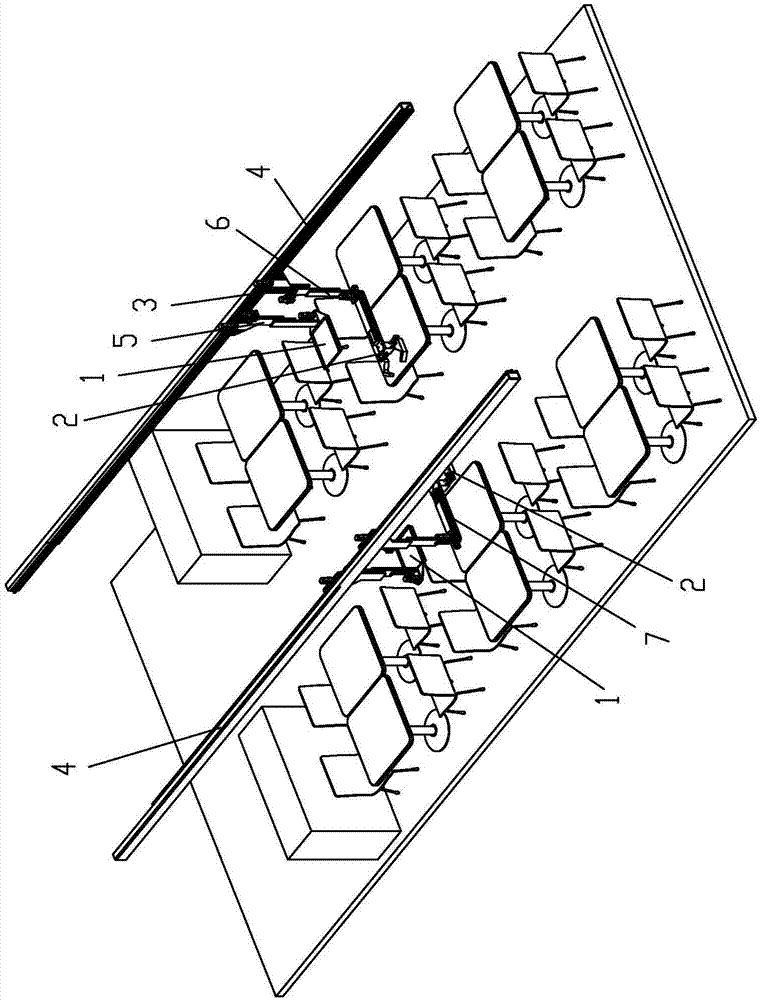

Intelligent dining room

InactiveCN107363839AMeet height change requirementsTake advantage ofProgramme-controlled manipulatorHotelsFood deliveryEngineering

The invention discloses an intelligent dining room. The intelligent dining room comprises a food delivery unit and a dining table service unit, wherein the food delivery unit and the dining table service unit are correspondingly provided with a food delivery tray and a manipulator respectively by virtue of conveying arms; each conveying arm is of a three-section composite structure formed by a conveying arm upper section, a conveying arm middle section and a conveying arm lower section; the conveying arm upper section is arranged on an overhead guide rail in a horizontal moving mode, and a self-walking driving unit is arranged between the conveying arm upper section and the overhead guide rail; the conveying arm middle section is arranged on the conveying arm upper section in an up-and-down moving mode, and a first lifting driving unit is arranged between the conveying arm upper section and the conveying arm middle section; and the conveying arm lower section is arranged on the conveying arm middle section in the up-and-down moving mode, and a second lifting driving unit is arranged between the conveying arm lower section and the conveying arm middle section. The intelligent dining room has the beneficial effects of high food delivery speed, complete service function, high space utilization rate, good service quality, high efficiency, simple structure, compact arrangement, high manufacturing efficiency, low manufacturing and use cost and long service life.

