Shifting fork type telescopic pin mobile mechanism for crane

A plug-in mechanism and telescopic pin technology, which is applied to cranes and other directions, can solve the problems of high machining accuracy, high heat treatment requirements, and complicated working conditions, and achieve high efficiency requirements, simple and compact structure, and stable and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

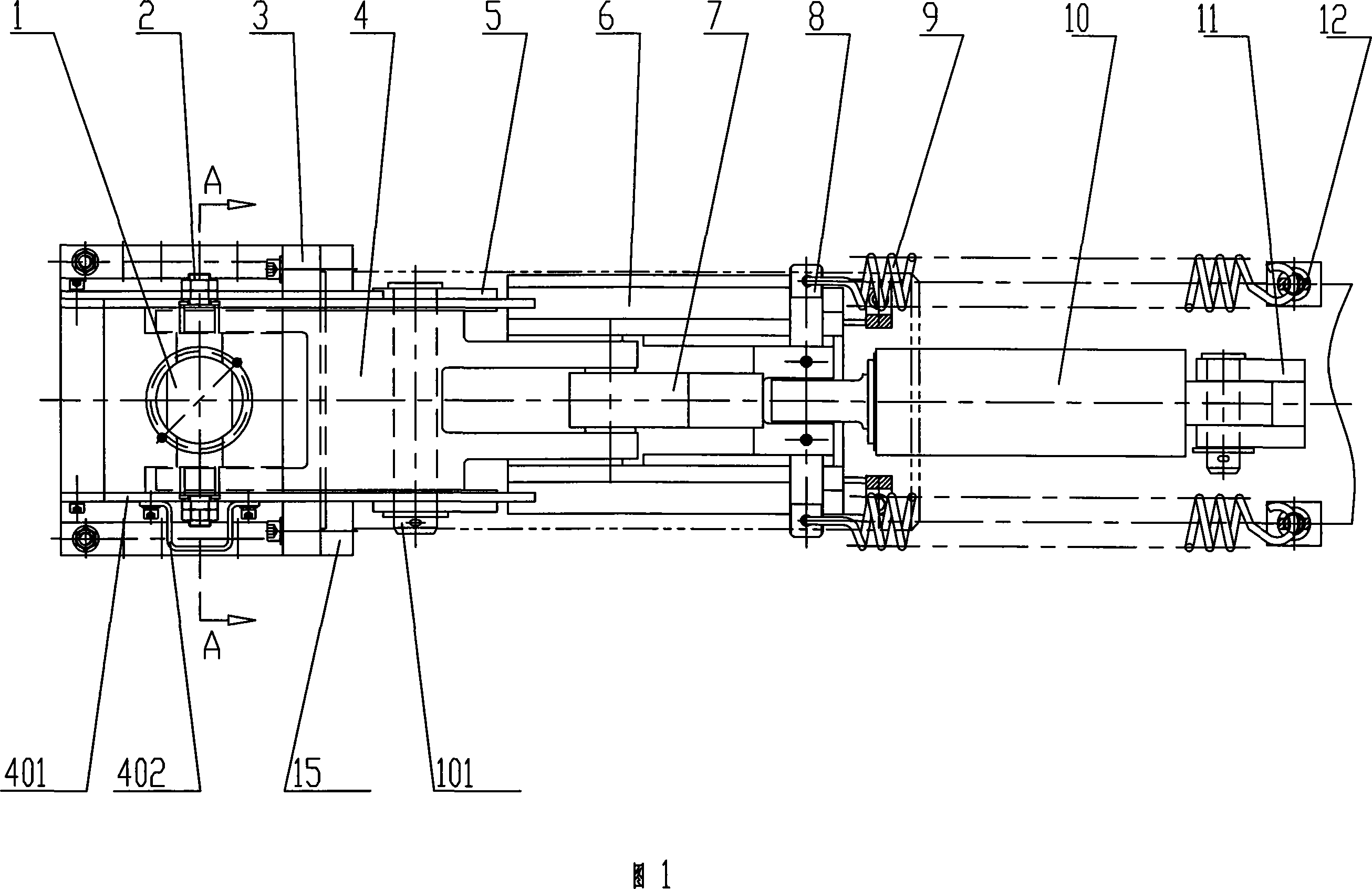

