A marine main unit modular integrated rack with steam emission function

A main engine unit, modular technology, applied in the direction of motor-driven engine, ship propulsion, vessel components, etc., can solve the problem that the frame structure of the marine main engine unit cannot meet the requirements of compactness, integration, modularization and vibration reduction installation, etc. To save space, ensure high integration, and meet the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

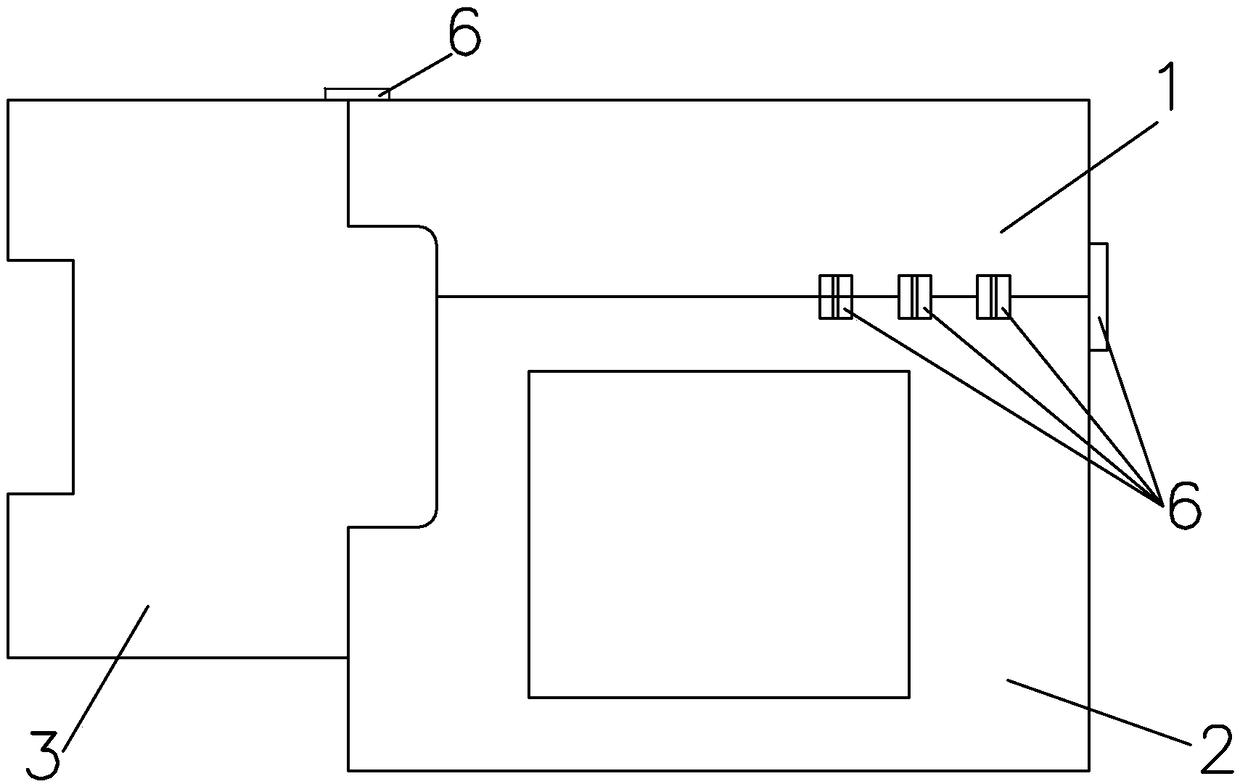

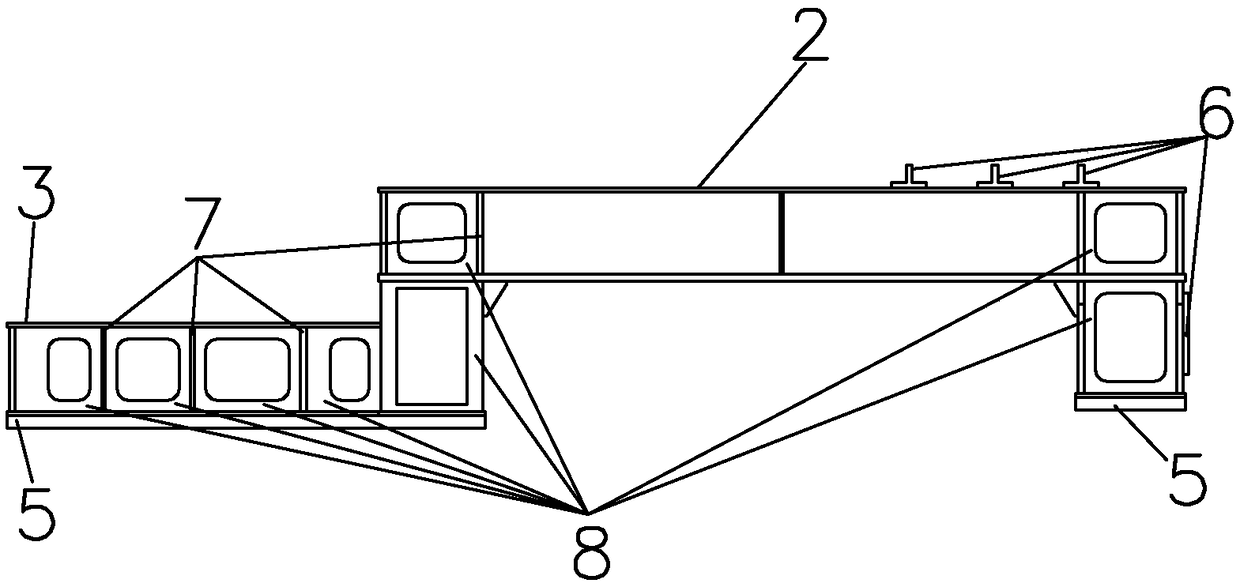

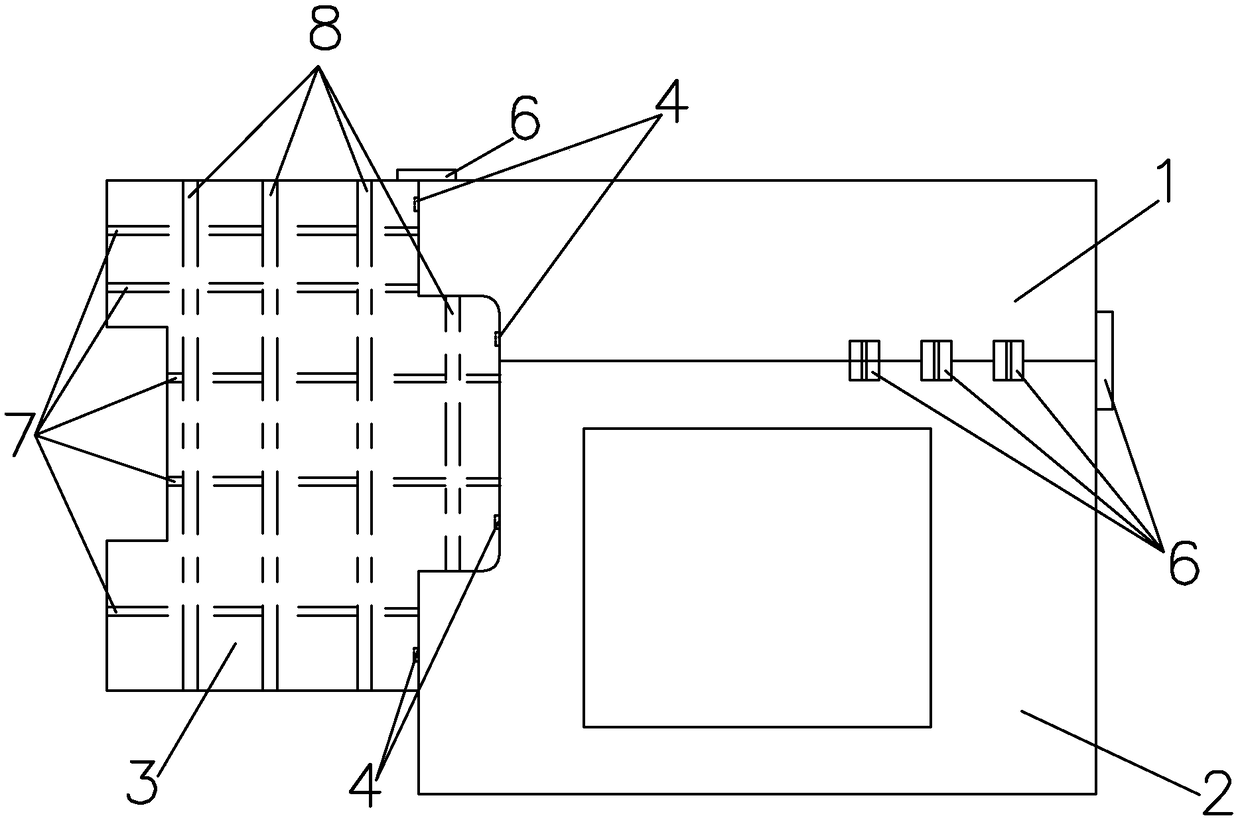

[0009] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a marine main unit modular integrated frame with steam discharge function described in this embodiment, the integrated frame includes a high-pressure steam turbine frame 1, a low-pressure steam turbine frame 2 and a reducer frame 3, a high-pressure steam turbine Frame 1 is connected with low-pressure steam turbine frame 2, reducer frame 3 is respectively connected with high-pressure steam turbine frame 1 and low-pressure steam turbine frame 2, and each frame is connected through connecting piece 4, and low-pressure steam turbine frame 2 There is a through hole in the center part of the through hole, the upper part of the through hole is connected with the steam exhaust end of the steam turbine, and the lower part is used to connect with the condenser. A vibration isolator 5 is also provided at the bottom of the frame.

specific Embodiment approach 2

[0010] Specific implementation mode two: combination Figure 1 to Figure 3 This embodiment will be described. In this embodiment, a marine main unit modular integrated frame with steam discharge function is described. The steam side of the through hole of the low-pressure steam turbine frame 2 is provided with a heat insulation layer. Other components and connections are the same as those in the first embodiment.

[0011] Such a design can effectively avoid damage to the interface caused by the steam discharged from the steam turbine.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination Figure 1 to Figure 3 This embodiment is described. In this embodiment, a modular integrated frame of a marine main unit with a steam discharge function is provided, and a supplementary plate 6 is provided at the joint of every two frames. Other components and connections are the same as those in the second embodiment.

[0013] Such a design can increase the stability of the connection between the two racks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com