Patents

Literature

54results about How to "Meet the integration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

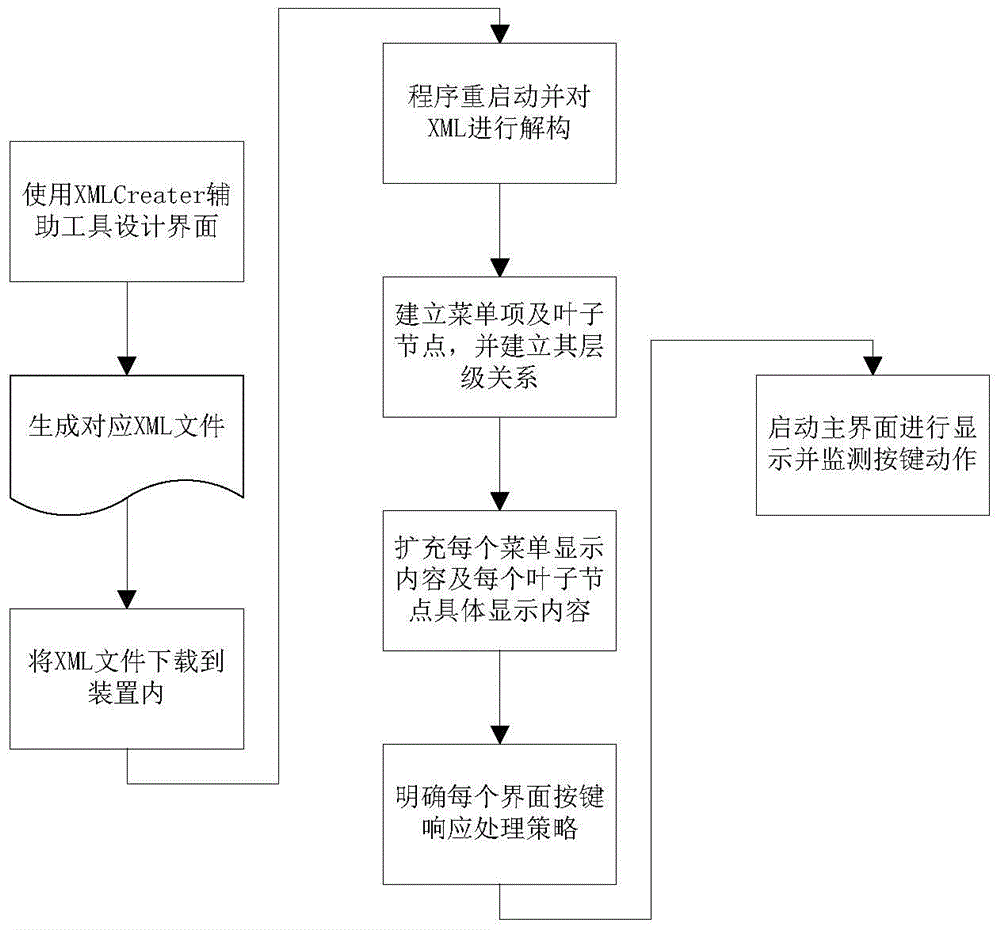

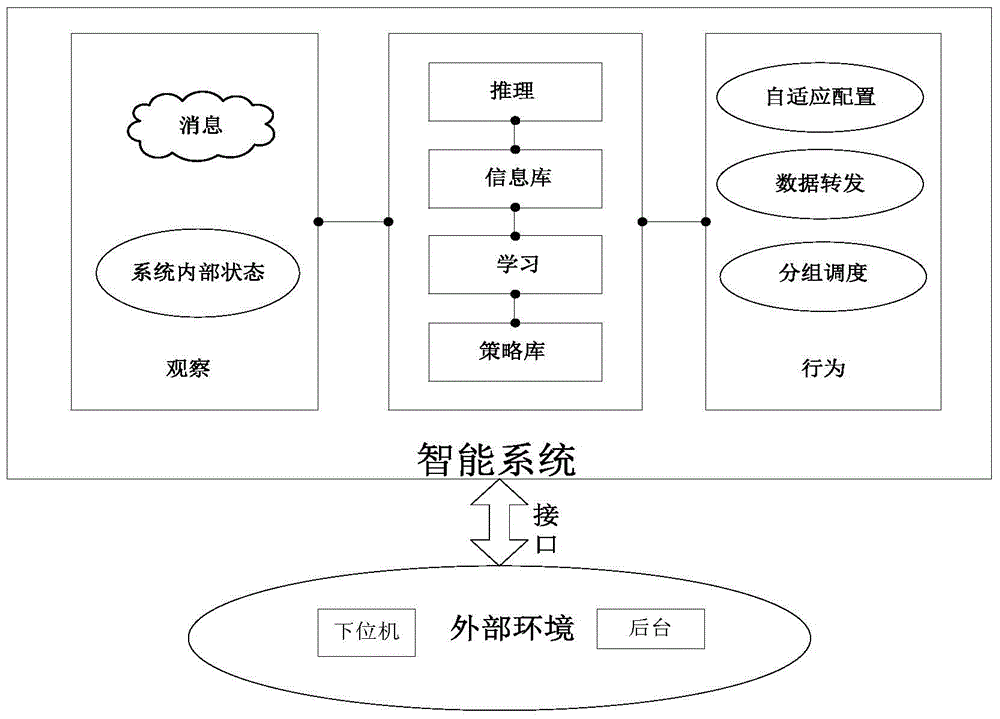

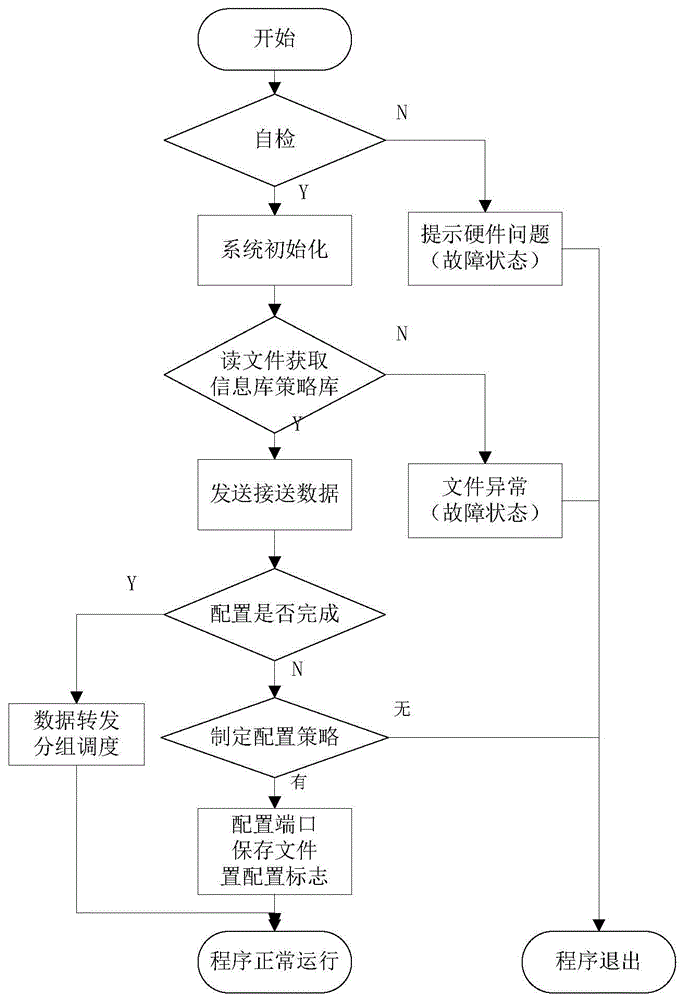

Intelligent auxiliary monitoring system and method for substation

ActiveCN104617665ACentralized collectionRealize centralized collectionCircuit arrangementsHuman–machine interfaceIntegrated monitoring

The invention discloses an intelligent auxiliary monitoring system and method for a substation. The system comprises an adaptive communication module, an intelligent electronic device (IED) model automatic configuration module, a version automatic matching module and an XML based interface configuration module. The adaptive communication module is used for achieving adaptive communication between a comprehensive monitoring host and various sub-monitoring systems. The IED model automatic configuration module is used for generating IED performance description files rapidly after the system configuration is changed. The version automatic matching module is used for achieving automatic matching of an integrated power supply system and the comprehensive monitoring host software version. The XML based interface configuration module is used for enabling XML files to perform description modeling on the whole character lattice LCD human-computer interface to generate an interface according to the model files. By the aid of the system and the method, high multi-system fusion is performed on technologies of IED model automatic configuration, version automatic matching, adaptive communication, interface configuration and the like, and a uniform novel intelligent auxiliary monitoring system platform which is intelligent and efficient and adaptive to substation development requirements is built.

Owner:SHANDONG LUNENG SOFTWARE TECH

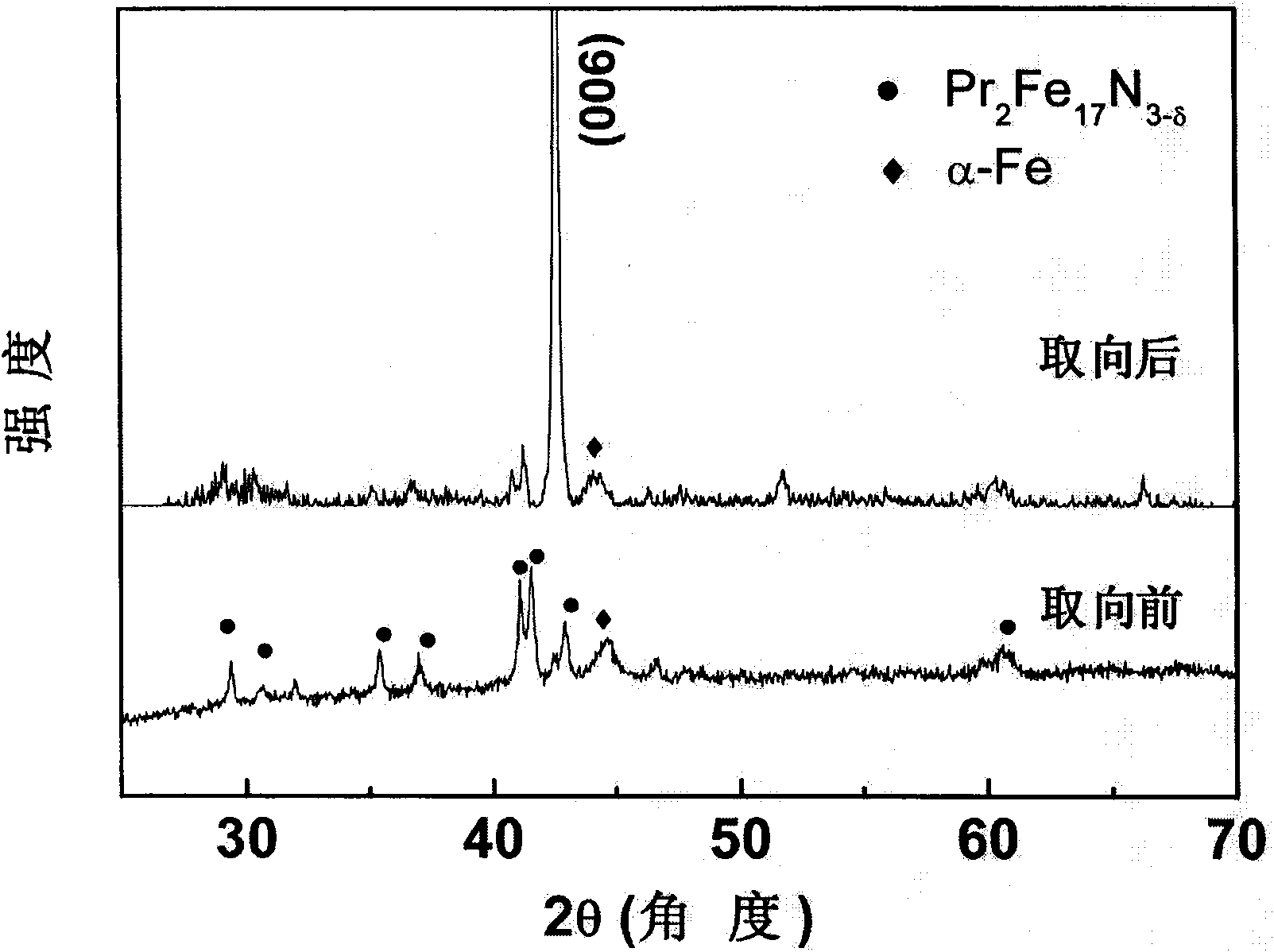

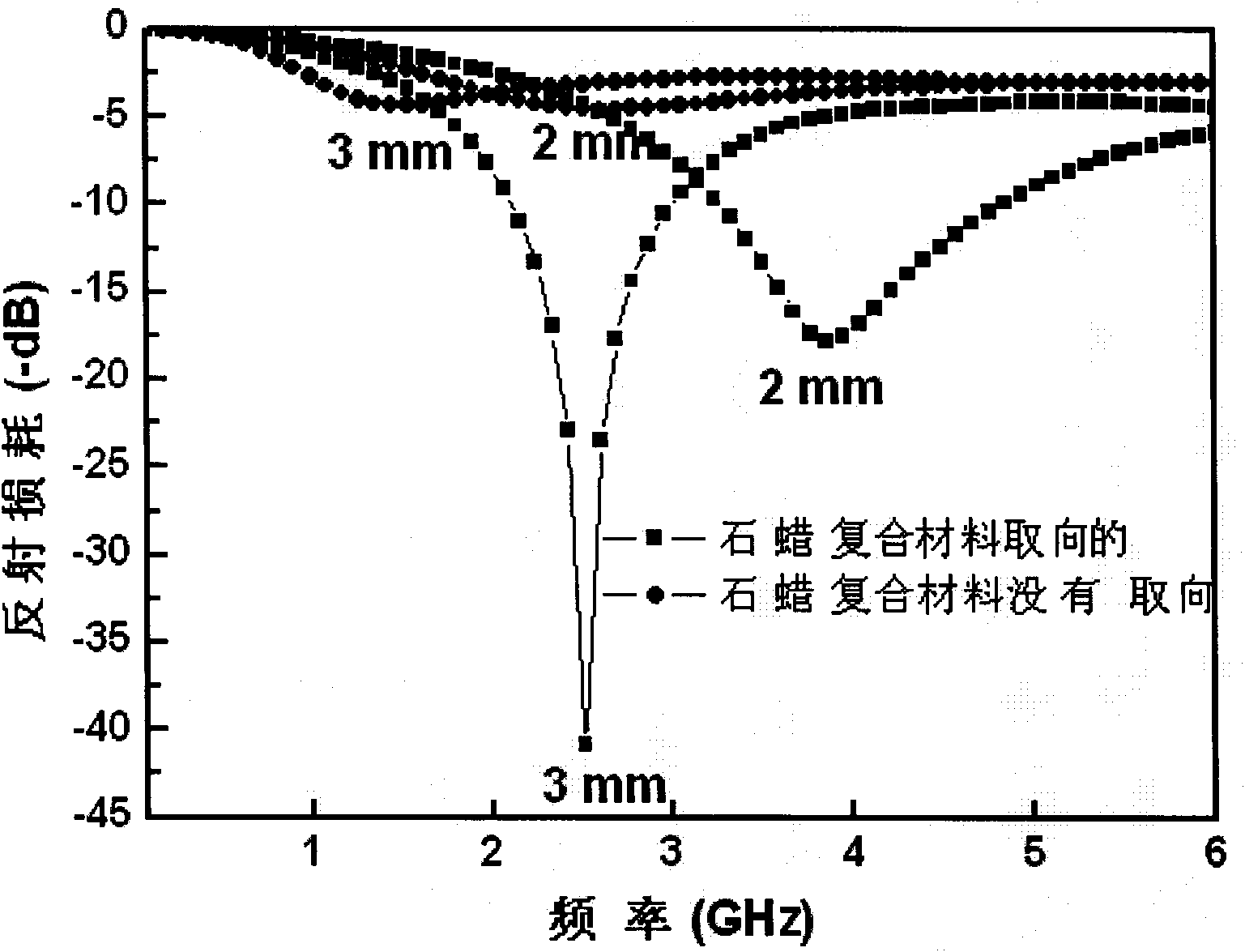

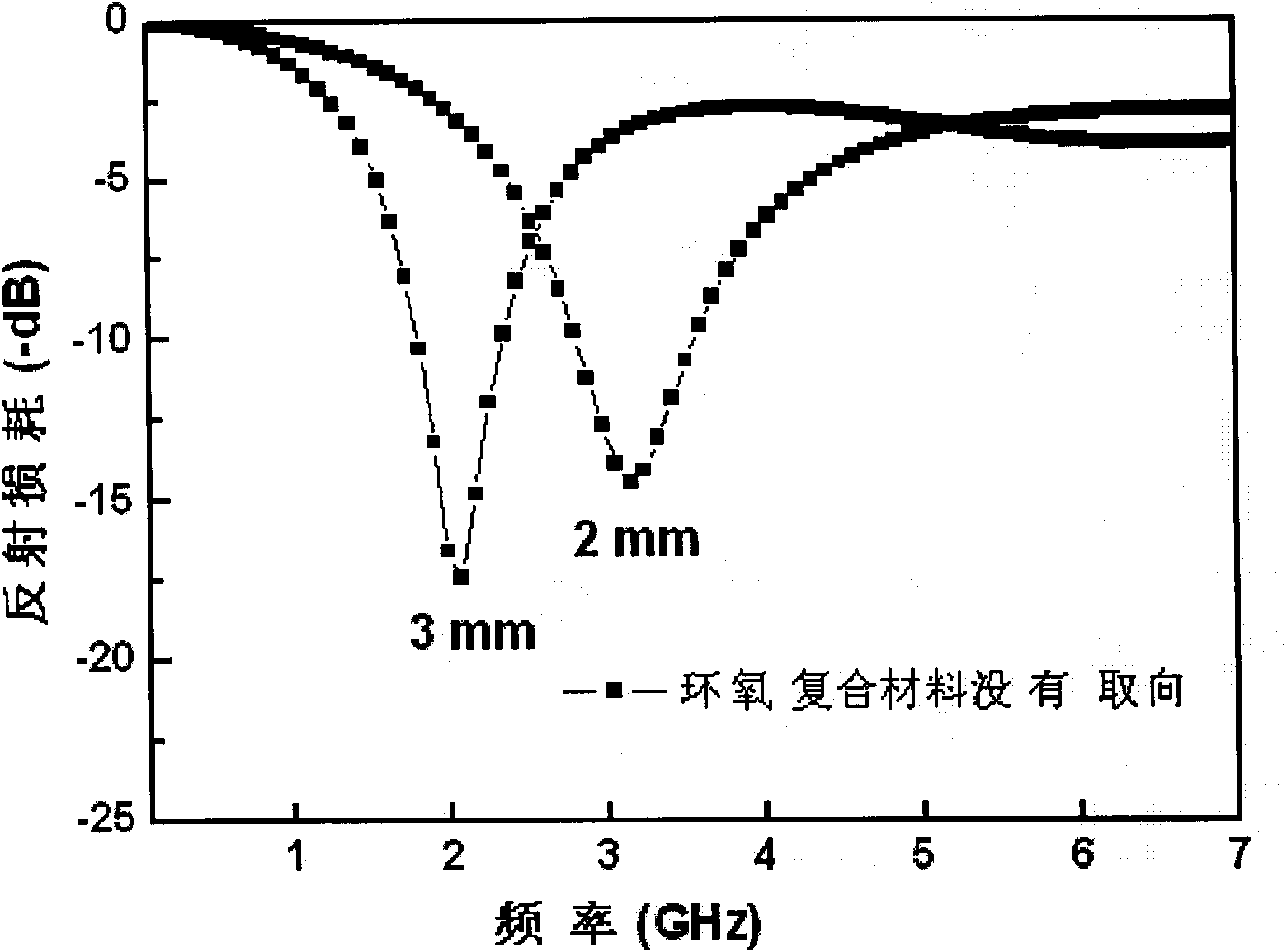

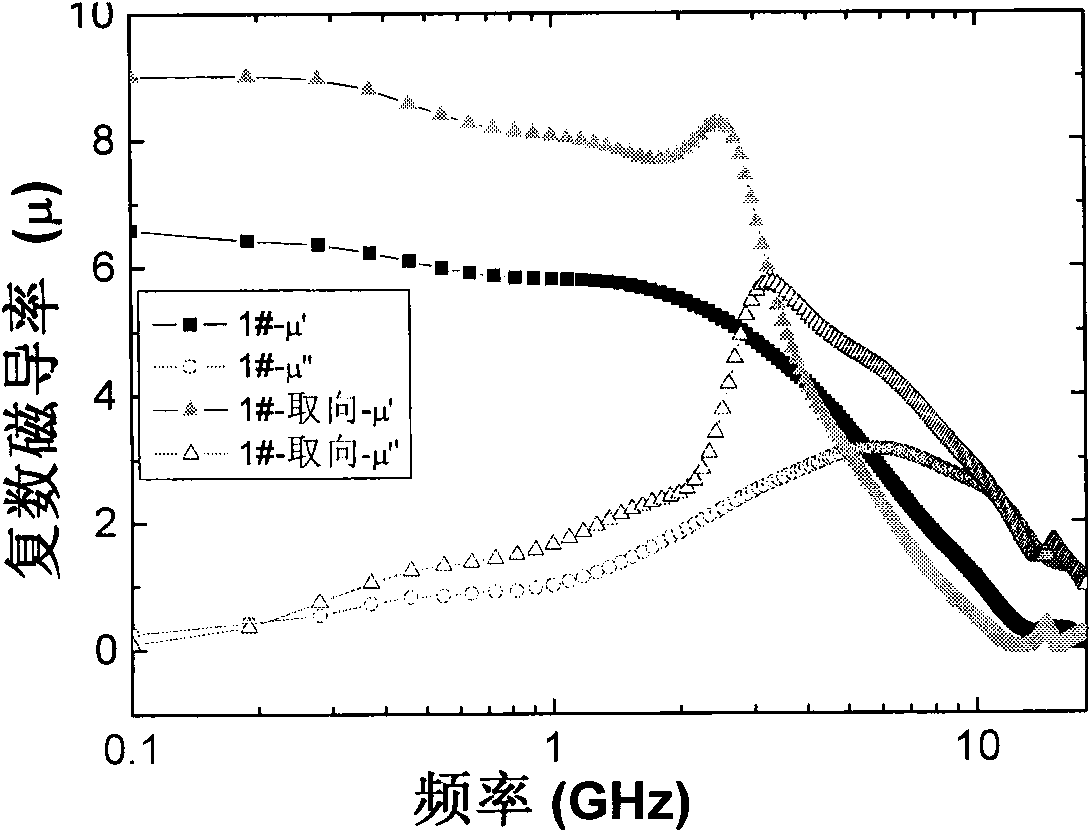

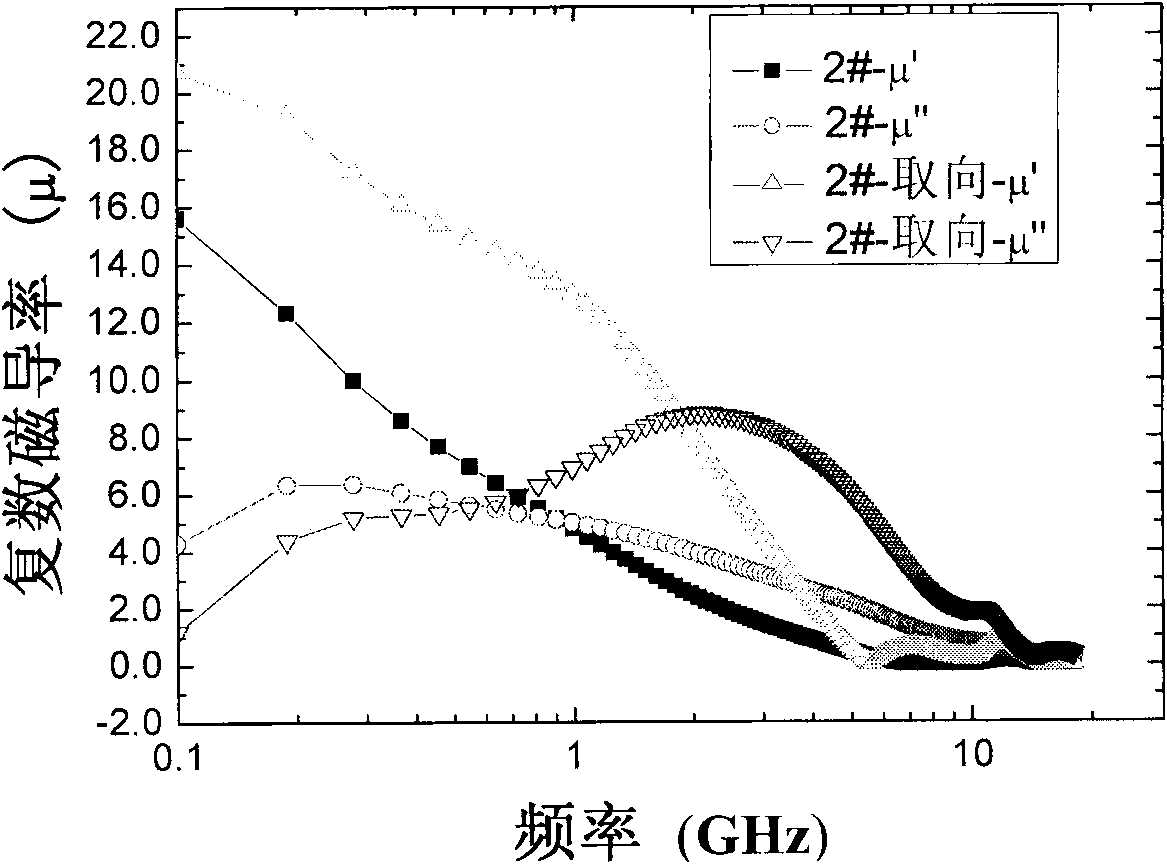

Electromagnetic wave absorbing material

InactiveCN101886214AMatching thickness thinMeet miniaturizationMagnetic/electric field screeningInorganic material magnetismRare-earth elementMagnetization

The invention discloses a material which comprises rare earth elements and iron nitrogen according to a phase ratio of 2:17 and has high capability of absorbing high-frequency electromagnetic radiation from 1G to 100G and an electromagnetic wave absorbing composite material which is made of the material and has better wave absorbing properties. The general formula of the electromagnetic wave absorbing material is R2Fe17N3-delta, and the preferred magnetization direction of the material meeting the general formula needs to be perpendicular to the C axis. In the general formula, R is one or a combination of any two of Y, Ce, Nd, Pr, Gd, Tb, Dy, Ho, Er, Tm and Lu. The method for preparing the electromagnetic wave absorbing material comprises the following steps of: adding the materials in an uncured binding material, thoroughly and uniformly mixing, then putting into a mold made of non-magnetic materials, and finally placing the mold in a magnetic field for orientation treatment.