Owner:重庆臻憬科技有限公司

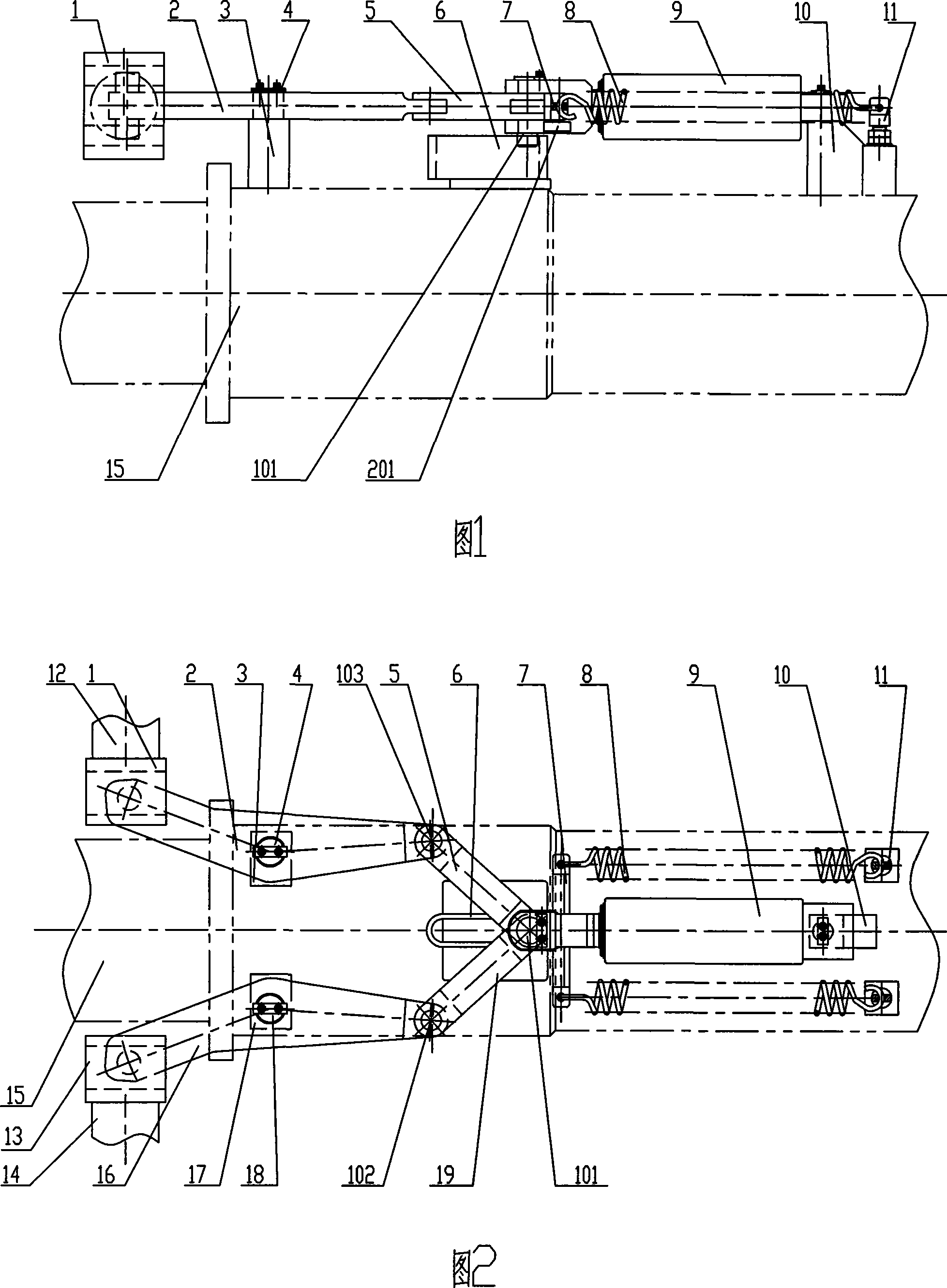

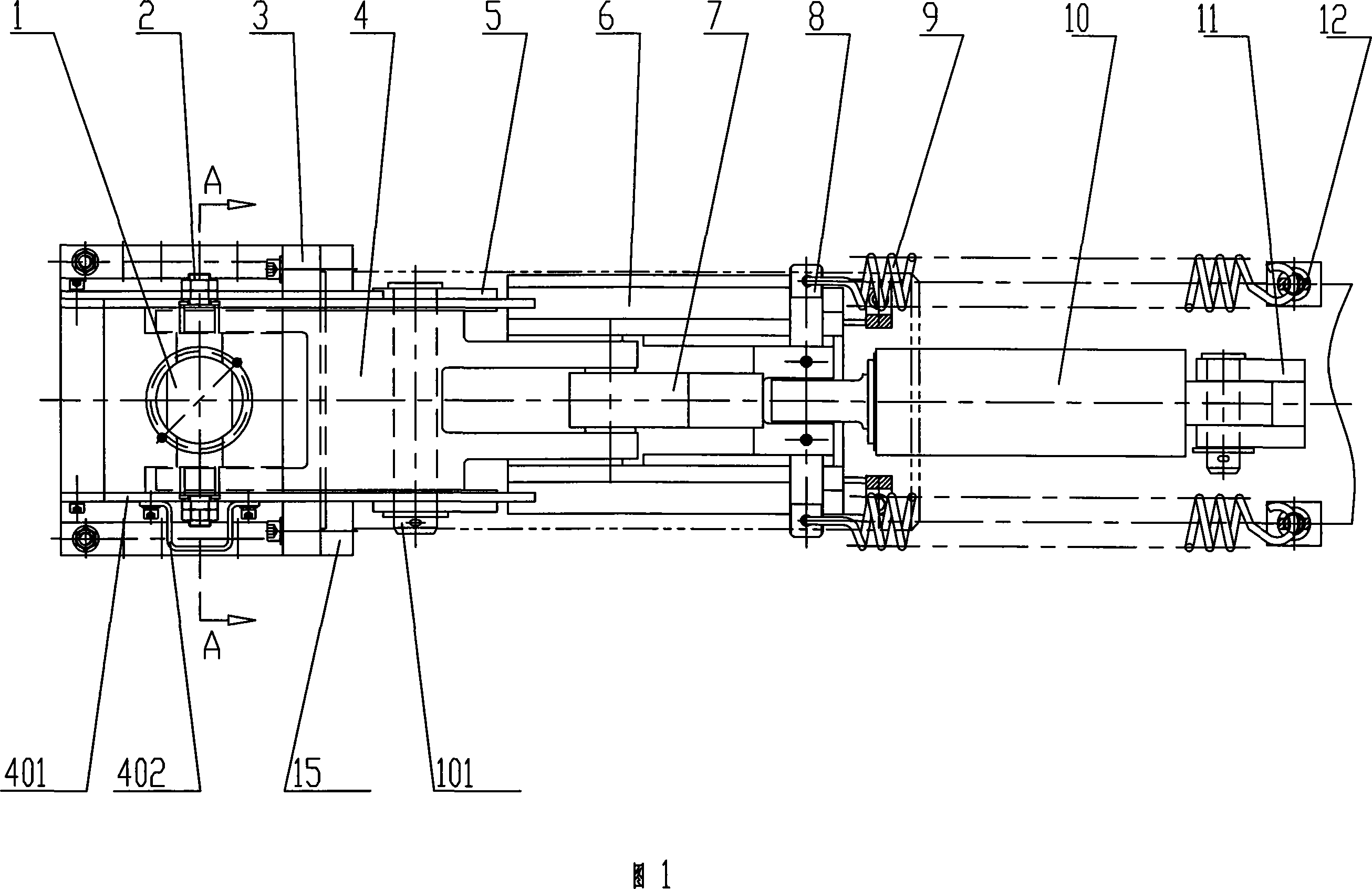

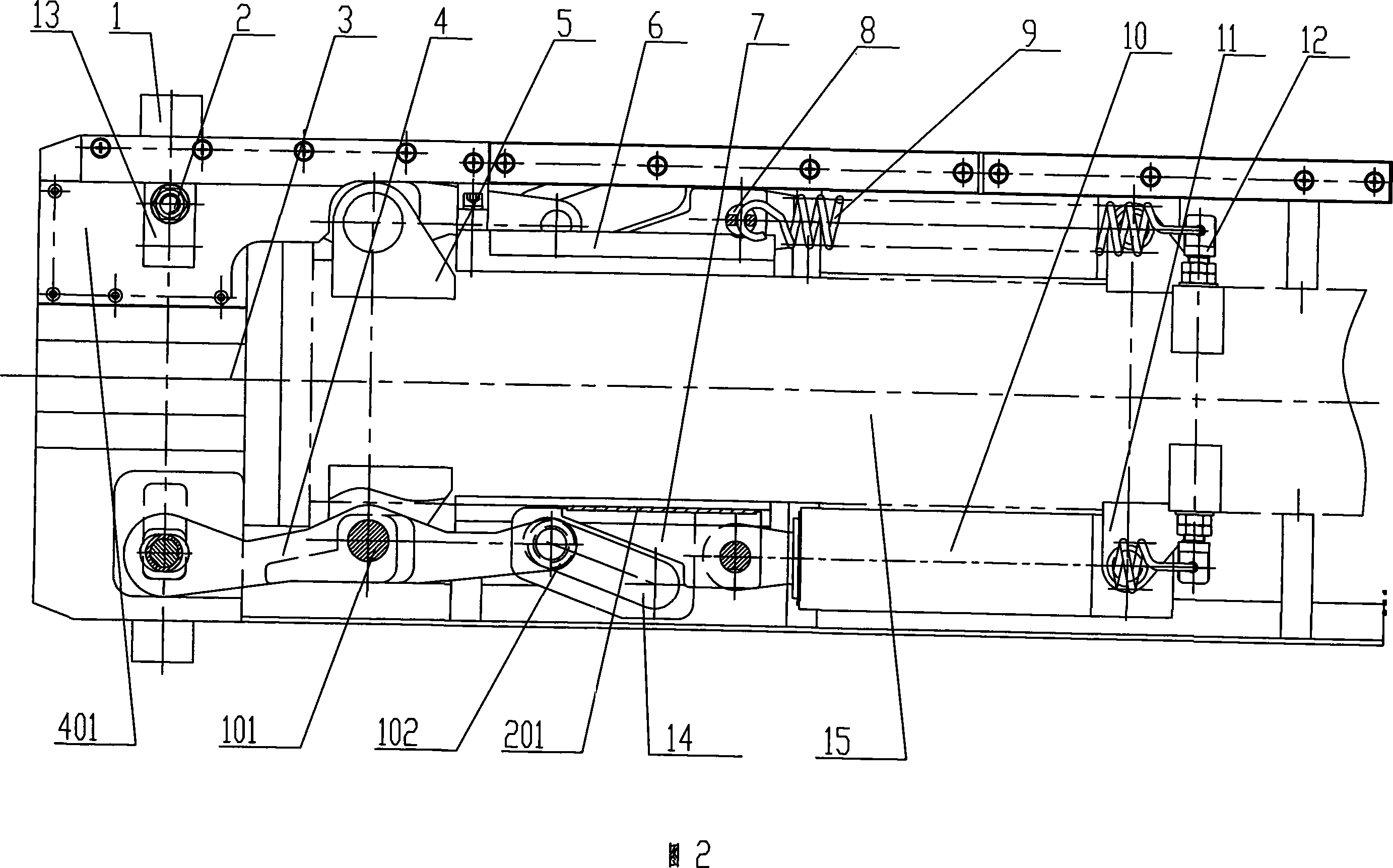

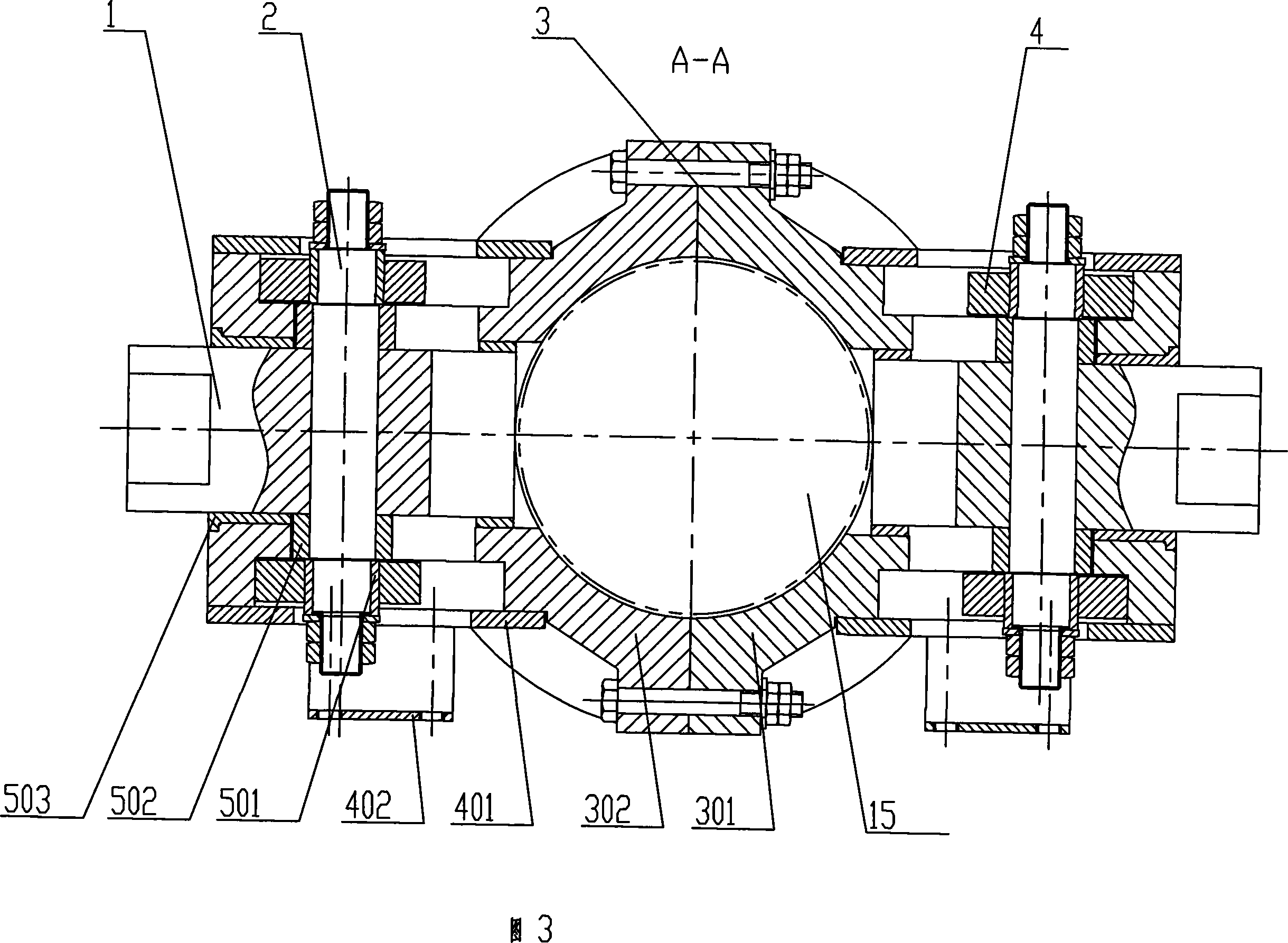

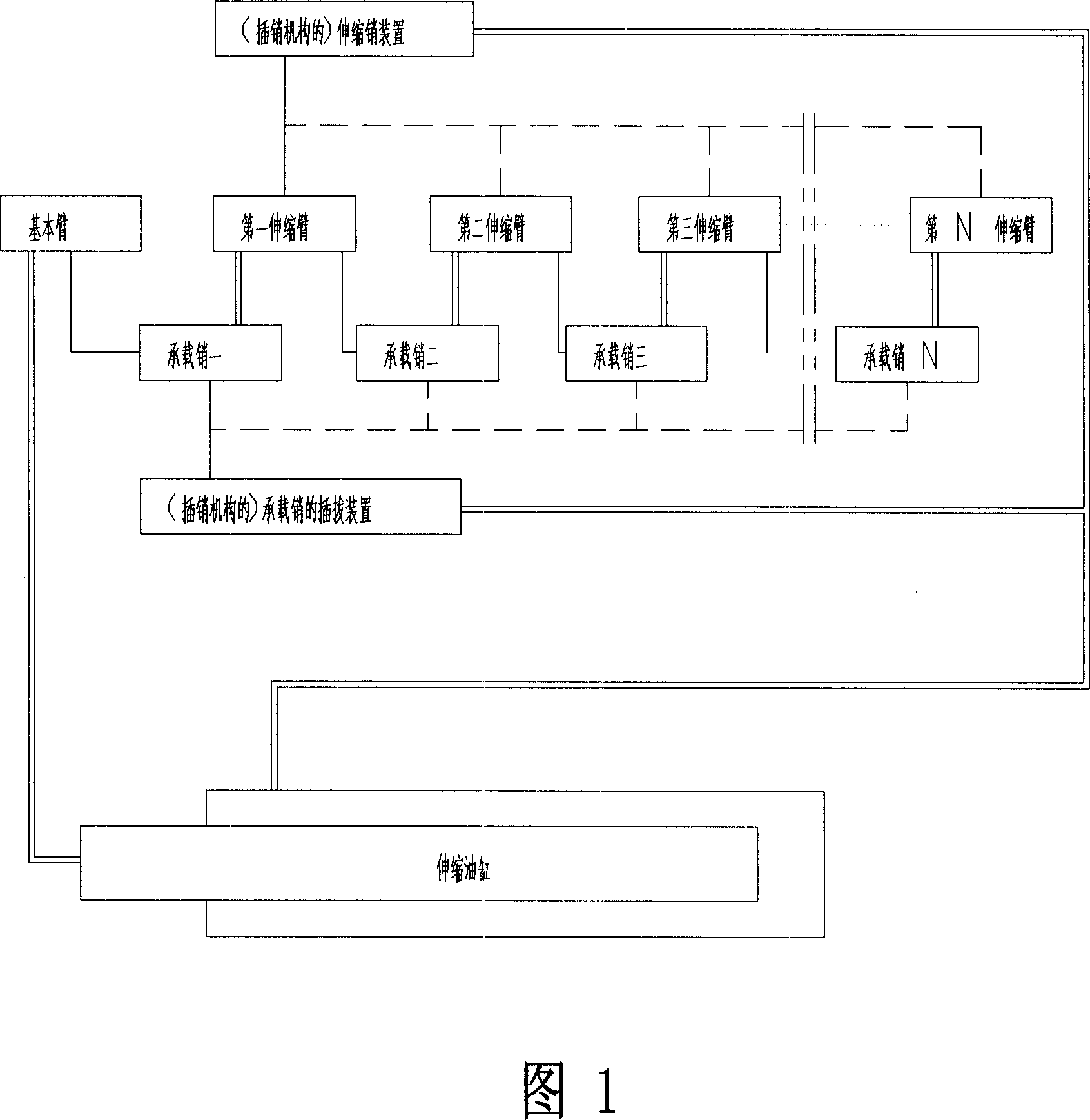

Transverse double-connecting rod type carrying pin mobile mechanism for crane

ActiveCN101214910AHigh reliability and high efficiency requirementsEasy to assemble and disassembleCranesEngineeringMechanical engineering

The invention discloses a horizontal double connecting rod bearing pin insert-draw mechanism for cranes; a first pin drawing plate (1) and a second pin drawing plate (13) are respectively fixed on a bearing pin (12) and a second bearing pin (14); an expansion oil cylinder (15) is provided with a power oil cylinder (9); the piston rod of the power oil cylinder (9) is hinged with a first connecting rod (5) and one end of a second connecting rod (19) and provided with a spring reset mechanism and a limit mechanism; the expansion oil cylinder (15) is hinged with a first swing rod (2)and a second swing rod (16); one end of the first swing rod (2) is drivingly connected with the first pin drawing plate (1), and the other end is hinged with the first connecting rod (5); one end of the second swing rod (16) is drivingly connected with the second pin drawing plate (13) and the other end is hinged with the second connecting rod (19). The invention is a horizontal double connecting rod bearing pin insert-draw mechanism for cranes which has the advantages of simple and compacted structure, convenience in installation and maintenance, stable and reliable performance, and the improved efficiency of the complete machine, and is widely applicable in the series products of large-tonnage crane.

Owner:ZOOMLION HEAVY IND CO LTD

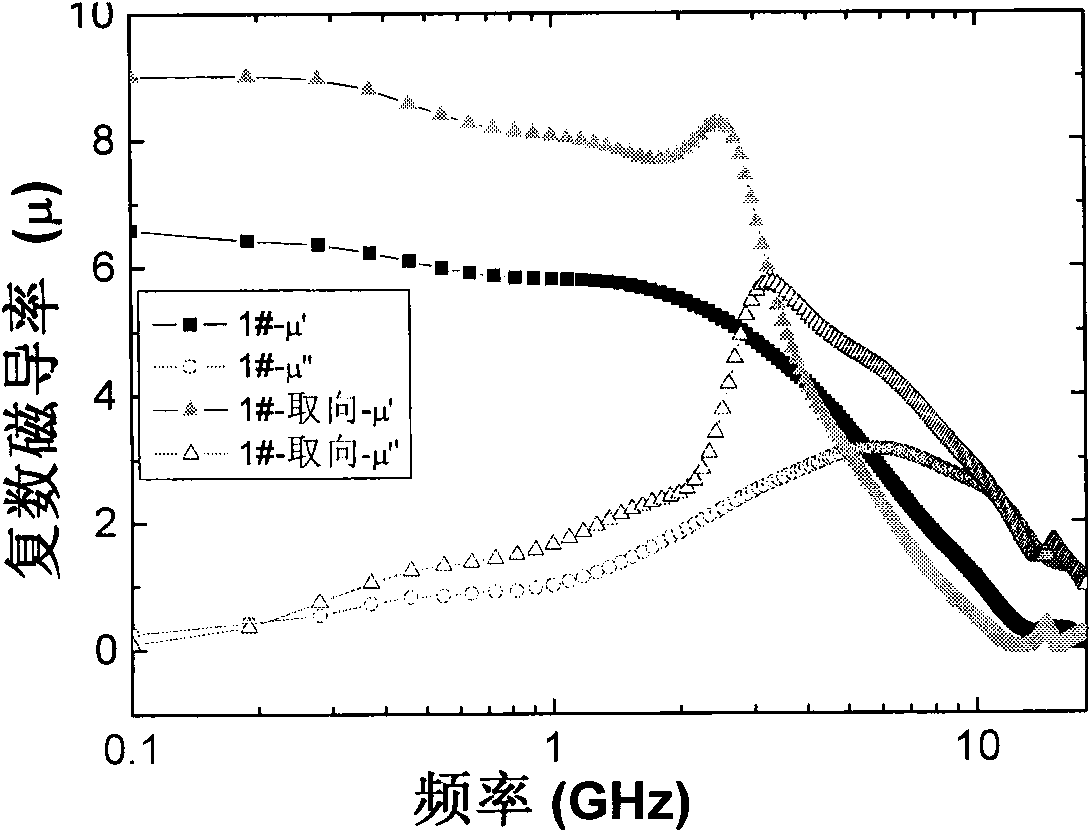

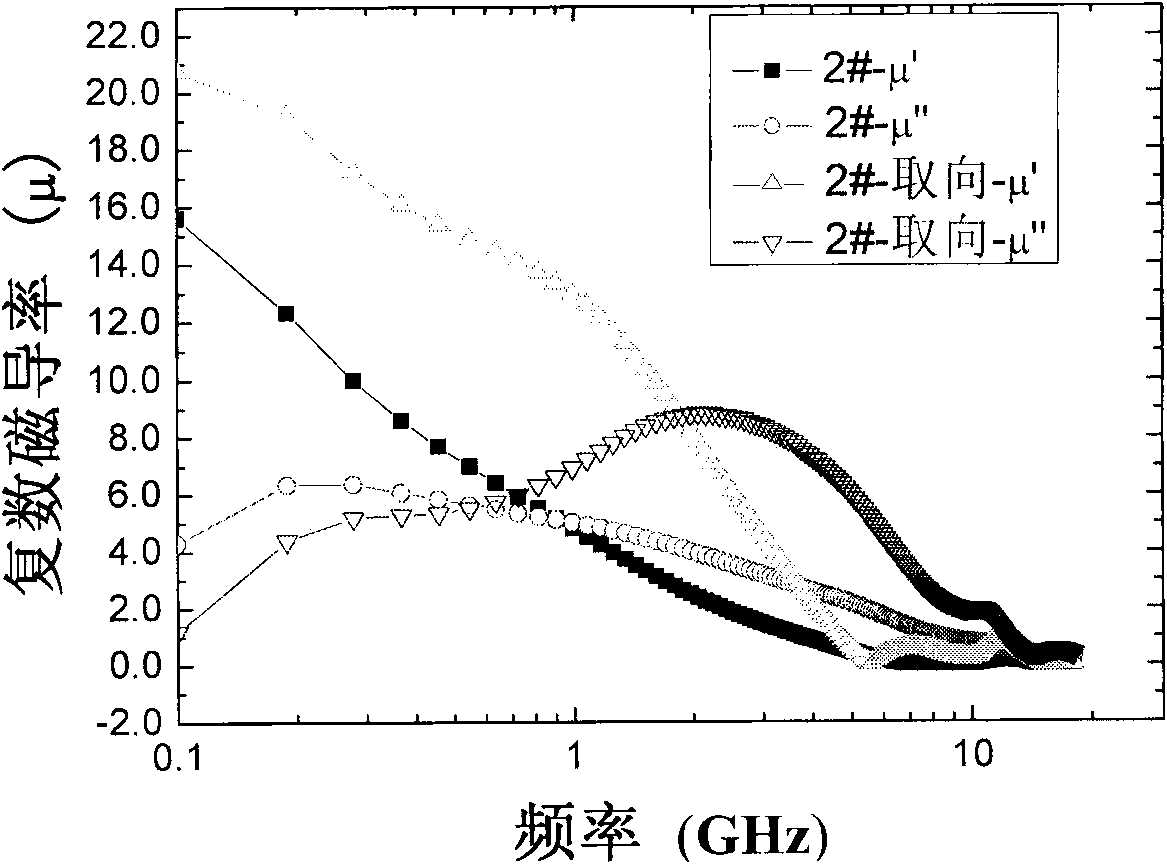

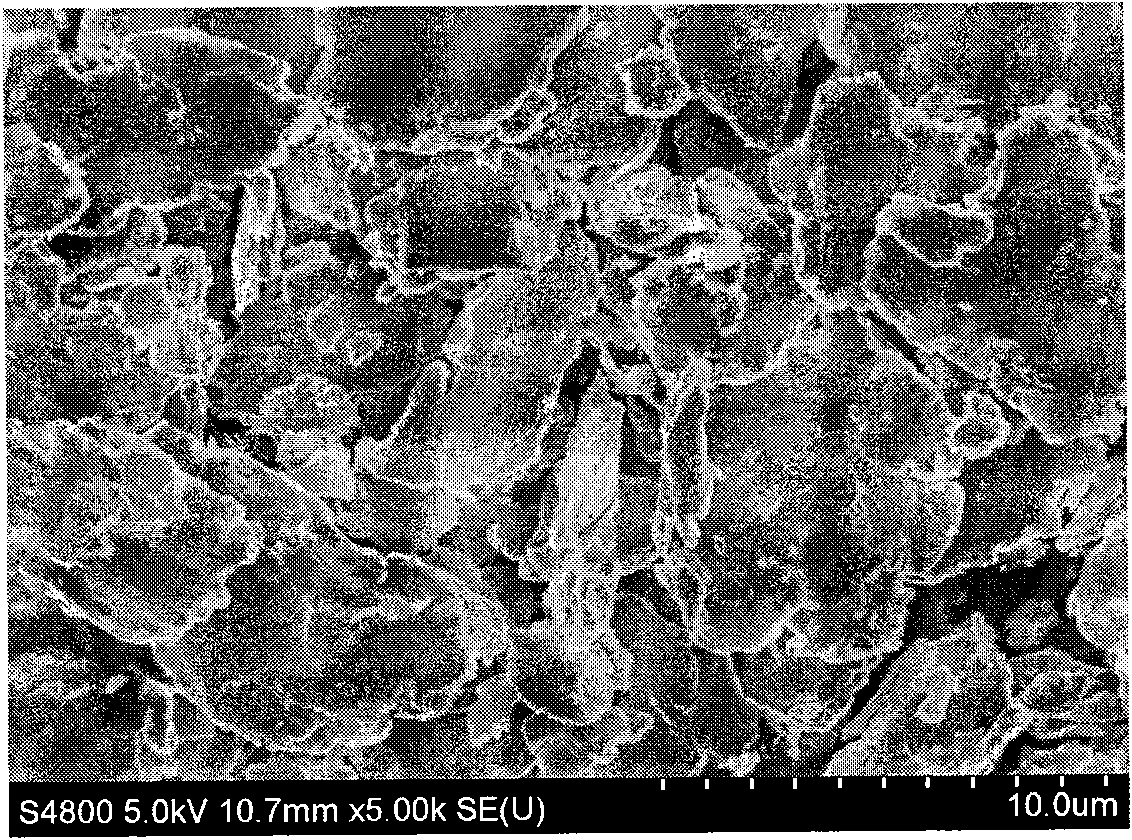

Magnetic field oriented flaky soft magnetic composite material and preparation method thereof

InactiveCN101604568AGood effectImprove permeabilityInorganic material magnetismMetal powderMaterials science

The invention relates to a material compounded by a magnetic material and a binding material and a preparation method thereof, wherein the magnetic material is flaky and has orientation property. The material is prepared by the following method: firstly, evenly mixing flaky soft magnetic metal powder with the uncured binding material with volume ratio of 1-9:9-1; secondly, putting the evenly-mixed compound into a mould made of a nonconductive magnetic material; and finally, placing the mould in a magnetic field with 10 to 10 Tesla, making the mould rotate in the magnetic field at a rotational speed of between 1 to 20 revolutions / minute for more than 1 minute, and curing the binding material.

Owner:LANZHOU UNIVERSITY

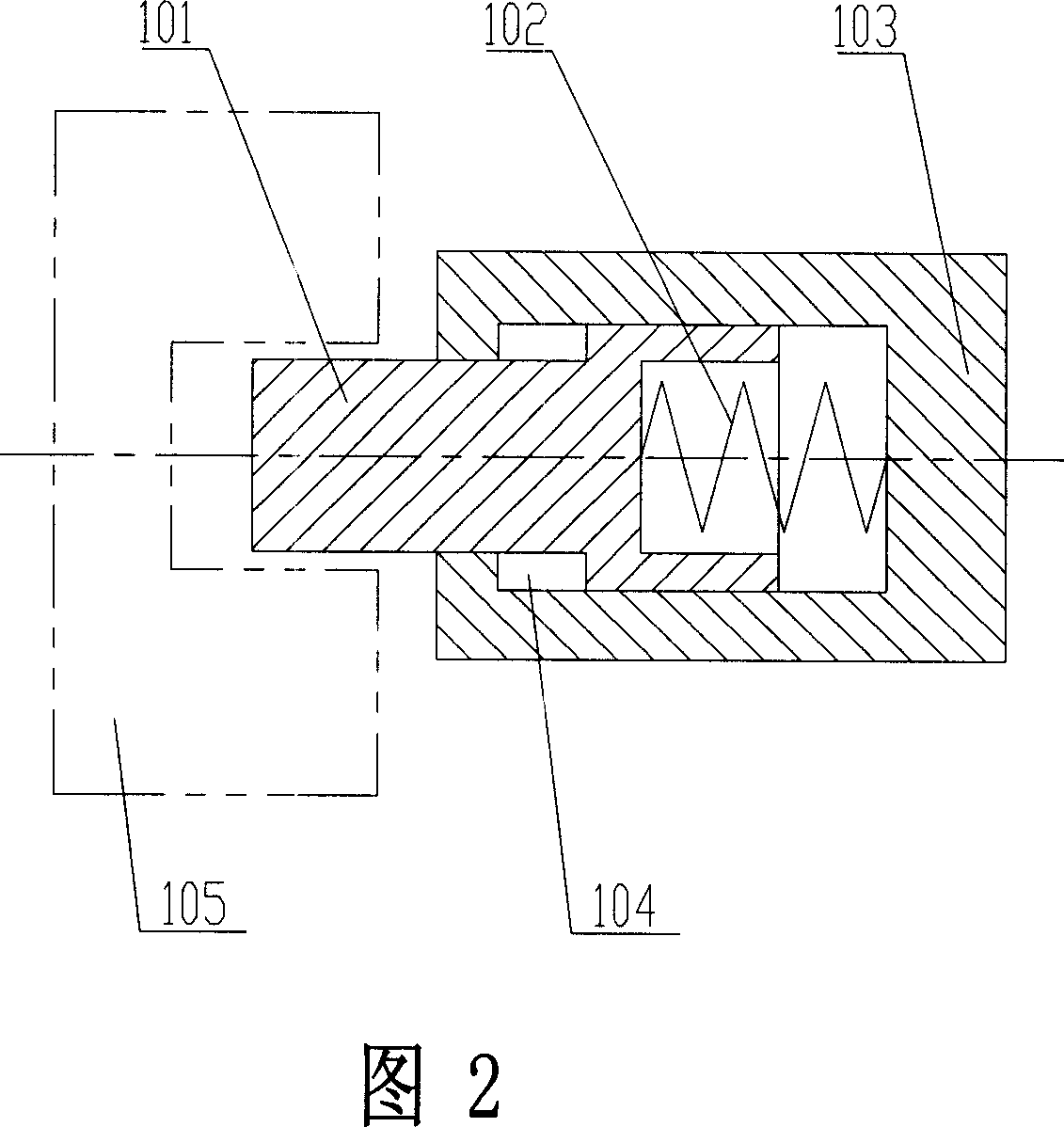

Shifting fork type telescopic pin mobile mechanism for crane

The invention discloses a shifting fork type expansion pin insert-draw mechanism for cranes, which includes an expansion oil cylinder (15) and a main body (3) fixed on the cylinder tube of the expansion oil cylinder (15) as well as an expansion pin (1); the cylinder tube of the expansion oil cylinder (15) is provided with a guide rail (6) and a power oil cylinder (10); the guide rail (6) is provided with a slider (7) capable of sliding relatively to the guide rail (6); the slider (7) is drivingly connected with the piston rod of the power oil cylinder (10) and is provided with a spring reset mechanism; the middle part of a shifting fork plate (4) is hinged with the main body (3); one end of the shifting fork plate (4) is hinged with the expansion pin (1), and the other end slides and transmits correspondingly to an inclined trough (14) on the slider (7); the main body (3) is provided with a guiding slot (13) guiding correspondingly with the expansion pin (1). The invention is a shifting fork type expansion pin insert-draw mechanism for cranes which has the advantages of simple and compacted structure, convenience in installation and maintenance, stable and reliable performance, and the improved efficiency of the complete machine. Different from any other products, the invention adopts a novel structure form, has advanced quality and is widely applicable in the series products of large-tonnage crane.

