Multi-die high-power diode shell and manufacturing method thereof as well as chip packaging method

A high-power diode and multi-die technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of low flexibility, low reliability, and high cost, and achieve reliable mechanical strength and heat dissipation performance Excellent, excellent heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

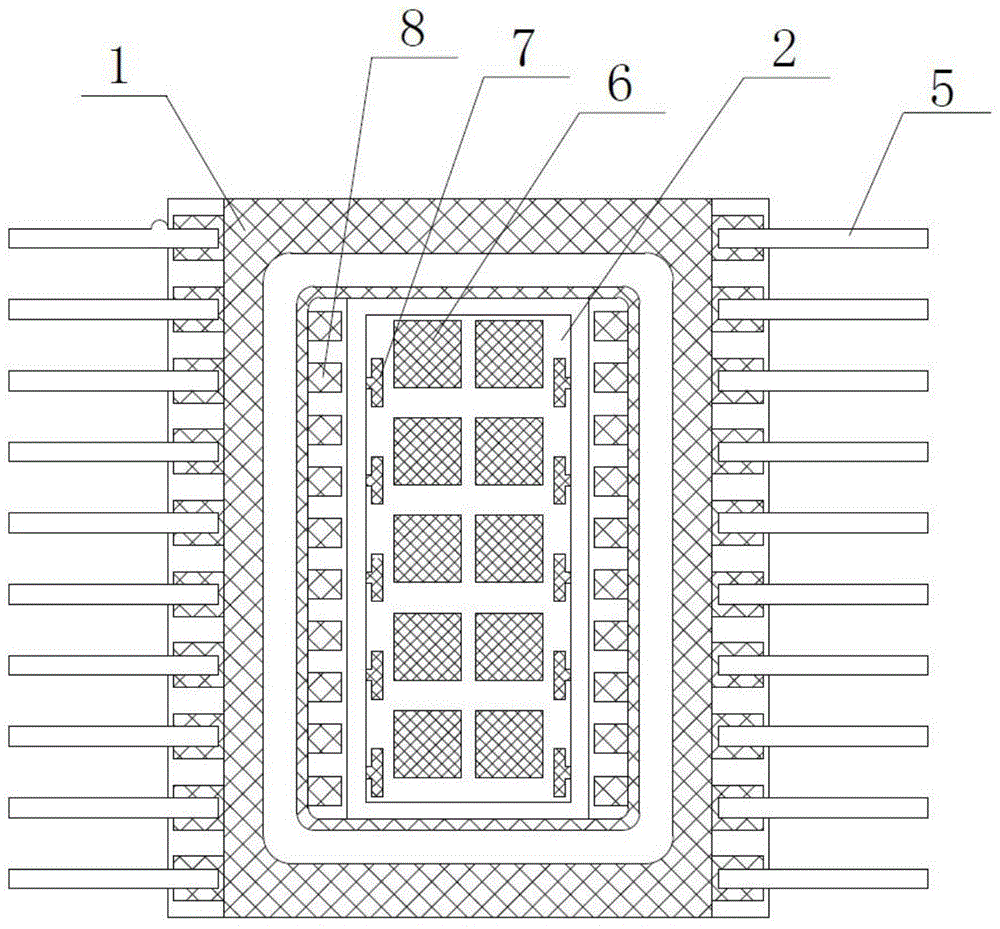

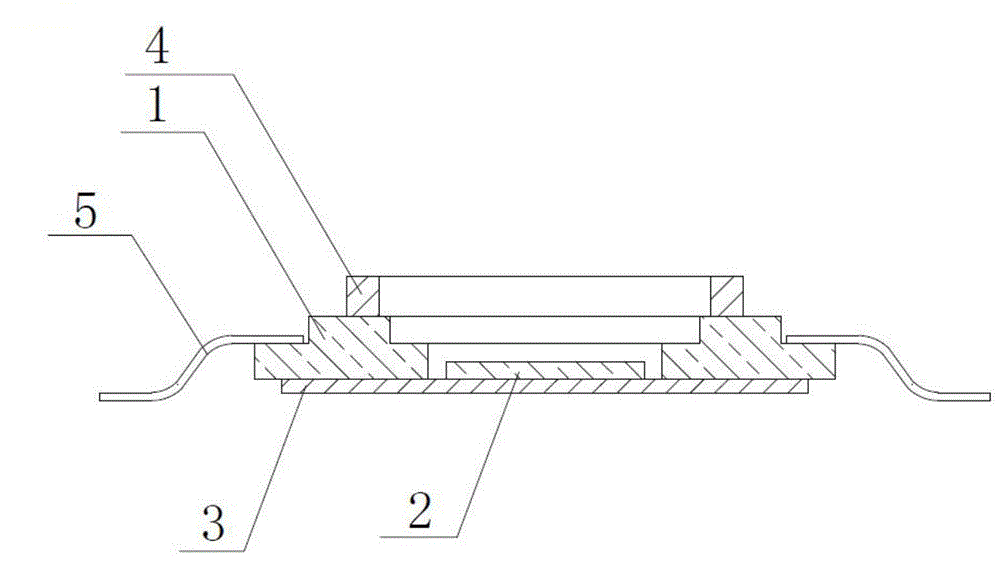

[0045] The preparation method of the multi-tube-core high-power diode casing of the present invention adopts high-temperature co-fired ceramic production technology and brazing technology. On the precise and dense AlN raw ceramic tape with a size of 180mm×180mm×0.2mm, the required circuit pattern and solderable metallization layer are produced by using precision conductive paste printing, blocking paste printing and other processes, and precision printed wiring The minimum line width is 100μm, and the minimum wiring spacing is 150μm; use laser cavity opening, lamination and other processes to produce green ceramic sheets with specific cavities and shapes; use high-precision temperature-controlled furnaces to sinter at high temperatures under certain sintering process conditions. Shaped high-temperature co-fired ceramic substrate and ceramic frame; the interconnection between ceramic components and metal components is realized through brazing technology, and a high-reliability s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com