Austenite heat-resistant valve steel and manufacturing method thereof

A manufacturing method and technology of valve steel, which is applied in the field of austenitic heat-resistant valve steel and its manufacture, can solve the problems of easy corner cracking, poor performance, surface cracking and other problems of steel, and achieve the effect of improving efficiency and power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

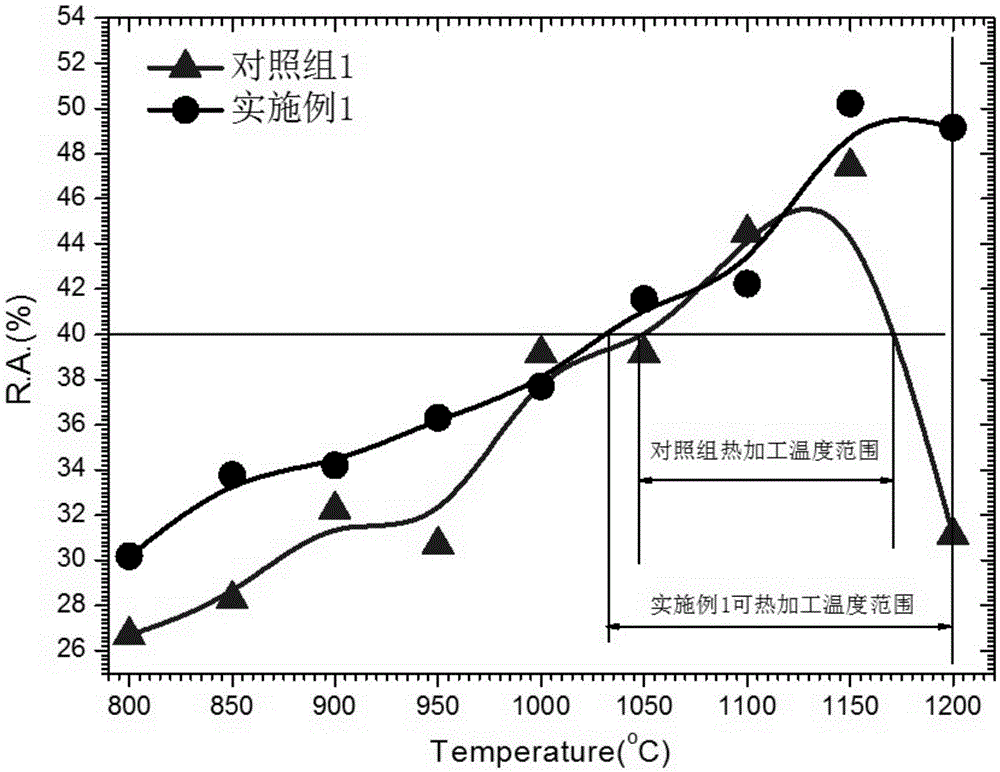

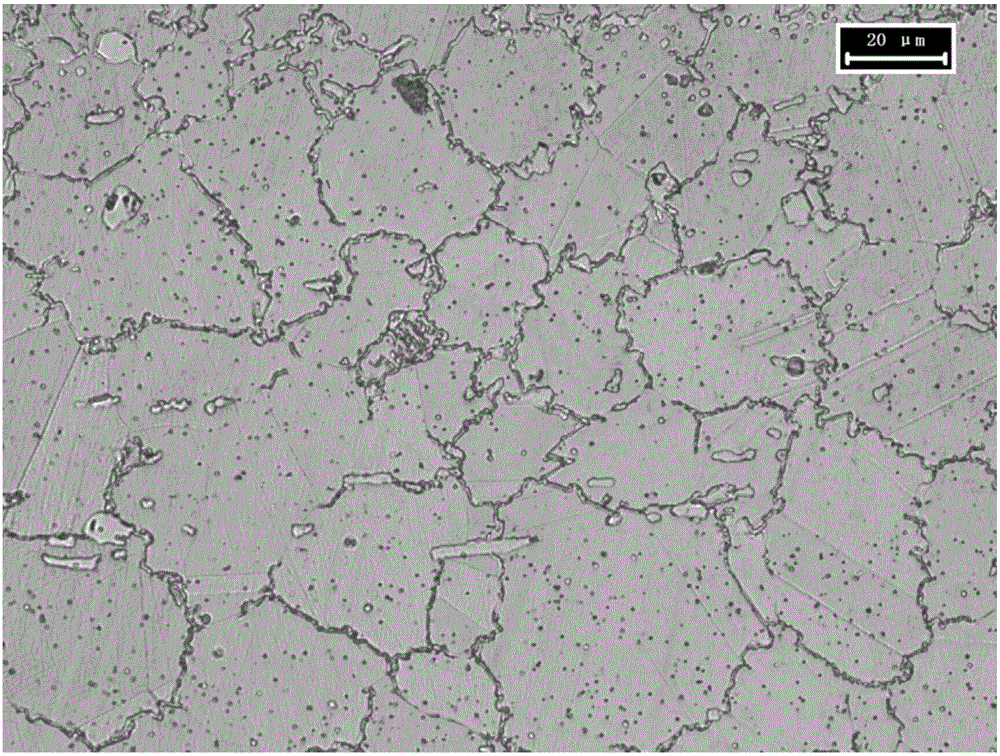

[0027] In order to solve the problems of cracks, skins and folds that are easy to occur in the process of producing bars (diameter greater than 14mm) or wires (diameters between 5.5-14mm) from 21-4NWNb steel large ingots, improve the difficulty of straightening and increase the finished product The present invention proposes to add alloy elements to improve high temperature thermoplasticity on the basis of the composition of 21-4NWNb steel, and select reasonable production process parameters based on the results of thermal simulation tensile tests. The main content and technical features of the present invention are as follows:

[0028] The chemical composition (mass percentage) is:

[0029] C 0.45-0.55%, Si 0.08-0.45%, Mn 8.00-10.00%, Cr 20.00-22.00%, Ni 3.50-5.00%, Cu≤0.30%, W 0.80-1.50%, N 0.45-0.55%, Nb1.80 -2.50%, Al≤0.02%, Mg≤0.010%, Ca 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com