Owner:ZOOMLION HEAVY IND CO LTD

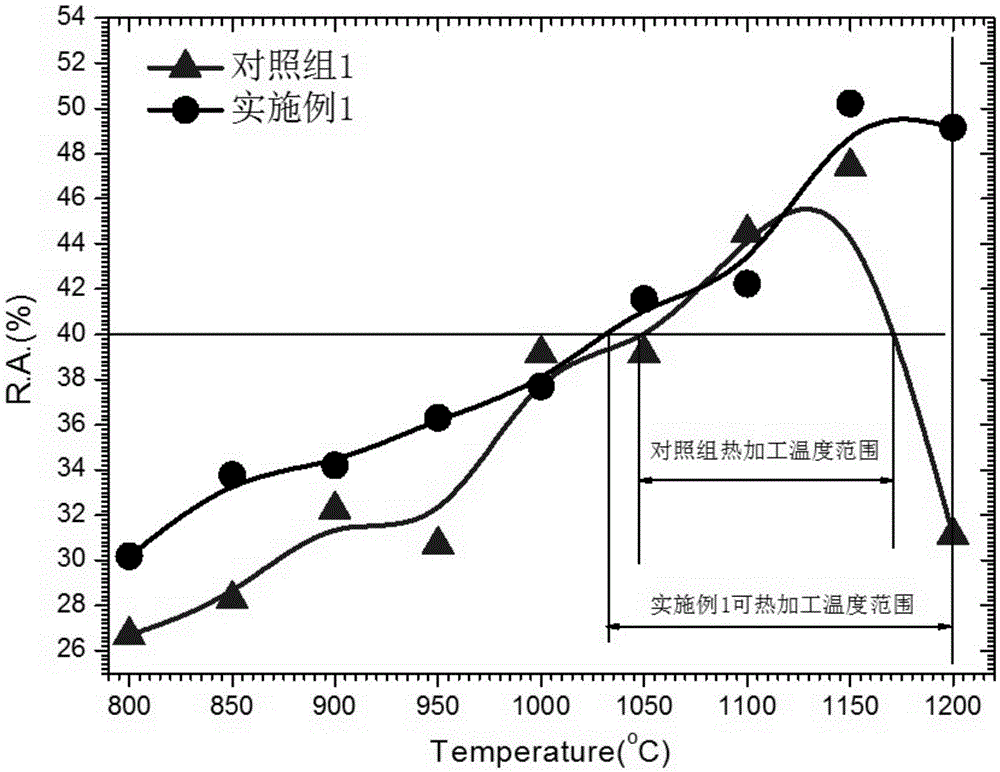

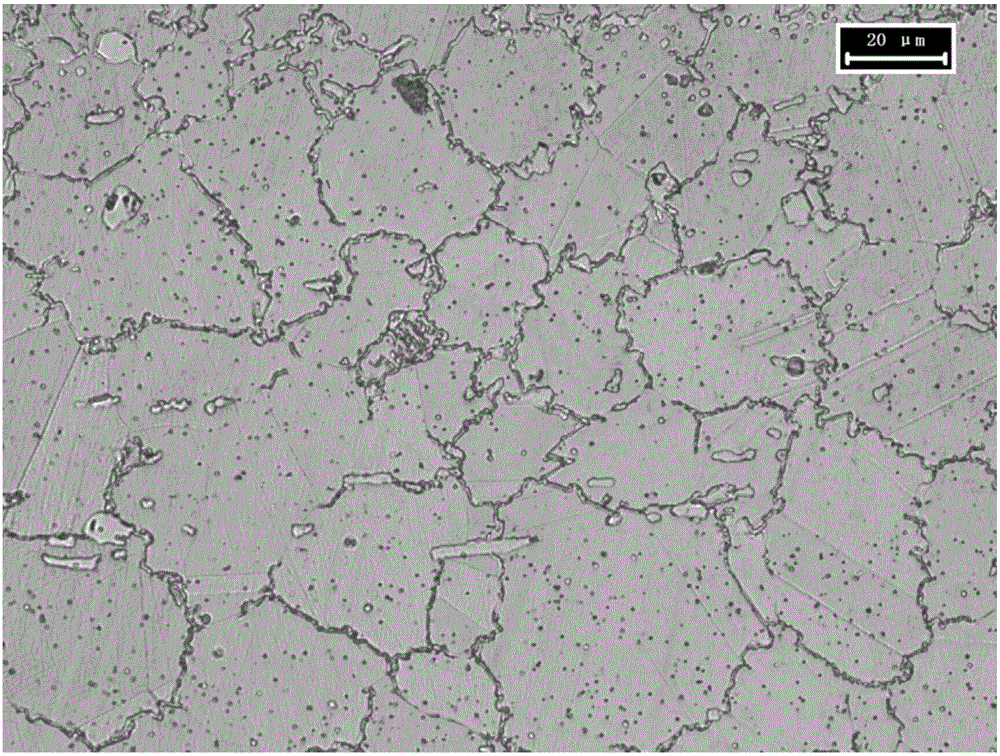

Austenite heat-resistant valve steel and manufacturing method thereof

ActiveCN105839028ASolve the problem of poor high-temperature thermoplasticity and cannot produce large-scale steel ingotsStable productionImpurityHeat resistant

The invention discloses austenite heat-resistant valve steel and a manufacturing method thereof. The steel comprises the following components, by mass percentage, 0.45-0.55% of C, 0.08-0.45% of Si, 8.00-10.00% of Mn, 20.00-22.00% of Cr, 3.50-5.00% of Ni, no more than 0.30% of Cu, 0.80-1.50% of W, 0.45-0.55% of N, 1.80-2.50% of Nb, no more than 0.02% of Al, no more than 0.010% of Mg, 0.001-0.01% of Ca, 0.001-0.006% of B, and 0.005-0.020% of RE, with the balance being Fe and inevitable impurities, wherein C+N>=0.09, Nb / C is in a range of 2-5, and (Mn+Si)>=200. The manufacturing method mainly comprises smelting, casting, blooming, rolling, complete solution and aging treatment.

Owner:宝钢特钢长材有限公司

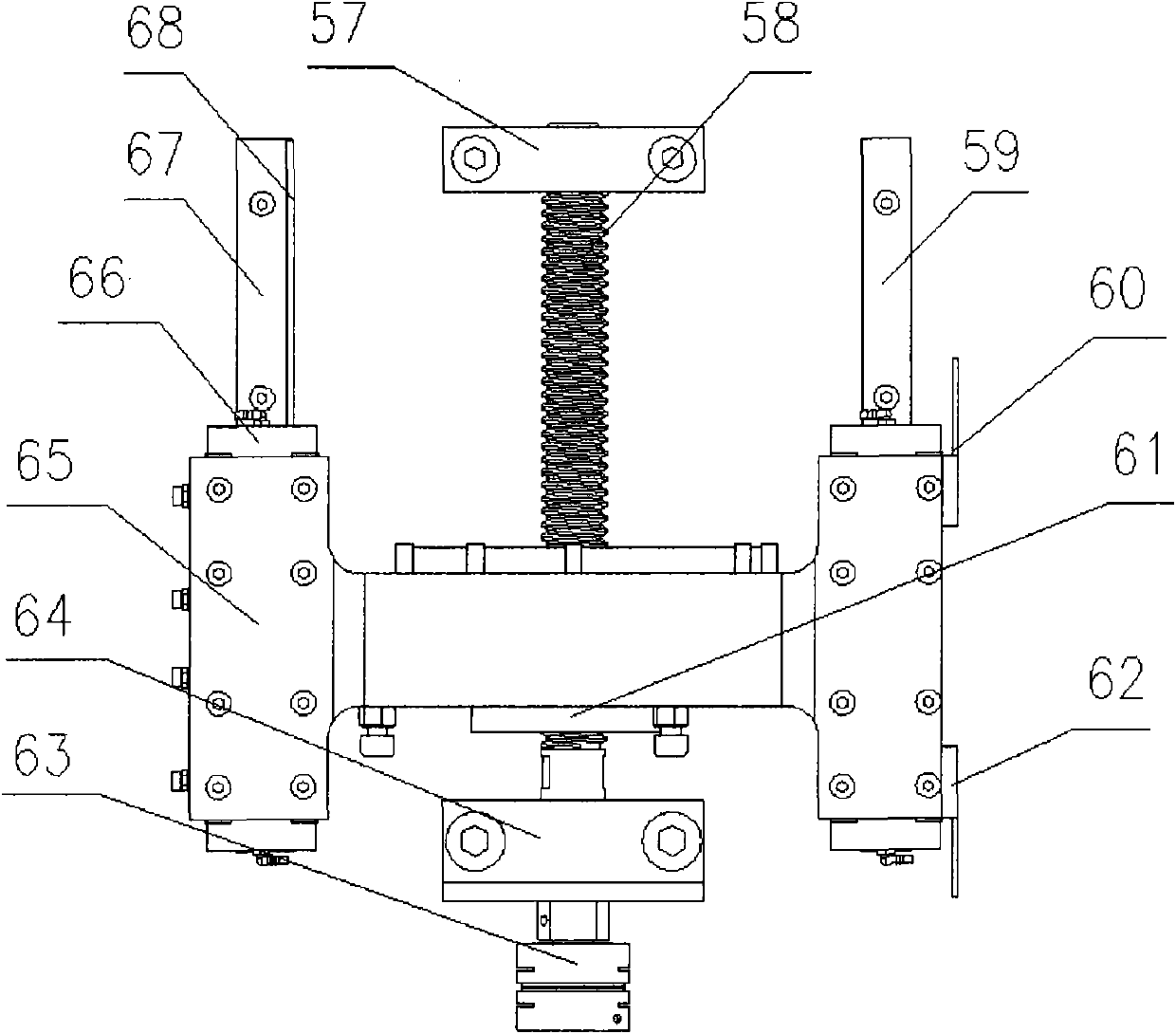

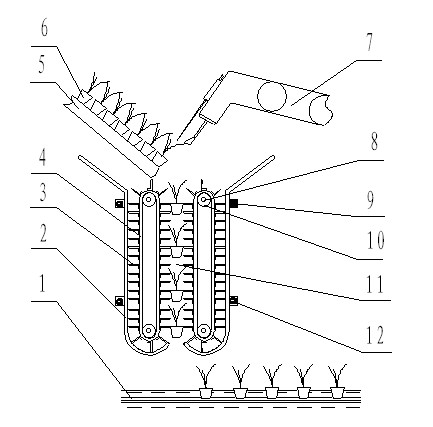

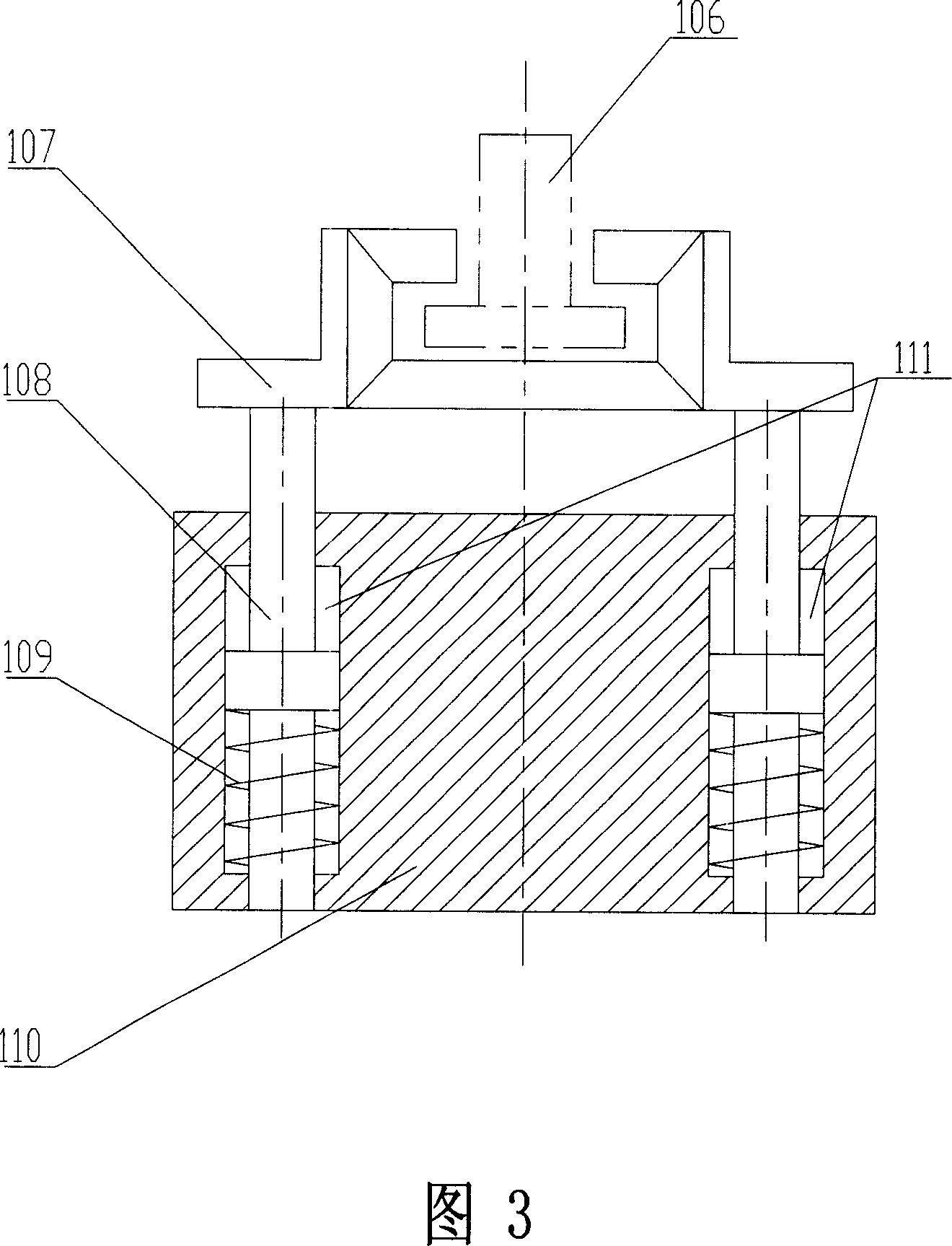

Rice seedling sowing mechanism matched with rice seedling sowing machine with stepless and rapidly-adjustable row space

The invention relates to a rice seedling sowing mechanism matched with a rice seedling sowing machine with stepless and rapidly-adjustable row space. The rice seedling sowing mechanism comprises a seedling collecting bucket, a seedling placing device, a rice nutritional bowl box plate, and a rice seedling grabbing mechanism. The rice nutritional bowl box plate and the rice seedling grabbing mechanism are arranged above the seedling collecting bucket. The seedling placing device is placed inside the seedling collecting bucket, and is provided with a step motor, a synchronous tooth-shaped belt, a synchronous tooth-shaped belt wheel, and two parallel synchronous conveying belts formed by flexible projections, wherein the flexible projections are uniformly arranged and fixed on the synchronous tooth-shaped belt. The rice seedling grabbing mechanism grabs the rice nutritional bowl placed on the rice nutrition bowl box plate, and places the rice nutritional bowl on the seedling collecting bucket between the two parallel synchronous conveying belts. The bottom of the seedling collecting bucket is provided with a seedling discharge port. The two parallel synchronous conveying belts with the flexible projections of the seedling placing device push the rice nutritional bowl on the seedling collecting bucket, such that the rice nutritional bowl glides to the seedling discharge port of the seedling collecting bucket so as to sow the seedling into the field. According to the present invention, the rice seedling sowing mechanism of the present invention has characteristics of stable operation, compact structure, and flexible operation, and is suitable for the rice sowing operation with characteristics of precise sowing and less seed injuring; and the requirements of precise sowing, accurate seed placing, cavity reducing and high efficiency can be met.

Owner:YANGZHOU UNIV

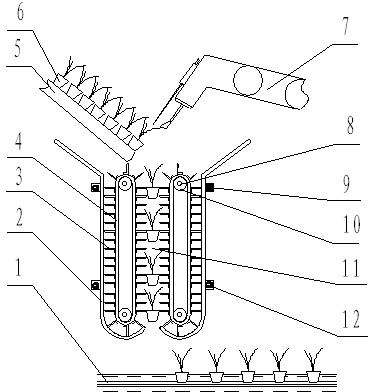

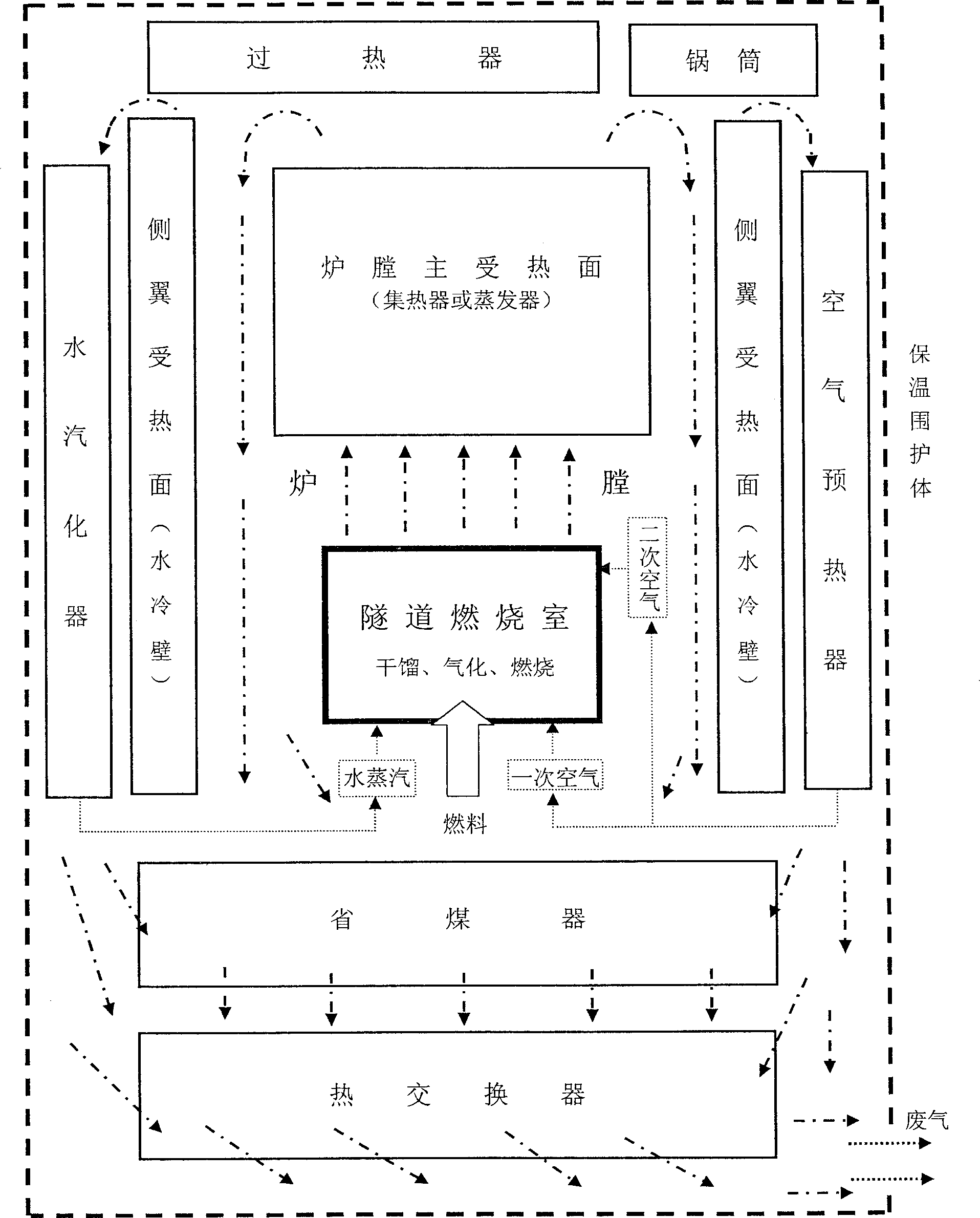

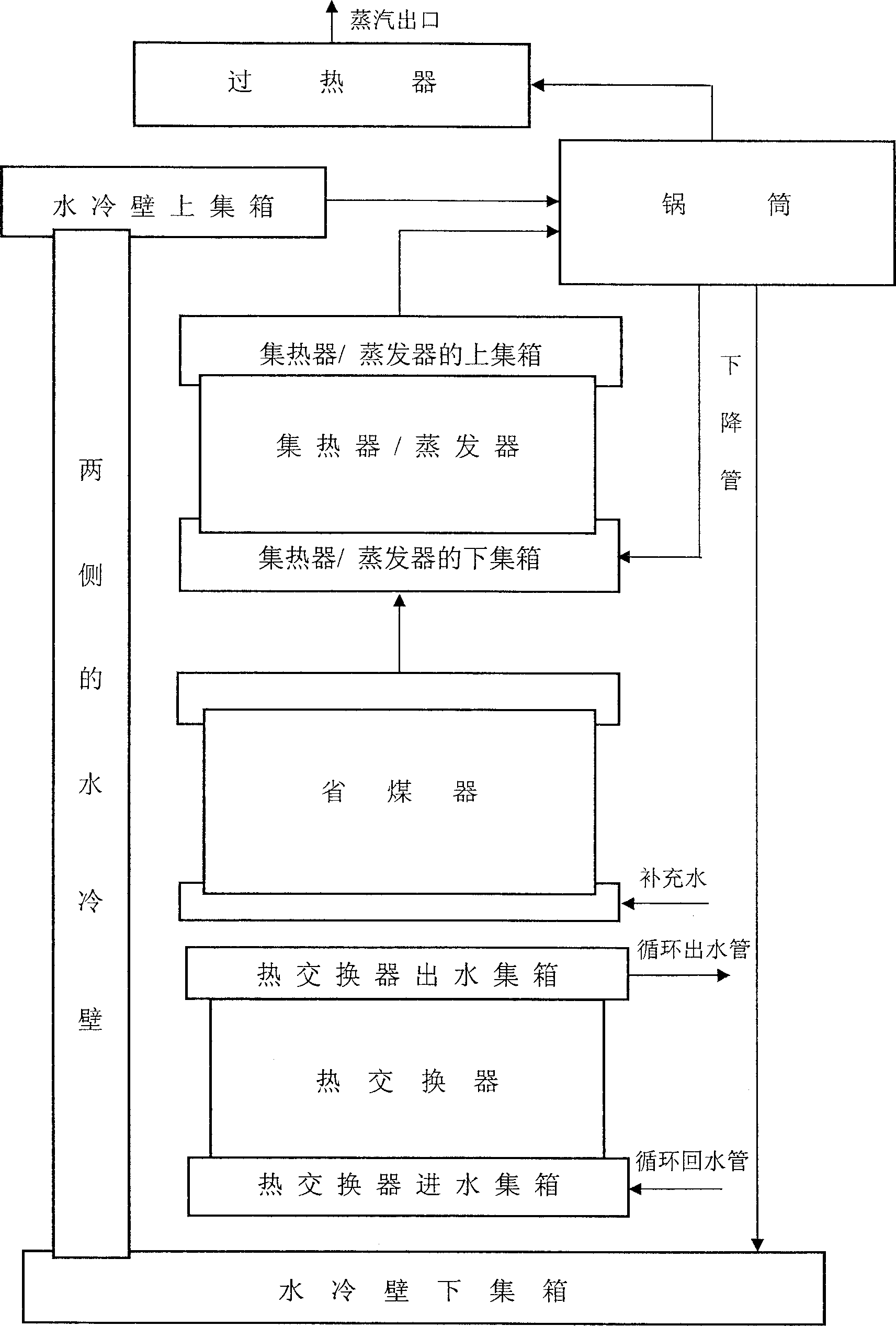

Tunnel combustion chamber and its constructed smoke dust less fuel coal and biomass equipment