Owner:LANZHOU UNIVERSITY

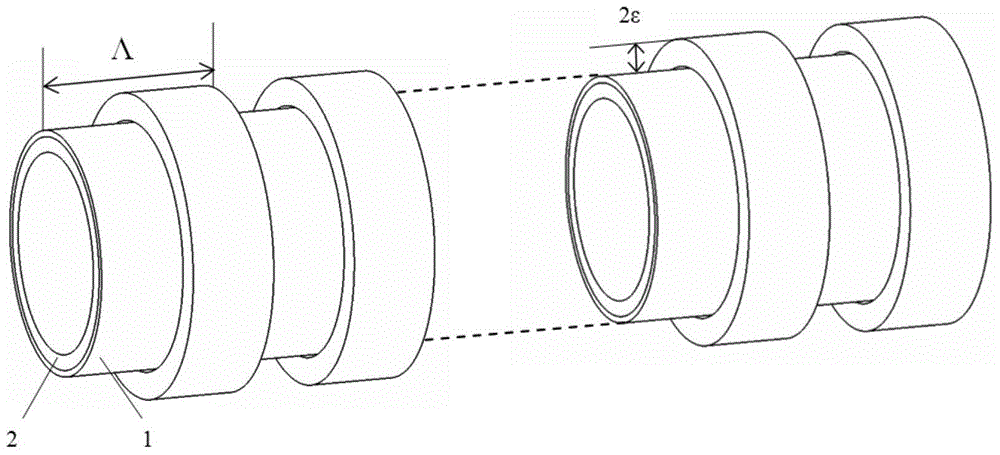

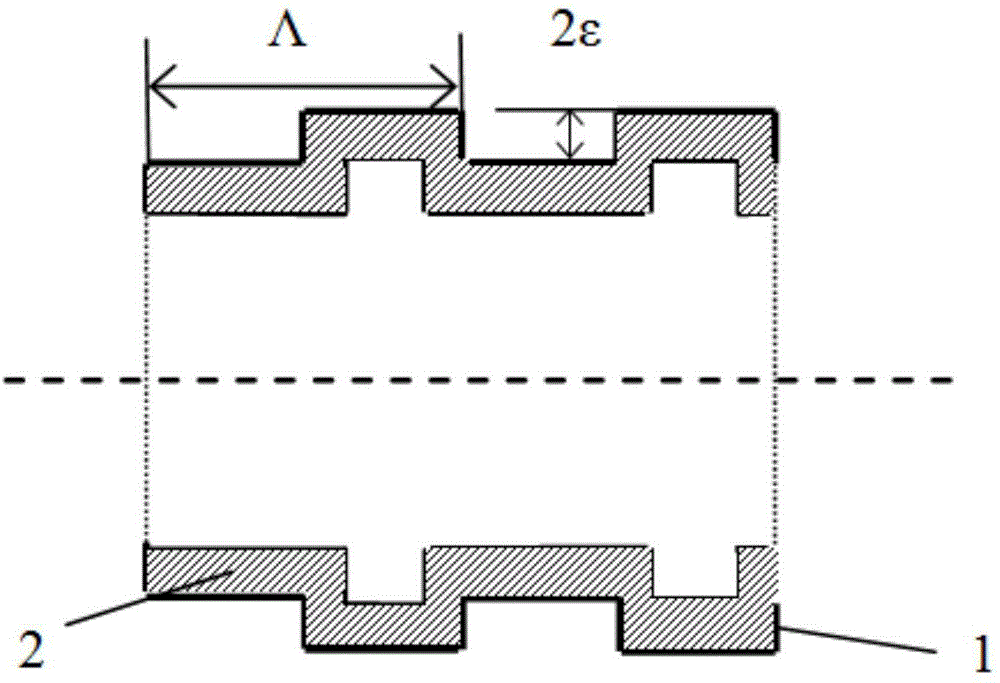

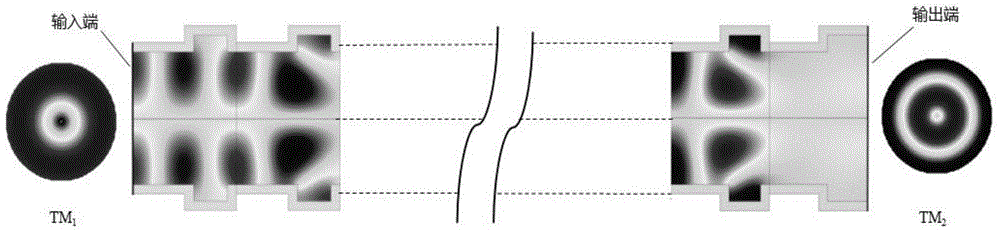

Terahertz wave tunable mode converter

ActiveCN104914503AAvoid lossMeet miniaturizationOptical waveguide light guideWaveguide type devicesMetal coatingResonance

The invention provides a terahertz wave tunable mode converter, which comprises a hollow cylindrical metal inner-wall waveguide formed by rectangular periodically fluctuating structures. According to the invention, resonance interaction among different transverse standing wave modes in the waveguide is utilized to realize conversion of terahertz waves from a fundamental mode to a single high-order mode. Furthermore, tuning for output frequency of the terahertz wave mode converter can be realized through changing the thickness of a metal coating in the rectangular periodically fluctuating pipe wall, and the tunable mode converter can realize that the output center frequency is linearly tunable in broadband. The terahertz wave tunable mode converter is reasonable in design, has the characteristics of simple structure, wide tunable range, low loss, high conversion efficiency, convenient integration and the like, can acquire wide applications in fields which have special requirements for terahertz wave mode field distribution and the operating frequency, and provides a new choice for designing and manufacturing functional devices in a terahertz wave application system.

Owner:HARBIN ENG UNIV

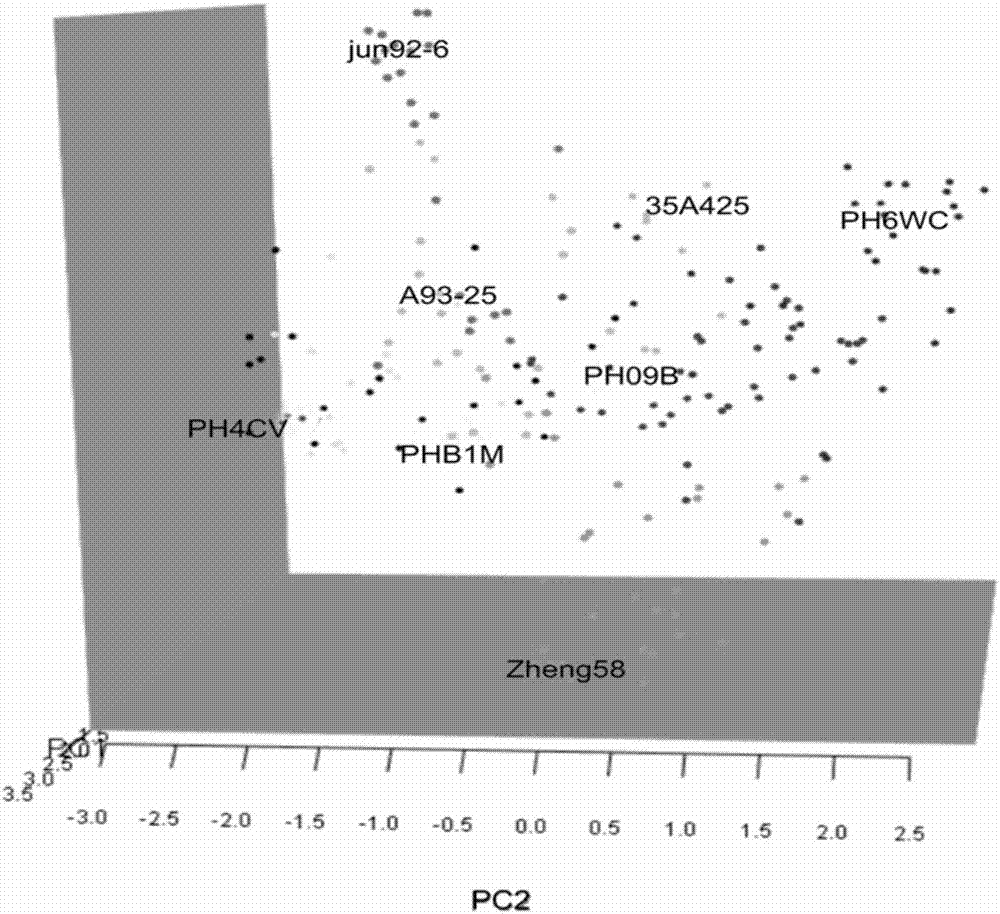

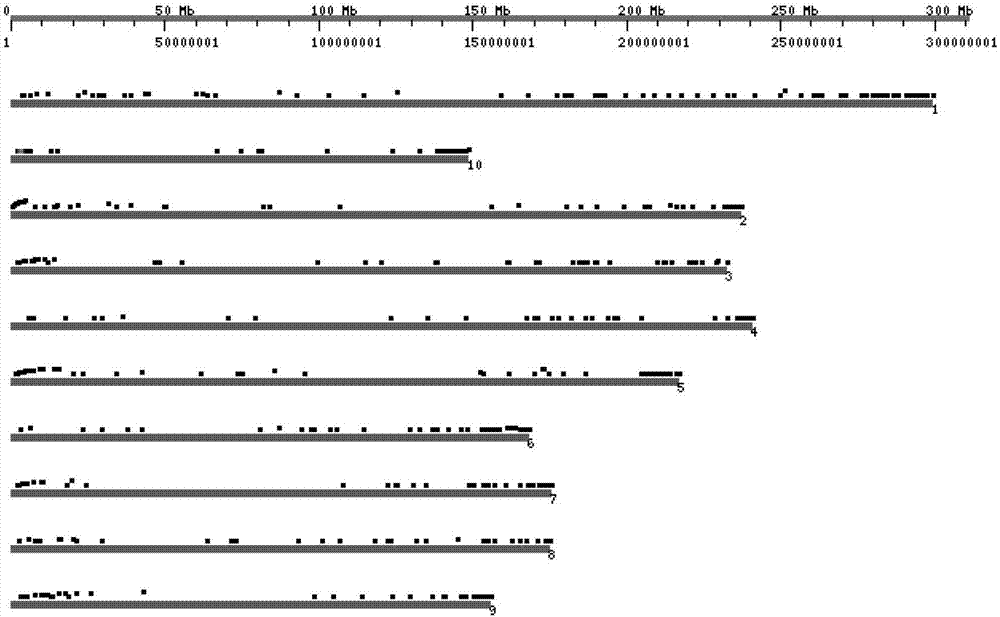

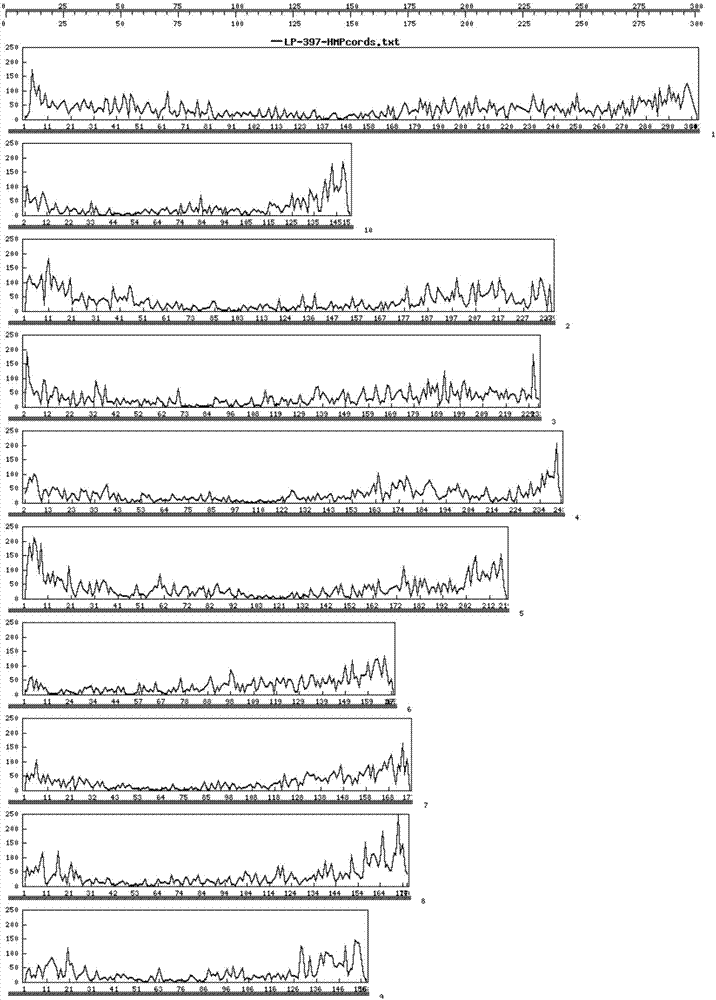

SNP molecular marker combination for maize genotyping and application thereof

ActiveCN107090504ATyping data is accurate and reliableGood genetic stabilityMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceNucleotide

The invention provides an SNP molecular marker combination for maize genotyping. The SNP molecular marker combination comprises 448 SNP markers, wherein the numbers of the SNP markers are ZmSNP001-ZmSNP448, and nucleotide sequences thereof are as shown in SEQ ID NO:1-448 separately. Molecular marker fingerprint analysis of maize variety resources, genotype identification of offspring of hybrid population, variety authentication, analysis and screening of genetic backgrounds of breeding materials, and correlation analysis of agronomic characters can be carried out by using the SNP molecular marker combination, and the SNP molecular marker combination has wide application prospects.

Owner:YUAN LONGPING HIGH TECH AGRI CO LTD +1

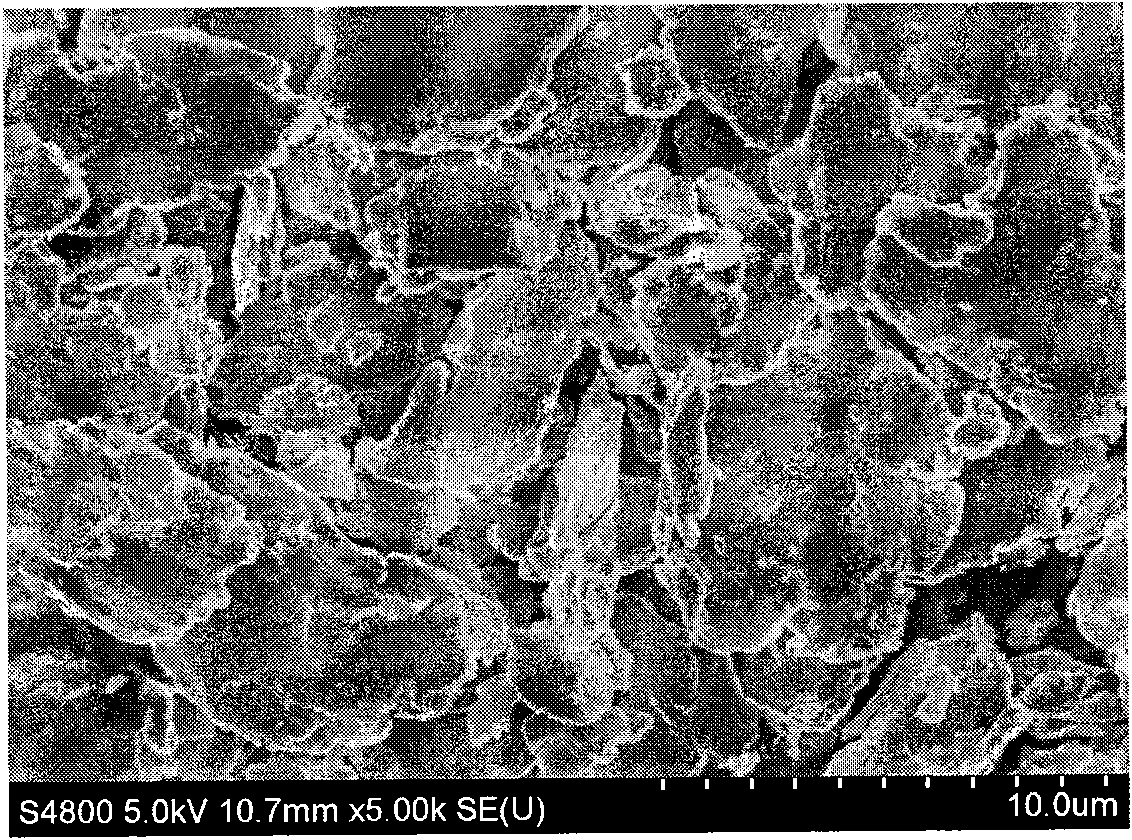

Magnetic field oriented flaky soft magnetic composite material and preparation method thereof

InactiveCN101604568AGood effectImprove permeabilityInorganic material magnetismMetal powderMaterials science

The invention relates to a material compounded by a magnetic material and a binding material and a preparation method thereof, wherein the magnetic material is flaky and has orientation property. The material is prepared by the following method: firstly, evenly mixing flaky soft magnetic metal powder with the uncured binding material with volume ratio of 1-9:9-1; secondly, putting the evenly-mixed compound into a mould made of a nonconductive magnetic material; and finally, placing the mould in a magnetic field with 10 to 10 Tesla, making the mould rotate in the magnetic field at a rotational speed of between 1 to 20 revolutions / minute for more than 1 minute, and curing the binding material.

Owner:LANZHOU UNIVERSITY

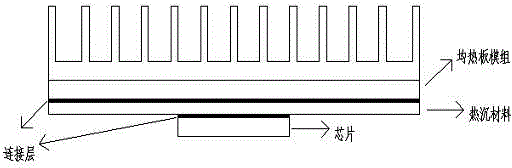

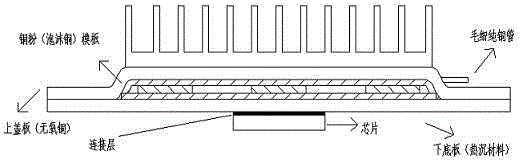

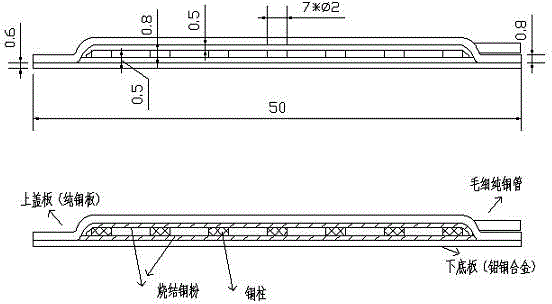

Manufacturing method of composite vapor chamber with base plate made of molybdenum-copper or tungsten-copper alloy and other heat sink materials

InactiveCN105202956ASuitable for heat sink applicationsHeat sink application realizationIndirect heat exchangersHeat exchange apparatusThermal dilatationHeat resistance

The invention discloses a manufacturing method of a composite vapor chamber with a base plate made of molybdenum-copper or tungsten-copper alloy and other heat sink materials. The vapor chamber is of a composite structure of heat sink materials and oxygen-free copper. A wick of the vapor chamber is of a copper powder sintered or foamy copper structure. The method comprises the steps that high-temperature reduction treatment is carried out on molded copper powder or foamy copper, the treated copper powder or foamy copper is sintered to a pure-copper upper cover plate and the thin molybdenum-copper or tungsten-copper alloy base plate, a thin copper column or a foamy copper column is used as a supporting column, the oxygen-free copper cover plate and the molybdenum-copper or tungsten-copper alloy base plate are welded through copper-silver alloy, and the needed vapor chamber is manufactured. The vapor chamber is of the composite structure of the oxygen-free copper plate and the base plate made of the high-conductivity low-expansion heat sink materials like molybdenum-copper or tungsten-copper alloy, wherein the molybdenum-copper or tungsten-copper alloy face can directly make tight contact with chips of high-power electric and electronic devices such as a thyristor, an IGBT and an IGCT. It is ensured that the heat expansion coefficients of the chips are matched with those of the heat sink materials in the heated process, the heat sink materials and the vapor chamber are integrated, the heat resistance is greatly reduced, and the requirement for rapid temperature equilibrium and efficient heat dissipation is met.

Owner:JIANGSU GREEN NEW MATERIALS TECH CO LTD

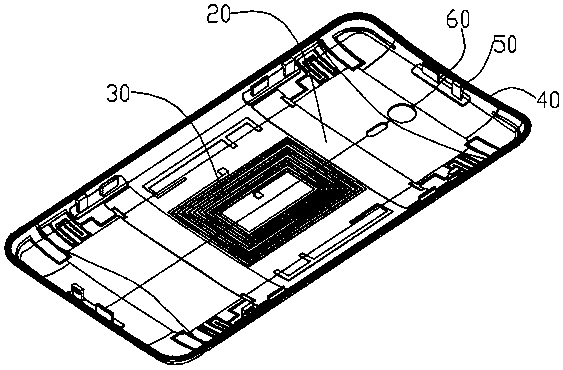

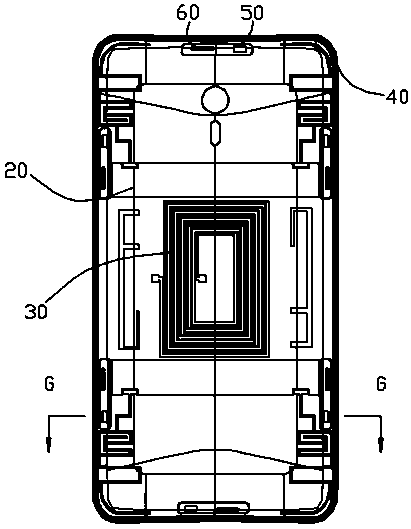

Glass shell structure and preparation method thereof

ActiveCN109291560AMeet the integrationNo distractionSynthetic resin layered productsLiquid/solution decomposition chemical coatingEngineeringPet substrate

The invention discloses a glass casing structure, which comprises a glass shell and a PET composite decorative film attached to the inner surface of the glass shell. The PET composite decorative filmcomprises a PET substrate. The side face of the PET substrate that is attached to the glass shell is a binding surface; and the side face of the PET substrate that is far from the glass shell is a decorative surface. The decorative surface of the PET substrate is successively provided with an ink printing layer, a UV grained layer and an optical coating layer. The optical coating layer of the PETcomposite decorative film is equipped with an LDS antenna. The invention also discloses a manufacturing method of the glass shell structure. By the utilization of the large area of the back glass shell, the antenna can be designed freely. In addition, there is no shell interference or shielding, an excellent antenna effect can be realized, and the requirements of millimeter wave of 5G antenna canbe met. Meanwhile, the glass shell structure has a decorative function, has novel appearance, is light and stylish, can further meet the detachable requirement of personalized customization, and has waterproof, anti-drop and anti-cracking characteristics.

Owner:GUANGZHOU HUAXIA VOCATIONAL COLLEGE

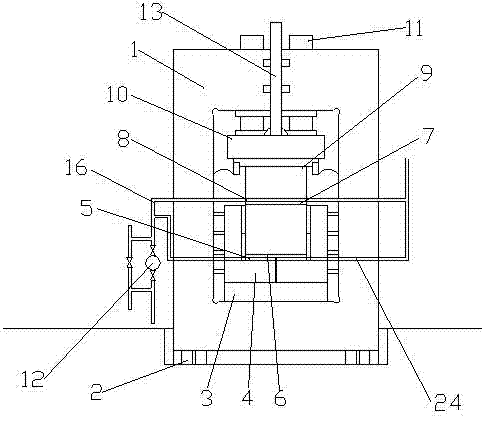

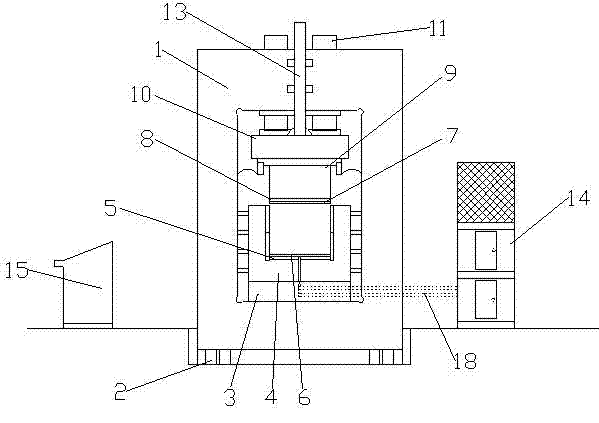

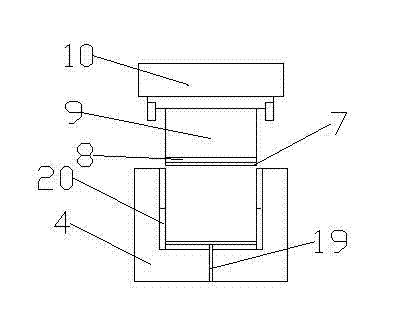

High-frequency mould-pressing hot press machine

The invention relates to a high-frequency mould-pressing hot press machine which comprises a frame, a fixed cross beam, a hot-pressing plate, an upper pressing mould head, a pressure cylinder, a hydraulic rod, a lifting block, a guiding rod and an electric control system, wherein the frame is arranged on a bottom beam; the fixed cross beam is arranged on the lower part of the frame; the hot-pressing plate is arranged above the fixed cross beam; the upper pressing mould head is arranged above the hot-pressing plate; the pressure cylinder is connected with the upper pressing mould head; the hydraulic rod is communicated with the pressure cylinder; the lifting block is arranged above the pressure cylinder; the guiding rod is connected with the lifting block; the electric control system is arranged on one side of the frame; a steam heat supply system which is connected with the upper pressing mould head and the hot-pressing plate is arranged on one side of the frame; a mould is arranged above the fixed cross beam; the hot-pressing plate is arranged at the bottom of the mould; a lower electrode guiding plate is arranged above the hot-pressing plate; an upper electrode guiding plate is fixedly mounted under the upper pressing mould head; a high-frequency heating emitter is connected under the lower electrode guiding plate; the high-frequency heating emitter is connected with a high-frequency emitting device through a flat cable; the hot-pressed heavy wood is great in thickness and width; the molding is quick; the control is accurate; and the integration of the industrial production is met.