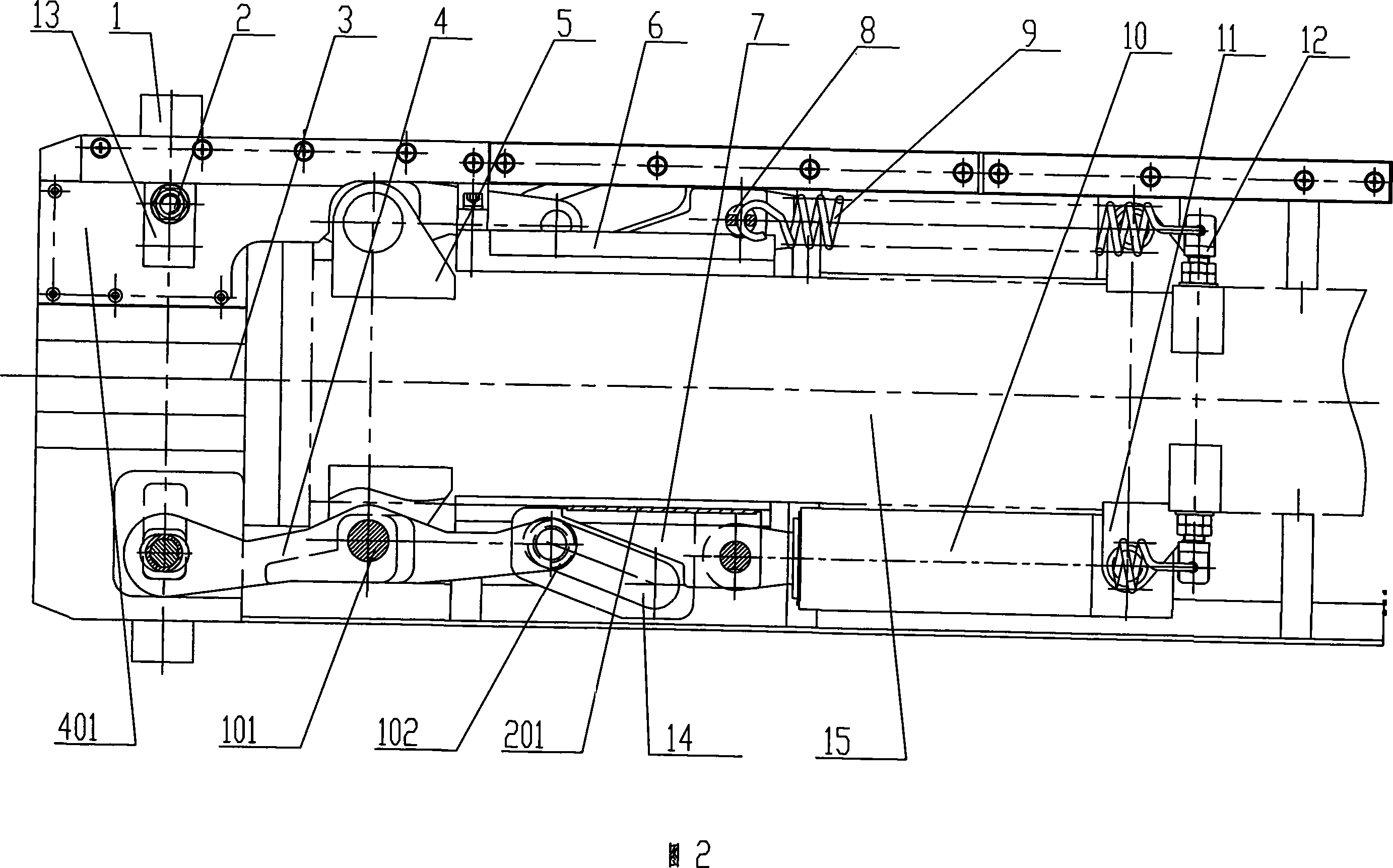

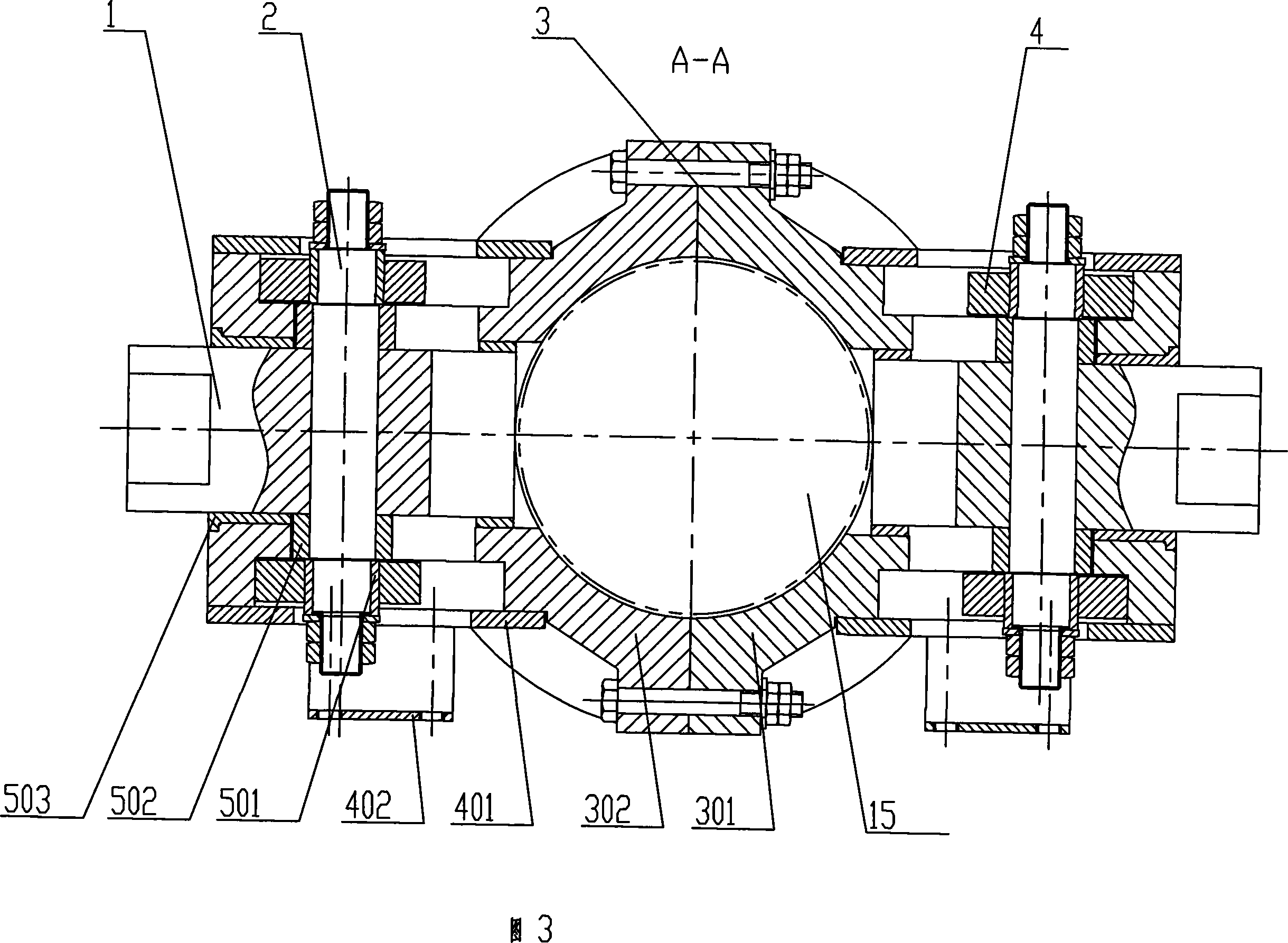

[0019] As shown in Figure 1, Figure 2 and Figure 3, the crane uses a fork-type telescopic pin insertion mechanism. This mechanism adopts a left-right symmetrical arrangement relative to the telescopic oil cylinder, and the two symmetrical parts move independently of each other. The main body 3 is composed of a symmetrical right side main body 301 and a left side main body 302 connected by bolts, and the main body 3 is fixed on the cylinder barrel of the telescopic oil cylinder 15 by screws. The telescopic pin 1 and the bushing 503 are arranged in the pin hole on the main body 3, and friction occurs with the bushing 503 when the telescopic pin 1 stretches and contracts. The power transmission shaft 2 vertically passes through the telescopic pin 1 and is symmetrical up and down with respect to the telescopic pin 1 . The above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com