InactiveCN1904479ARaise the gradePrevent escapeCasings/liningsNon-combustible gases/liquids supplyResource depletionCombustion chamber

The tunnel combustion chamber and its constitute of burning coal and organism without smoke and dust relate to boiler, furnace and aerify equipment whose fuel is coal and organism. The tunnel combustion chamber has wide fuel scope. It can carry out the cleanness combustion of the smoke raw coal, the spread coal, the organism, the type coal and the biologic coal. It applies the biologic fuels reasonably and has high thermal efficiency. It realizes the large-scale and mechanical burning. The invention resolves the problem of pollution atmosphere environment by coal burning device. It makes the equipments the cleanness combustion when burning the coals. The small equipment doesn't need air blast and induced air and it can burn. And it doesn't need the ash handling equipment to protect the environment. The invention sends the vapour to the tunnel combustion chamber. It is used to restrain the smoke and translate to the gas fuel. It carries out cleanness combustion when realizes the increase the combustion value of the fuels. It lowers the resources depletion and relief the energy strain. It creates a condition for pushing economy social overall coordination sustained developing.

Owner:周开根

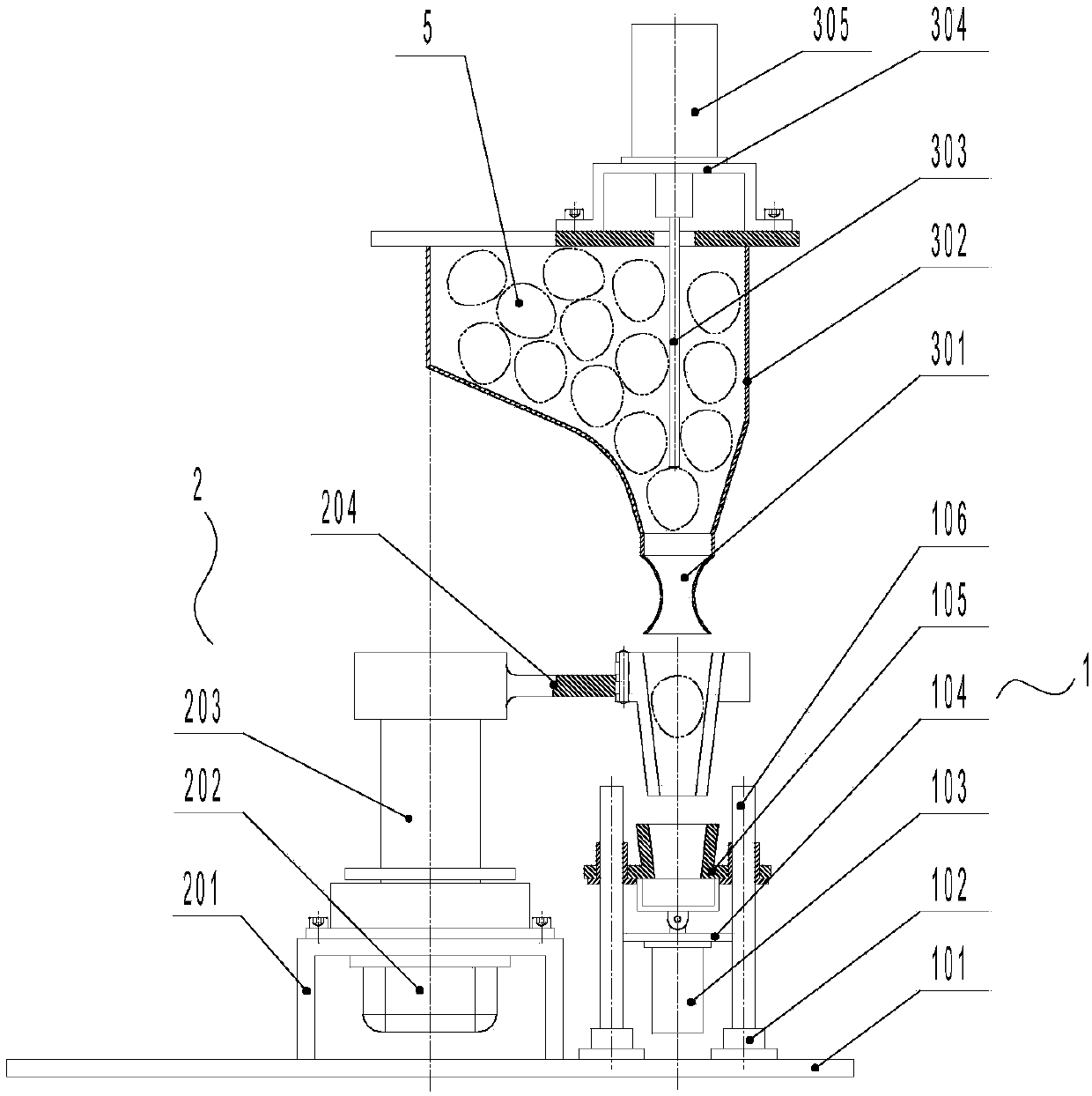

Automatic walnut shell opening device

PendingCN107811302AEasy to useImprove efficiencyKitchen equipmentHuskingEngineeringMechanical engineering

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

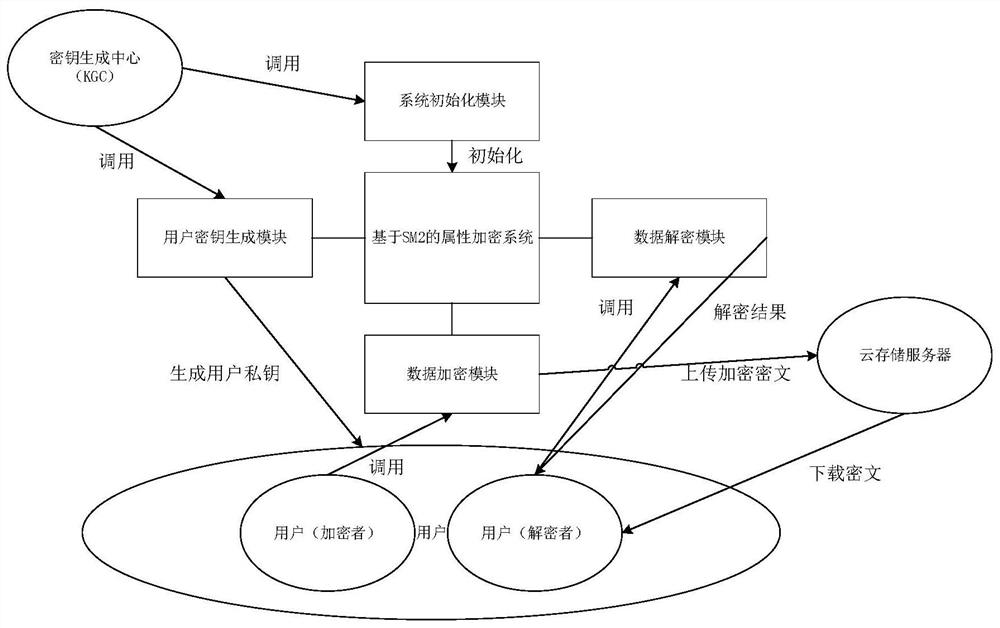

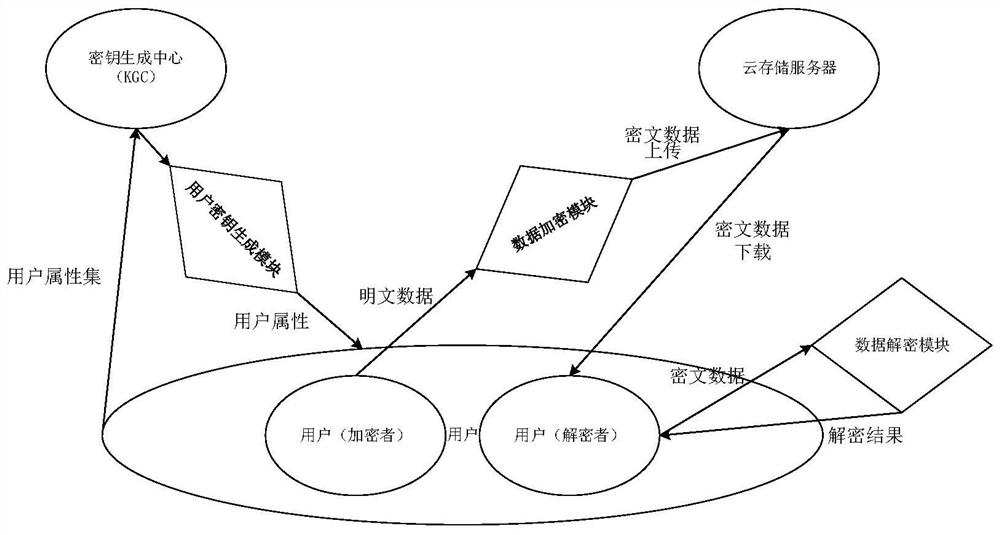

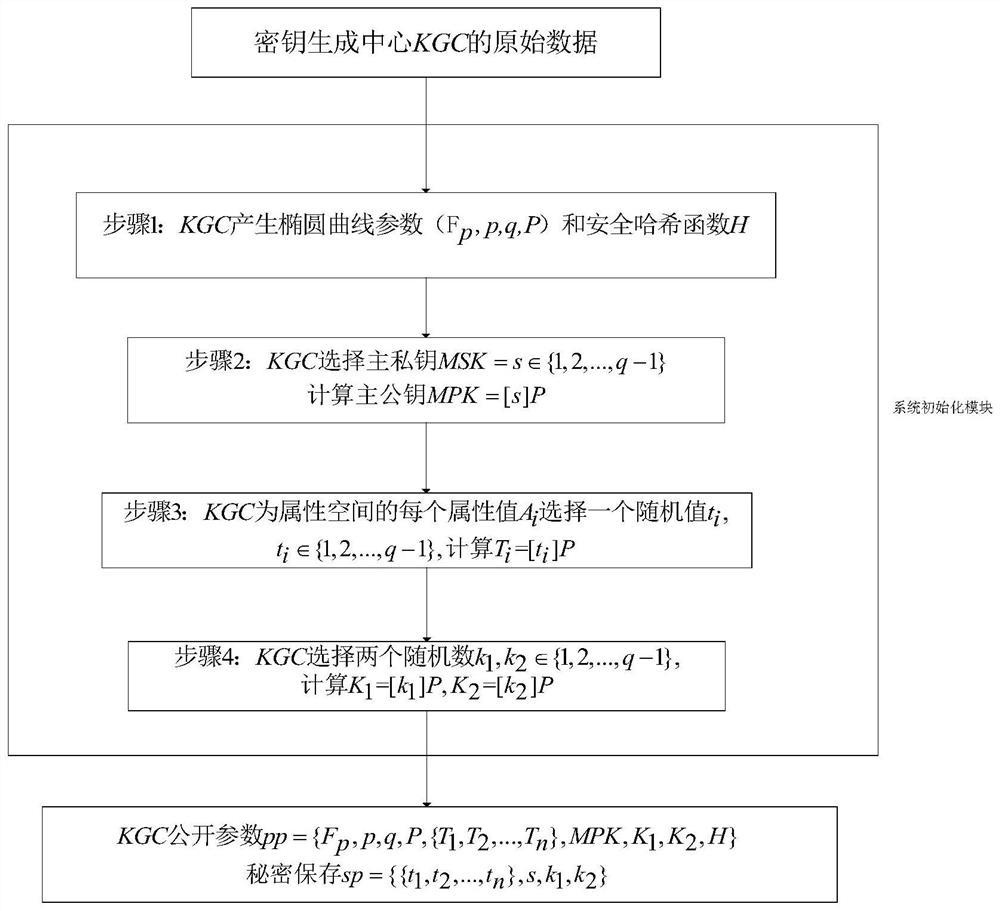

Cloud storage data encryption method and system and storage medium

ActiveCN111740988ASolve many problemsHigh efficiency requirementsKey distribution for secure communicationCiphertextEngineering

The invention discloses a cloud storage data encryption method and system and a storage medium. An encryption user initializes a generated public parameter according to a user access control tree constructed based on a preset user access control strategy and a trusted key generation center, and encrypts the data to be encrypted by using an attribute encryption mode to obtain an encrypted ciphertext, so that a decryption user conforming to the user access control tree decrypts the encrypted ciphertext according to a user private key generated by the trusted key generation center for the decryption user. According to the method, the use of a bilinear pair in an attribute-based encryption system (ABE) is canceled, the efficiency of an attribute-based encryption algorithm can be improved to agreater extent, and the high-efficiency requirement in a cloud storage environment is met.

Owner:WUHAN UNIV +7

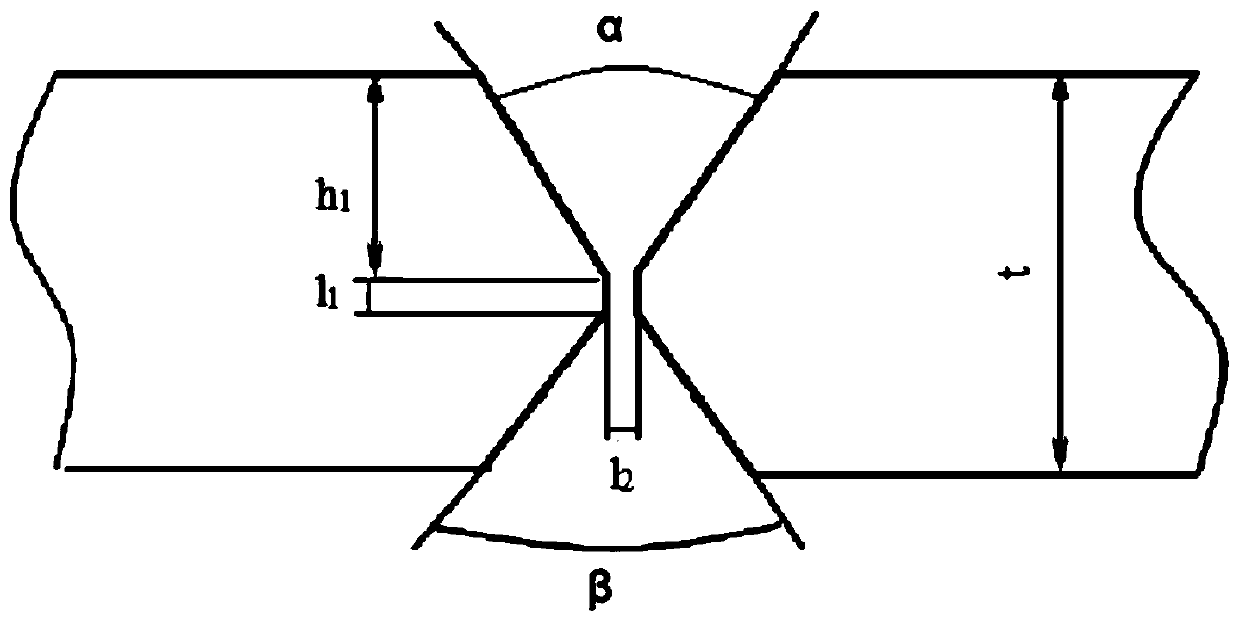

Marine high-strength steel plate double-wire submerged-arc welding process

InactiveCN109848526AImprove welding efficiencyHigh welding efficiencyArc welding apparatusSheet steelHigh strength steel

The invention discloses a marine high-strength steel plate double-wire submerged-arc welding process. An EH47 high-strength anti-cracking steel plate is selected, the thickness of the EH47 high-strength anti-cracking steel plate is 50-100 mm, a double-wire submerged-arc welding process with a front wire as a fine welding wire and a rear wire as a thick welding wire is adopted, and high-efficiencywelding of low heat input is realized. According to the marine high-strength steel plate double-wire submerged-arc welding process, the design requirements of the EH47 high-strength anti-crack steel plate welding joint high standard are met while the high efficiency of the double-wire submerged arc welding is guaranteed, so that the optimization of the welding quality and the efficiency is realized. The marine high-strength steel plate double-wire submerged-arc welding process is high in practicability, simple and convenient in welding operation, efficient and energy-saving, and is suitable for building and popularization and application of container ships.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

