Automatic walnut shell opening device

A walnut, automatic technology, applied in the field of walnut automatic shelling device, can solve the problems of low efficiency and inconvenient use, and achieve the effect of high efficiency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

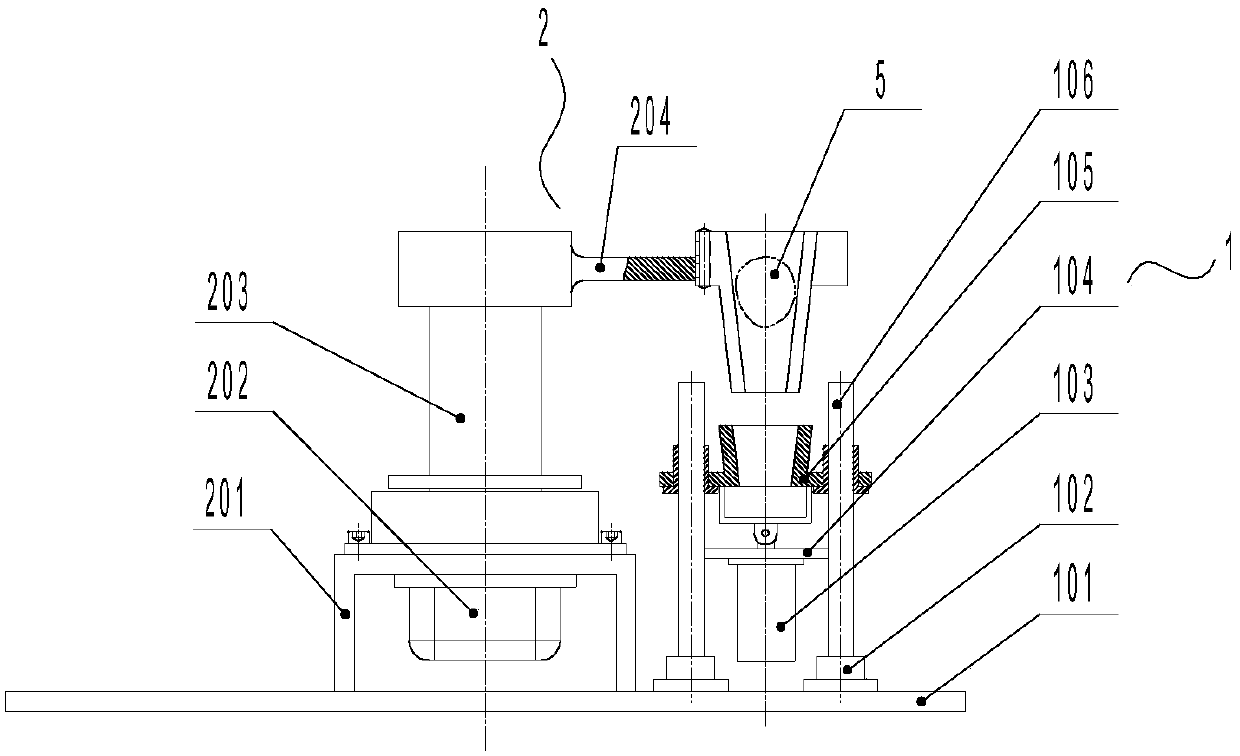

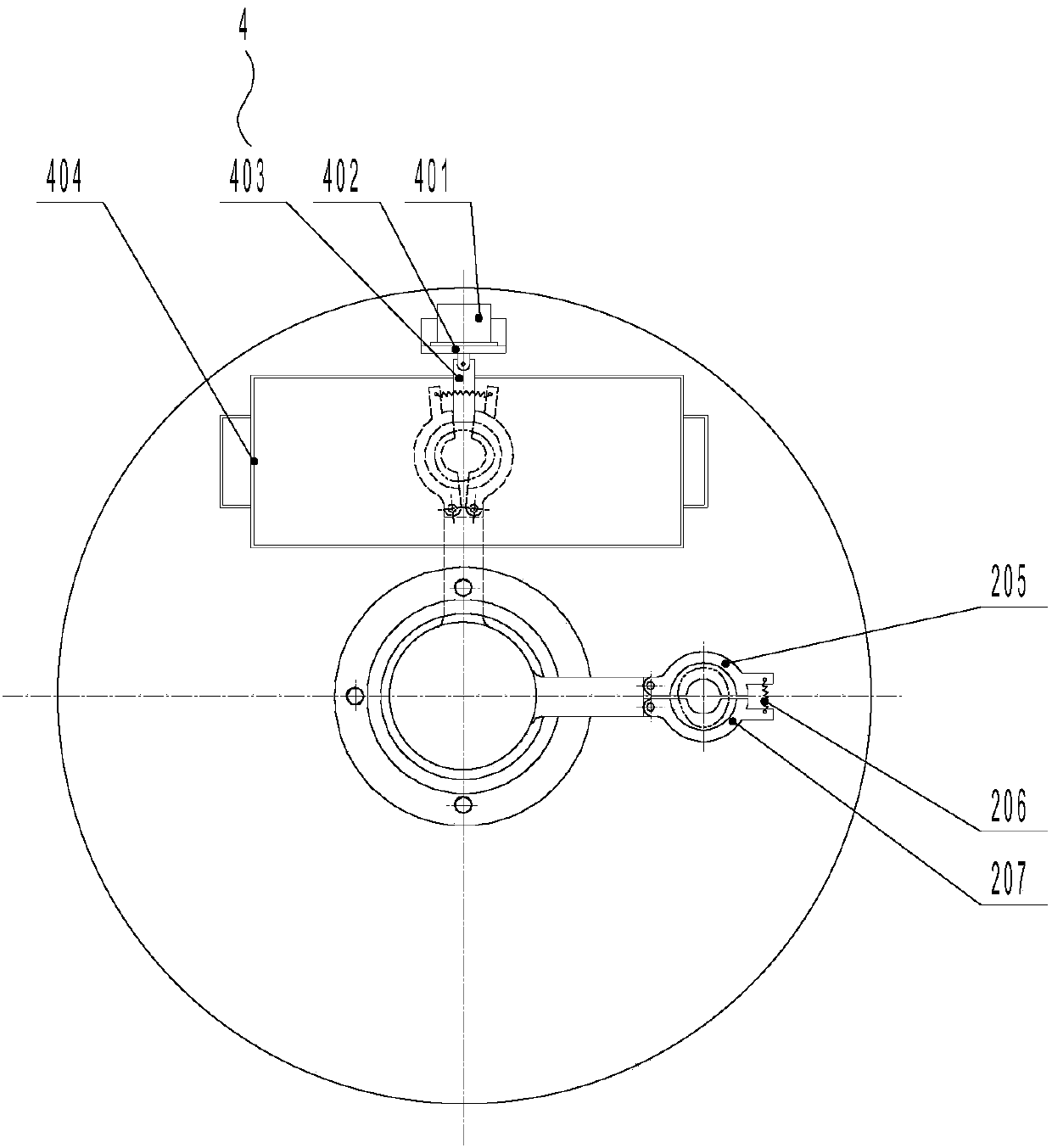

[0043] Figure 1 ~ Figure 2 Disclosed in is a walnut automatic shelling device, comprising a walnut shell opening mechanism 1, a walnut clamping and rotating mechanism 2, a walnut automatic unloading mechanism 4, and a control mechanism, the walnut shelling mechanism 1 and the walnut clamping and rotating mechanism The lower ends of 2 are connected with each other, and the walnut clamping and rotating mechanism 2 is also connected with the walnut automatic feeding mechanism 4. Mechanism output connection.

[0044] Described walnut shell opening mechanism 1 comprises base plate 101, directional guide rod base 102, shell opening cylinder 103, cylinder mounting frame 104, walnut shell opening cover 105, directional guide rod 106, and described directional guide rod base 102 is installed On the base plate 101, the shell cylinder 103 is installed on the cylinder mounting frame 104, the input end of the shell cylinder 103 is connected with the output end of the control mechanism, a...

