Magnetic field oriented flaky soft magnetic composite material and preparation method thereof

A kind of soft magnetic composite material and flake technology, which is applied in the direction of inorganic material magnetism, can solve the problems of low and unsatisfactory magnetic permeability, and achieve the effect of improving magnetic permeability and meeting miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

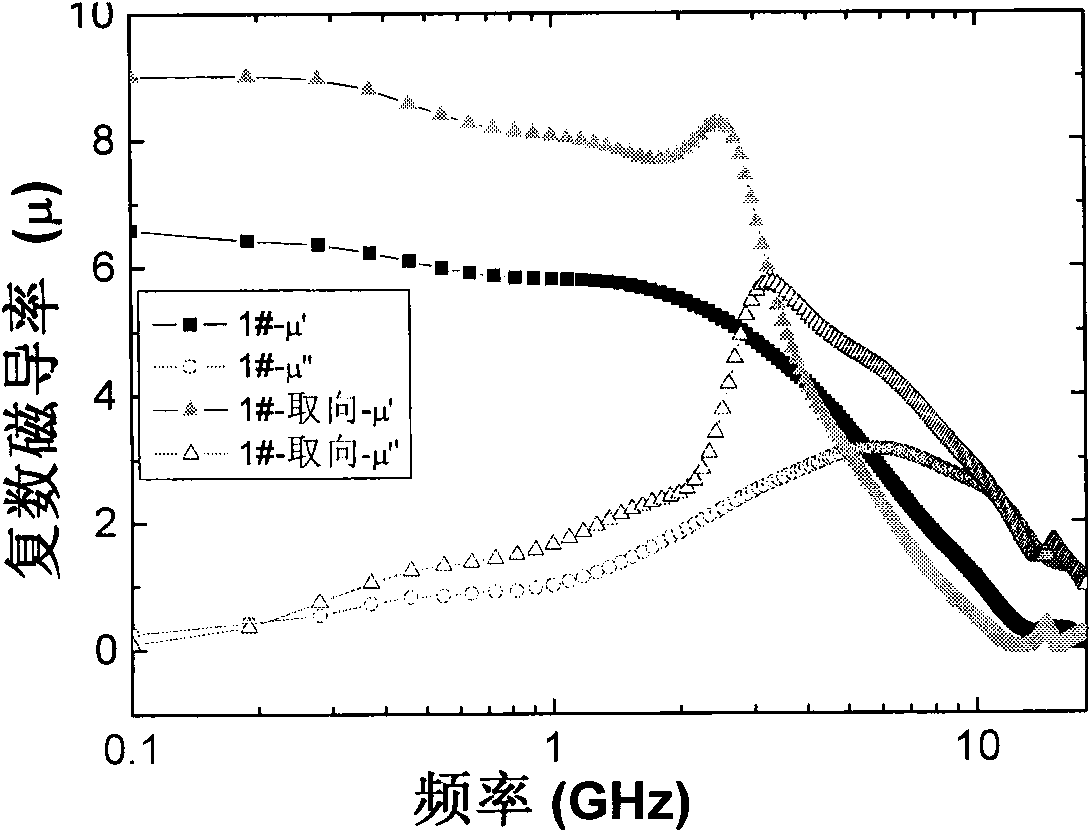

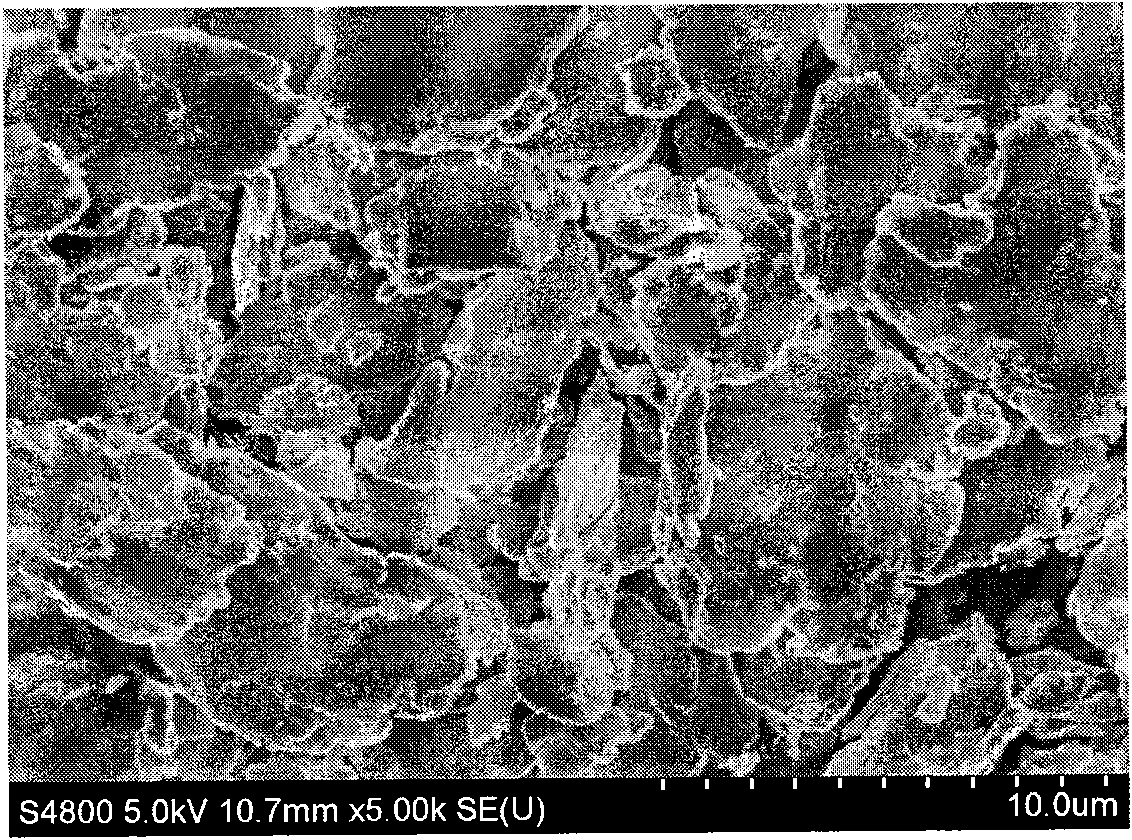

[0019] Spherical carbonyl iron samples with an average particle size of 3 to 4 microns were wet-milled by adding 50ml of n-hexane into a planetary ball mill, the ball-to-material ratio was 25:1, the ball-milling speed was 300r / min, and the ball-milling time was set to 8 hours. After ball-milling, the sample The thickness of the sample is about 0.2 microns, and the aspect ratio is 50. After ball milling for 8 hours, the sample is dried in a vacuum oven (25° C.) for later use. See the appendix for the morphology of the samples obtained by grinding image 3 , From the scanning electron microscope photos, it can be seen that the metal particles are irregular flakes.