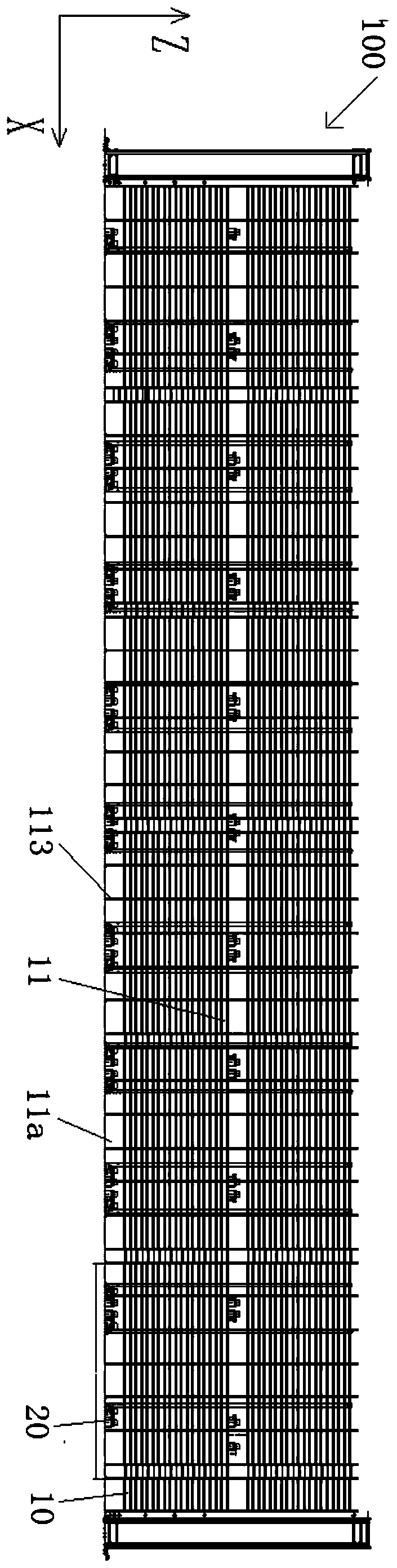

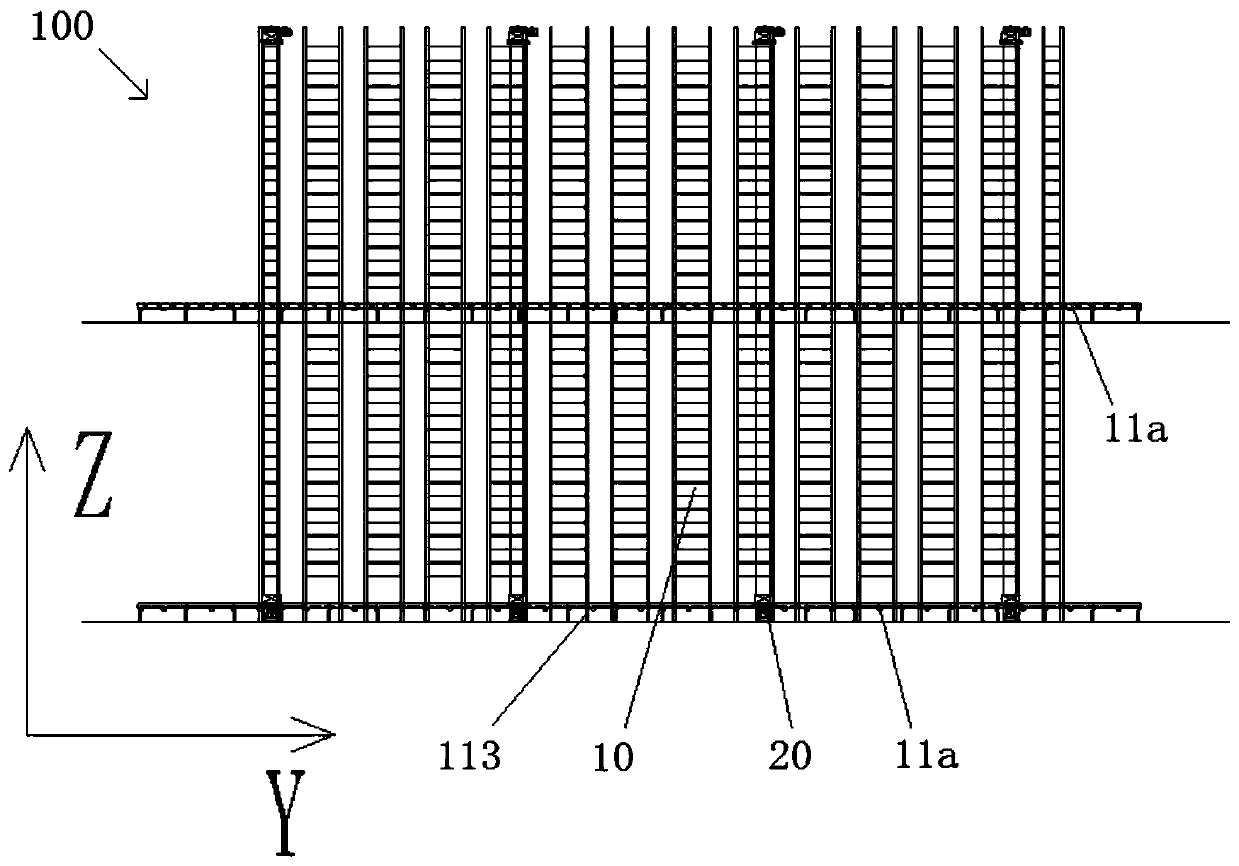

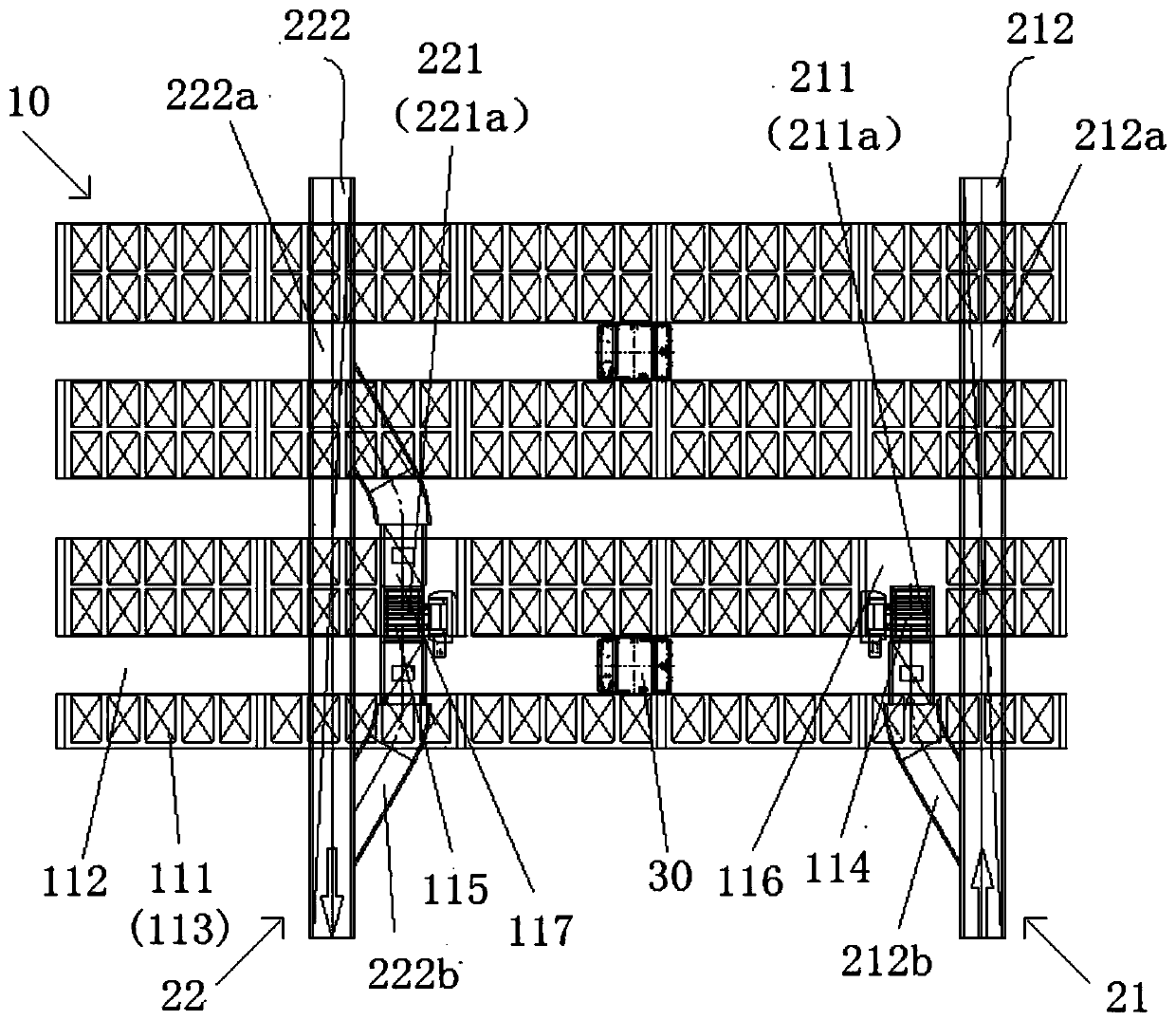

Multilayer box type shuttle vehicle stereoscopic warehouse

InactiveCN110498178AImprove cargo throughputReduce waiting timeStorage devicesTransport engineeringStorage garage

The invention provides a multilayer box type shuttle vehicle stereoscopic warehouse. The multilayer box type shuttle vehicle stereoscopic warehouse is characterized by comprising a goods storage mechanism, a plurality of warehouse exiting and entering mechanisms and at least one goods transport mechanism, wherein the goods storage mechanism comprises a plurality of storage layers, at least one ofthe storage layers is a warehouse exiting and entering conveying layer, each storage layer is provided with a plurality of goods sites and at least one transport channel, the plurality of the warehouse exiting and entering mechanisms are arranged on the warehouse exiting and entering conveying layer, each warehouse exiting and entering mechanism comprises a warehouse entering assembly and a warehouse exiting assembly, the at least one goods transport mechanism is used for transporting goods, the goods storage mechanism is provided with a plurality of lifting channel units, the lifting channelunits are arranged in a matrix mode, and each lifting channel unit comprises a warehouse entering lifting channel and a warehouse exiting lifting channel which extend in the vertical direction. The warehouse entering assemblies are used for moving the goods to the preset storage layers in a lifting mode, and then the at least one goods transport mechanism is enabled to move the goods to the presetgoods sites, and furthermore the warehouse exiting assemblies are used for moving the goods to the warehouse exiting and entering conveying layer in a descending mode after the at least one goods transport mechanism moves the goods to the warehouse exiting lifting channels.