Owner:常乐融融

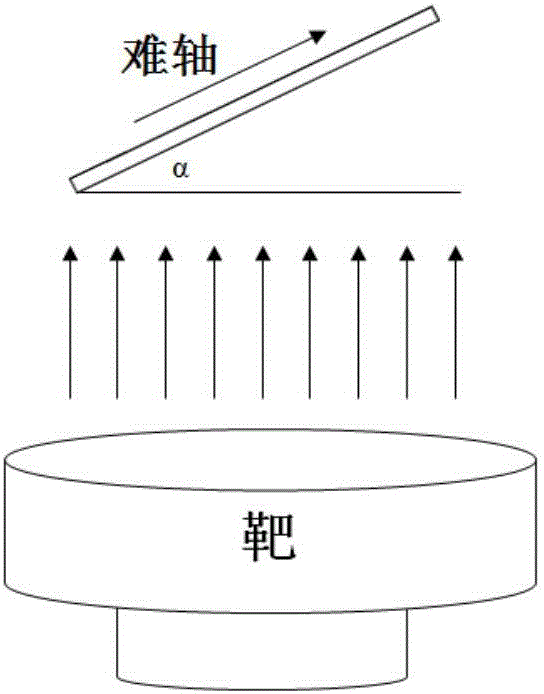

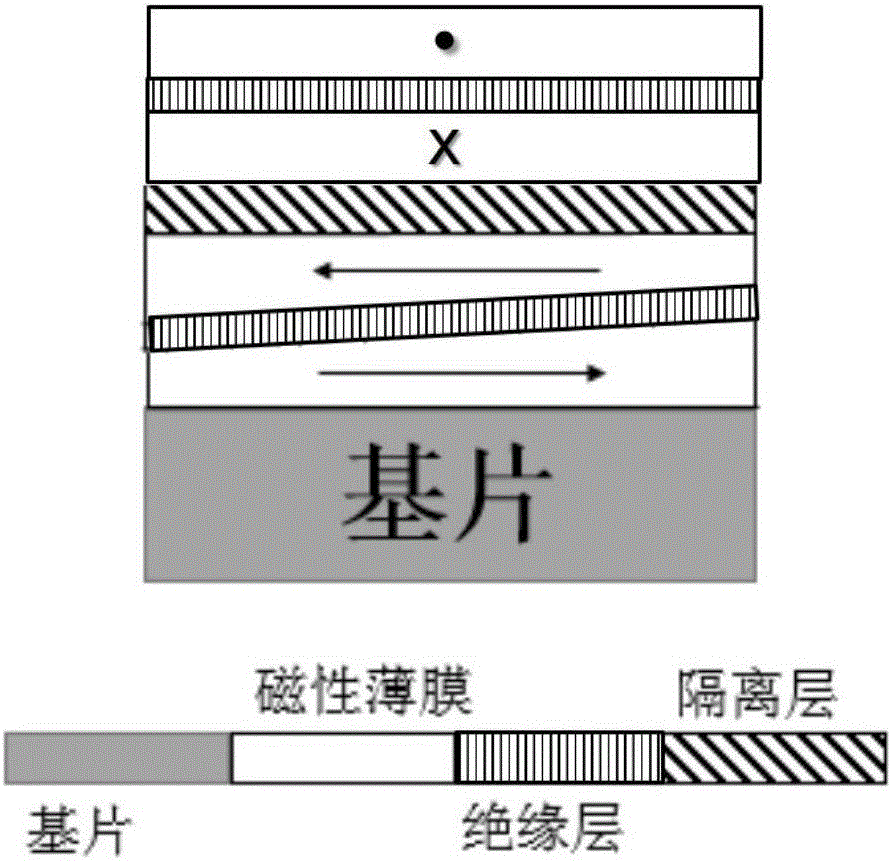

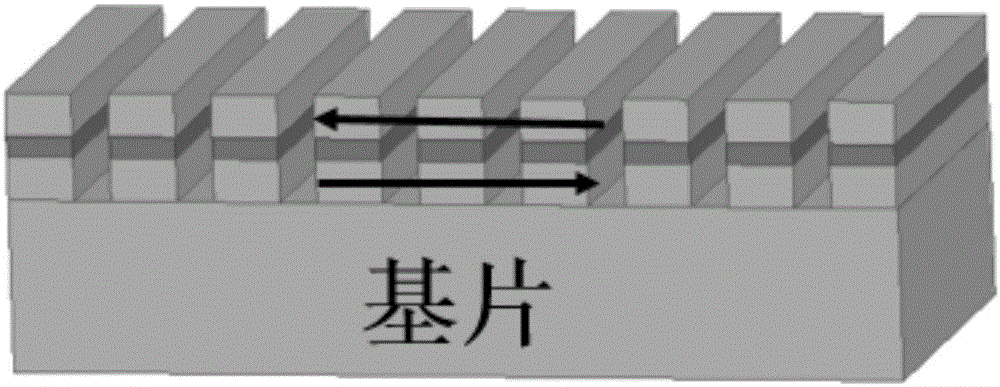

Preparation method of quasi isotropic magnetic core film

InactiveCN106504891AImprove permeabilityMeet the integrationCathode sputtering applicationMagnetic layersSputteringInductor

The invention provides a preparation method of a quasi isotropic magnetic core film, and relates to the field of preparation of magnetic thin films in high-frequency magnetic devices, especially on-chip integrated inductors. According to the preparation method, a substrate inclines, the substrate and target materials are sputtered at a certain angle to form an inclined columnar structure, and a uniaxial anisotropy field is introduced. In a magnetic thin film / insulating layer / magnetic thin film sandwich structure, the upper and lower layers of magnetic thin films are of an inclined columnar structure with opposite easy-axis directions to generate an appropriate interlayer exchange coupling effect and to offset a shape anisotropy field caused by different length-width ratios, so that the total effective anisotropy field only depends on an inclined sputtering-induced anisotropy field. The magnetic core film is formed by stacking a plurality of sandwich structures, easy axes of the magnetic thin films in adjacent sandwich structures are vertical to one another, and the interlayer exchange coupling effect is isolated through isolating layers which are greater than 20nm in thickness, so that the magnetic core film has similar effective anisotropy fields and relatively high magnetic conductivity in various directions.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

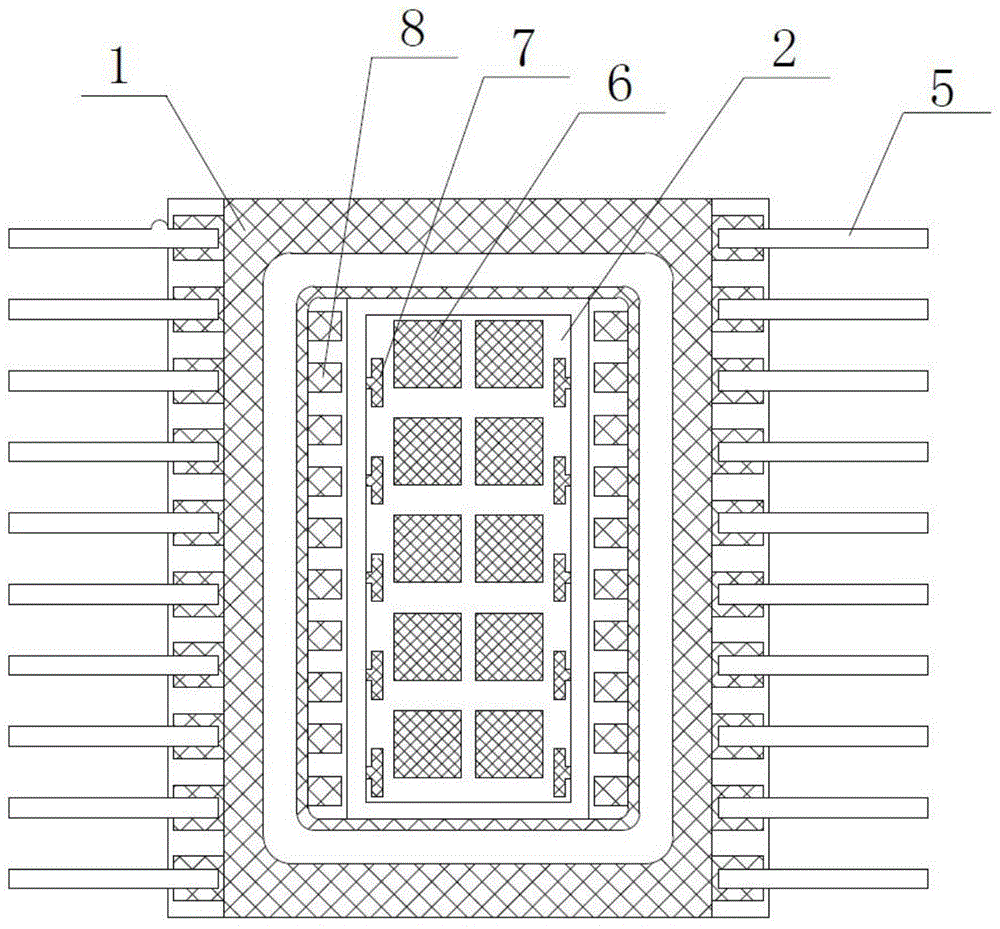

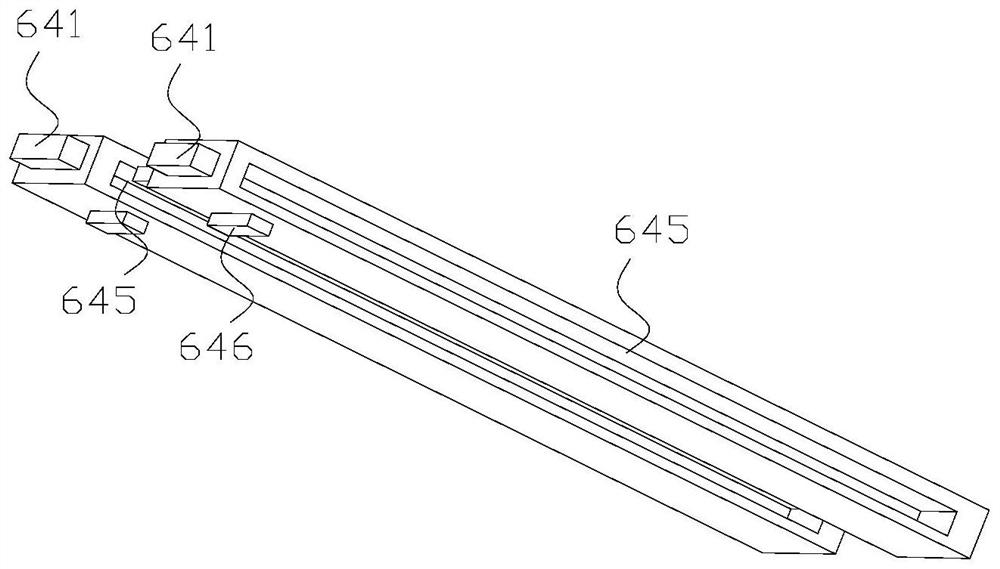

Multi-die high-power diode shell and manufacturing method thereof as well as chip packaging method

InactiveCN104600037AImprove cooling effectSimple structural designSemiconductor/solid-state device detailsSolid-state devicesPower flowPower diode

The invention discloses a multi-die high-power diode shell and a manufacturing method thereof as well as a chip packaging method. The multi-die shell comprises a ceramic frame and a substrate; a plurality of microstrip lines are put through the frame; a first bonding region is arranged on the inner side of the frame, while a plurality of leads are arranged on the outer side of the frame; the substrate is arranged at the bottom of the inner side of the ceramic frame, and provided with a ceramic base body, and an upper side surface and a lower side surface for metallizing the ceramic base body; a plurality of isolation regions and a second bonding region are formed on the upper side surface; the isolation regions are used for receiving the chip. According to the manufacturing method, a high-temperature cofiring ceramic process is adopted, and high-heat dissipation and high-reliability multi-die packaging is realized by virtue of a structure in which a metal heat sink is brazed under the chip substrate and a kovar weld ring is brazed and sealed on the upper surface of the ceramic frame, and meanwhile, the requirements of large current and high power property are achieved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

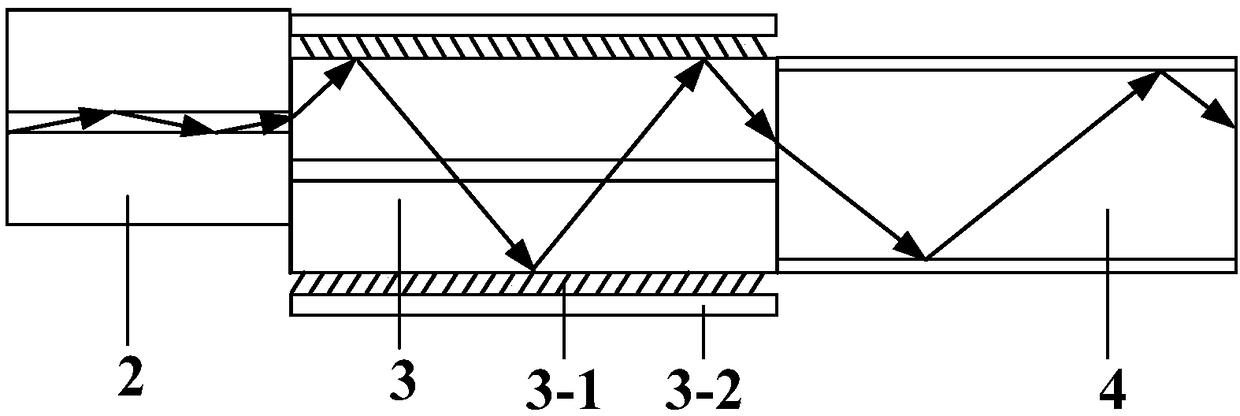

Optical fiber cladding SPR micro-bending sensor and calibration device thereof

The invention belongs to the field of optical fiber sensing, and mainly relates to an optical fiber cladding SPR micro-bending sensor and a calibration device thereof. The optical fiber cladding SPR micro-bending sensor disclosed by the invention has the advantages that the manufacturing difficulty and the manufacturing cost of the optical fiber SPR sensor are reduced; the measurement of the bending curvature through the SPR effect is innovatively proposed and verified, and the research field of the traditional optical fiber type micro-bending sensor is expanded to a certain extent. The optical fiber cladding SPR micro-bending sensor has obvious advantages in landslide disaster monitoring, the large landslide disaster frequency generation points are buried, and once tiny deformation occurson the earth surface, and the landslide intensity can be speculated by observing the depth and the displacement of the SPR resonance peak on the spectrometer, so that the landslide disaster can be monitored, and the optical fiber cladding SPR micro-bending sensor has a wide application value.

Owner:CHONGQING THREE GORGES UNIV

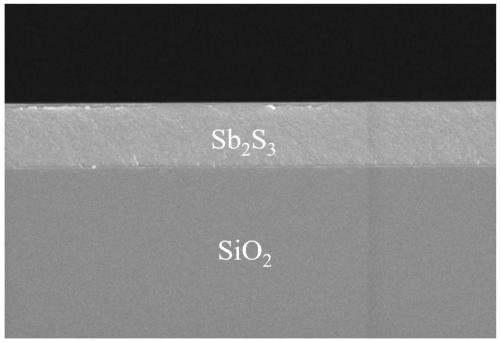

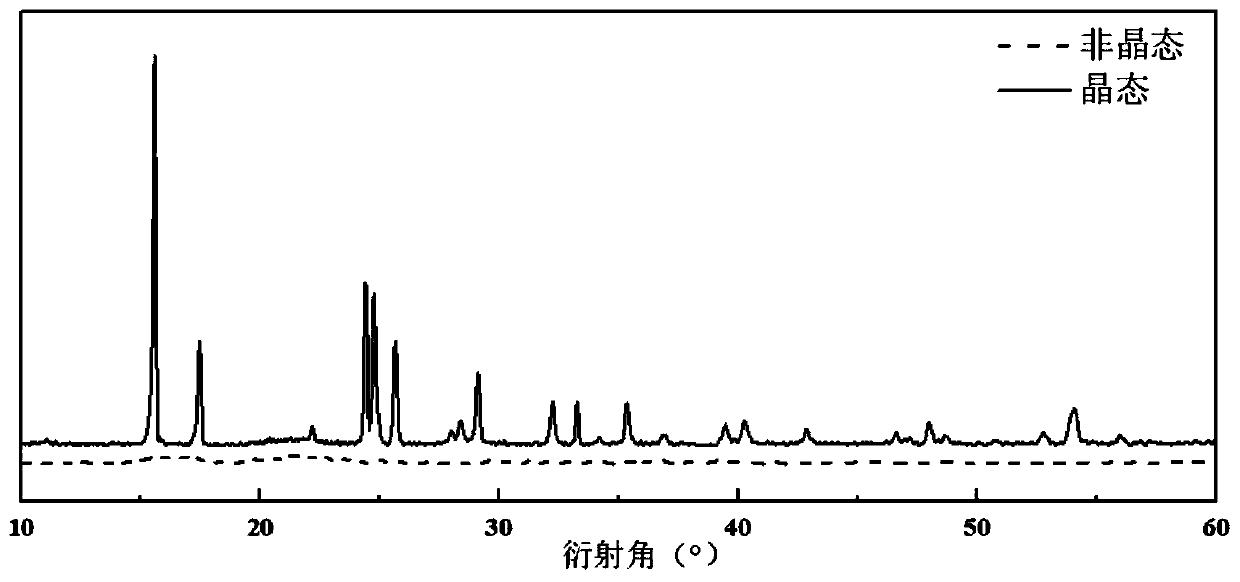

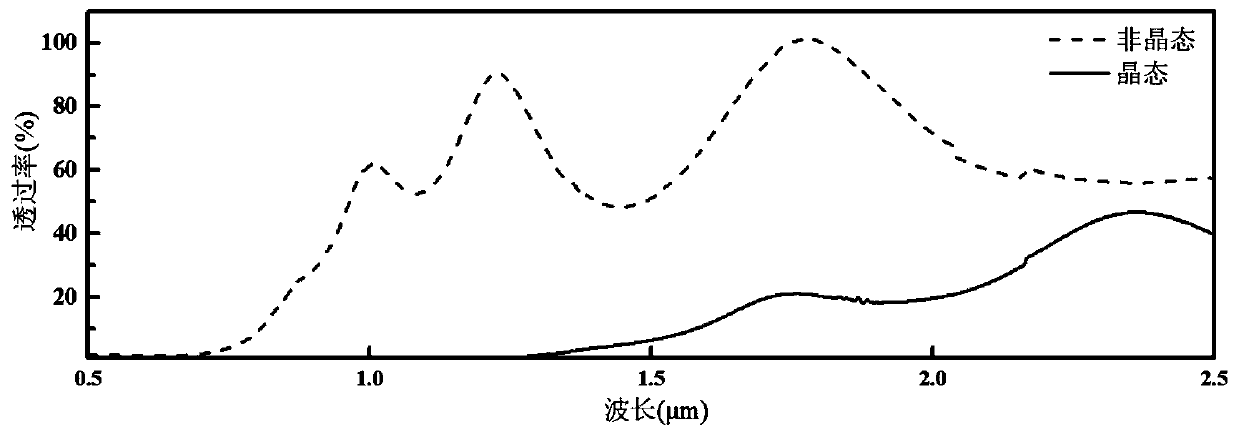

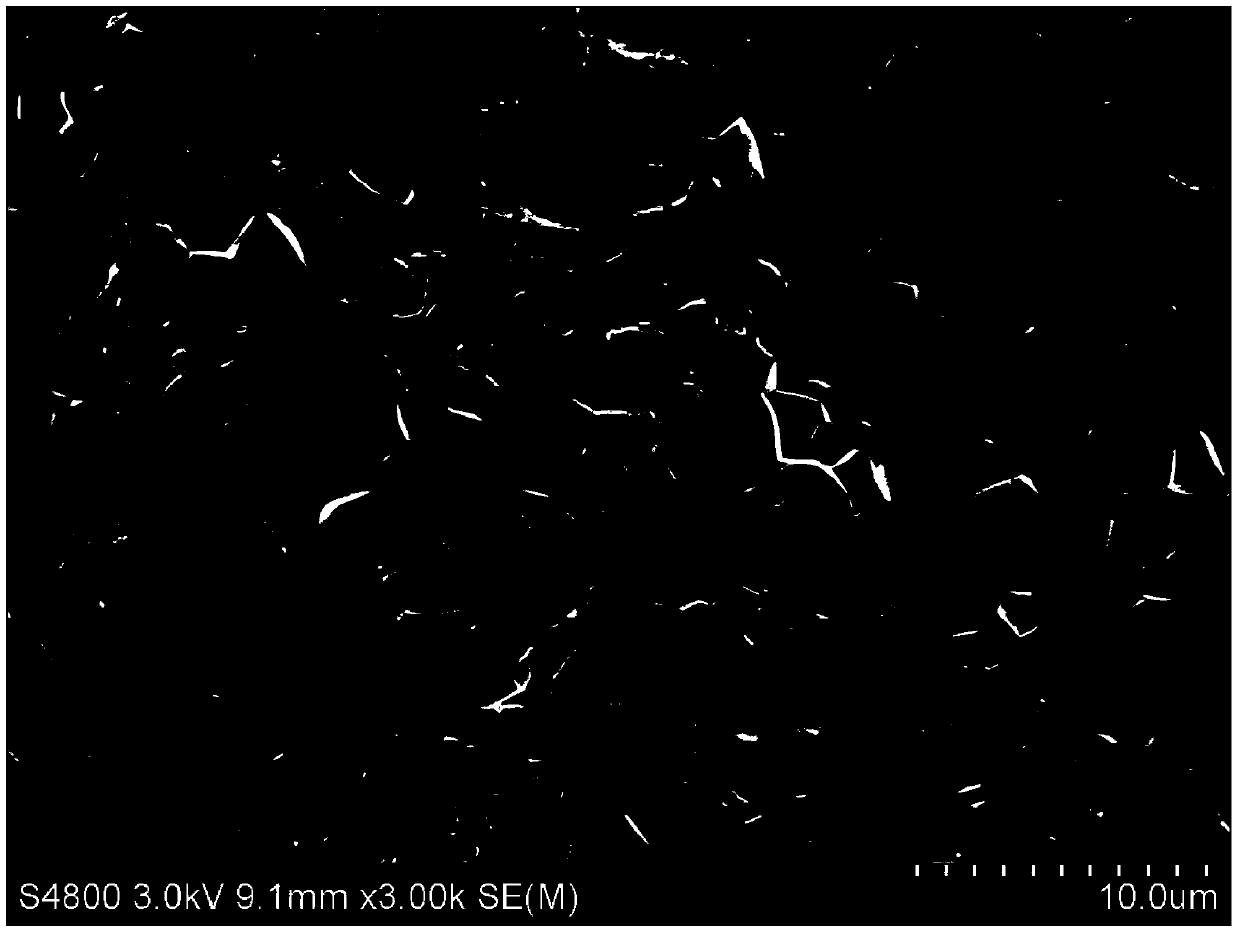

Chalcogenide phase-change film capable of being used for multispectral active optical regulation and preparation method thereof

InactiveCN111399255AMeet the integrationSatisfy functionVacuum evaporation coatingSputtering coatingThermal depositionRefractive index

The invention relates to a chalcogenide phase change film capable of being used for multispectral active optical regulation and a preparation method, and belongs to the field of optical films and optical phase change materials. The chemical formula of the phase change thin film is Sb<x>S<100-x>, wherein x is greater than 20 and less than 50. The amorphous high-quality optical thin film is preparedby adopting a high-vacuum rapid thermal deposition method. The film can be reversibly converted between a high refractive index (amorphous state) and a low refractive index (crystalline state) underthe thermal action of an external field. The crystalline state and the amorphous state of the material film can have obvious difference in refractive index within the range of 0.55-25 [mu]m, the lighttransmittance is good, the material film can be used for preparing a multispectral light field active regulation and control device, and the development requirements for integration, miniaturizationand multifunction of a traditional light field regulation and control device can be met.