[0020] Weigh a certain amount of flake-shaped particles obtained through the aforementioned treatment, add it into the titanate coupling agent diluted with isopropanol at a mass ratio of 100:1, and perform ultrasonic treatment in an ultrasonic cell pulverizer for 30 minutes, with an ultrasonic power of 180W, so that...

Embodiment 2

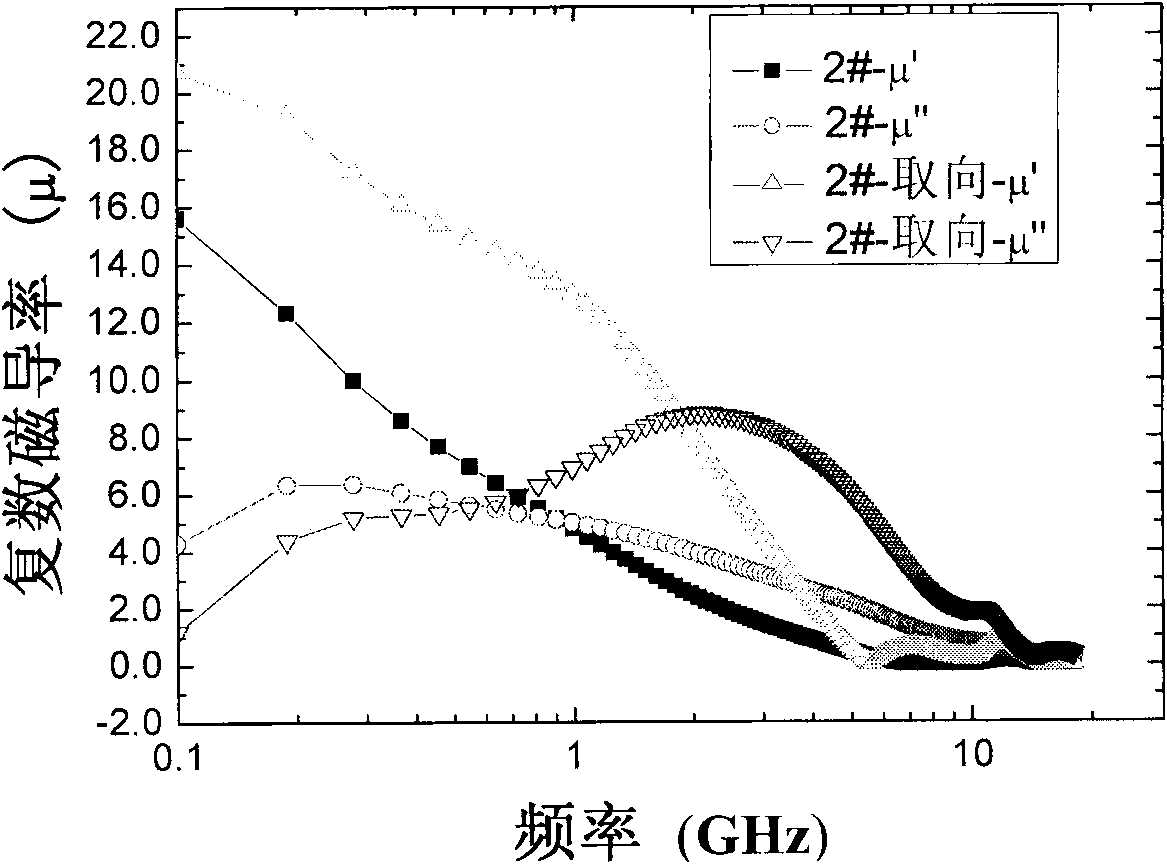

[0023] Fe with a particle size of about 10 microns 50 Ni 50 The alloy is milled with a planetary ball mill, using a 100ml stainless steel tank, adding about 50ml of n-hexane, the ball-to-material ratio is 25:1, the revolution speed is 280r / min, the ball milling time is 16 hours, and the sample is about 0.5 microns thick after ball milling. The aspect ratio is 100, and the sample morphology is shown in the attached Figure 4 . Depend on Figure 4 It can be seen that the metal particles after grinding are in the form of irregular flakes.

[0024] Weigh a certain amount of metal flake particles after the aforementioned ball milling treatment, add them into titanate coupling agent diluted with isopropanol at a mass ratio of 100:1, and sonicate in an ultrasonic cell pulverizer for 30 minutes with an ultrasonic power of 180W , so that the titanate coupling agent is fully adsorbed on the metal powder. The ultrasonic sample and paraffin are mixed evenly at a volume concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com