Owner:HUBEI JOINTOWN TECH

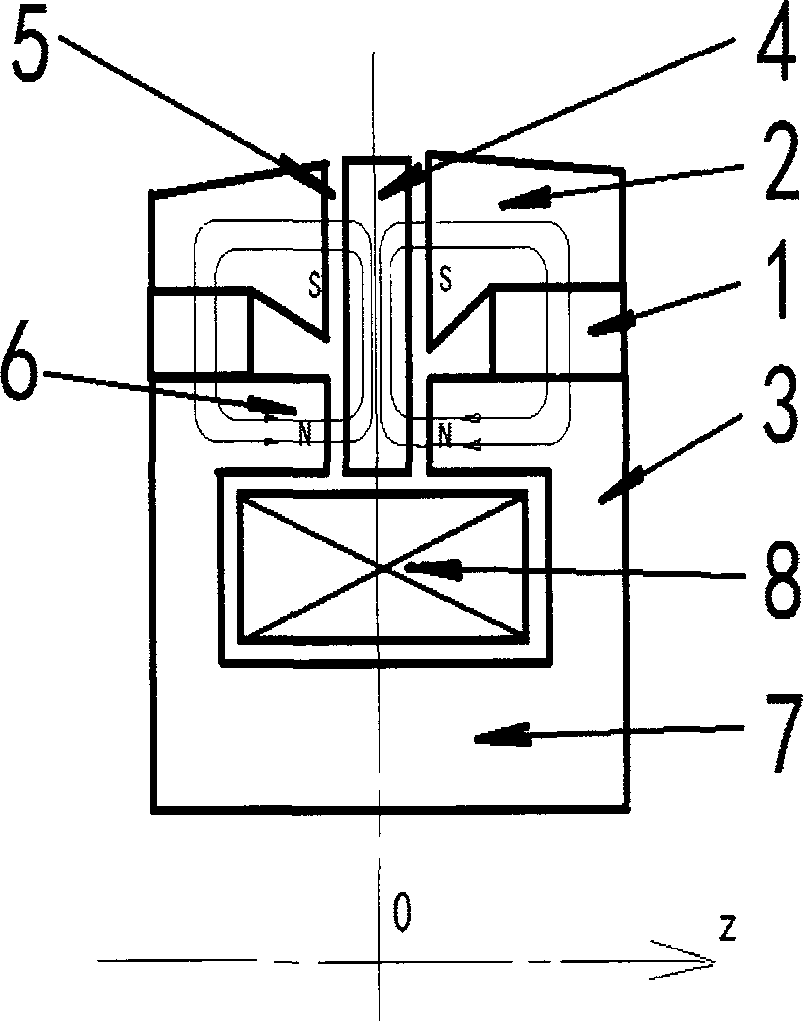

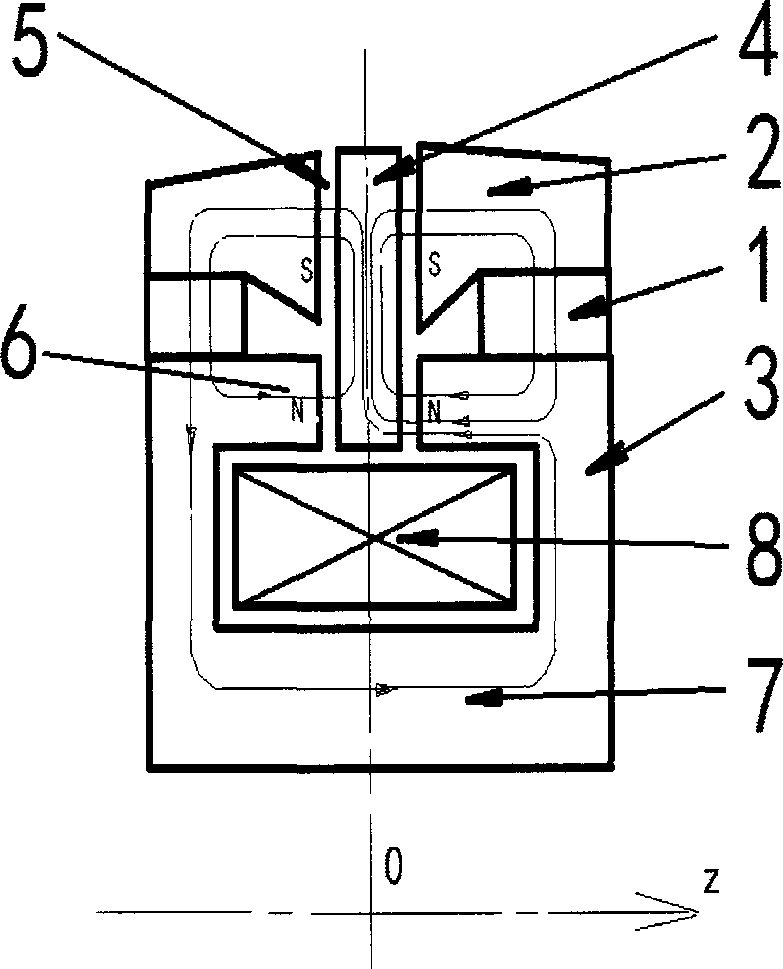

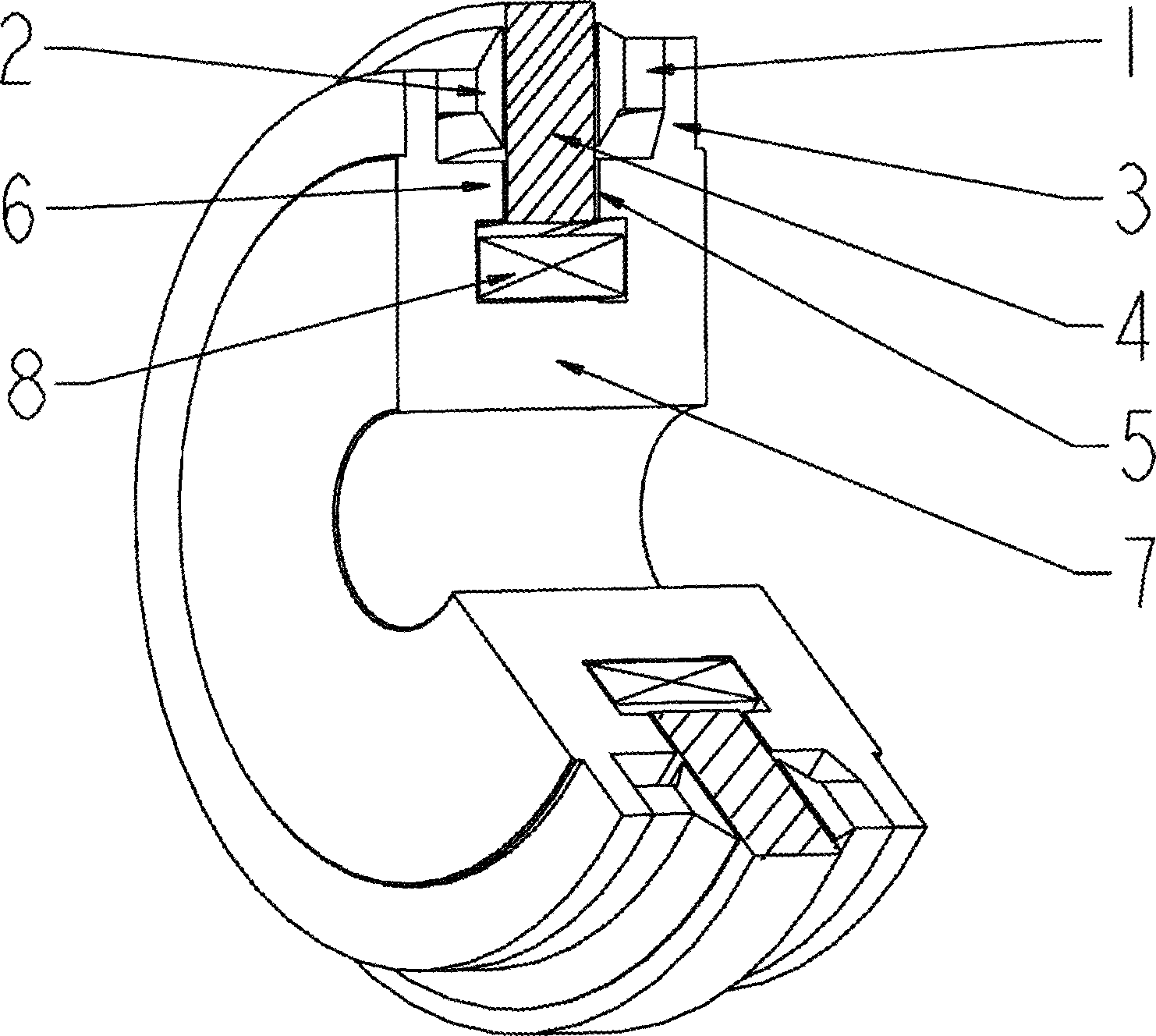

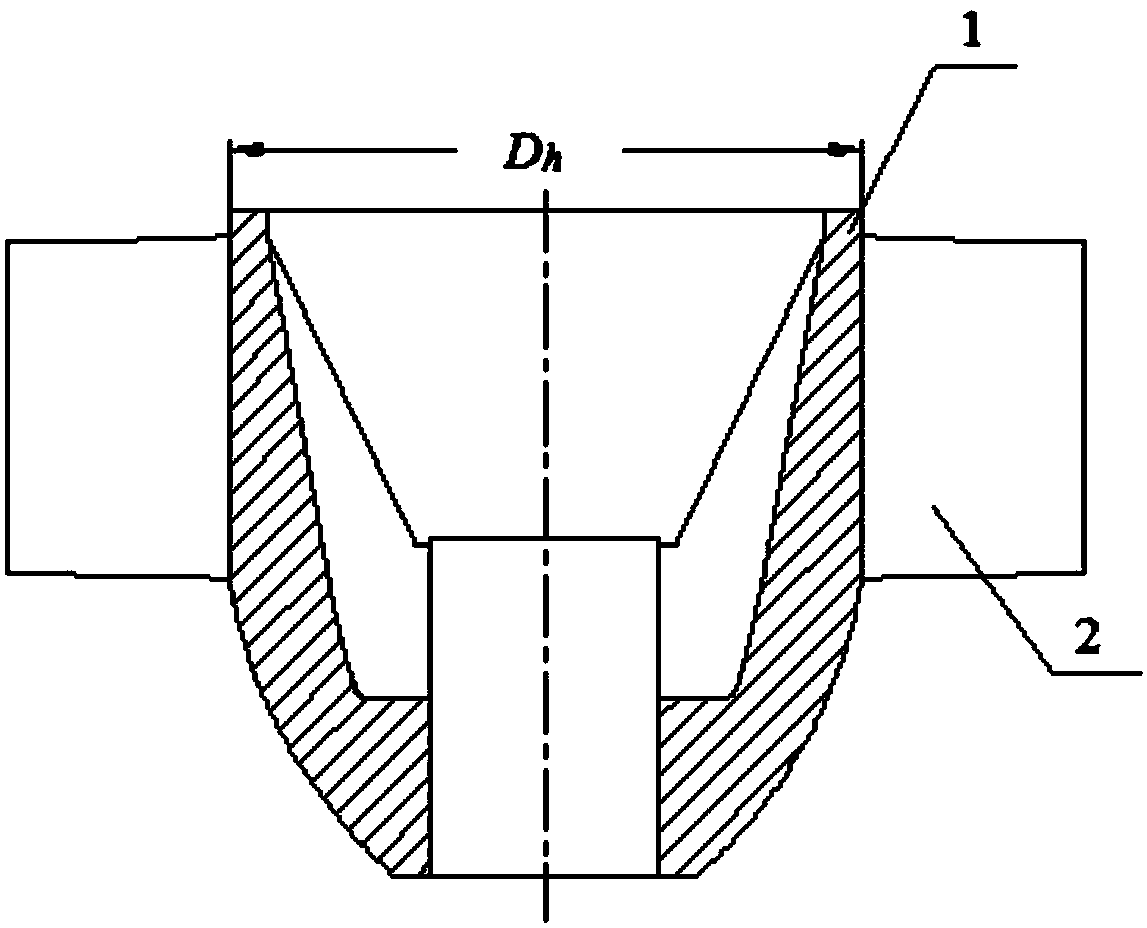

Axial electromagnet bearing

The invention discloses a permanent magnet polarization axial electromagnet bearing, which is compact in structure, simple in manufacture process, large in executive force contribution and high in electricity efficiency. The axial electromagnet bearing is provided with a polarization permanent magnet (1), stator cores (3), a rotor sucking disc (4) and a gap (5). A high magnetic flux density small pole (6) and a low magnetic flux density big pole (2) are both arranged on the stator cores (3) on two sides of the rotor sucking disc (4), polar area ratio is smaller than and equal to 0.5, the polarization permanent magnet (1) is absorbed between the high magnetic flux density small pole (6) and the low magnetic flux density big pole (2), polarity of the high magnetic flux density small pole (6) on the two sides is same, the high magnetic flux density small poles (6) axially face to the rotor sucking disc (4) and are linked through a winding iron core (7), and a concentrated winding (8) is located in a radial space of the rotor sucking disc (4) and located in a cavity of winding iron core (7). The axial electromagnet bearing of the structure is small in volume, particularly the axial dimension is small enough, support of an axis-free outer rotor is effective, manufacture is simple, force contribution is big, the permanent magnet is safe and lose no magnetism, magnetism stiffness is big, reliability is strong, and efficiency is high.

Owner:刘延风

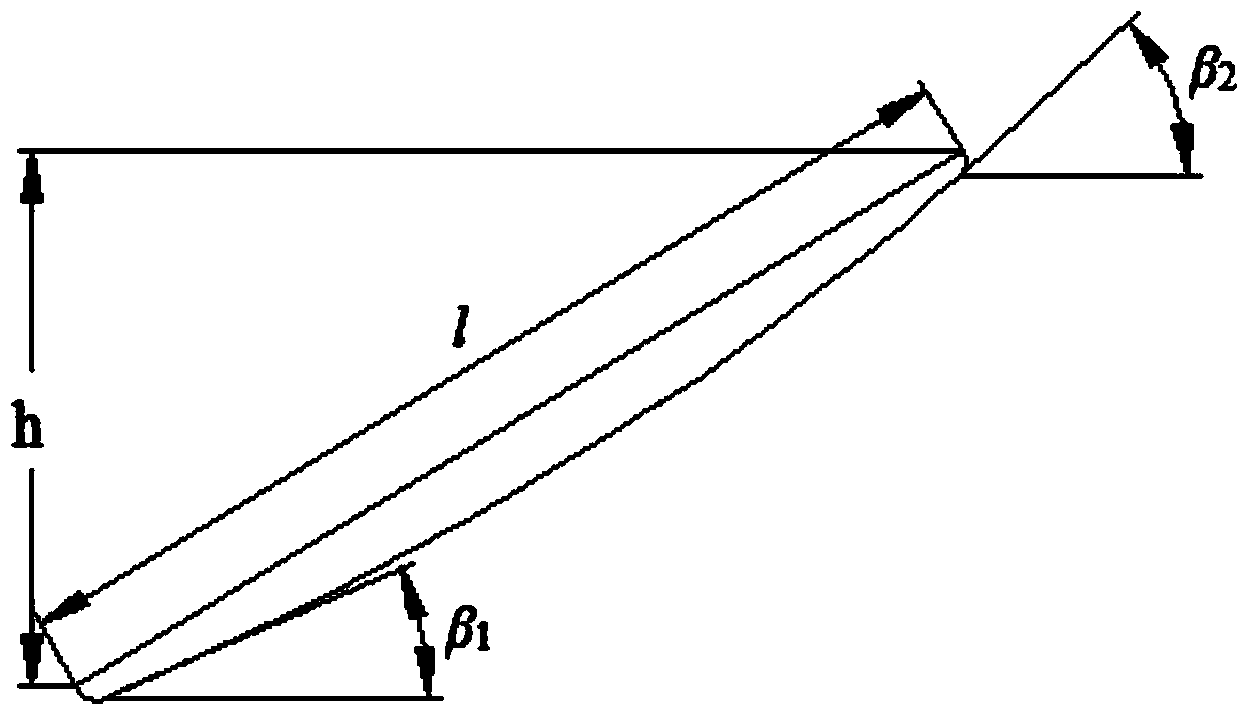

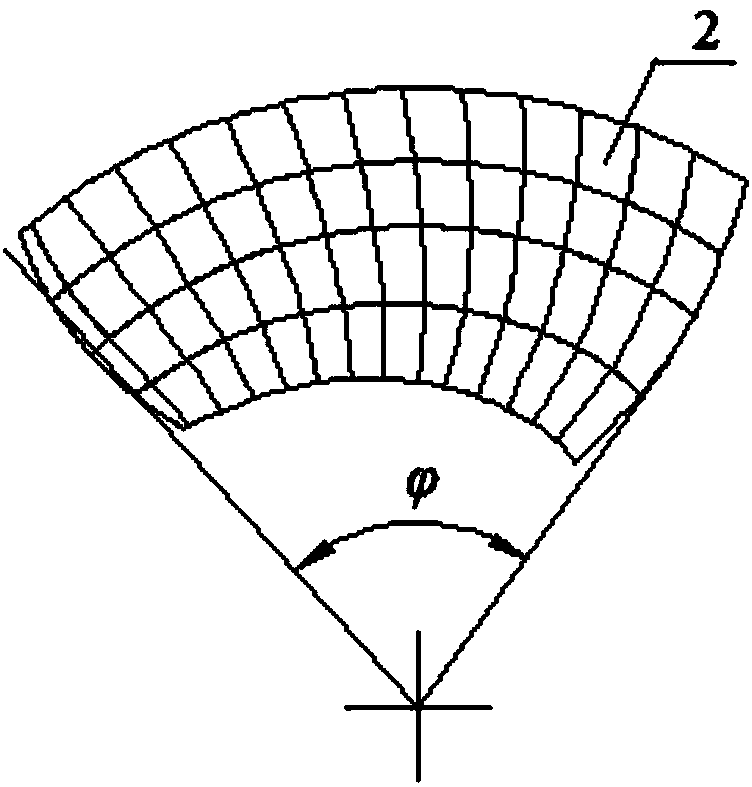

Multi-condition design method for multi-phase mixed transportation axial flow pump impeller

ActiveCN104389810AImprove efficiencyHigh efficiency requirementsPump componentsPumpsImpellerPerformance curves

The invention relates to a multi-condition design method for a multi-phase mixed transportation axial flow pump impeller. The geometric parameters of an axial flow impeller are linked with the performance requirements of a plurality of conditions of an axial flow pump, and the axial flow pump capable of working normally under the conditions is designed through regulation of the geometric parameters of a blade. By adopting the design method, the working performance curve of the axial flow pump can be consistent with a practically-required performance curve; the design method is particularly suitable for a normal running situation under a plurality of conditions; meanwhile, the pump can keep high efficiency in a plurality of multi-phase-flow conditions by controlling the rotating speed, specific speed and the like of the pump.

Owner:JIANGSU UNIV

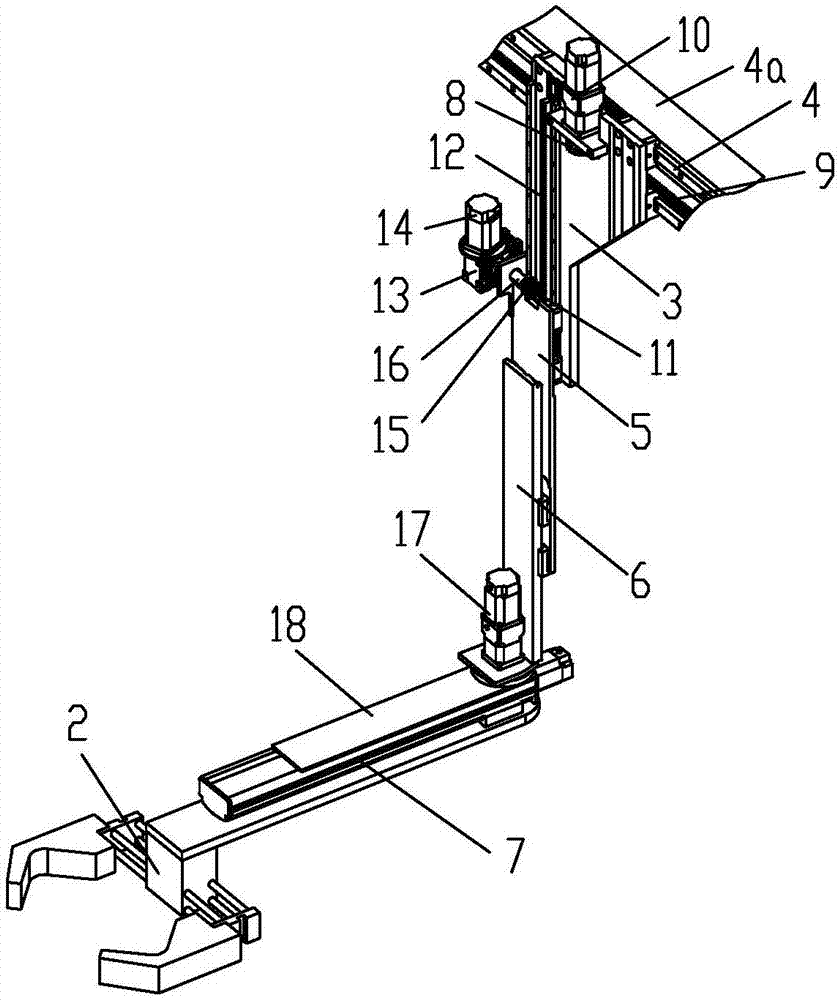

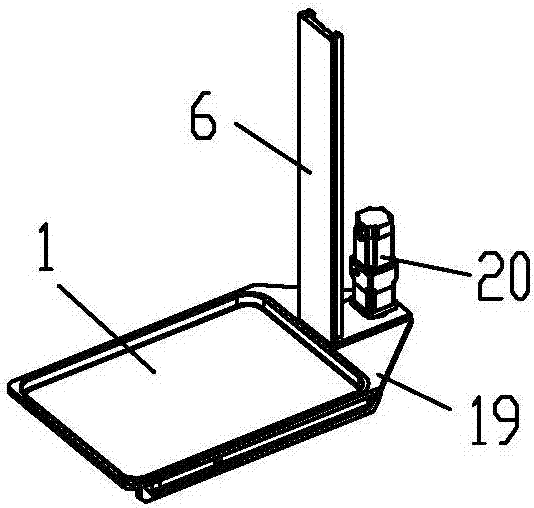

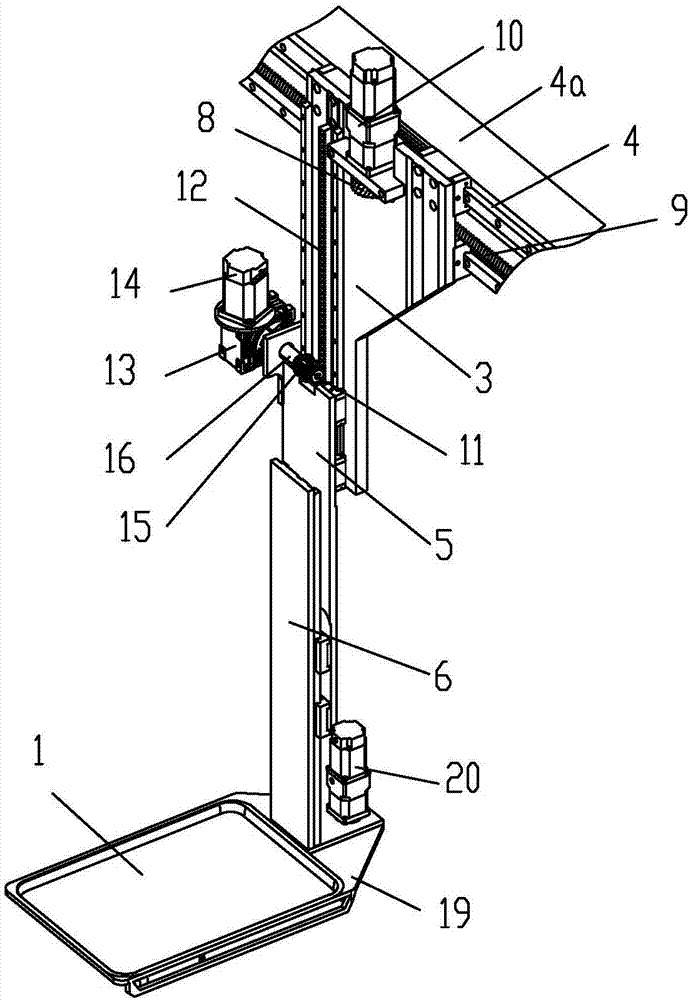

Meal sending device for intelligent dining room

ActiveCN107323985ATake advantage ofMeet height change requirementsManipulatorMechanical conveyorsEngineeringUtilization rate

The invention discloses a meal sending device for an intelligent dining room. According to the meal sending device, a meal sending tray is arranged through a conveying arm and is of a three-section combined structure composed of a conveying arm upper section, a conveying arm middle section and a conveying arm lower section. The conveying arm upper section is arranged on an aerial guide rail in a horizontal movement manner. A self-walking drive unit is arranged between the conveying arm upper section and the aerial guide rail. The conveying arm middle section is arranged on the conveying arm upper section in an up-down movement manner. A first lifting driving unit is arranged between the conveying arm upper section and the conveying arm middle section. The conveying arm lower section is arranged on the conveying arm middle section in an up-down movement manner. A second lifting driving unit is arranged between the conveying arm lower section and the conveying arm middle section. The meal sending device has the beneficial effects that the meal sending speed is high, efficiency is high, and the space utilization rate is high; and the structure is simple, layout is compact, the manufacturing efficiency is high, the manufacturing and using cost is low, and the service life is long.

Owner:深圳智胜机器人科技有限公司

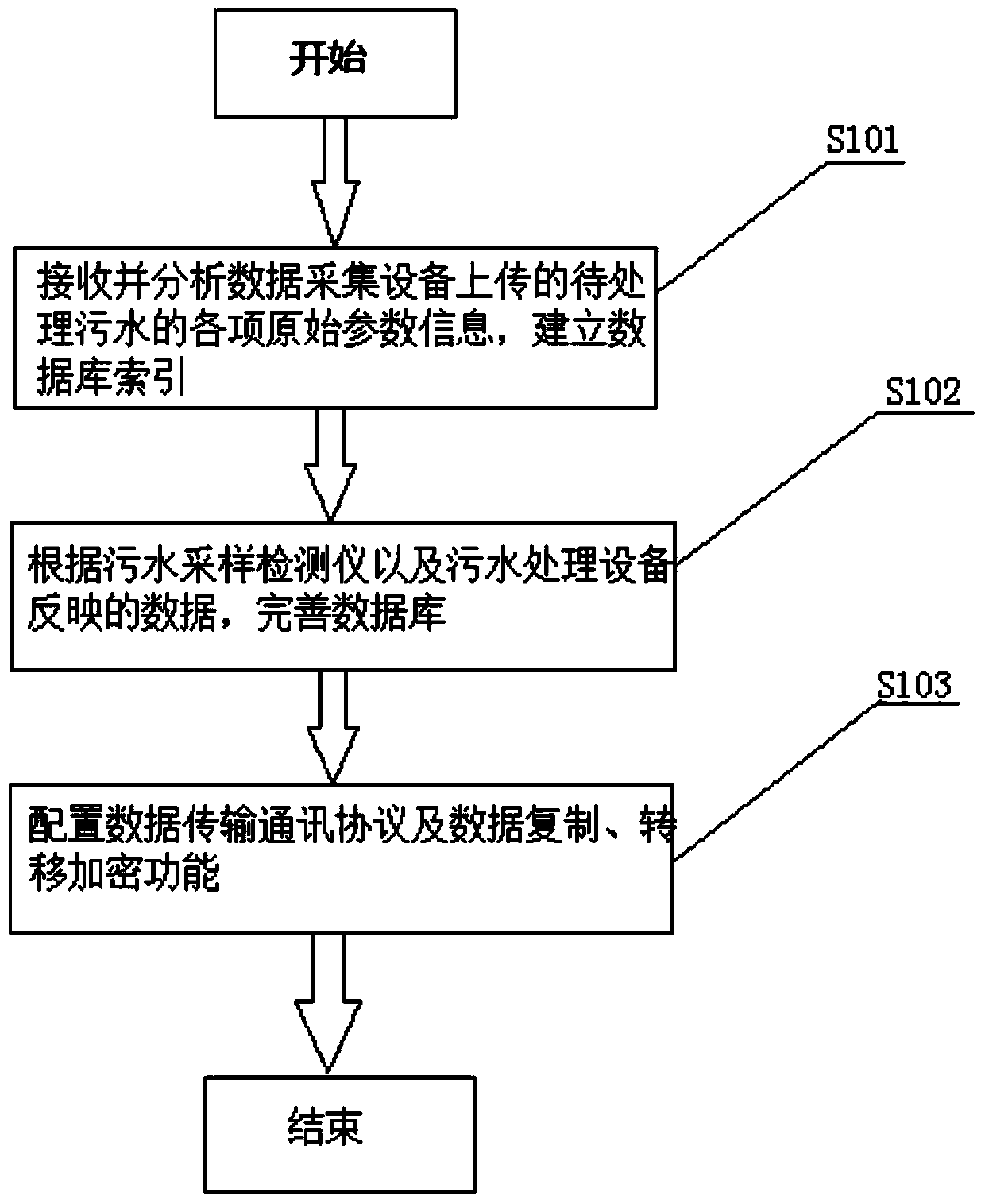

Wastewater electrochemical treatment database establishment method and device thereof

InactiveCN103745403AHigh precision requirementsHigh efficiency requirementsData processing applicationsGeneral water supply conservationData acquisitionWater quality

The invention discloses a wastewater electrochemical treatment control system private database establishment method. The method comprises the following steps: (1) original parameter information of wastewater before treatment and the wastewater before treatment that uploaded by a data acquisition device are acquired and stored to establish a database index; (2) random technical data support is provided for wastewater electrochemical treatment module parameter adjustment and production process management and control according to the data uploaded by the water quality detector in the wastewater treatment production process; (3) and the data transmission communication protocol and data reproduction, transfer and encryption functions are configured. The invention also discloses a wastewater electrochemical treatment control system private database establishment device. The wastewater electrochemical treatment control system private database establishment method and the device thereof provided in the invention can be used to lay a good foundation for the improvement of the wastewater treatment water quality standard accuracy and the electrochemical treatment efficiency, and the reduction of the production energy consumption.