Owner:SUN YAT SEN UNIV

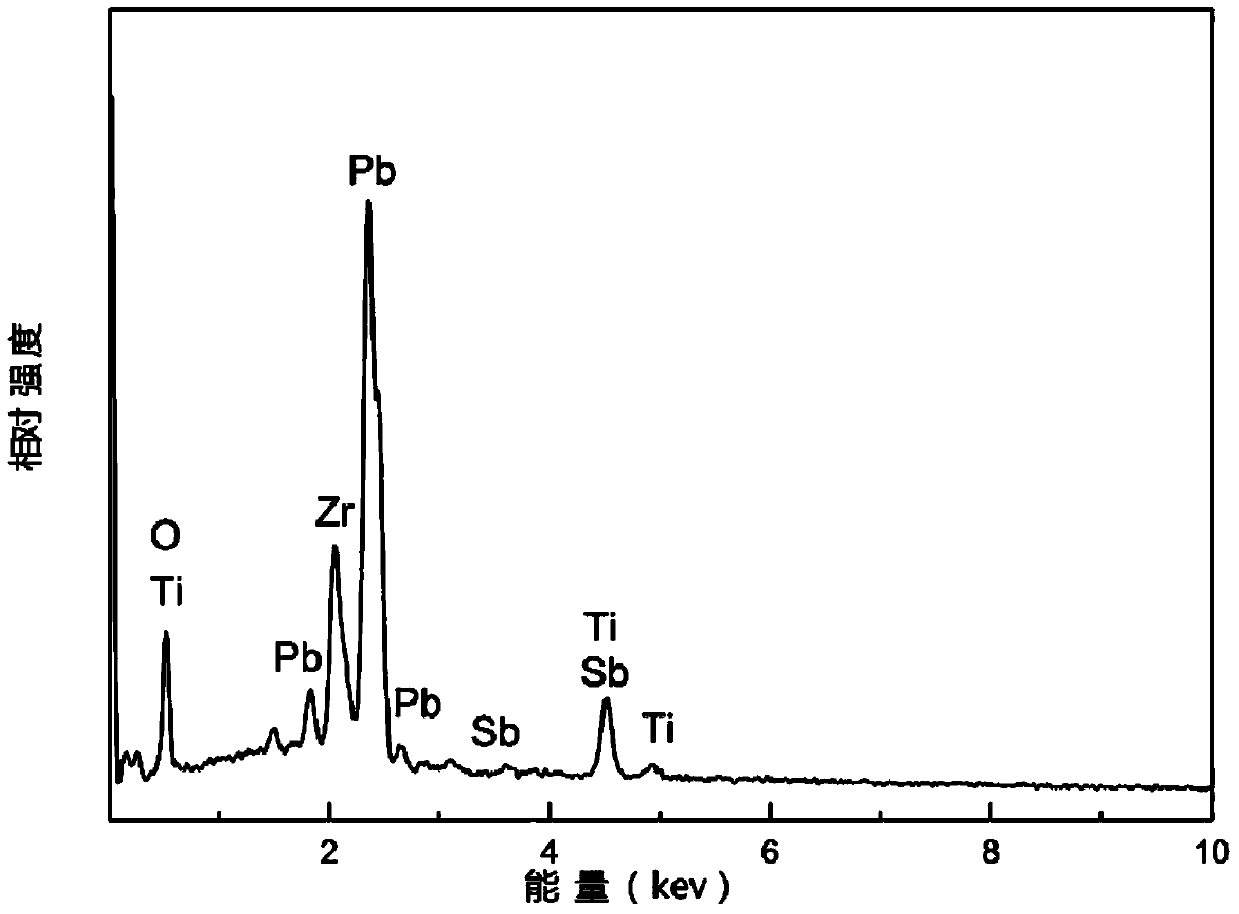

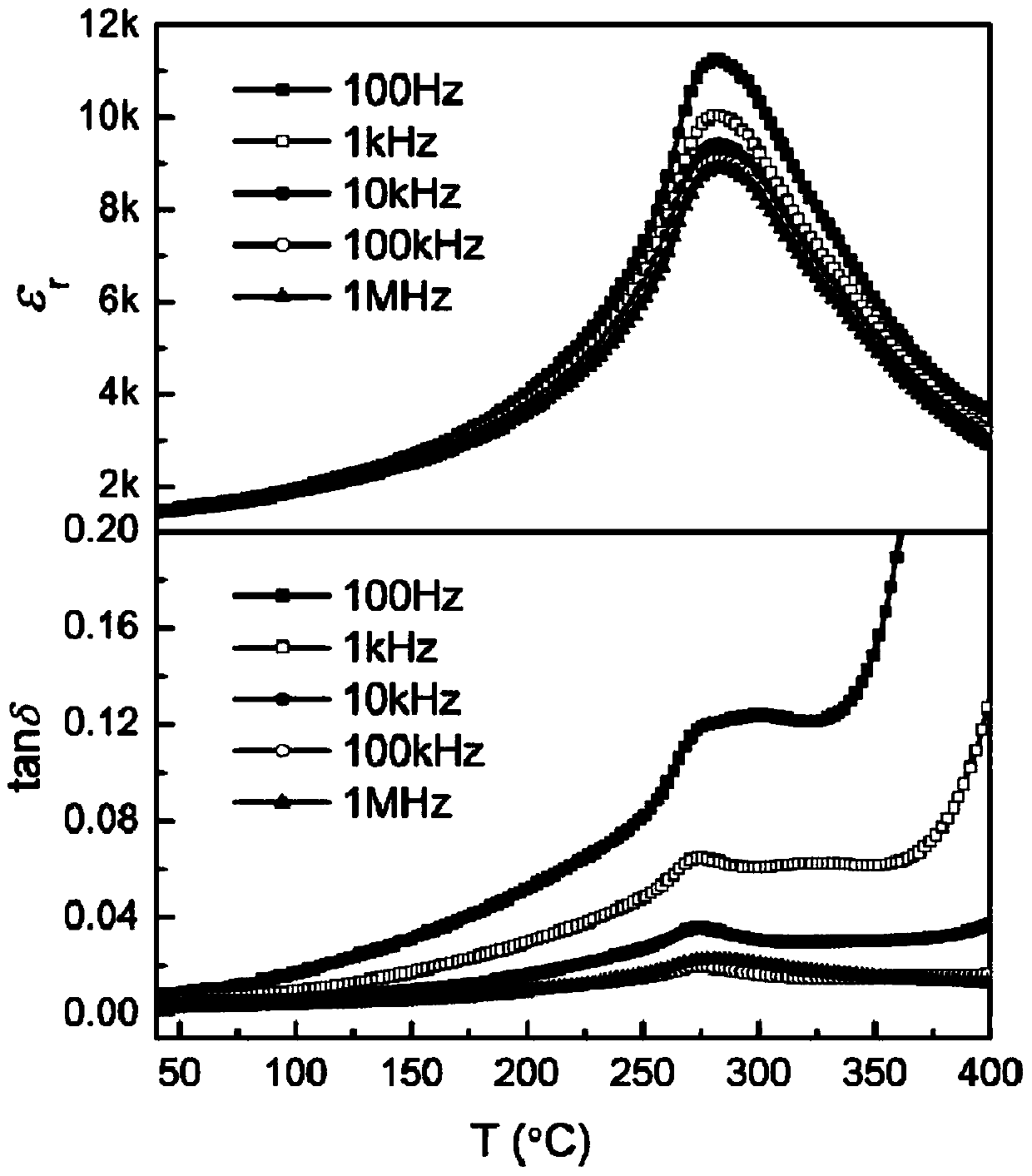

Piezoelectric ceramic material, sintered body and preparation method thereof, and piezoelectric ceramic device

The invention provides a piezoelectric ceramic material of which the chemical general formula is PbxSr1-x(Mn1 / 3Sb2 / 3)yZrzTi1-y-zO3+m%CeO2+n%Cr2O3, wherein 0.9<=x<=1, 0<=y<=0.15, 0.4<=z<=0.62, 0<=m<=1, and 0<=n<=1. The running method is especially suitable for forming flaky ceramic products which are 20-300 mu m thick, has the advantages of high speed, high automation degree, high efficiency, uniform product structure, good quality and the like, and therefore, can satisfy the development requirements of miniaturation, integration, low noise and multifunction for modern electronic components; and by adjusting the formula, the piezoelectric ceramic has excellent piezoelectricity and temperature stability at the same time, thereby satisfying the operational requirements of the product.

Owner:AAC PRECISE MFG TECH CHANGZHOU

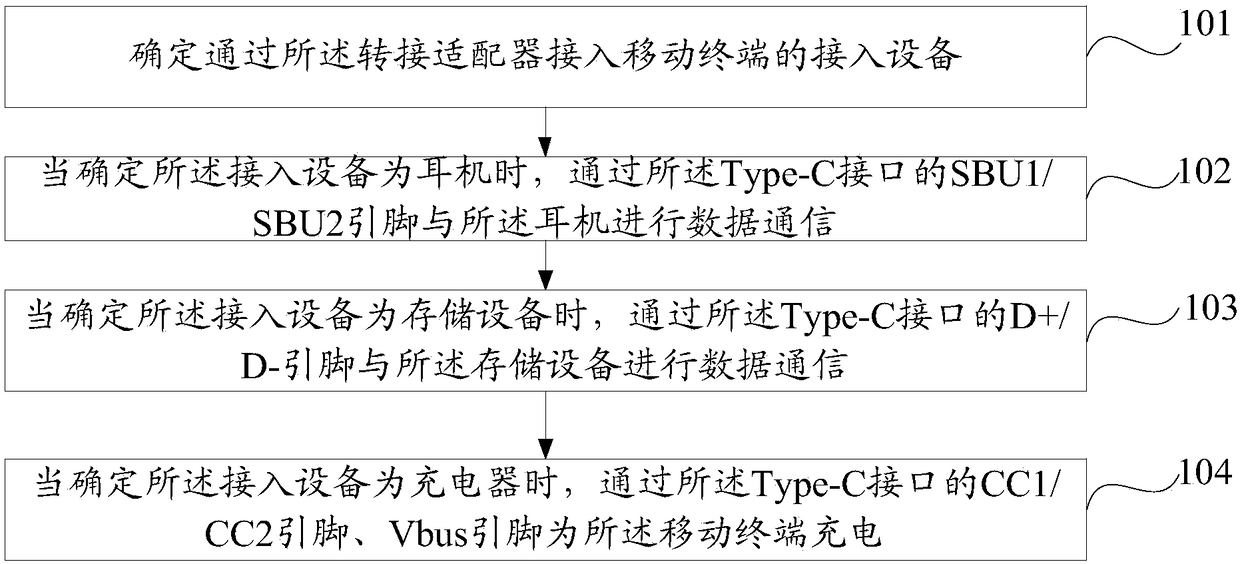

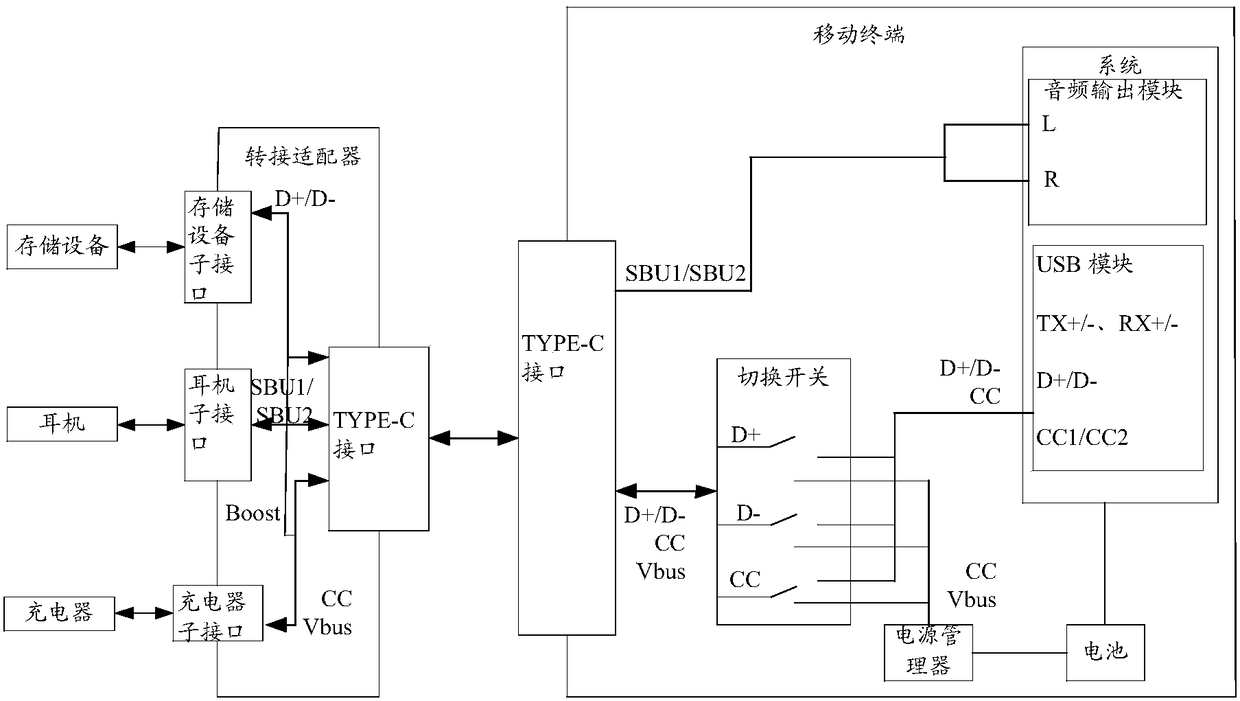

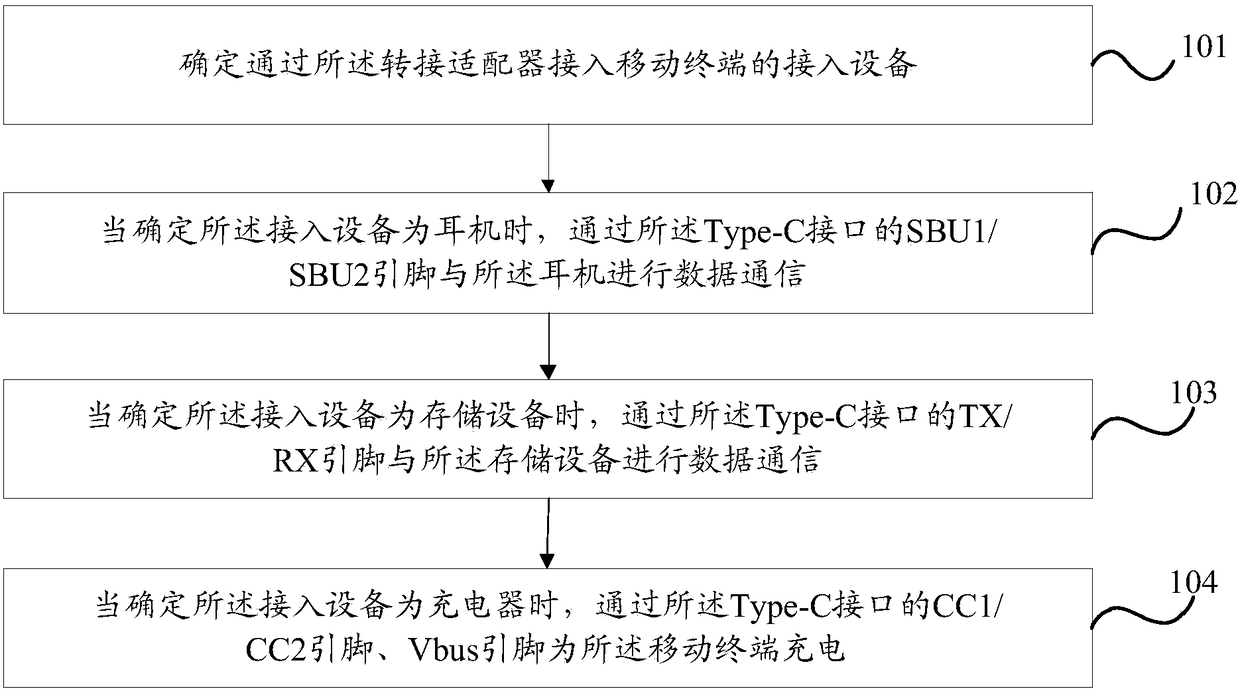

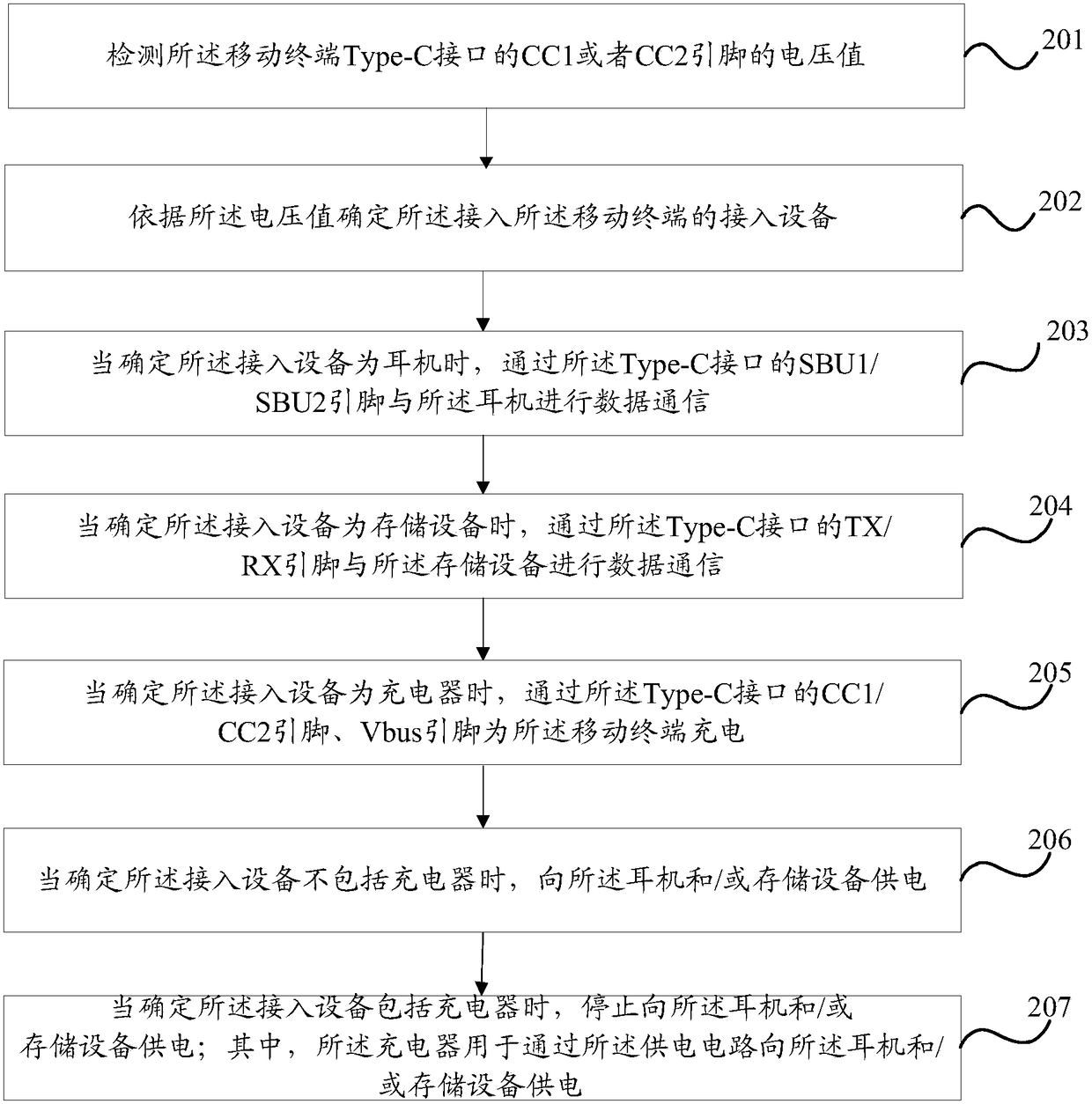

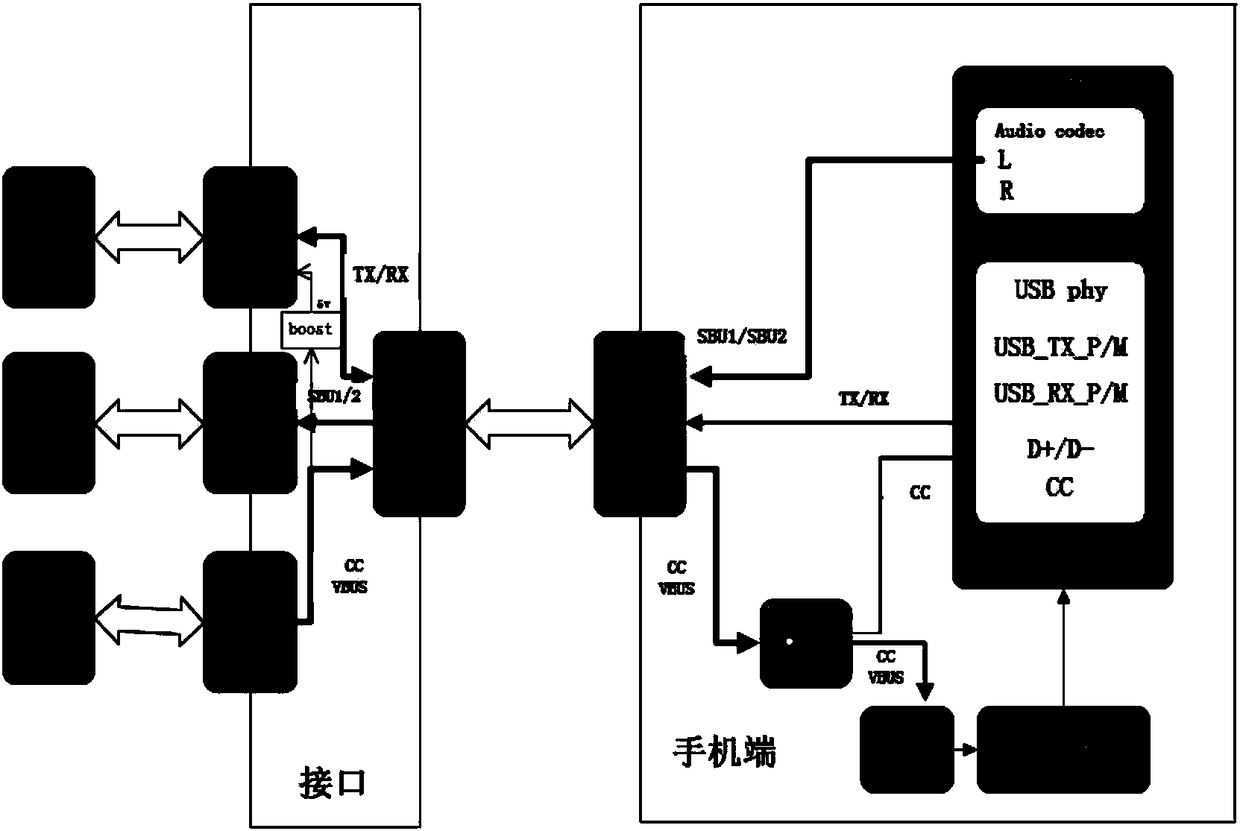

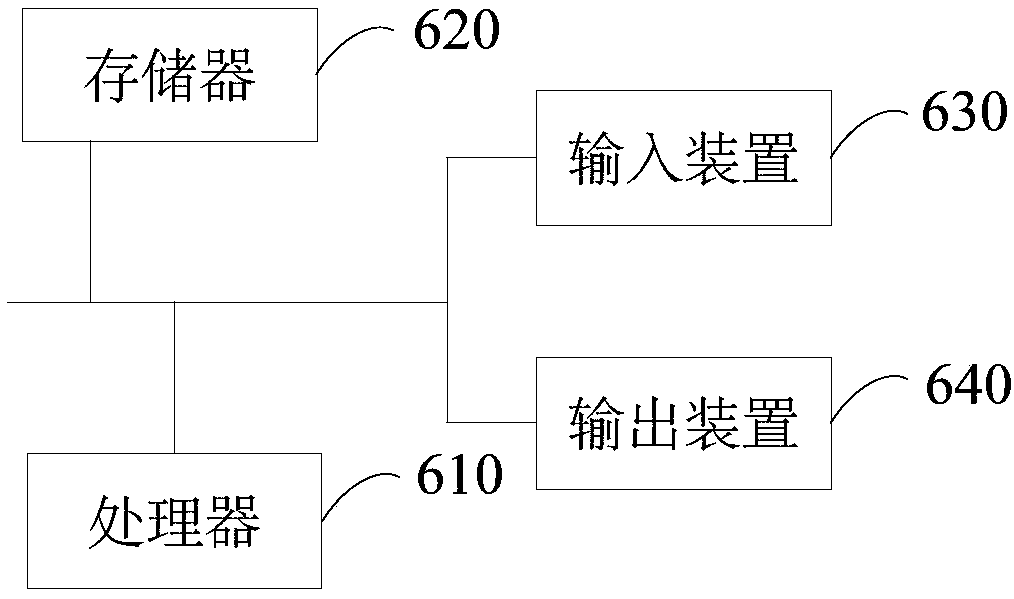

Processing method of access equipment and mobile terminal

ActiveCN108268396AMeet ultra-thinMeet the integrationElectric powerArrangements for several simultaneous batteriesComputer terminalData transmission

The embodiment of the invention provides a processing method of access equipment and a mobile terminal. The mobile terminal is connected with a forwarding adapter through a Type-C interface. The method comprises the following steps: determining access equipment which is accessed to the mobile terminal through the forwarding adapter; carrying out data communication with an earphone through a SBU1 / SBU2 pin of the Type-C interface when the access equipment is the earphone; carrying out data communication with storage equipment through a D+ / D- pin of the Type-C interface when the access equipmentis the storage equipment; and charging the mobile terminal through a CC1 / CC2 pin and a Vbus pin of the Type-C interface when the access equipment is a charger. By applying the embodiment of the invention, the problems that music listening, data transmission and charging of the mobile terminal cannot be realized simultaneously by using one Type-C interface and access of a plurality of equipment cannot be processed so that a development trend of ultra-thinness and integration of the mobile terminal cannot be met are solved; and moreover, the phenomenon that the mobile terminal is simultaneouslyconnected with the plurality of equipment by using one Type-C interface, so that the requirements on the ultra-thinness and the integration of the mobile terminal can be met.

