Mixed-flow turbocharger variable nozzle ring

A turbocharger, nozzle ring technology, applied in the direction of machine/engine, engine components, internal combustion piston engine, etc., to achieve sensitive operation, smooth and good transition, and improve the effect of internal flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

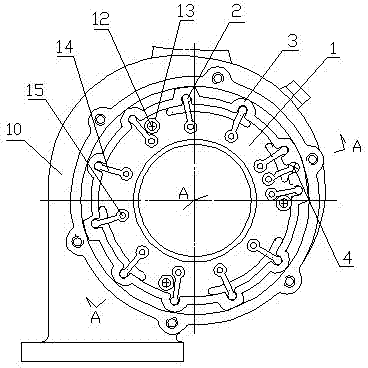

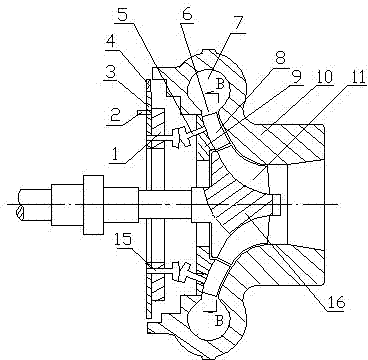

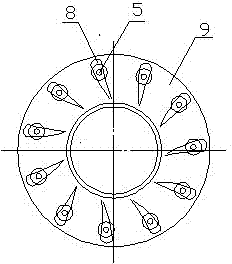

[0035]The organization of the inlet and outlet airflow of the improved mixed-flow turbocharger nozzle ring is optimized through the design of the flow channel of the turbine casing and the application of three-dimensional blades, aiming at the air leakage loss and complex structure caused by the external crank-link mechanism , and the problems of low transmission efficiency of the built-in space four-bar mechanism are solved by designing a built-in nozzle ring actuator in the present invention. The blades of the nozzle ring are also changed from the original symmetrical or aerodynamic blades to adjustable anti-spherical concentric arc-shaped two-dimensional or three-dimensional curved blades. The specific implementation of the mixed-flow turbocharger nozzle ring involved in the present invention is set forth below in conjunction with the accompanying drawings: when the operating conditions of the engine change, the pneumatic actuator or electric actuator acts on the rocker asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com