Owner:铸神科技无锡有限公司

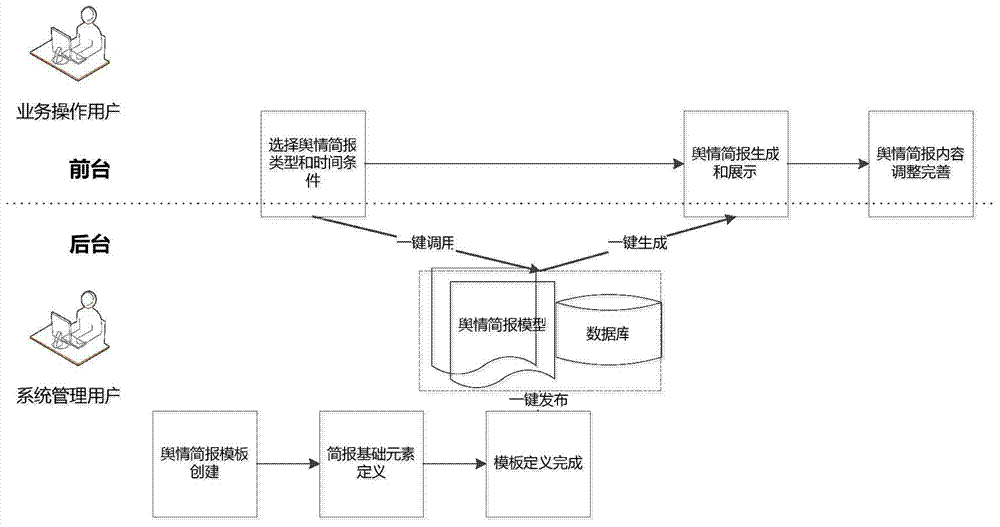

Method for dynamically generating public opinion brief report

InactiveCN104268194AEasy to useRealize dynamic generationSpecial data processing applicationsTime conditionSystems management

The invention provides a method for dynamically generating a public opinion brief report. The method comprises the steps that: a system management user establishes a public opinion brief report template, configures and defines basic elements, issues by one key after the public opinion brief report template is completed, and thereby a public opinion brief report model is formed; in a downstage business process, a business operating user selects public opinion brief report business, also selects the type and time condition of the brief report, and invokes the background public opinion brief report template and business data in a database to generate the public opinion brief report. According to the method, effective inheritance and fusion of original data analysis result are achieved, data interaction during a public opinion brief report producing process is greatly enhanced, repeated data organizing time in the public opinion brief report is reduced, and reusability is achieved.

Owner:STATE GRID CORP OF CHINA +1

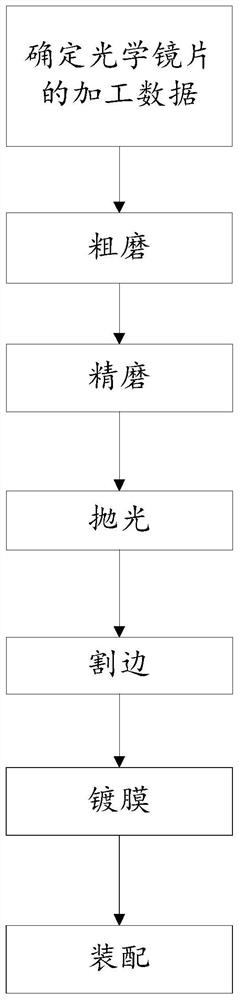

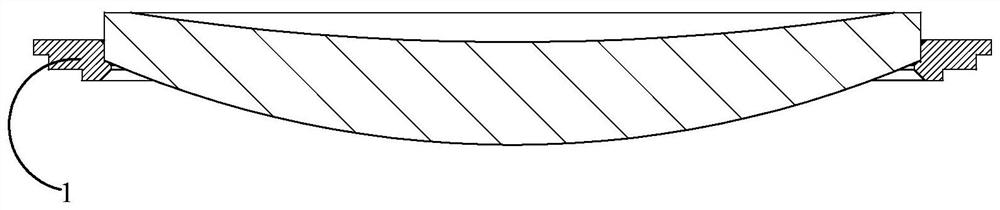

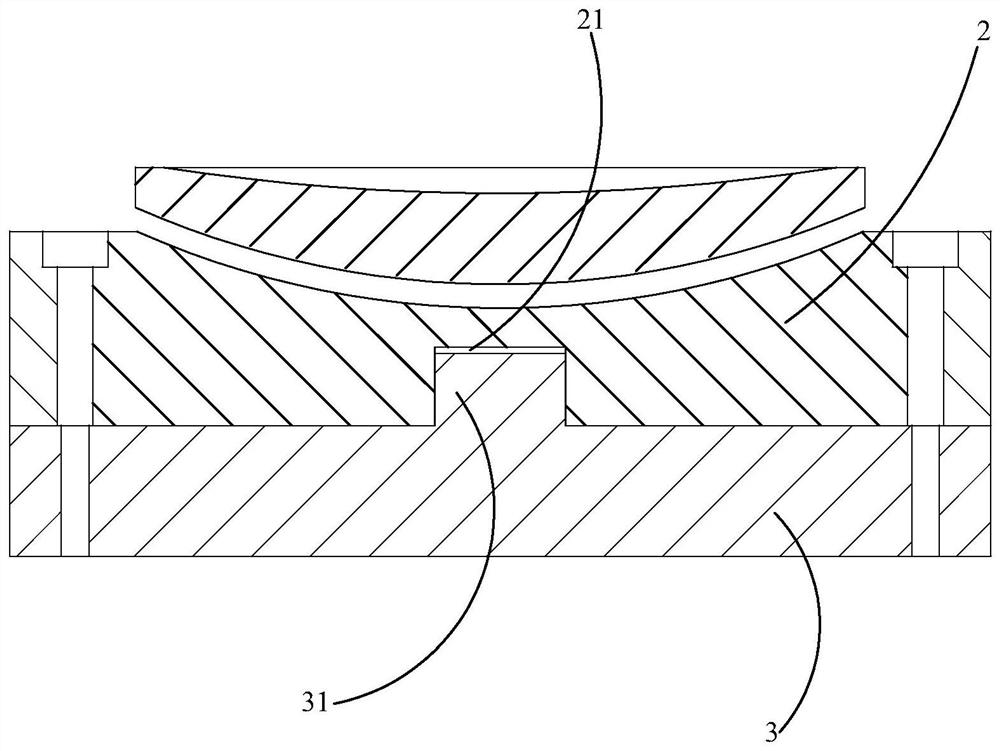

Optical lens processing method, optical lens and laser field lens

InactiveCN112068226AImprove surface roughnessGood precisionOptical surface grinding machinesLensTransmittanceOptic lens

The invention relates to the technical field of lens processing, and provides an optical lens processing method, which is used for processing the optical lens and comprises the following steps of 1, determining processing data of the optical lens, 2, according to the processing data of the optical lens, roughly grinding the optical lens through a spherical surface milling and grinding machine, andreserving allowance, and 3, fixing the optical lens subjected to rough grinding to a clamping jig, and using a ball head cutter for conducting accurate grinding on the optical lens. The invention also provides an optical lens and a laser field lens. According to the optical lens processing method, the efficiency and precision requirements of a subsequent polishing process and an edge cutting process can be effectively improved, the surface roughness, curvature radius precision and concentricity of the optical lens processed through the method are greatly improved, and a laser field lens adopting the optical lens is high in laser transmittance.

Owner:江门英讯通光电科技有限公司

Flange drilling indexing disc

InactiveCN108326633AEnsure drilling qualityImprove operational efficiency and quality requirementsPrecision positioning equipmentRocker armEngineering

The invention provides a flange drilling indexing disc. The indexing disc comprises a base, a rotating shaft, an upper ratchet wheel, a lower ratchet wheel, a table top fixing shaft seat and a flangefixing table top, wherein the rotating shaft is arranged on the base, and the flange fixing table top is connected with the table top fixing shaft seat; a containing cavity is concavely formed in thebase, one end of the rotating shaft is connected with the base, and the other end of the rotating shaft is connected with the flange fixing table top; the upper ratchet wheel and the lower ratchet wheel are arranged in the containing cavity in a stacked mode, and the rotating shaft penetrates through the upper ratchet wheel and the lower ratchet wheel at the same time; the table top fixing shaft seat is arranged at the top of the base, and the inner side of the table top fixing shaft seat is connected with a table top rotating shaft seat through table top fixing balls; table top rotating ballsare arranged between the table top fixing shaft seat and the flange fixing table top; and two ratchet wheel clamping pins are inserted into the circumferential wall of the base, one end of each ratchet wheel clamping pin extends into the containing cavity, and the other end of each ratchet wheel clamping pin is located outside the peripheral wall of the base. The flange drilling indexing disc ishigh in precision, time-saving and labor-saving and capable of improving the drilling operation efficiency of a radial drill and the flange drilling quality at the same time.