Owner:VIVO MOBILE COMM CO LTD

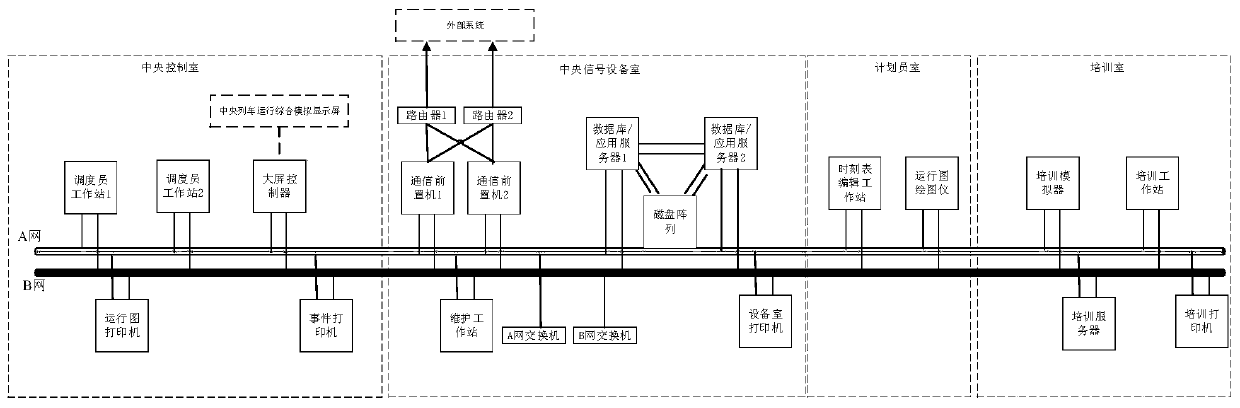

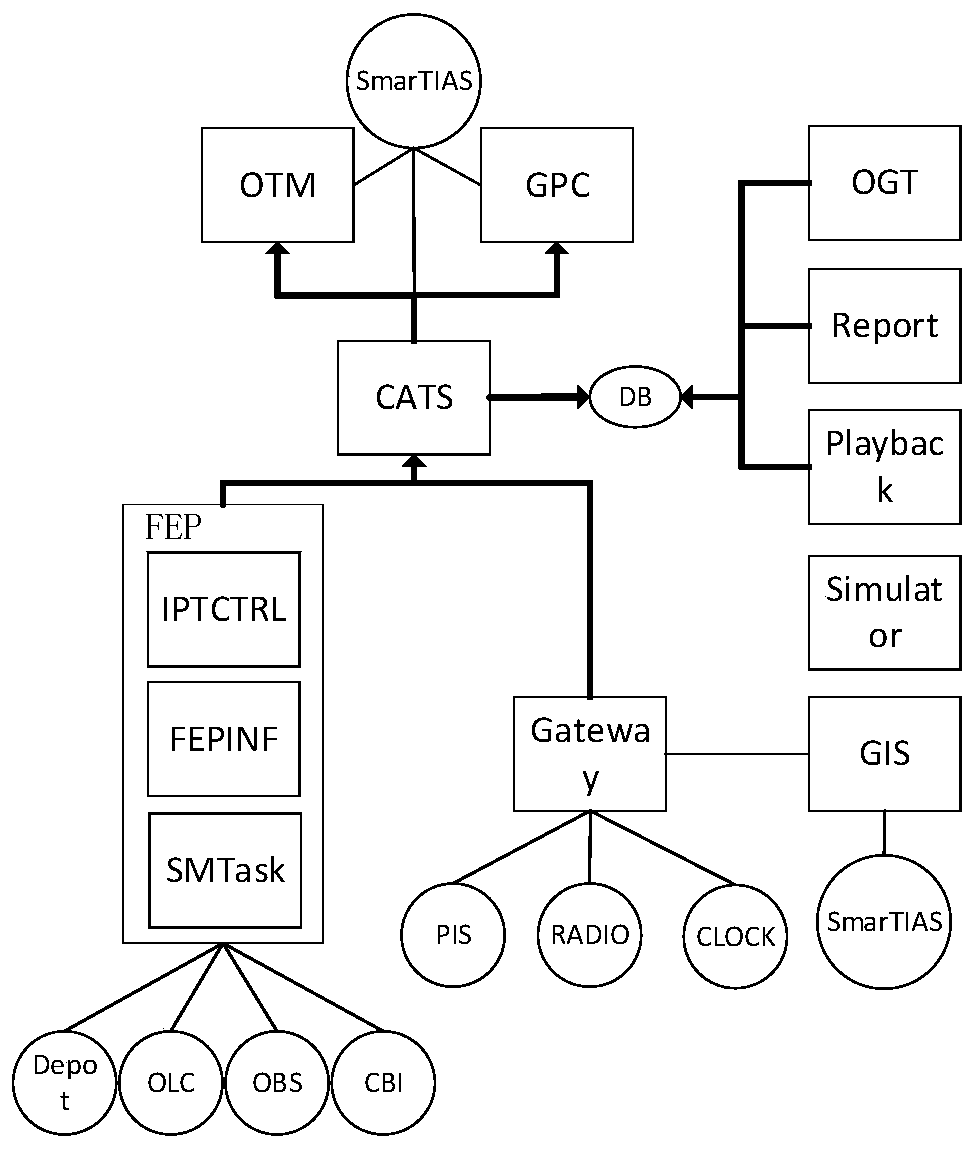

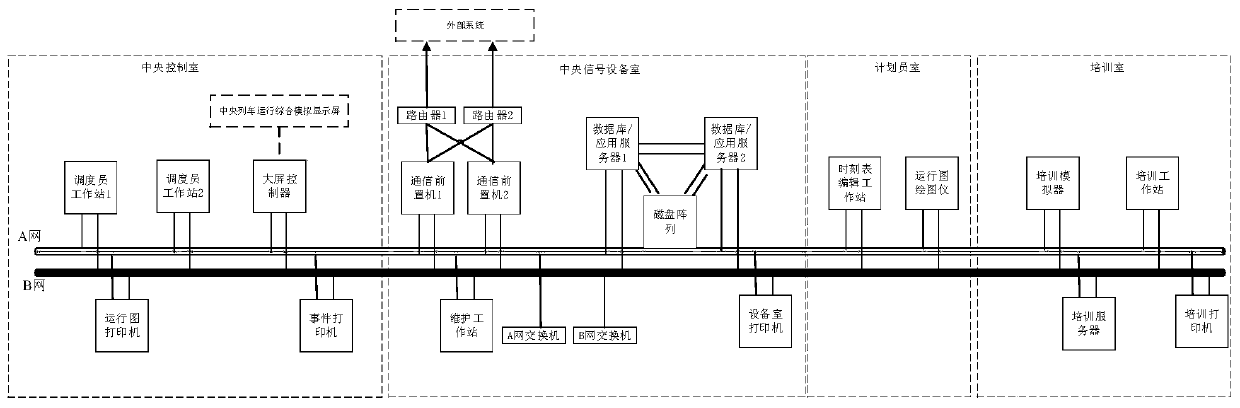

Tramcar driving scheduling management system

PendingCN111137328AEasy to upgradeFlexible configurationError preventionRailway traffic control systemsComputer printingControl room

The invention relates to a tramcar driving scheduling management system. The system comprises a communication network, and a central control room, a central signal equipment room, a planner room and atraining room which are connected with one another through a communication network, wherein the central signal equipment room comprises a server, a communication front-end processor, a maintenance workstation and an equipment room printer which are respectively connected with the communication network, and the server adopts a dual-computer hot standby redundancy mechanism. Compared with the priorart, the system has the advantages of high reliability, flexible structure, convenience in expansion, safety, high efficiency, convenience in integration and the like.

Owner:CASCO SIGNAL

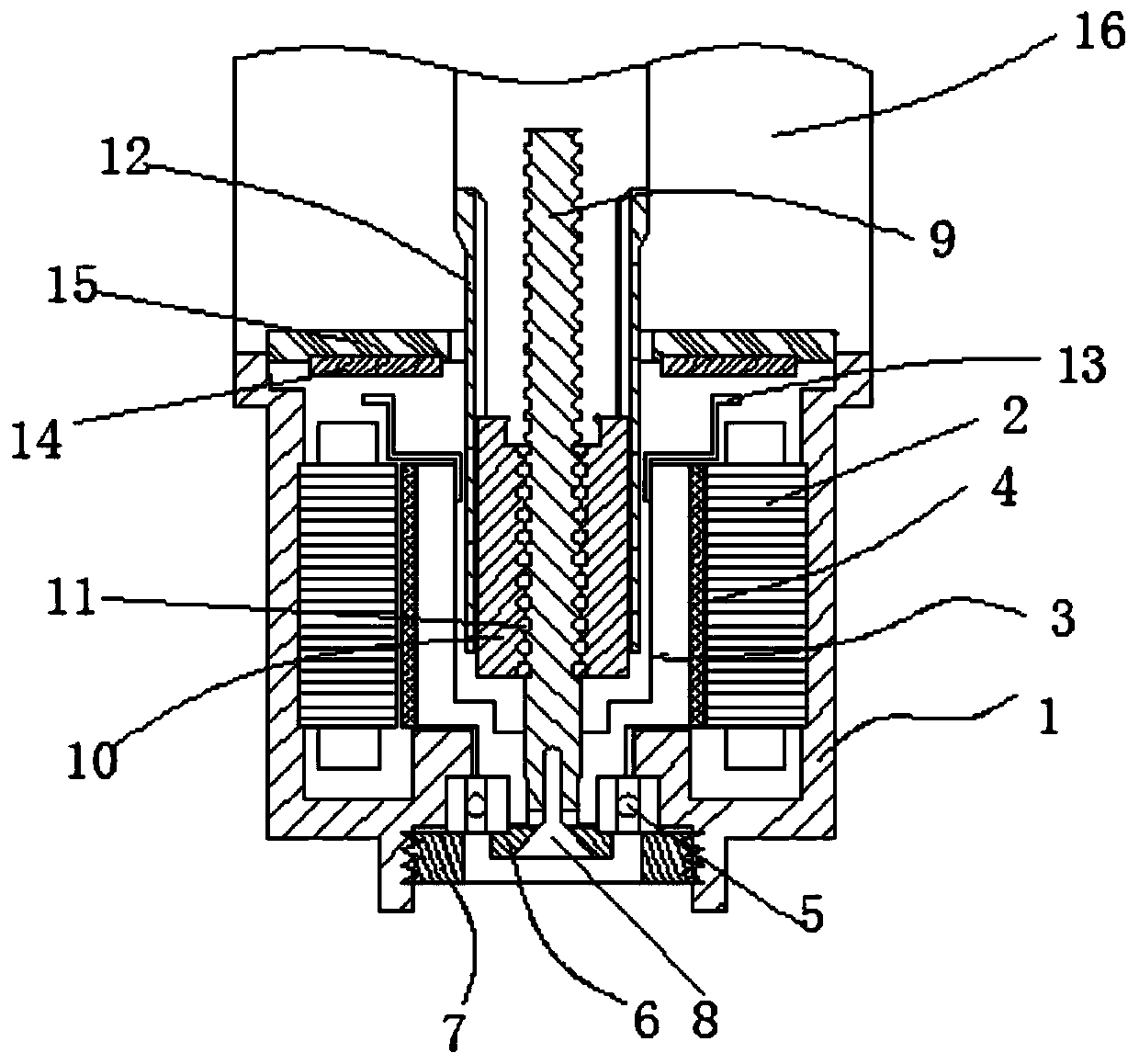

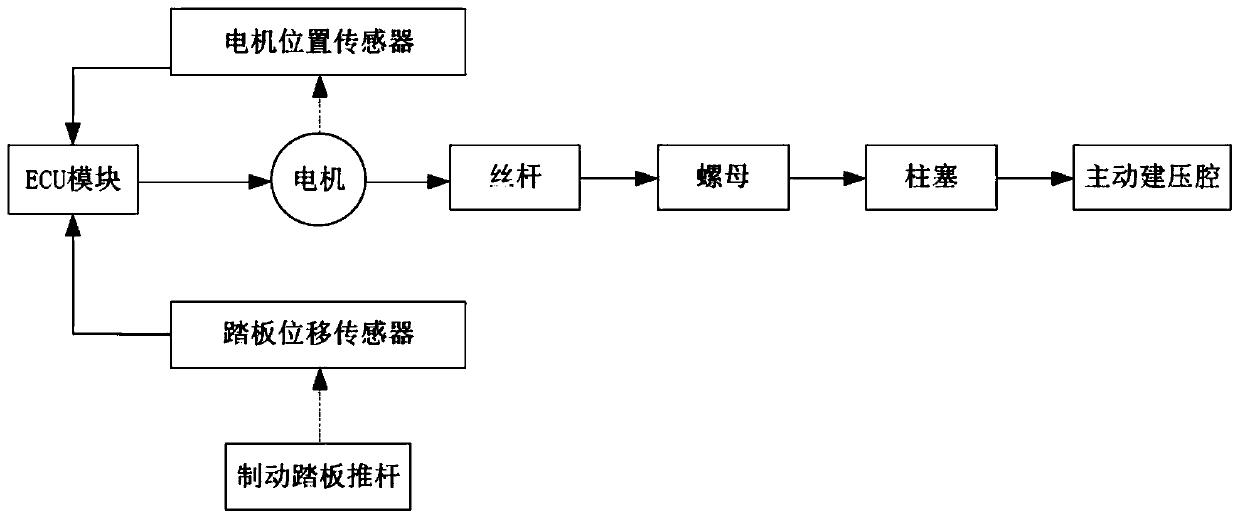

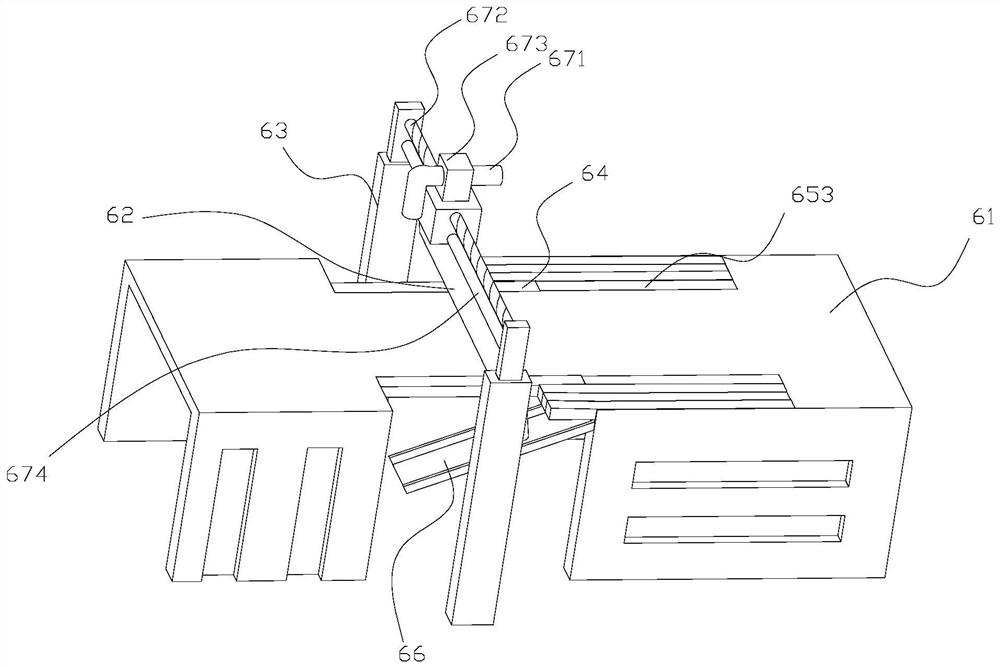

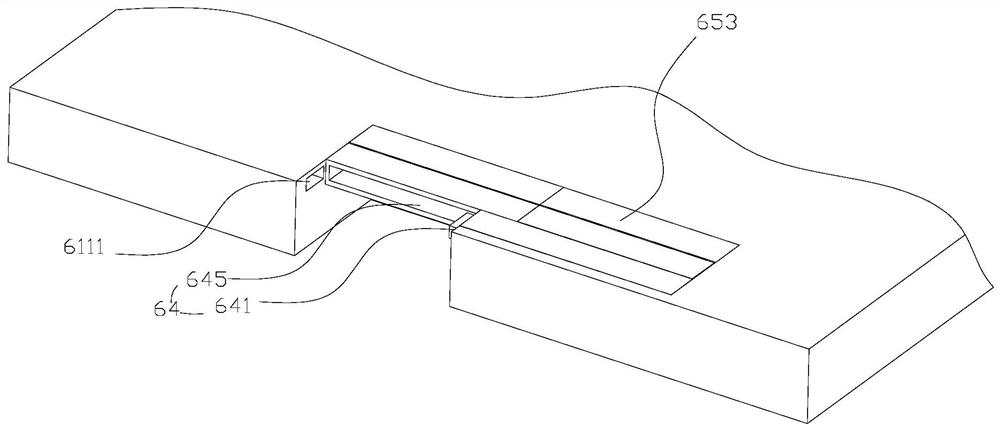

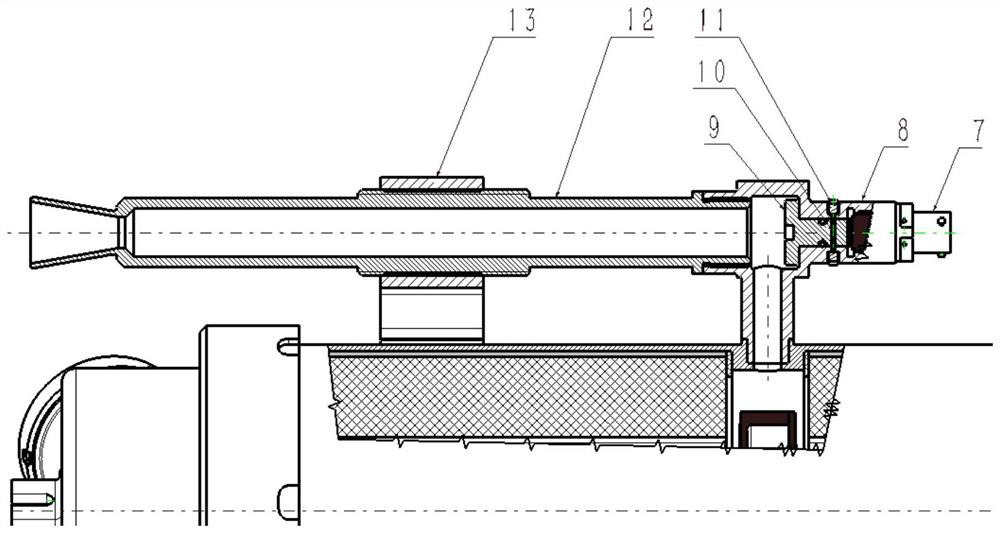

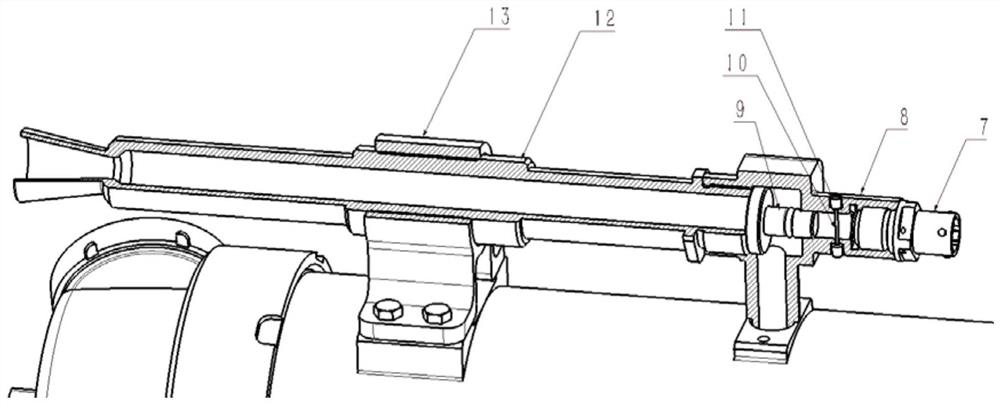

Active pressure building mechanism

InactiveCN109774693AMeet the integrationLight in massBraking action transmissionMechanical energy handlingHydraulic control unitPulp and paper industry

The invention discloses an active pressure building mechanism. According to the active pressure building mechanism, a hydraulic control unit is connected with a motor shell, the bottom face of the hydraulic control unit is provided with a sensor stator supporting piece and a sensor stator, a screw rod, a driven piece and an anti-rotation piece are inserted into the hydraulic control unit via through holes in the sensor stator supporting piece and sensor stator, a bearing is locked on the shell through a second connecting piece, a first connecting piece is fixedly clamped by the bearing, the upper portion of the anti-rotation piece is inserted into the hydraulic control unit and fixed in the hydraulic control unit, the lower portion of the anti-rotation piece is inserted into a hollow rotorof a motor, the driven piece is fixed in the anti-rotation piece, the driven piece is connected with the penetrating screw rod through a transmission piece, a sensor rotor and the hollow rotor of themotor are located under the sensor stator, the bottom of the hollow rotor of the motor is provided with a stepped shaft, a third connecting piece penetrates through the first connecting piece and thehollow rotor of the motor and then is connected with the bottom face of the screw rod, and a tapered surface cooperating with the tapered bottom face of the hollow rotor of the motor is formed on thebottom of the screw rod. Compared with the prior art, the active pressure building mechanism has the advantages that the weight is lower, the inertia moment is smaller, the size is smaller, and the integration level is higher.

Owner:LIANCHUANG AUTOMOBILE ELECTRONICS +1

Composite melt-blown fabric production device and composite melt-blown fabric production method

ActiveCN112371451ATechnical defects affecting normal coatingGuaranteed support effectLiquid surface applicatorsCoatingsMechanical engineeringCotton material

The invention discloses a coating device. A notch and a placing groove are formed in a coating platform; in the adjacent widening plates, a second long-strip open groove in the widening plate locatedinside is in sliding fit with a second long-strip convex block of the widening plate located outside, and a pushing convex block of the widening plate located outside extends into the long-strip guidegroove in the widening plate located inside to be in contact with the front inner wall of the long-strip guide groove; the widening plate located outside can move forwards to drive all the widening plates on the inner side of the widening plate to move forwards synchronously; and a cover plate can cover the placing groove, and the top surface of the cover plate is flush with the top surface of the coating platform. The invention further discloses a composite melt-blown fabric production device and a composite melt-blown fabric production method. The composite melt-blown fabric production device and the composite melt-blown fabric production method have the advantages that the coating breadth can be changed in real time to meet coating of cloth with different breadths, residues of coatingmaterials on the coating platform are reduced, the cloth function is improved, and the production efficiency is improved.

Owner:福建智罗科技有限公司

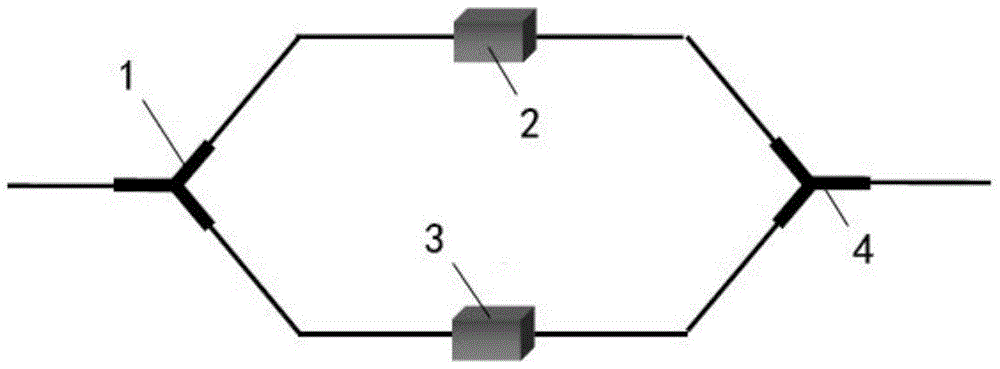

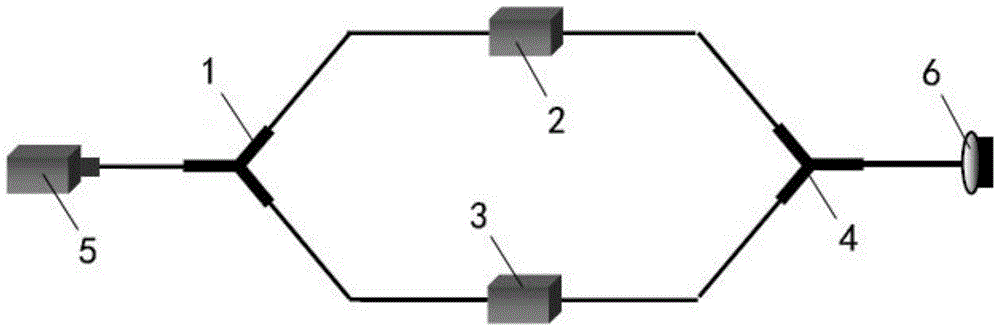

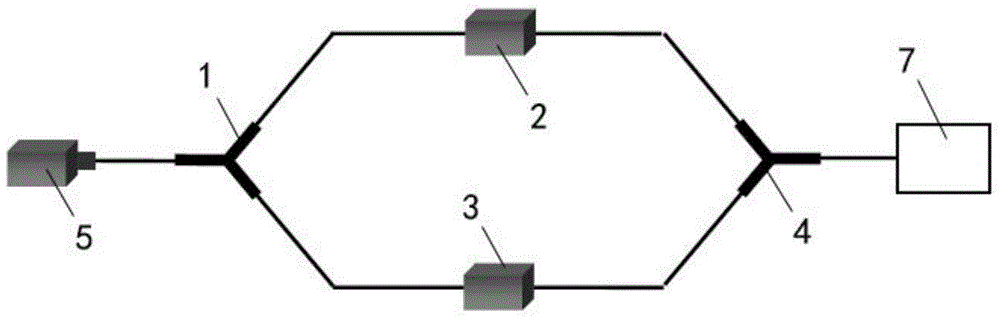

Frequency domain depolarizer and depolarization method of Mach-Zehnder interferometer structure

InactiveCN105044919ASimple structureMeet the integrationOptical elementsMach–Zehnder interferometerOptoelectronics

The invention discloses a frequency domain depolarizer and depolarization method of a Mach-Zehnder interferometer structure. The frequency domain depolarizer comprises a polarization beam splitter, a first attenuator, a second attenuator and a polarization beam combiner. A light source to be depolarized is split into two paths of linear polarized light through the polarization beam splitter; light intensities of the two paths of linear polarized light are controlled by adjusting attenuation amount of the first attenuator and the second attenuator respectively; and the two paths of linear polarized light are combined through the polarization beam combiner and then, are output. When the light intensities of the two paths of linear polarized light output by the polarization beam combiner are same, a best depolarization effect is achieved, and the degree of polarization of depolarized light output by the polarization beam combiner is lower than 0.5%, so that high index requirements for the depolarizer in a plurality of application occasions of high-precision inertial navigation technology and Y waveguide high extinction ratio test and the like can be met; and besides, the frequency domain depolarizer is simple in structure and easy to integrate, convenient to operate and high in reliability.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

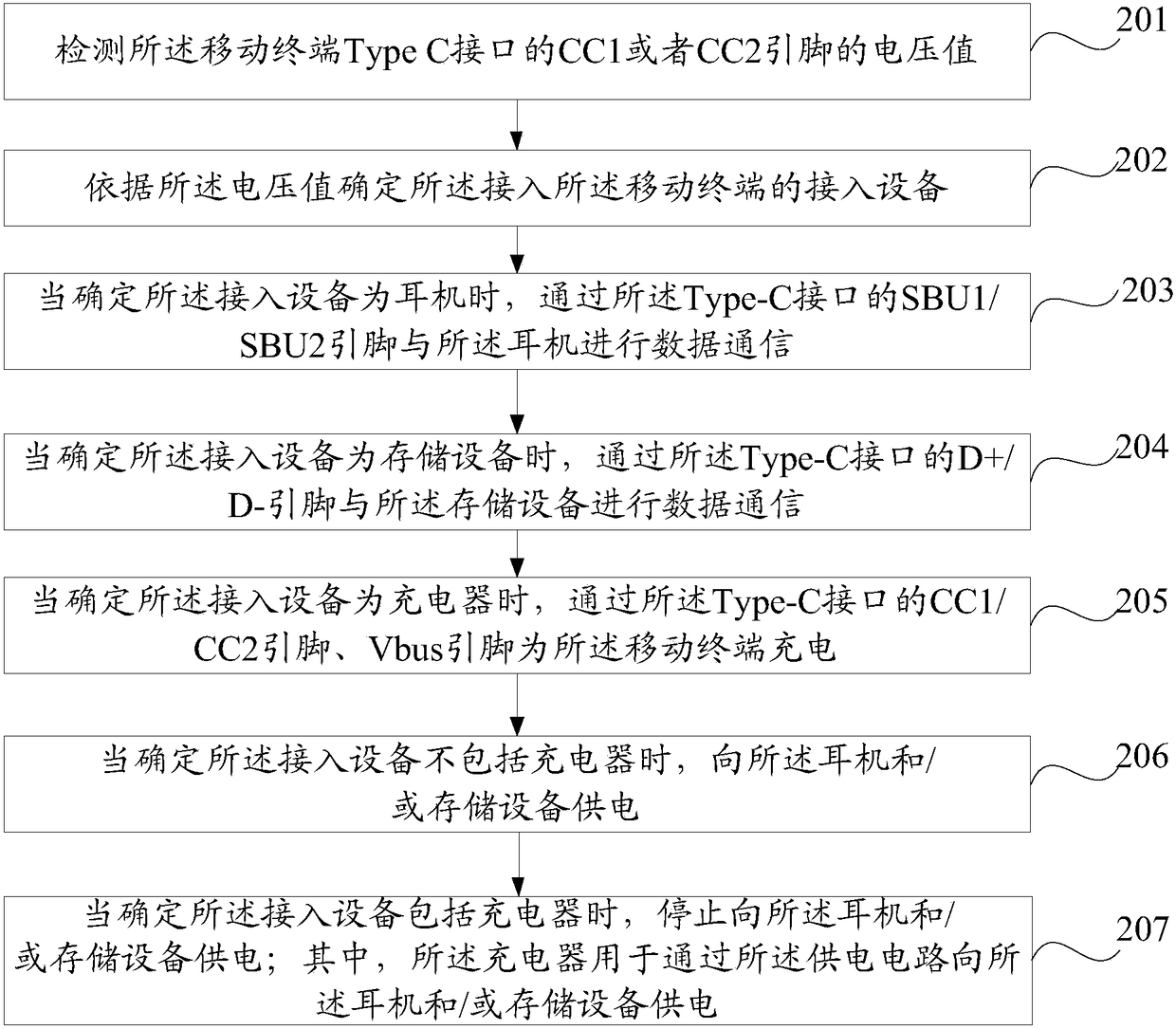

Access equipment processing method and mobile terminal

InactiveCN108268393AMeet ultra-thinMeet the integrationElectric digital data processingComputer terminalEmbedded system

The embodiment of the invention provides an access equipment processing method and a mobile terminal. The method comprises the following steps that: determining access equipment accessed into the mobile terminal through a switching adapter; when a determining result shows that the access equipment is an earphone, through the SBU1 / SBU2 pin of a Type-C interface, carrying out data communication withthe earphone; when a determining result shows that the access equipment is storage equipment, through the TX / RX pin of the Type-C interface, carrying out data communication with the storage equipment; and when a determining result shows that the access equipment is a charger, through the CC1 / CC2 pin and the Vbus pin of the Type-C interface, charging the mobile terminal. Through the embodiment ofthe invention, the problem that a tendency that the mobile terminal develops to be ultrathin and integrated can not be met since the mobile terminal uses one Type-C interface can not realize a purposeof simultaneously listening to music, transmitting data and charging and can not process the access of multiple pieces of equipment can be solved.

Owner:VIVO MOBILE COMM CO LTD

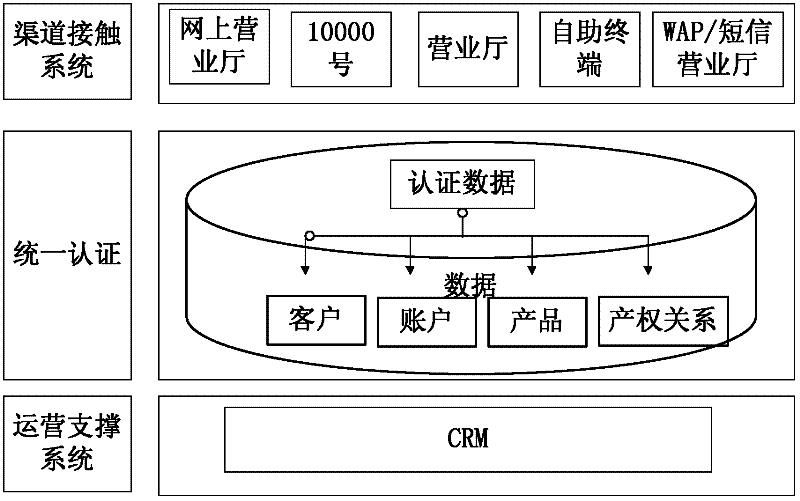

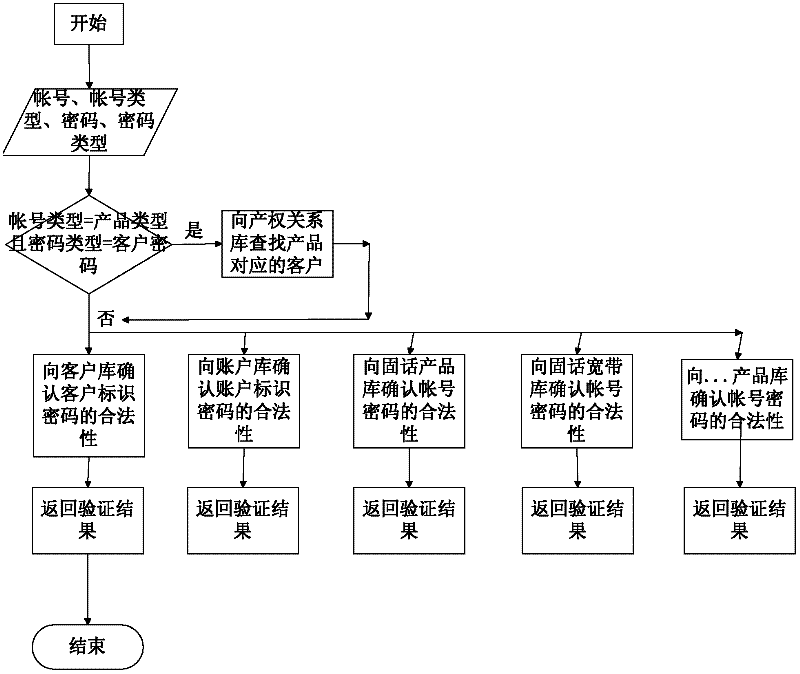

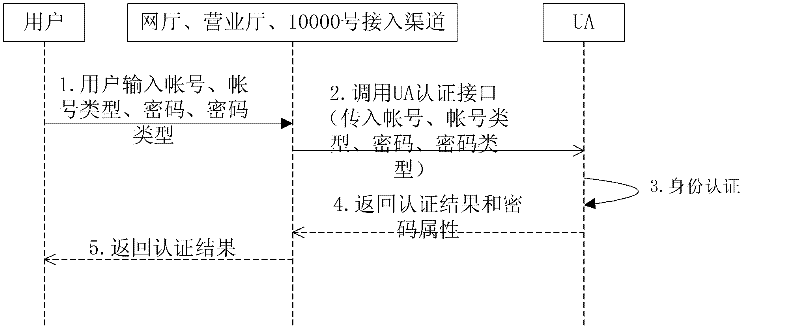

A Method of Realizing Centralized Authentication in Telecommunication Supporting System

InactiveCN102291258AOptimize IT architectureLow costData switching networksTelecommunicationsCustomer centric

A method for realizing centralized authentication in a telecommunications support system: a telecommunications user inputs one or more of the three household information through a telecommunications access channel; each channel contact system sends the three household information and user requests to The unified authentication platform UA performs authentication; the unified authentication platform UA compares the information in the received user's three-account information with the three-account information stored in the UAM, and performs identity authentication; the unified authentication platform UA returns the authentication information to the user. The present invention can promote customer-centered account management: with the rapid development of telecommunication value-added services, customer-centered account management has become a development trend, and it is necessary to integrate multiple account systems; it is also necessary to improve the efficiency of customer-oriented online business halls. Portal status drives the integration of business resources, realizes unified authentication across systems and platforms, and meets the requirements for integration of service interfaces and consistency of customer experience.

Owner:WHALE CLOUD TECH CO LTD

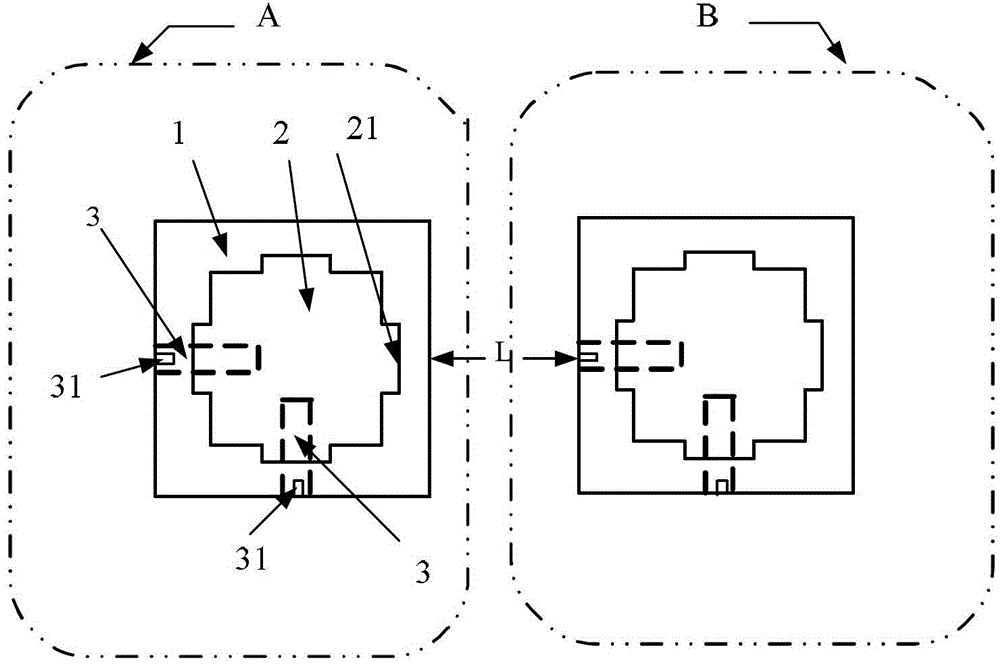

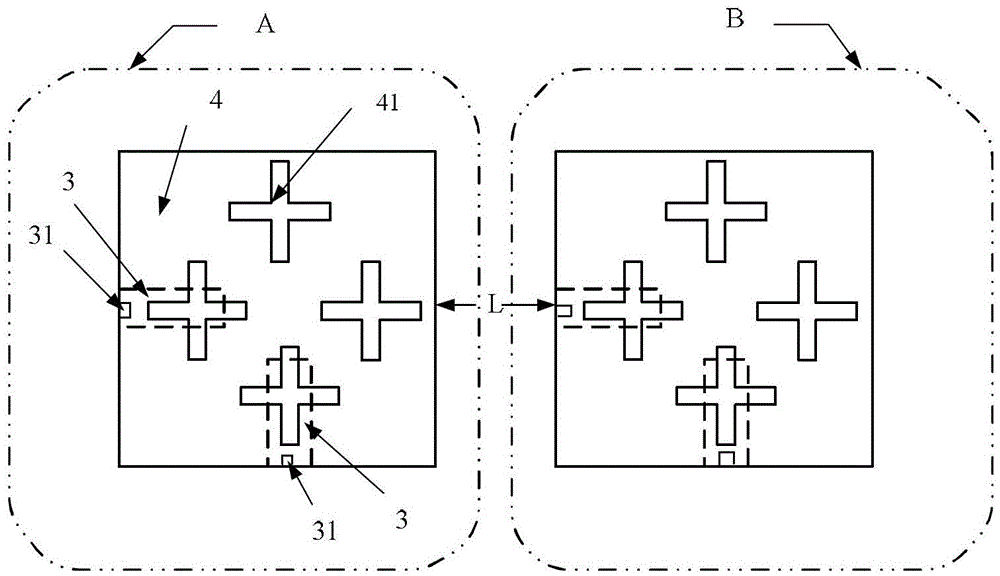

Dual-polarization MIMO (Multiple Input Multiple Output) antenna array

ActiveCN102842756BImproving Impedance BandwidthImprove polarization diversity effectAntenna arraysRadiating elements structural formsDielectric plateMimo antenna

The invention relates to a dual-polarization MIMO (Multiple Input Multiple Output) antenna array comprising two same dual-polarization antenna units. Each antenna unit is as follows: a first square dielectric slab, a second dielectric slab and a grounding plate are overlapped and stacked, a metal radiation patch is arranged on the upper surface of each antenna unit, two micro-strip feeder lines vertical to each other are arranged between the two dielectric plate and are respectively positioned on a middle of two adjacent sides of a square. The two antenna units are arranged on the same horizontal plane, the two opposite sides of the square of one antenna unit and the corresponding sides of the other square are arranged on the same straight line, namely, the squares of the two antenna units are positioned on the two sides of the same rectangle. The distance between the adjacent sides of the squares of the two antenna units is 0.1-100mm. The two antenna units are separated by air or insulated plastic foam. Convex rectangles are formed on the four sides of the metal radiation paster. Symmetrical cross-shaped slots are arranged on the grounding plate. According to the dual-polarization MIMO antenna array, the high performance of the antenna array is ensured, the miniaturization and the high-radiation performance are realized, the impedance bandwidth is improved, and the distance between the antenna units is adjusted, namely, the isolation is adjusted.

Owner:GUILIN UNIV OF ELECTRONIC TECH

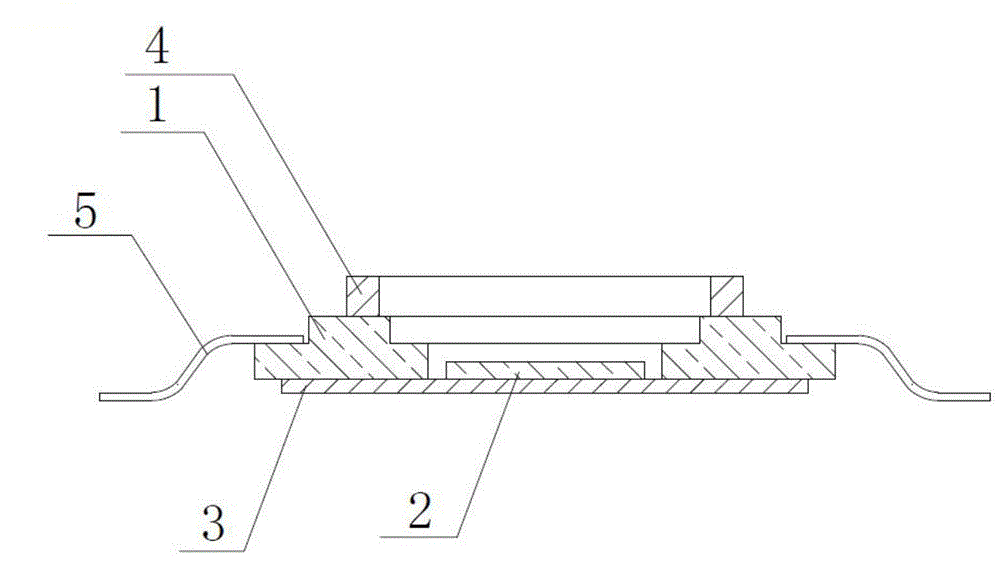

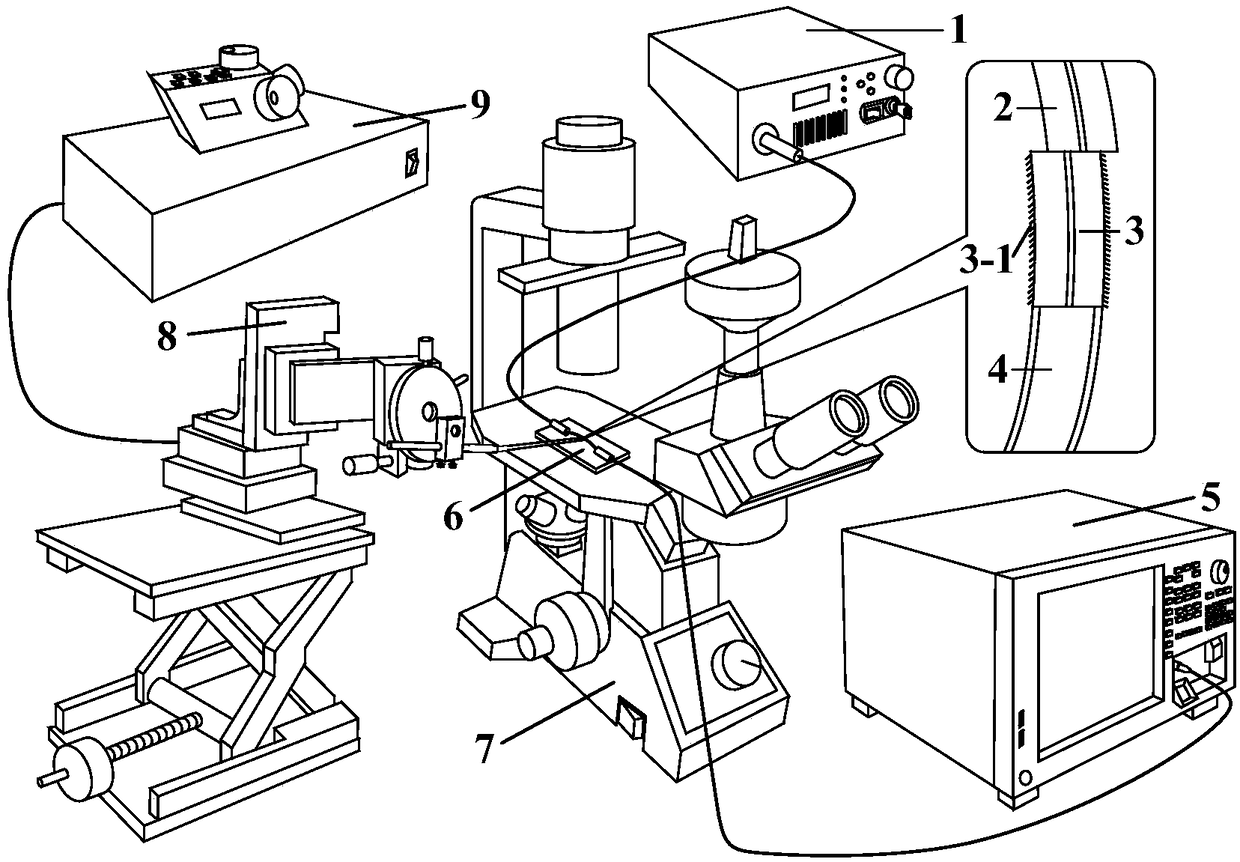

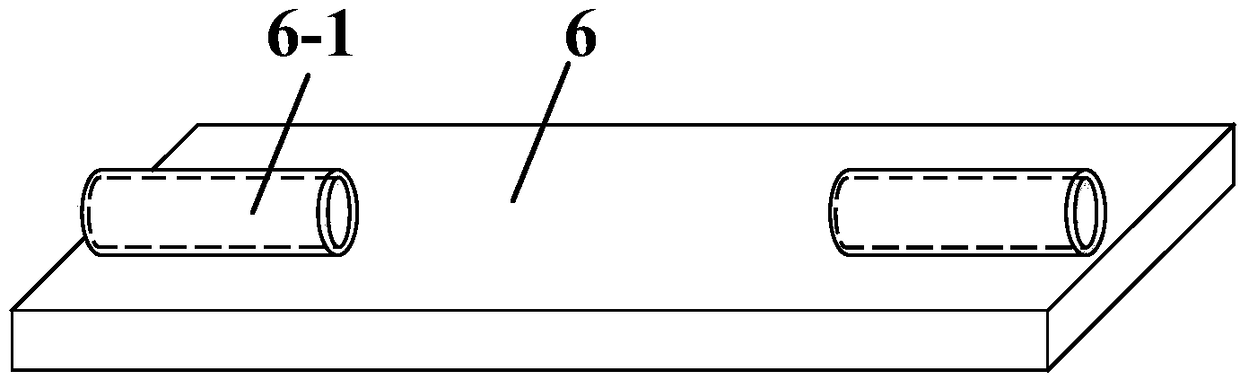

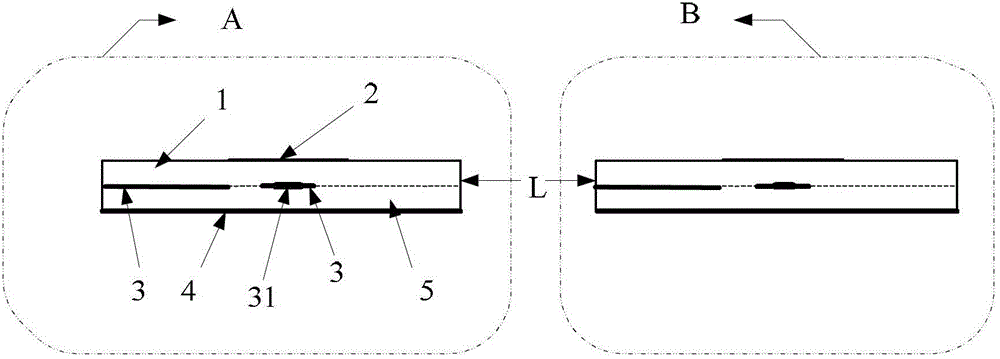

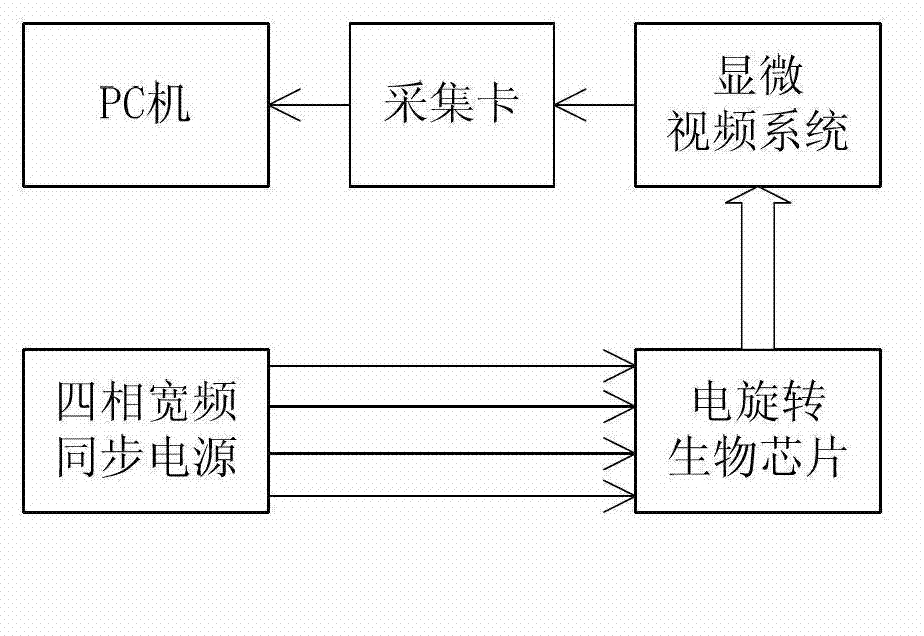

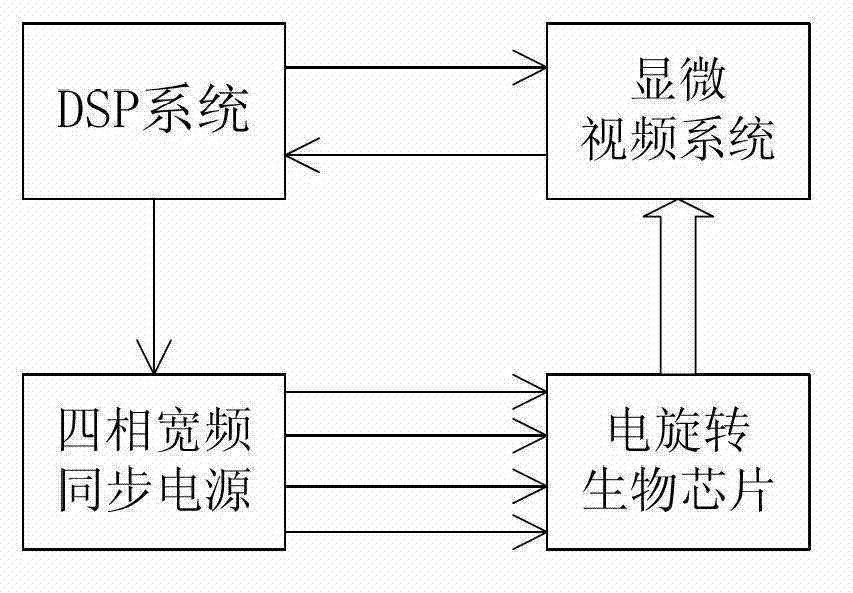

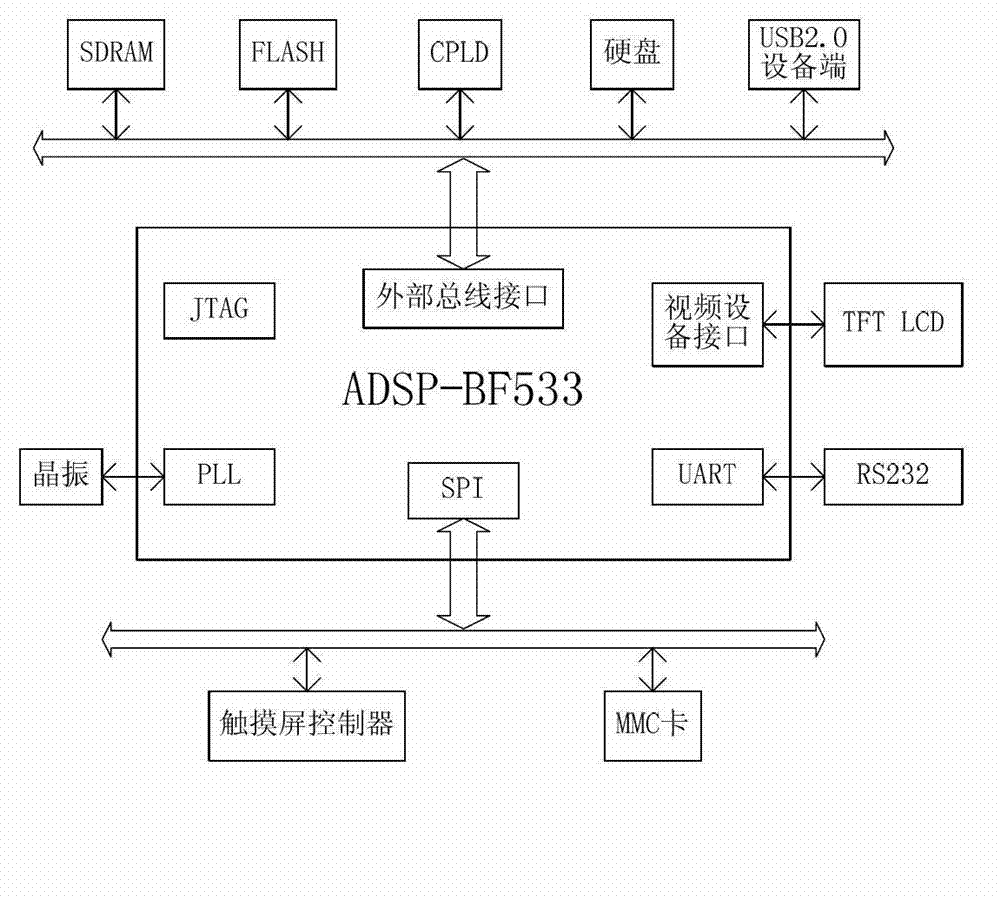

Measure and control device for electrorotation biological chip experiment and experiment system

InactiveCN103048256AMeet miniaturizationMeet the integrationIndividual particle analysisElectricityElectrorotation

The invention discloses an integrated experiment device for an electrorotation biological chip experiment. According to the invention, An experiment system comprises a biological chip experiment operation platform, an electrorotation drive power supply, a microscopic camera system composed of an optical microscope amplification device and an industrial camera, a measurement and control device, and an input display device, wherein the measurement and control device is respectively connected with the microscopic camera system, the electrorotation drive power supply and the input display device; and the output end of the electrorotation drive power supply is connected with a power supply connector of the biological chip experiment operation platform. According to the technical scheme, the microscopic camera system and the drive power supply are relatively independent, the special measurement and control device which replaces a conventional PC machine and a capture card integrates the functions of collecting and processing of image information of the microscopic camera system, and controls the microscopic camera system to take images and the drive power supply to output all parameters of signals; and the whole-process automation of the electrorotation biological chip experiment is realized. Therefore, the development requirements of miniaturization, integration and intelligentization of biological chip experiment equipment are met.