Owner:GUANGZHOU ZENGLI STEEL STRUCTURE

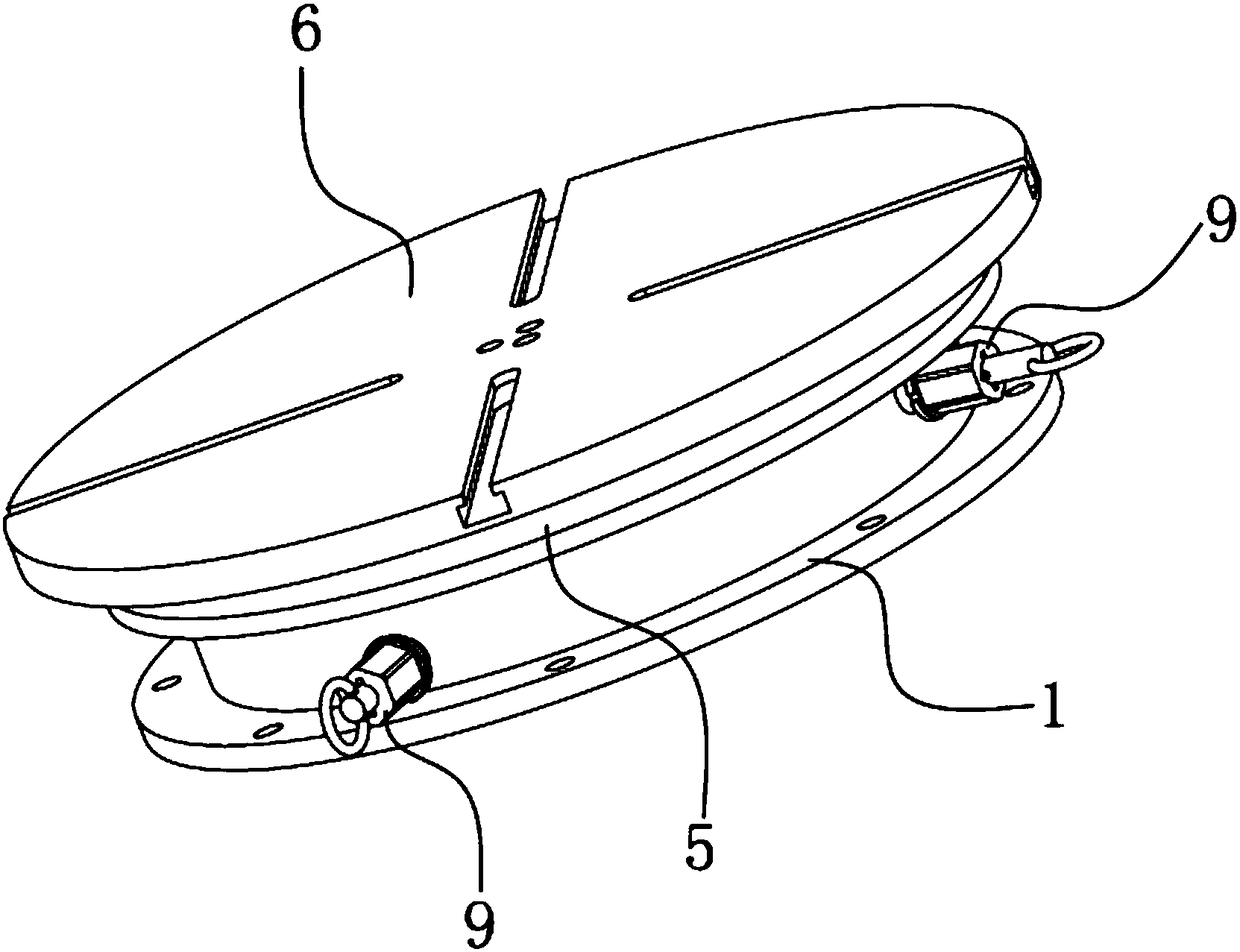

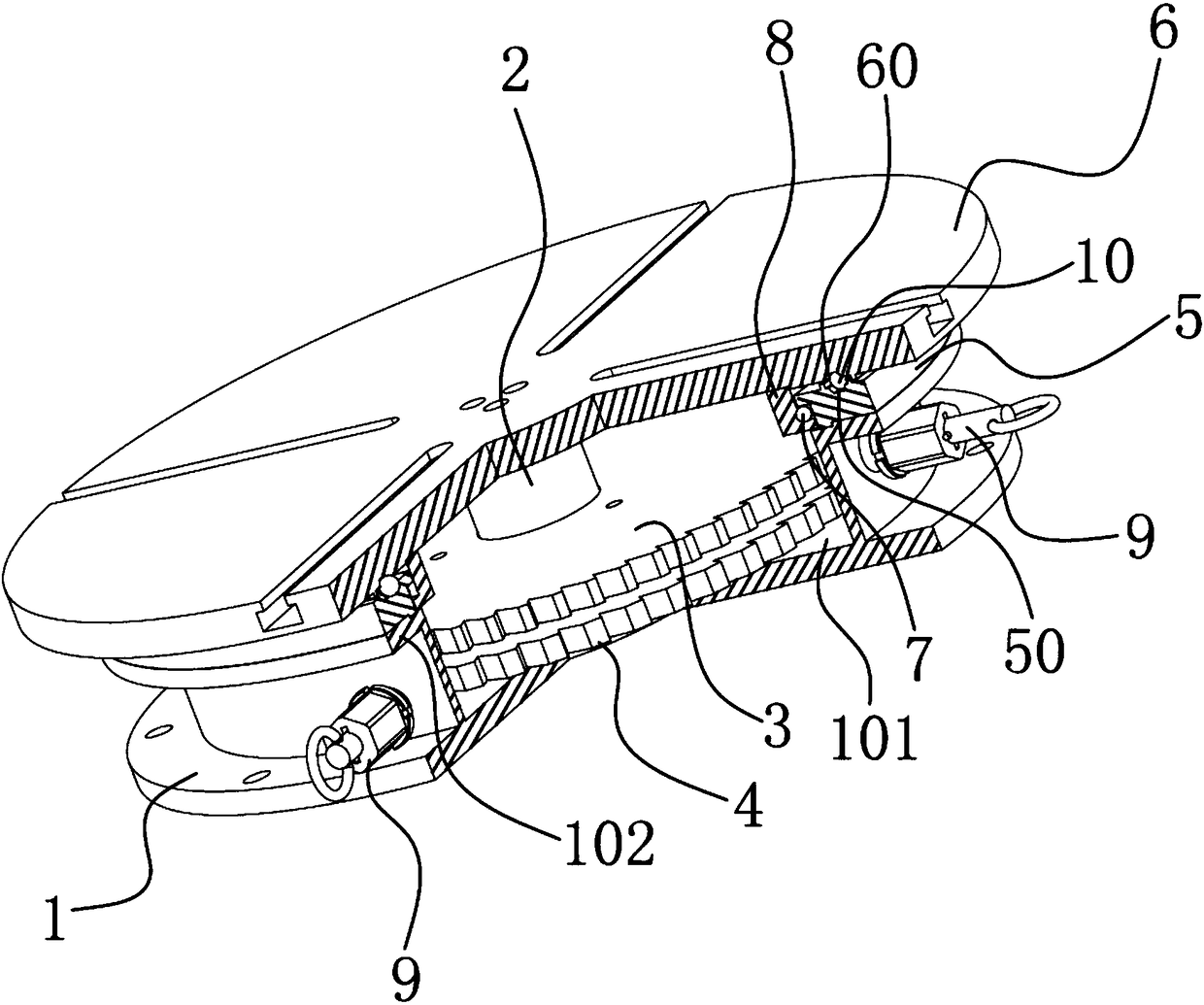

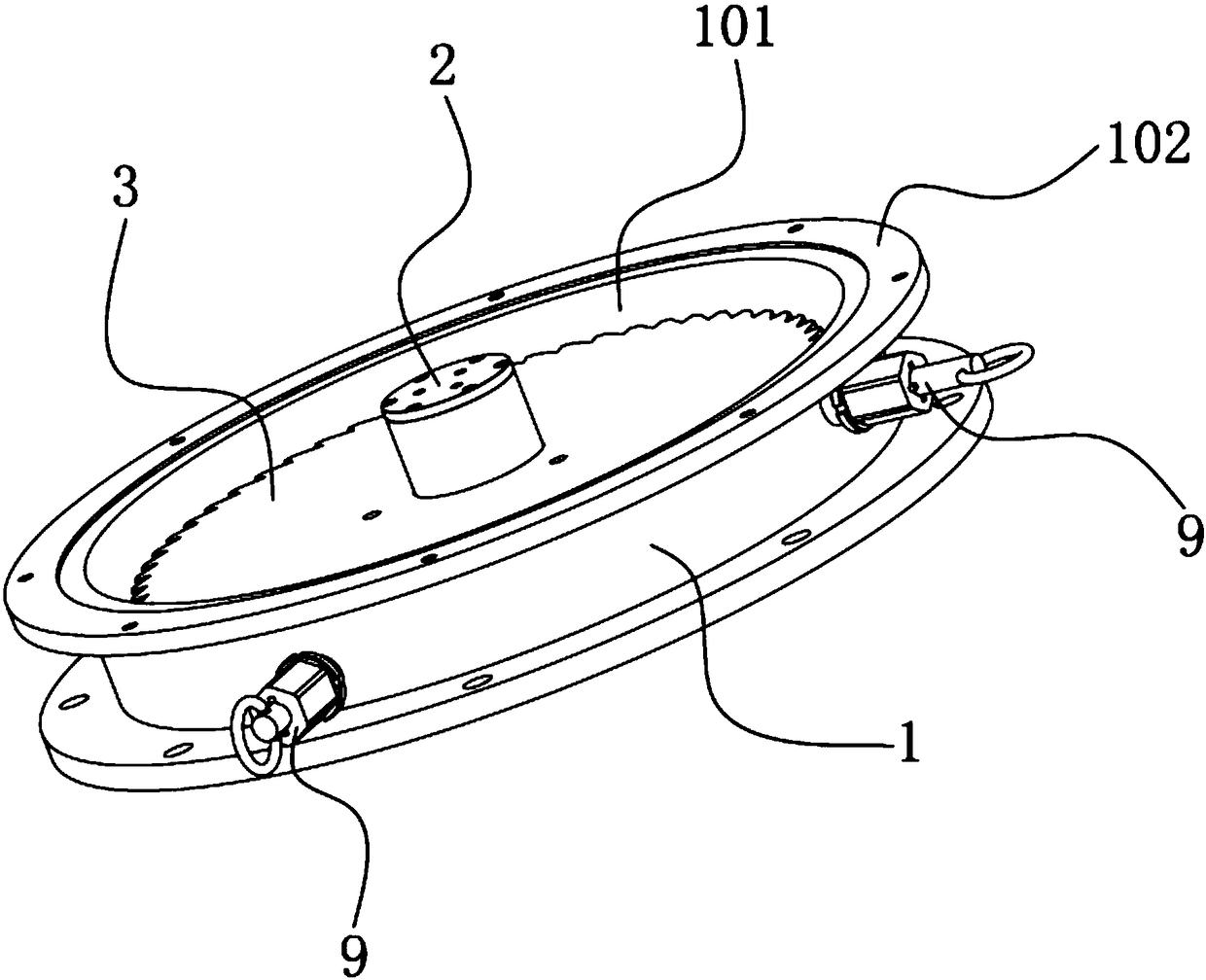

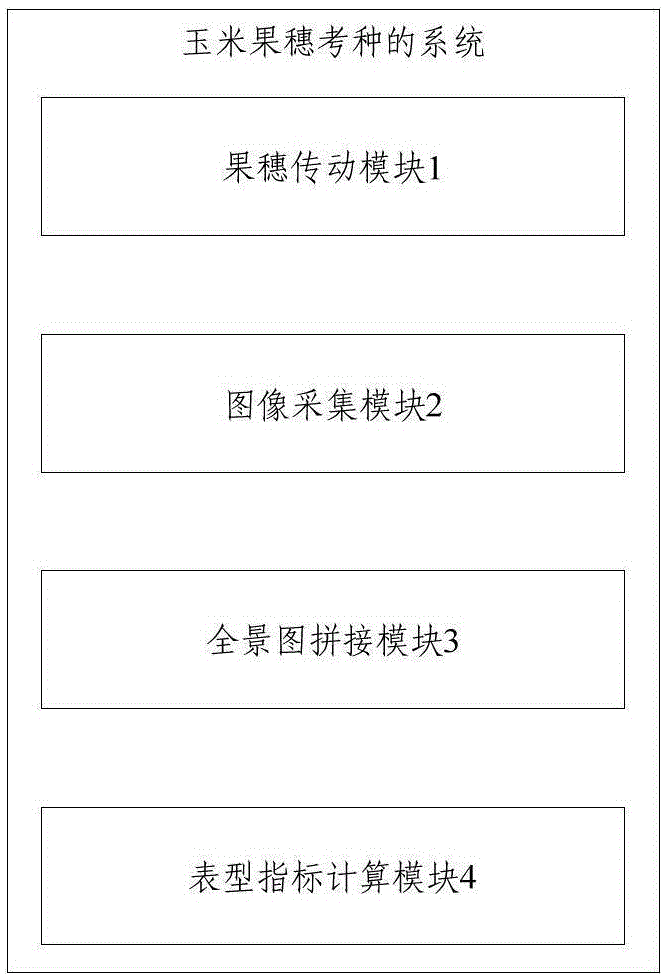

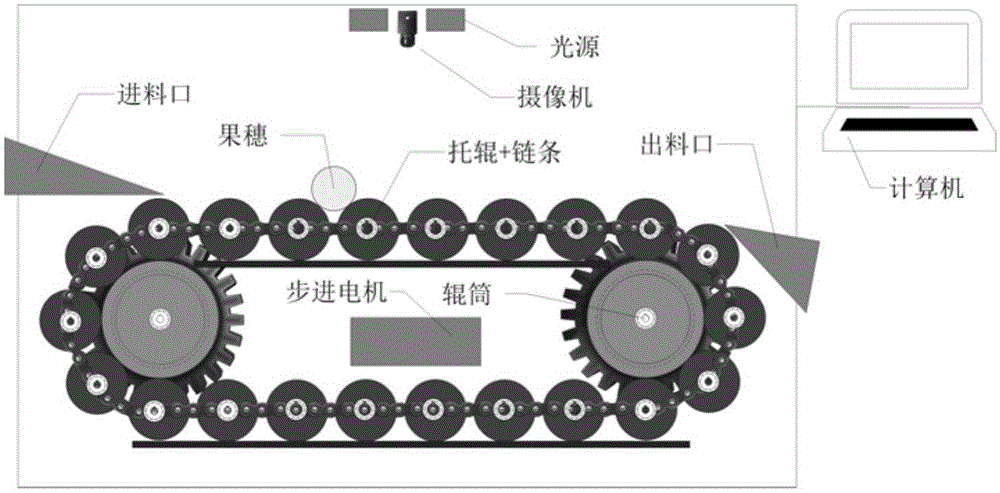

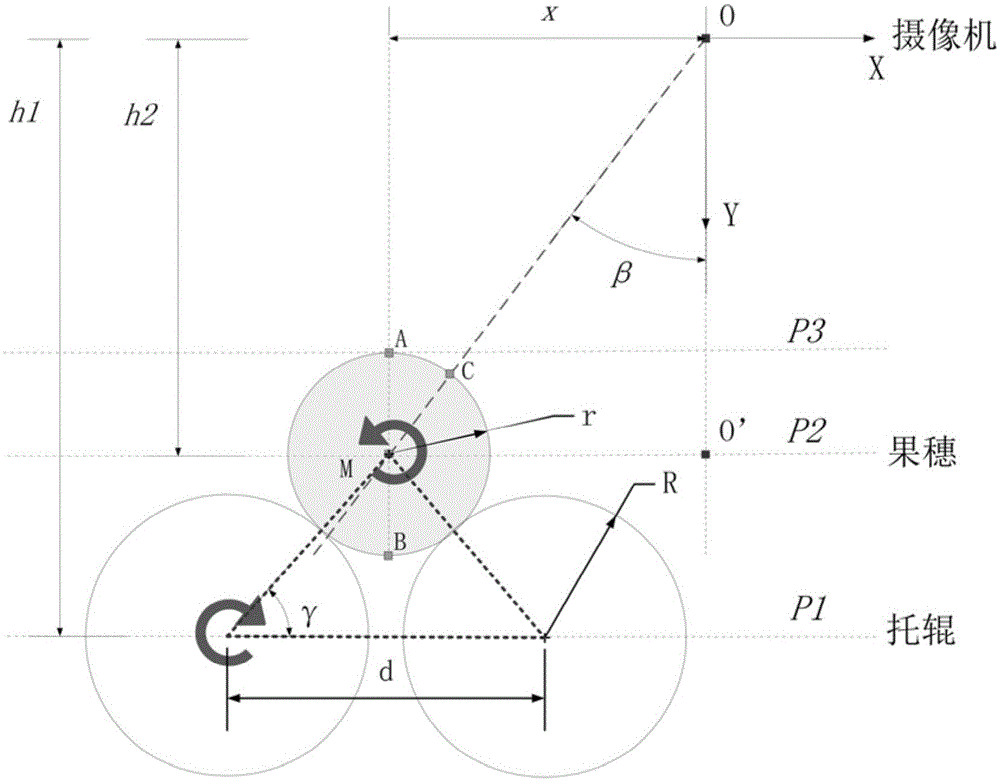

Method and system for corn ear seed test

ActiveCN105027732AImprove test efficiencyGuaranteed accuracySeed and root treatmentGrain distributionComputer science

The invention discloses a method and system for corn ear seed test. The method and the system can simultaneously meet the requirements of the corn ear seed test on high accuracy and high efficiency. The method comprises the steps: acquiring images of different side faces of corn ears by using an ear transmission device and a camera, so as to obtain image sequences of the corn ears; splicing the image sequences of the corn ears to form surface panoramas of the corn ears; and determining effective ear grain distribution graphs in the surface panoramas of the corn ears by using an ear grain segmentation and position analysis method, and calculating the phenotypic character index of the corn ears according to the effective ear grain distribution graphs.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

Cam type separated retractable pin mechanism for crane

The present invention discloses a cam-type split telescopic pin mechanism for crane. It includes upper cover plate, slide plate, main body upper portion, telescopic pin, main body lower portion, reset spring, lower cover plate and connecting board. The main body upper portion and main body lower portion are connected to form telescopic pin mechanism main body. The main body upper portion and main body lower portion are positioned between upper cover plate and lower cover plate, the telescopic pin and the slide plate connected with one-way action cylinder by means of connecting board are mounted between the main body upper portion and main body lower portion, the pin shaft extended from two sides of the telescopic pin are respectively slide-set in the central cam groove of slide plate and curved groove cut on the telescopic pin mechanism self-body, the tail end of said telescopic pin is connected with a reset spring.

Owner:ZOOMLION HEAVY IND CO LTD

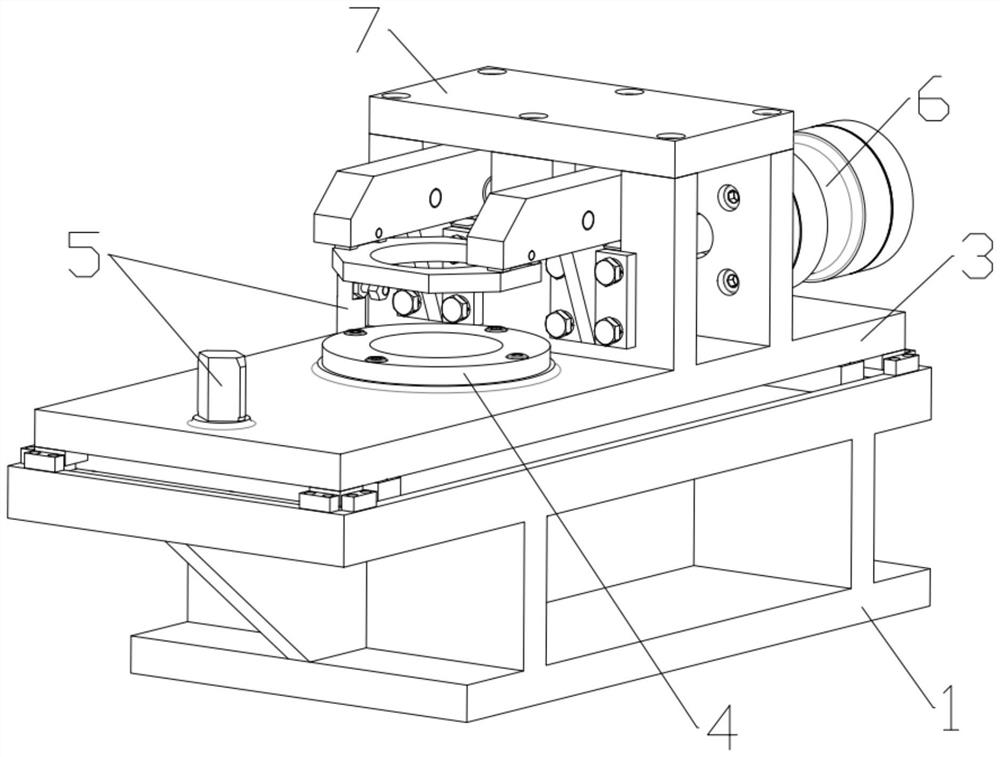

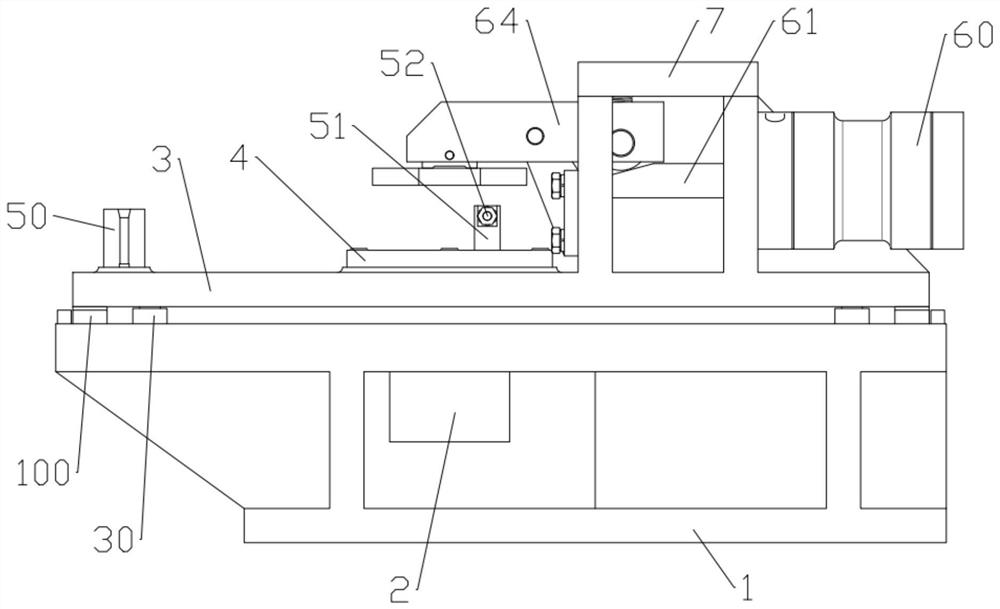

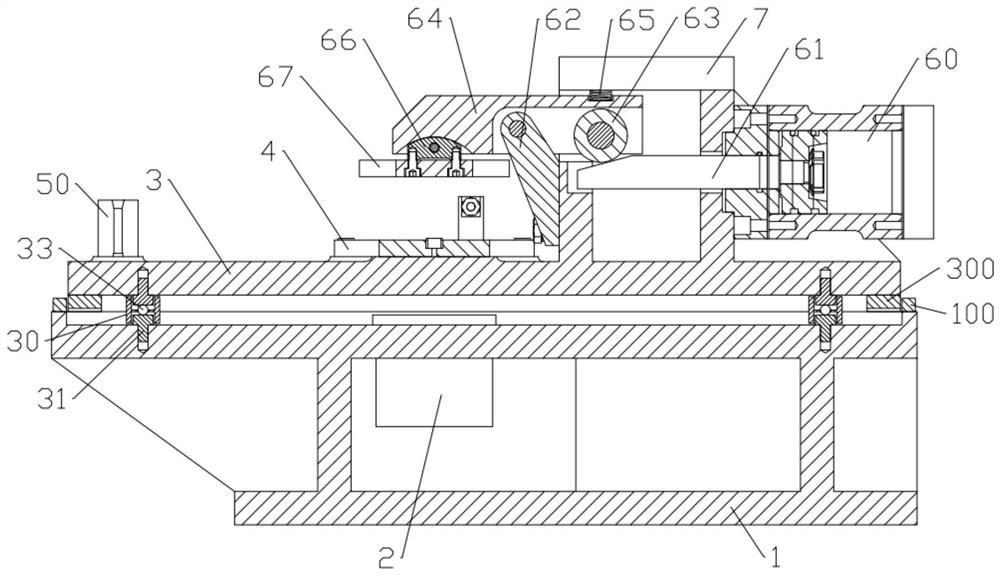

Floating clamp for honing connecting rod big end hole

ActiveCN112775831AGuaranteed sizeGuaranteed cylindricityGrinding drivesHoning machinesStructural engineeringMechanical engineering

The invention discloses a floating clamp for honing a connecting rod big end hole. The floating clamp comprises a base, a fixed guide sleeve, a floating plate, an end face positioning sleeve, a positioning device, a pneumatic clamping mechanism and a square cover plate. The fixed guide sleeve is of a central through hole structure and penetrates through the upper part of the base. The floating plate is connected to the upper portion of the base in a floating mode, and the floating plate can automatically adjust the center of the big end hole when the big end holeis honed. The end face positioning sleeve is of a central through hole structure and penetrates through the middle of the floating plate, the end face positioning sleeve and the fixed guide sleeve are coaxial, and the end face positioning sleeve is used for positioning the lower end face of a workpiece. The positioning device is arranged on the floating plate and is used for positioning a workpiece. The pneumatic clamping mechanism is arranged at the upper part of the floating plate and is used for clamping the workpiece. And the square cover plate is fixedly connected to the top of the floating plate. According to the clamp, shape errors during honing of the big end hole can be reduced, the size and cylindricity of the big end hole and the perpendicularity of the two end faces to the center line of the big end hole are well guaranteed, and abrasion of a connecting rod during working is relieved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

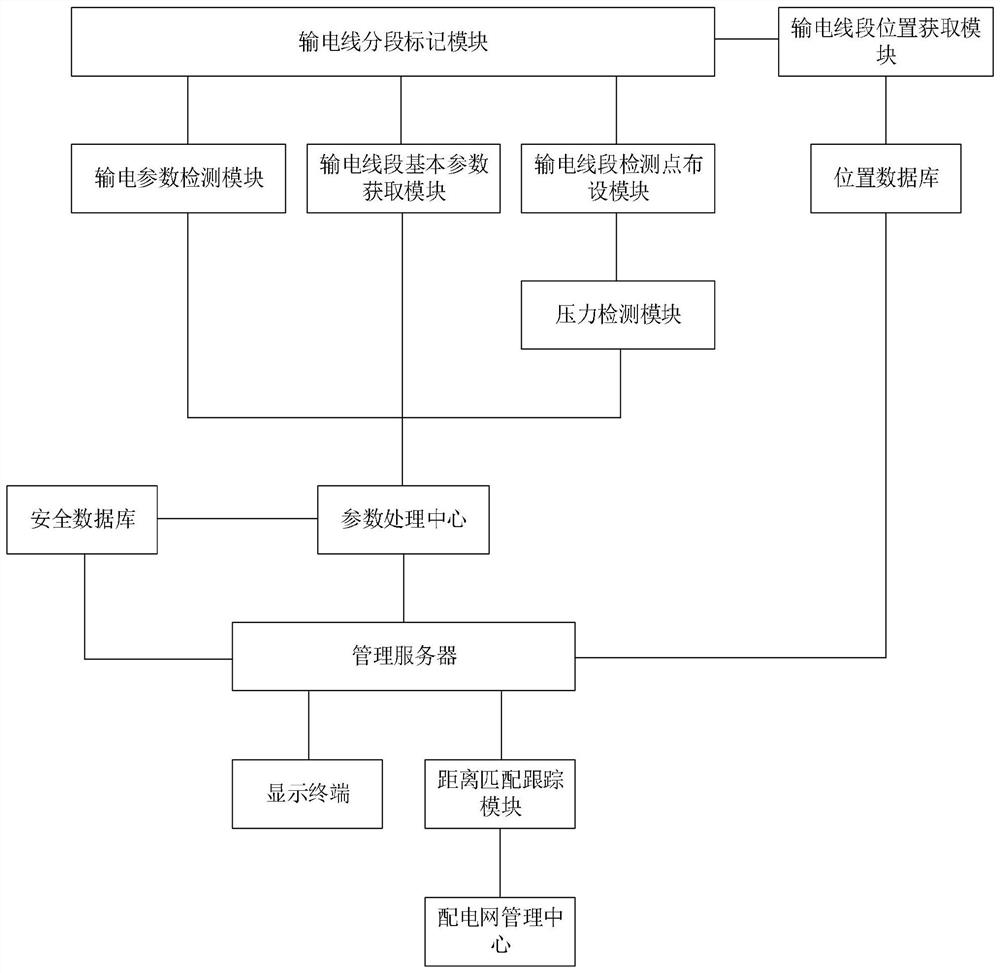

Intelligent power distribution network safe operation management system based on big data feature recognition

InactiveCN112633819AImprove the level of safe operationReduce safety concernsCircuit arrangementsOffice automationEngineeringServer

The invention discloses an intelligent power distribution network safe operation management system based on big data feature recognition. The system comprises a power transmission line segment marking module, a power transmission line segment basic parameter acquisition module, a power transmission line segment position acquisition module, a power transmission line segment detection point arrangement module, a safety database, a pressure detection module, a power transmission parameter detection module, a parameter processing center, a management server, a distance matching tracking module, a display terminal and a power distribution network management center. The whole power transmission line is divided into a plurality of power transmission line segments, and the external pressure danger coefficient and the power transmission danger coefficient of each power transmission line segment are counted, so the comprehensive operation danger coefficient of each power transmission line segment is obtained, and the power transmission line segments in a dangerous state are counted according to the comprehensive operation danger coefficient of each power transmission line segment; therefore, targeted processing is carried out, the safe operation level and management efficiency of the power distribution network are improved, and the personal safety of people around the power distribution network is guaranteed.

Owner:南京鼓佳玺电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com