Owner:CHINA JILIANG UNIV

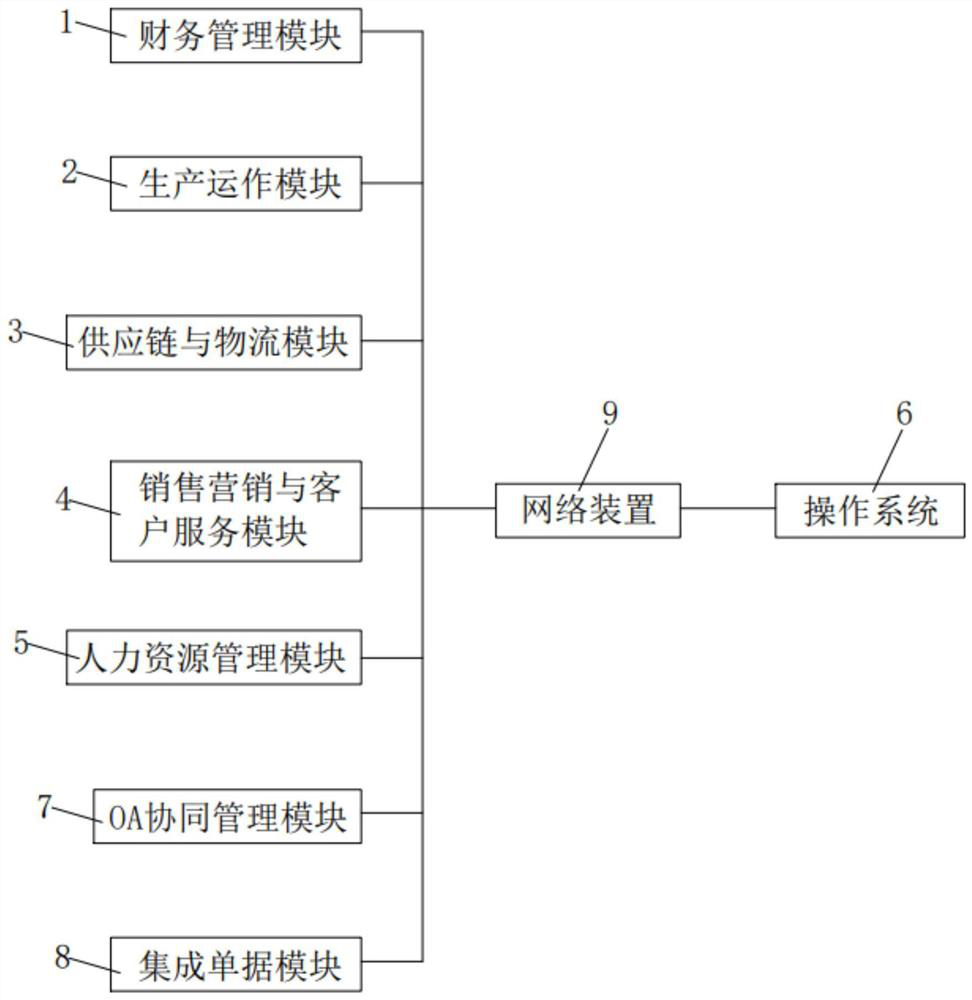

ERP system with OA collaborative function

PendingCN113159622ASolve difficultySolve usabilityOffice automationResourcesLogistics managementOperational system

The invention relates to an ERP system with an OA collaborative function, which comprises a financial management module, a production operation module, a supply chain and logistics module, a sales marketing and customer service module, a human resource management module, an operation system, an OA collaborative management module and an integrated document module; the financial management module, the production operation module, the supply chain and logistics module, the sales marketing and customer service module, the human resource management module, the OA collaborative management module and the integrated document module are respectively connected with the operation system through a network device. The integrated document module supports single piece management and batch-to-batch production mode through document circulation; and the OA collaborative management module is used for document sending management, document receiving management, workflow management, basic setting, to-do work, work query, process log, overtime statistics and completion data archiving. The OA collaborative management module is comprehensively introduced into the ERP system, so that the production cost is reduced, and the business decision and management capability of an enterprise is improved.

Owner:嘉兴佳士友软件有限公司

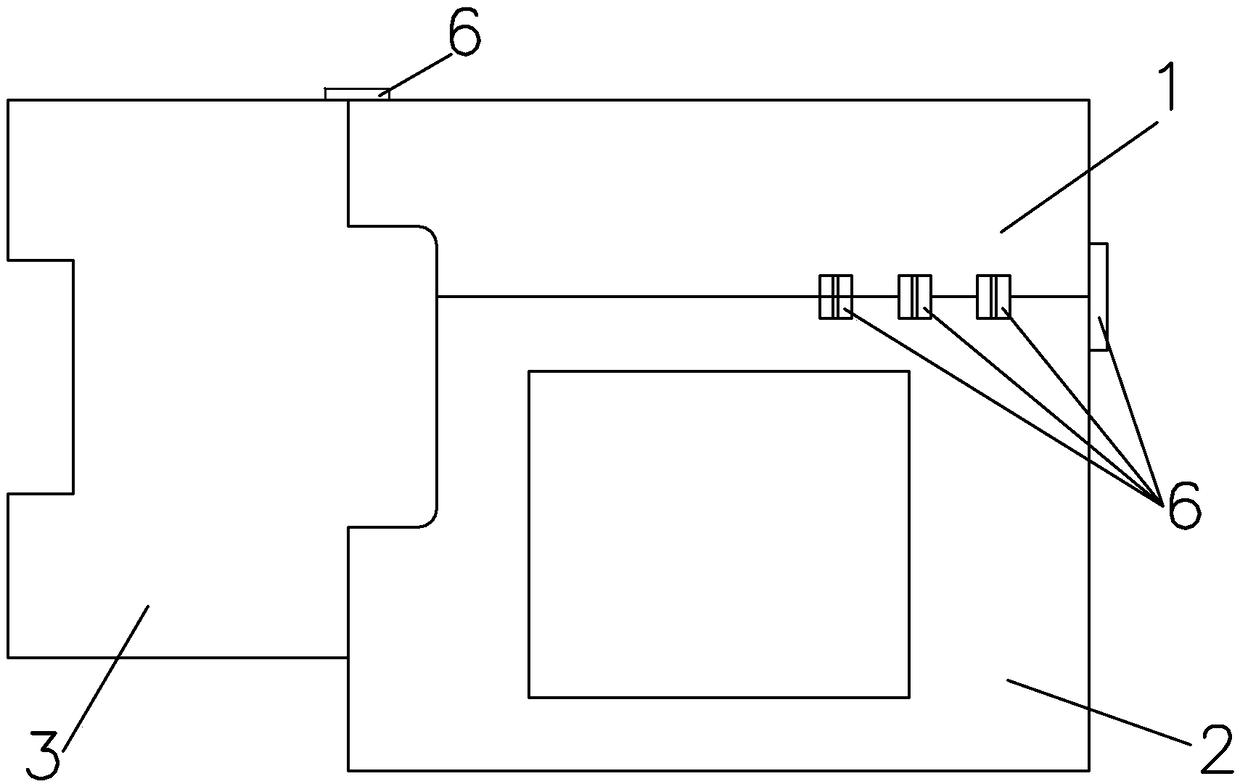

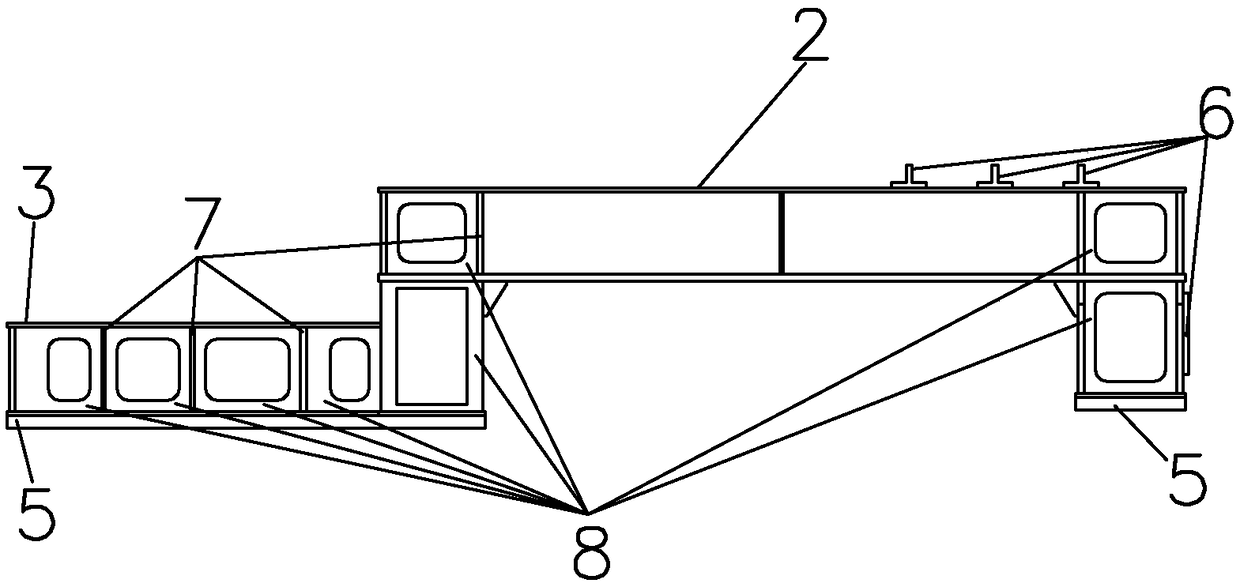

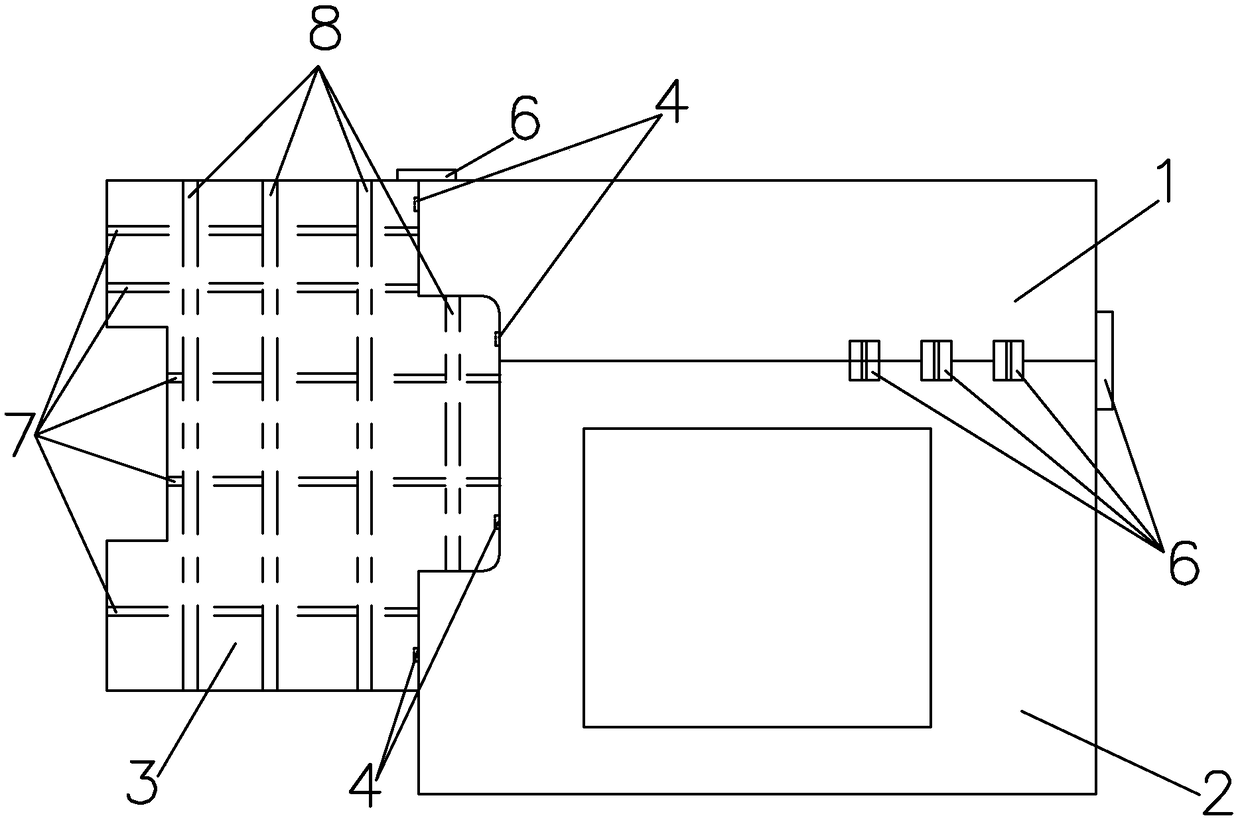

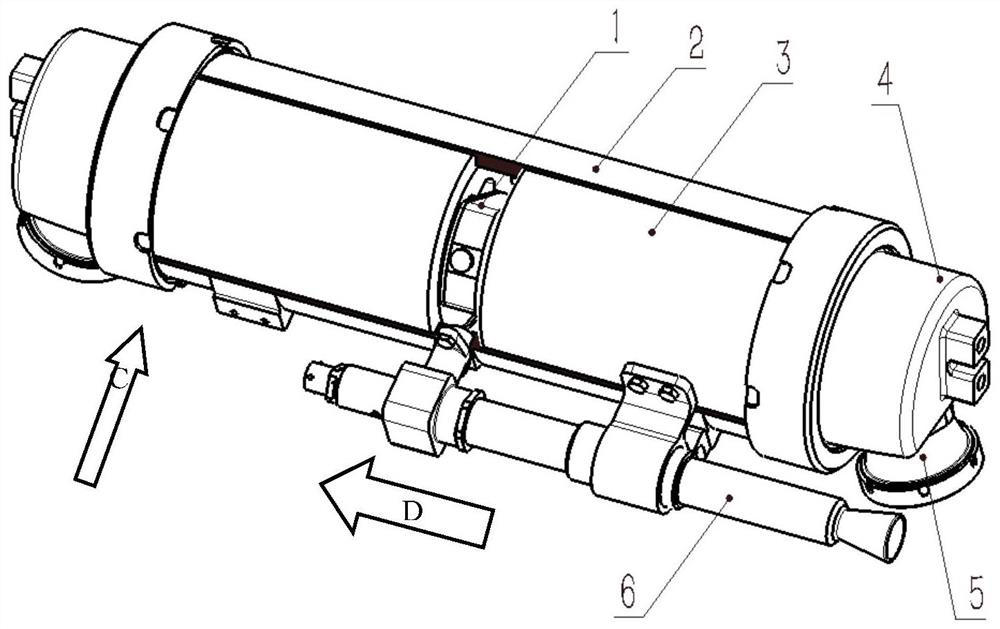

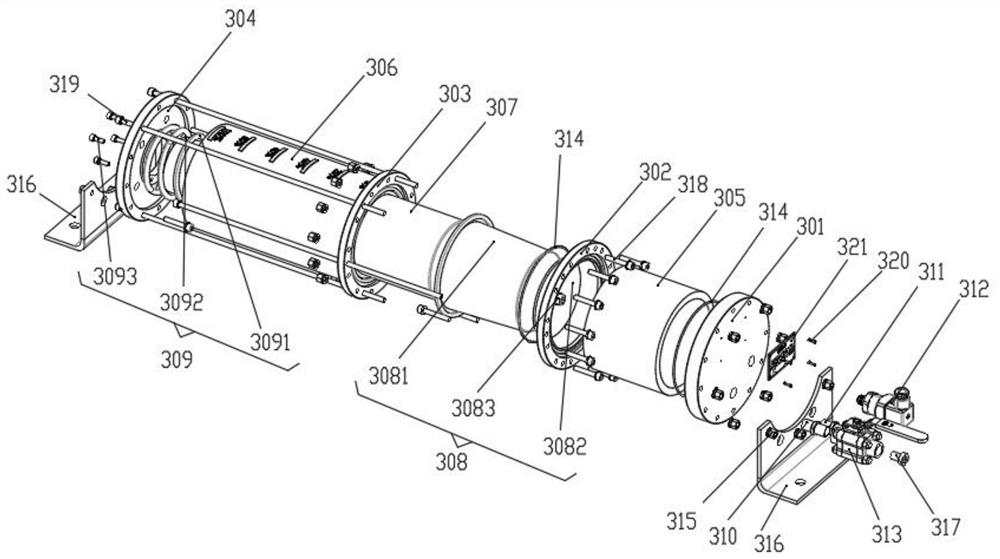

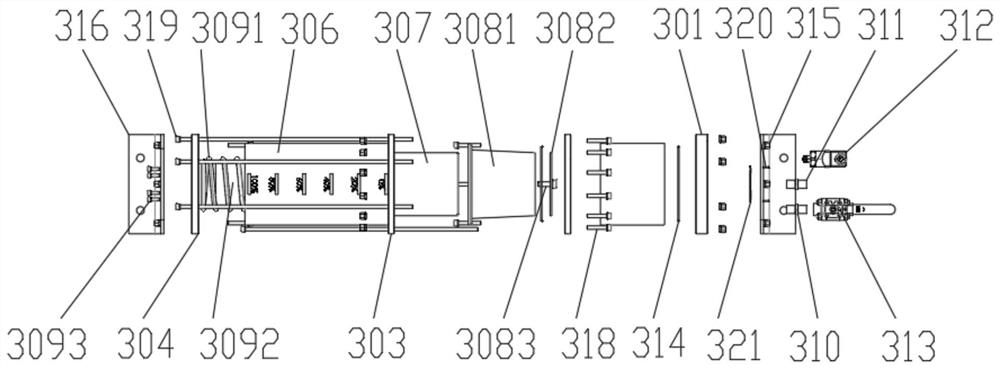

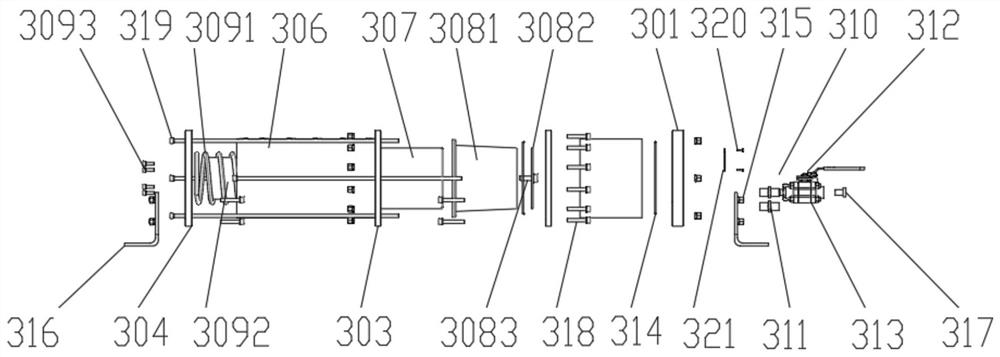

A marine main unit modular integrated rack with steam emission function

PendingCN109204761AMeet the requirements of compactnessMeet the requirements of vibration damping installationPower plants being motor-drivenPropulsive elementsReduction driveEngineering

The invention relates to a marine main unit integrated rack, particularly a marine main unit modular integrated rack with a steam emission function. To overcome a problem that exist marine main unit frame structures can not meet the requirements of compactness, integration, modularization and vibration damping installation, the marine main unit modular integrated rack having a steam emission function is provided and includes a high pressure steam turbine frame, a low-pressure steam turbine frame and a reducer frame. The high-pressure steam turbine frame is connected with the low-pressure steamturbine frame. The reducer frame is respectively connected with the high-pressure steam turbine frame and the low-pressure steam turbine frame, each frame is connected by a connector, the central part of the low-pressure steam turbine frame is provided with a through hole, the upper part of the through hole is connected with the steam turbine exhaust end, and the lower part is used for connectingwith the condenser. Each frame comprises two upper and lower panels; a reinforcing rib is arranged between the panels; and a vibration isolator is also arranged at the bottom of the frame. The modular integrated rack is used for supporting and placing the marine main unit.

Owner:中国船舶重工集团公司第七0三研究所

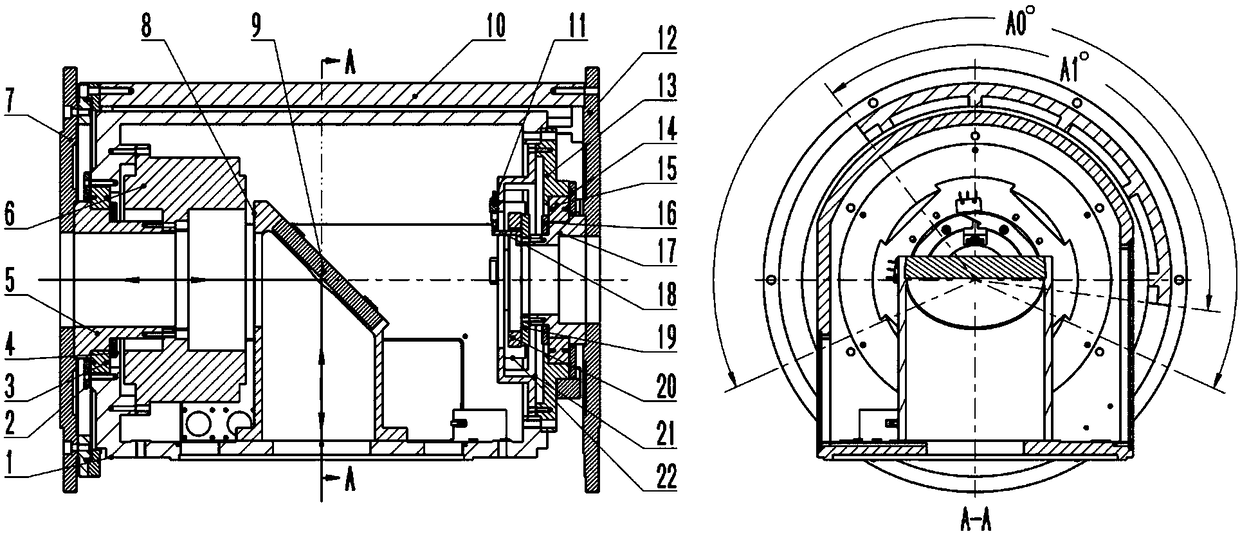

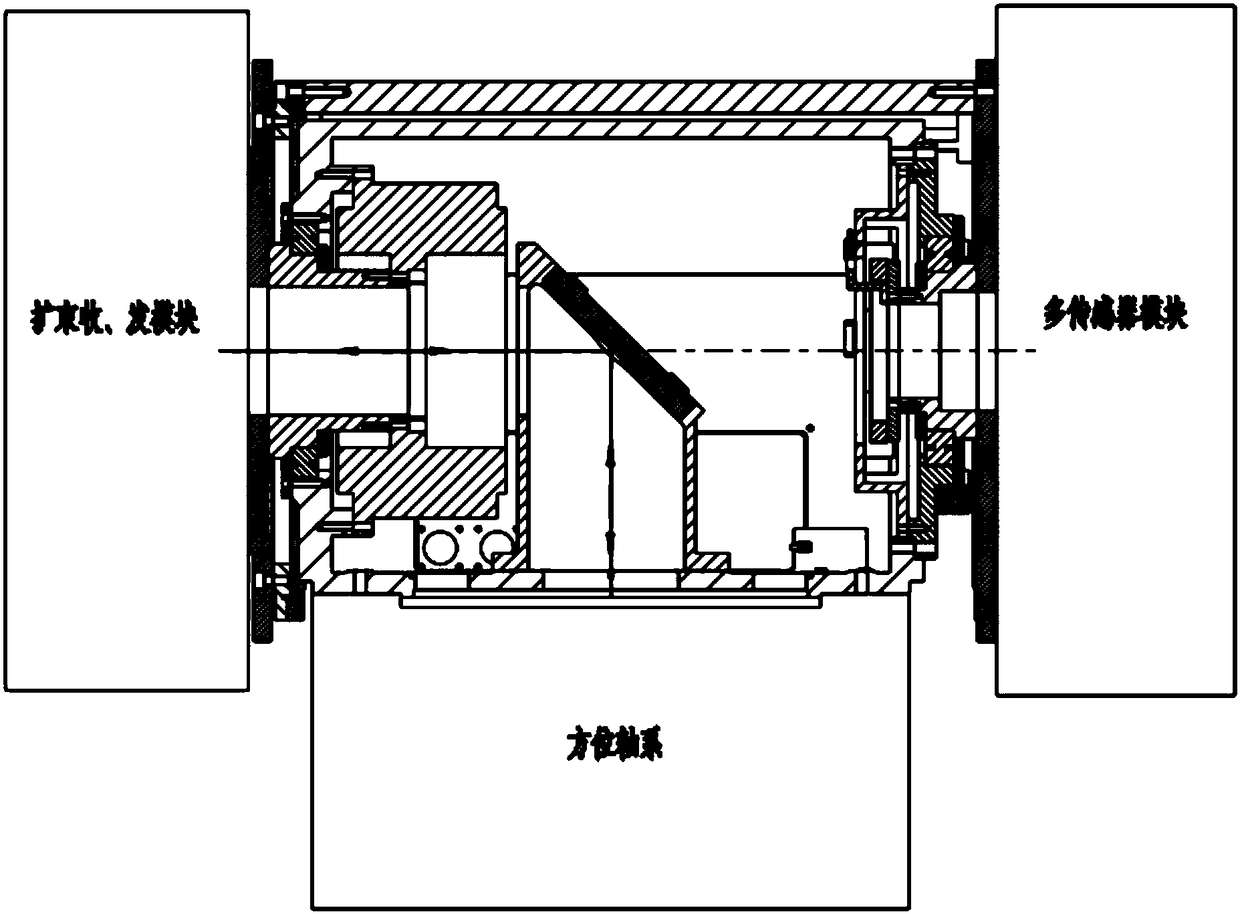

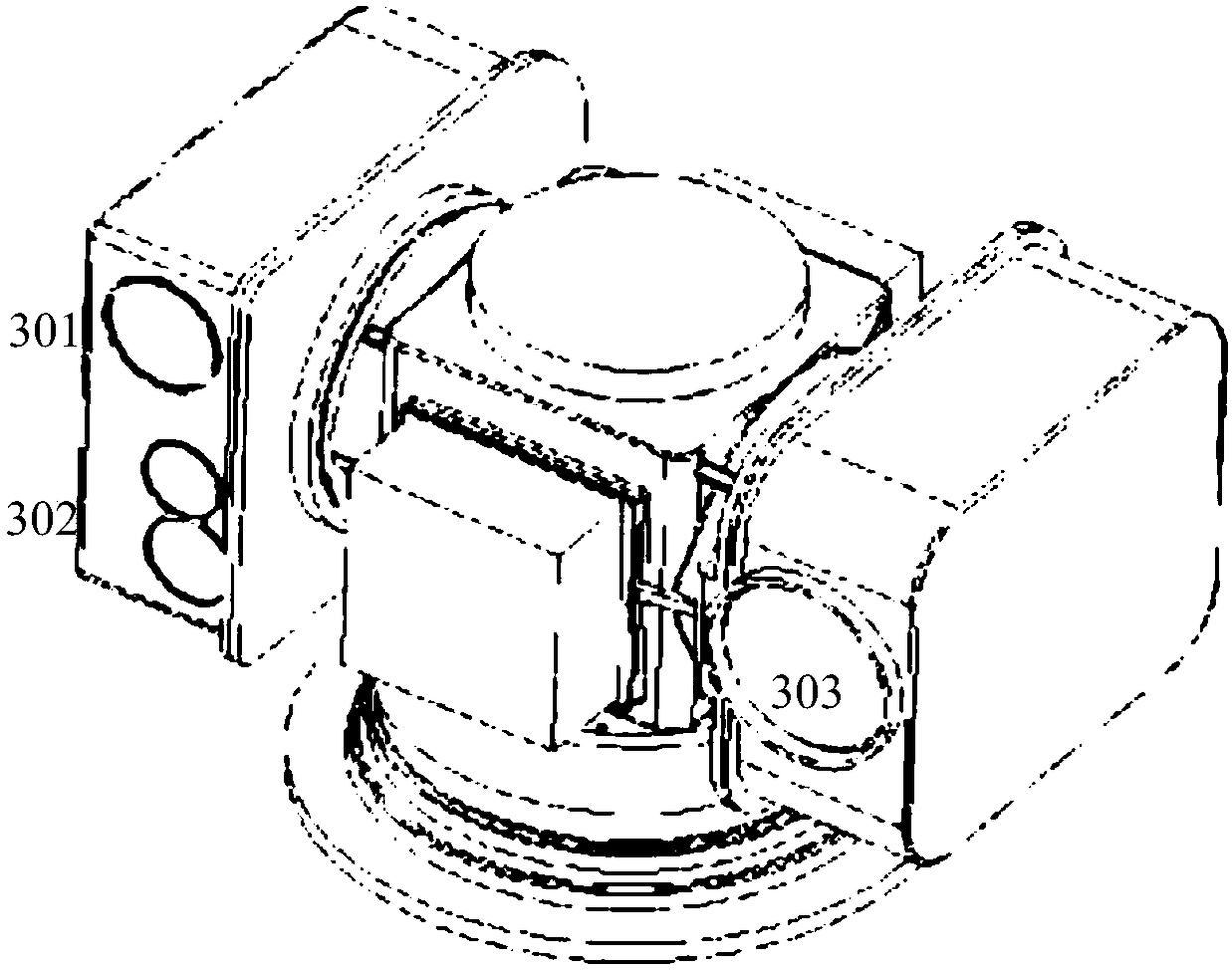

Rotating mechanism of intermediate support of T-shaped turntable

ActiveCN108361508AQuick installationQuick releaseStands/trestlesElectromagnetic transceiversMultiple sensorComputer module

The invention discloses a rotating mechanism of an intermediate support of a T-shaped turntable. The rotating mechanism is mainly composed of the intermediate support, a left shaft system and a rightshaft system, a circular ring connecting plate and a reflecting mirror module. The left shaft system and the right shaft system are connected with a left flange plate and a right flange plate to realize synchronous rotation through the circular ring connecting plate with a specific angle; and a reflecting mirror is arranged on a light path inside the intermediate support to change the transmissiondirection of light beam and ensure the transmission efficiency of the light beam to the greatest extent. The whole structure can realize the synchronous rotation of left shaft system and a right shaft system in the specific angle only by one motor without affecting the channel of light; the left shaft system is responsible for driving rotation, the right shaft system is responsible for measuringangles, and a reasonable layout is achieved; in addition, the left and right end loads can be easily removed and installed from the end faces of the left and right flange plates, and the degree of modularization is high. The structure can be applied to ATP systems with multiple sensor modules and emitting and incidence in a common light path.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Water-soluble fertilizer

InactiveCN112279731AReasonable collocationMeet growth needsMagnesium fertilisersAlkali orthophosphate fertiliserMicrobial agentPhosphate

The invention discloses a water-soluble fertilizer and a preparation method thereof. The water-soluble fertilizer is prepared from the following raw material in parts by weight: 20-40 parts of urea, 20-40 parts of potassium dihydrogen phosphate, 20-40 parts of potassium chloride, 2-8 parts of calcium nitrate, 2-8 parts of magnesium sulfate, 1-3 parts of ferrous sulfate, 1-3 parts of zinc sulfate,1-3 parts of borax, 1-5 parts of fulvic acid and 0.1-0.3 part of a microbial agent. The water-soluble fertilizer disclosed by the invention is reasonable in component matching and sufficient in nutrition, particularly has various promotion effects on the growth of plants by virtue of the microbial agent, and has very good fertilizer efficiency.

Owner:广西晋有有机肥有限公司

Multifunctional rocket based on rocket ejection seat

PendingCN113970278AAchieve openAchieve closureAircraft ejection meansSelf-propelled projectilesCombustion chamberEjection Seats

The invention provides a multifunctional rocket based on a rocket ejection seat. The multifunctional rocket comprises a combined lifesaving rocket and a long exhaust nozzle assembly, wherein the long exhaust nozzle assembly is arranged beside the combined lifesaving rocket and is fixedly connected with the combined lifesaving rocket, and the long exhaust nozzle assembly comprises an electric exploder, an air-entraining connector, a blocking plug and a long exhaust nozzle; the air-entraining connector adopts an air channel of a three-way structure, one end of the air-entraining connector is fixedly connected with the combined lifesaving rocket, the blocking plug is placed in the air-entraining connector, a gap air channel is reserved at one end of the long exhaust nozzle so that gas generated in a working combustion chamber of the lifesaving rocket can enter, and the other two ends of the air-entraining connector are connected with the long exhaust nozzle and the electric exploder respectively. When the electric exploder works to generate fuel gas, the fuel gas pushes the blocking plug through the air-entraining connector and moves along an inner cavity of the air entraining connector until the fuel gas makes contact with the long exhaust nozzle, at the moment, the fuel gas in the combustion chamber is blocked by the blocking plug, and the long exhaust nozzle stops working. The multifunctional rocket is simple in structure, quick in response and high in lifesaving success rate.

Owner:CHINA AVIATION LIFESAVING INST

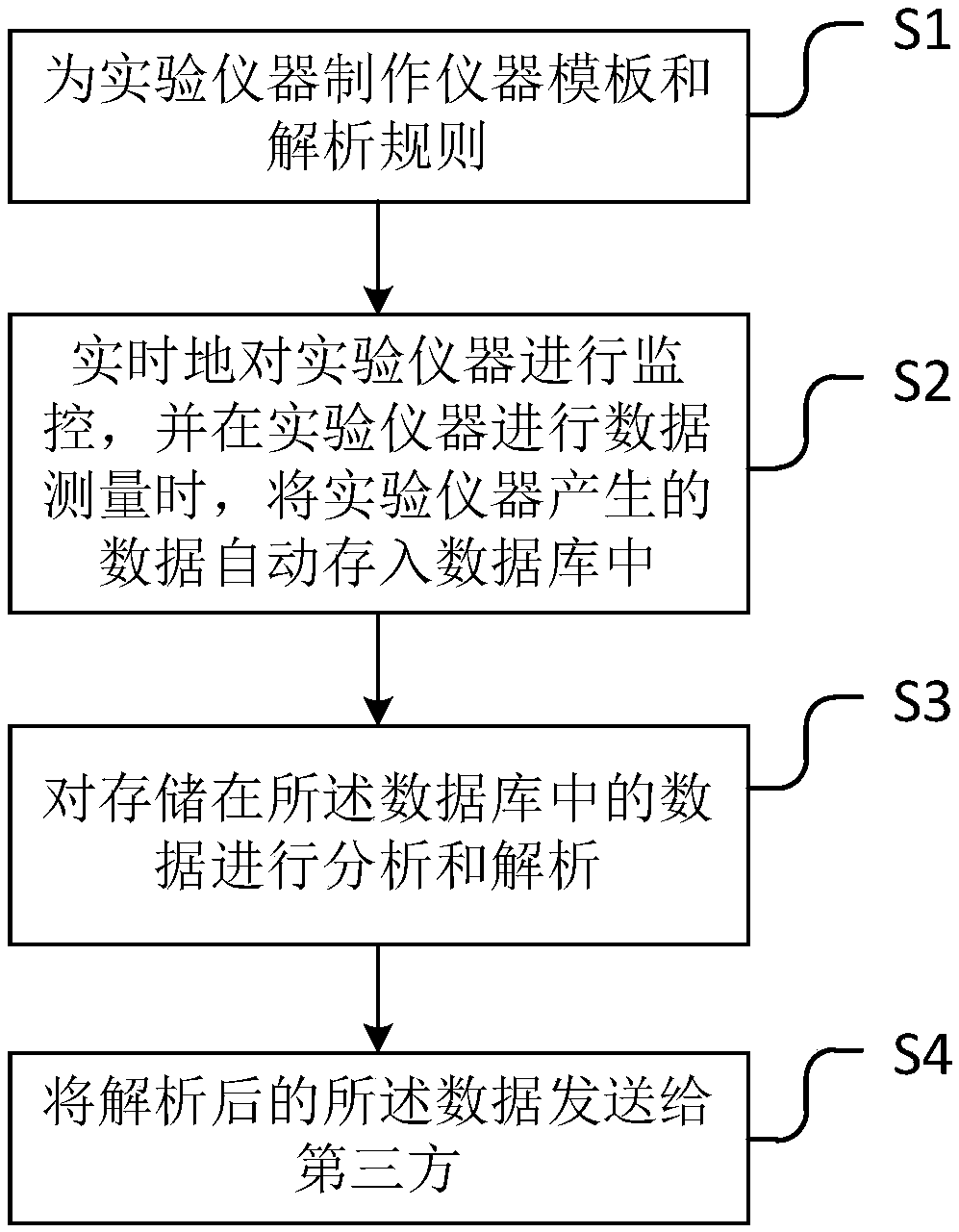

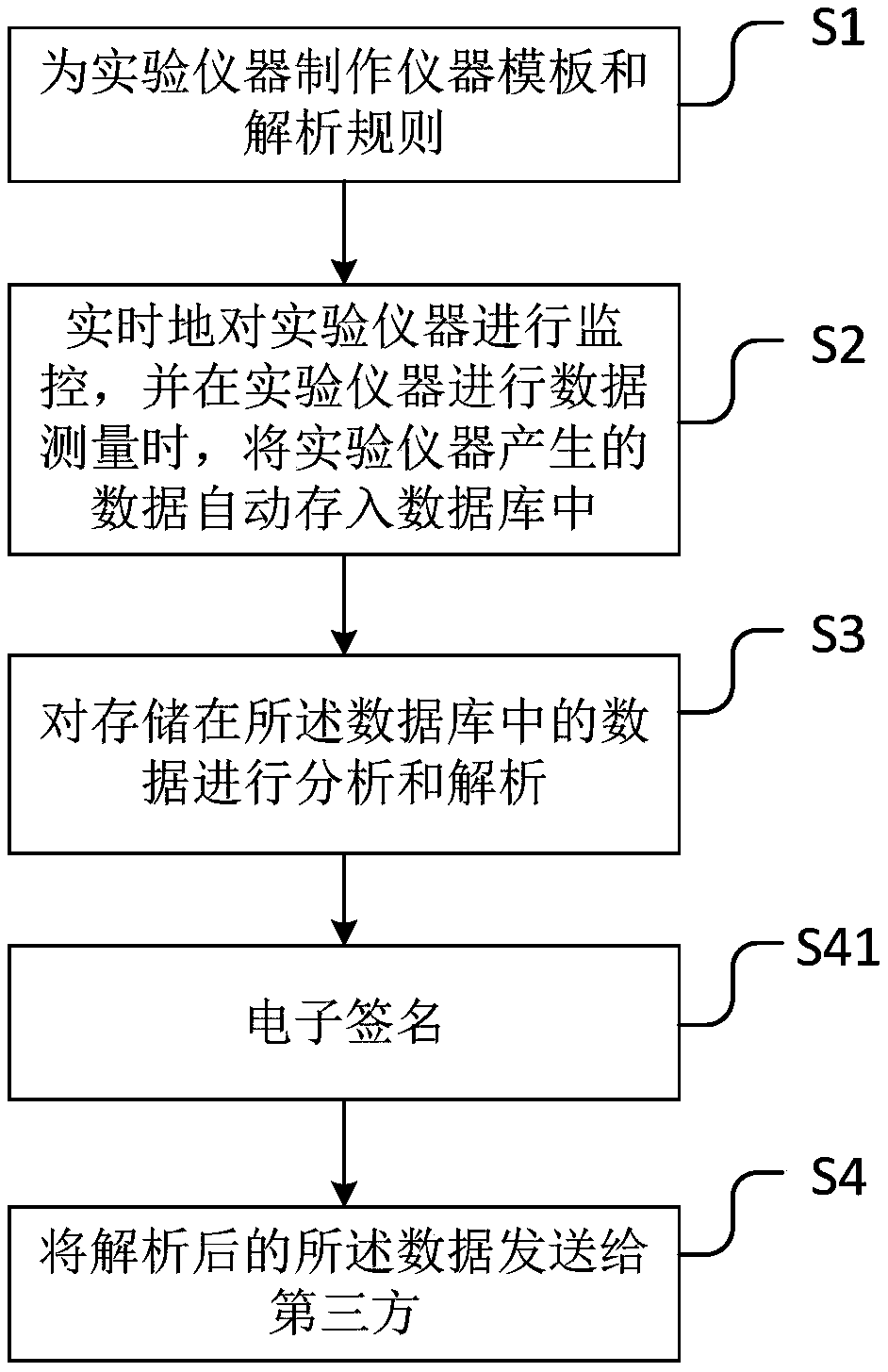

Method for sending experimental data in real time, electronic equipment and storage medium

ActiveCN109525638AData integrity meetsAvoid lossDatabase management systemsUser identity/authority verificationThird partyStorage security

The embodiment of the invention relates to a method for sending experimental data in real time, electronic equipment and storage medium. The method comprises the steps of producing an instrument template and an analysis rule for an experimental apparatus; monitoring the experimental apparatus in real time, and when the experimental apparatus performs data measurement, automatically storing data generated by the experimental apparatus into a database; analyzing the data stored in the database; and sending the analyzed data to a third party. According to the method for sending the experimental data in real time, the electronic equipment and the storage medium provided by the embodiment of the invention, the third party can conveniently acquire the experimental data, and ensures the storage security of the experimental data.

Owner:苏州创腾软件有限公司

Differential pressure compensator of underwater hydraulic system

PendingCN112594256AReduce manufacturing costChange the pre-pressure at any timePipeline expansion-compensationFluid-pressure actuator componentsMiniaturizationPlunger

The invention discloses an underwater hydraulic system differential pressure compensator which is arranged in an installation cabin of a desilting robot and comprises a hydraulic oil side sealing cover, a hydraulic oil side telescopic leather bag sealing flange, a water passing side telescopic leather bag sealing flange and a base, a hydraulic oil side PC sleeve is arranged on the side wall of thehydraulic oil side telescopic leather bag sealing flange and the side wall of the hydraulic oil side sealing cover, the hydraulic oil side telescopic leather bag sealing flange is fixedly connected with the water passing side telescopic leather bag sealing flange, and a water passing side PC sleeve is arranged on the side wall of the water passing side telescopic leather bag sealing flange and the side wall of the base, sliding plungers are connected with the hydraulic oil side PC sleeve and the water passing side PC sleeve in a sliding mode, the invention provides a series of products with the random volume compensation from 2L to 16L, the pre-pressure can be changed at any time, the structure is simple, the manufacturing cost is low, the size is small, the technical universality is high, batch production can be achieved through a prefabricated grinding tool, the product quality is reliable, and the production efficiency is high, and the requirements of integration and miniaturization are achieved.

Owner:POWERCHINA XIBEI ENG +1

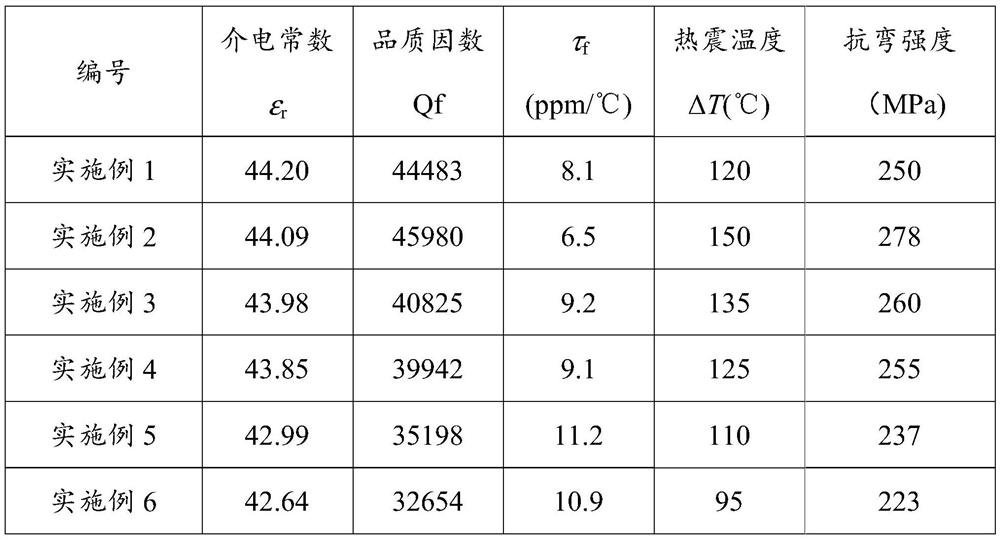

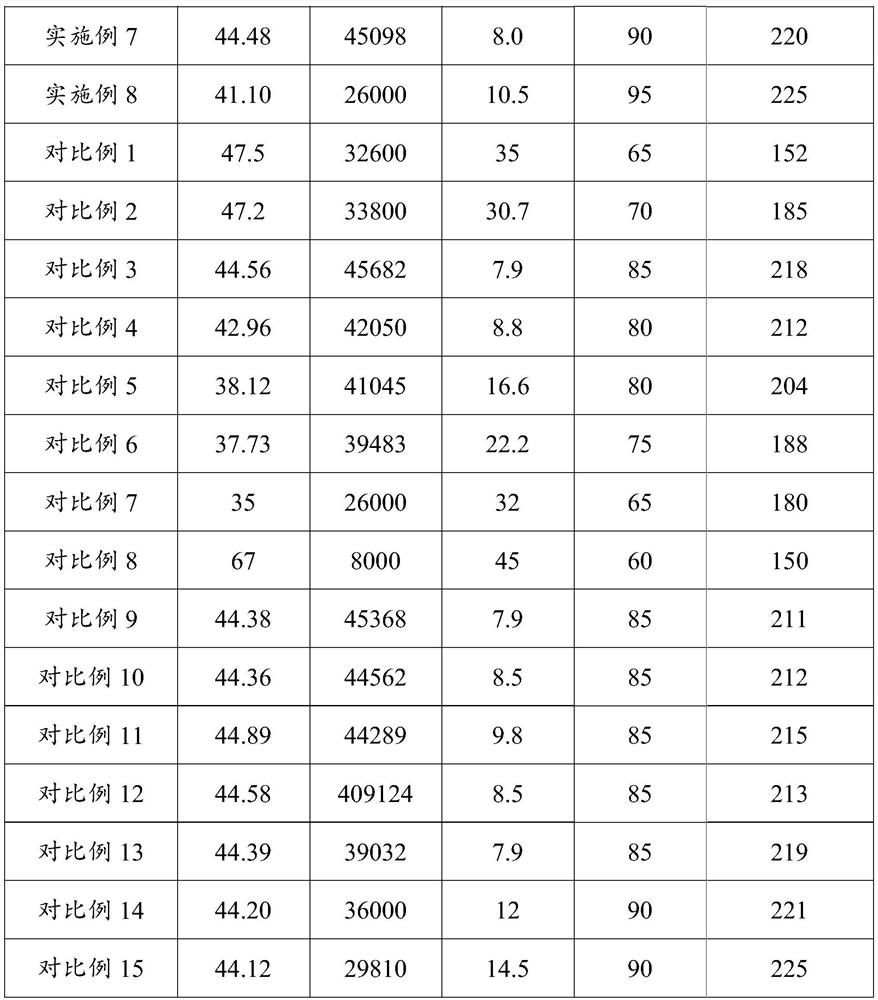

Cordierite-doped multiphase microwave dielectric ceramic material as well as preparation method and application thereof

InactiveCN112876239AImprove performanceSatisfy the continuous trend towards high frequencyDielectricMiniaturization

The invention provides a cordierite-doped multiphase microwave dielectric ceramic material as well as a preparation method and application thereof, and relates to the technical field of 5G microwave dielectric ceramic materials. The cordierite-doped multiphase microwave dielectric ceramic material provided by the invention comprises a main material and a modified doping agent, and the main material is CaTiO3-SmAlO3; the modified doping agent is cordierite, the composition of the cordierite is 2MgO. 2Al2O3. 5SiO2, and the addition amount of the cordierite in the multiphase microwave dielectric ceramic material is 0.5%-2%. The multiphase microwave dielectric ceramic material provided by the invention has good comprehensive performance, the dielectric constant epsilon r of the multiphase microwave dielectric ceramic material can reach 45, the quality factor Qf is greater than or equal to 45,000, the bending strength is greater than or equal to 278 MPa, the thermal shock temperature is 150 DEG C, the reliability is higher, the requirements of high frequency, miniaturization and multi-functionalization of microwave elements can be met, the multiphase microwave dielectric ceramic material can also adapt to severe working environments, and the multiphase microwave dielectric ceramic material has good application prospects.

Owner:无锡市高宇晟新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com