Embodiment 2

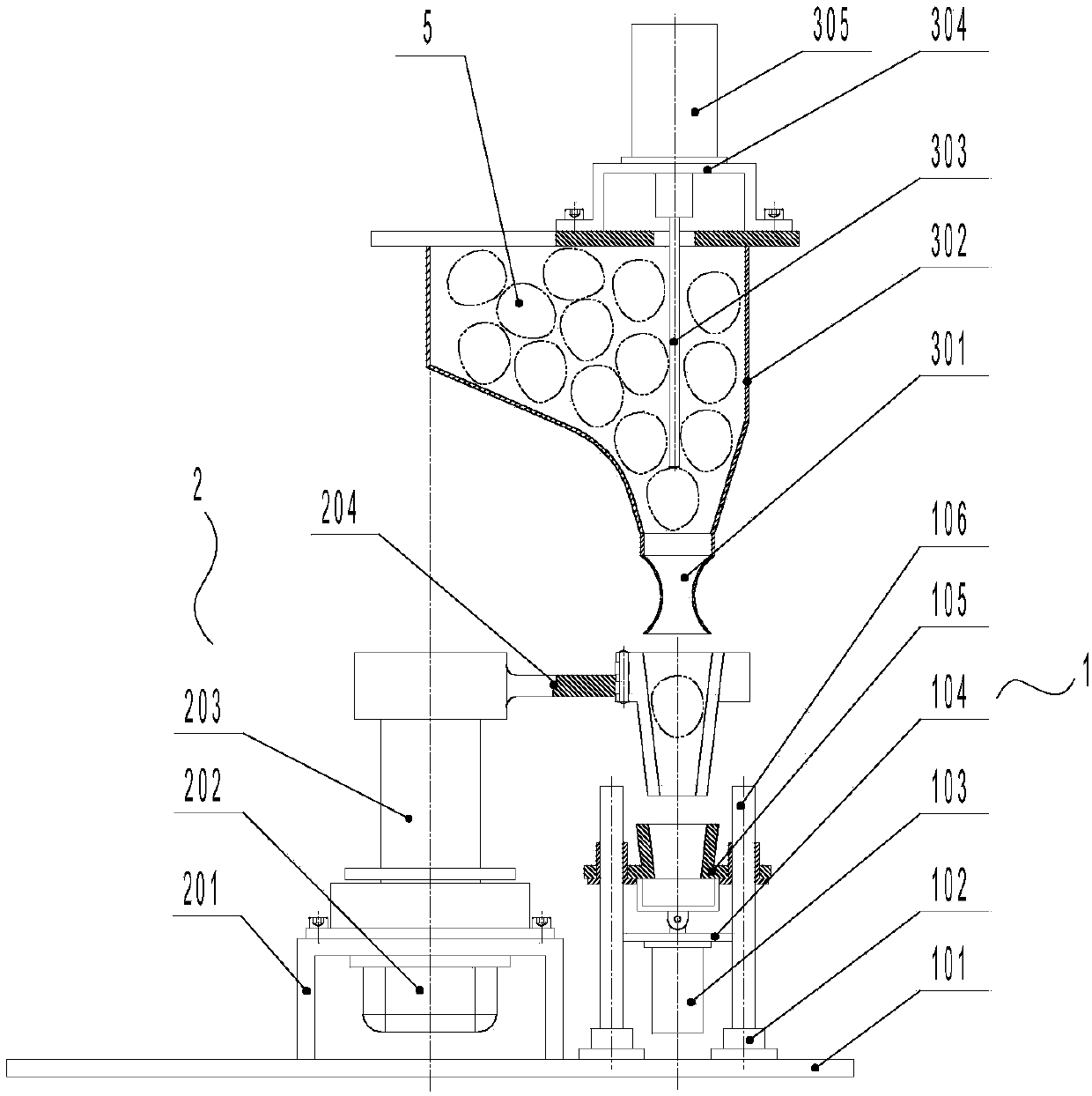

[0048] An automatic walnut shelling device, the basic structure of which is the same as that of Embodiment 1, including a walnut shell opening mechanism 1, a walnut clamping and rotating mechanism 2, a walnut automatic unloading mechanism 4, and a control mechanism. The difference is that it also includes: Walnut automatic feeding mechanism 3, this walnut automatic feeding mechanism 3 comprises telescopic rubber sleeve 301, walnut hopper 302, walnut pusher rod 303, cylinder seat 304 and material pushing cylinder 305, described telescopic rubber sleeve 301 is installed At the bottom of the walnut hopper 302, and the position of the retractable rubber sleeve 301 corresponds to the position of the holding body, the cylinder base 304 is installed on the top of the walnut hopper 302, and the pushing cylinder 305 is installed on the cylinder base 305 One end of the walnut push rod 304 is connected with the output shaft of the push cylinder 305, and the other end of the walnut push ro...

Embodiment 3

[0056] An automatic walnut shelling device, the basic structure of which is the same as that of Embodiment 2, including a walnut shell opening mechanism 1, a walnut clamping and rotating mechanism 2, a walnut automatic feeding mechanism 3, a walnut automatic unloading mechanism 4, and a control mechanism. The feature is that: the walnut shell opening mechanism 1 and the walnut automatic feeding mechanism 4 are respectively provided with two sets, and the walnut clamping and rotating mechanism 2 and the walnut automatic feeding mechanism 3 are left-right symmetrical structures.

[0057] The operating principle of the walnut automatic shelling device of the present invention described in embodiment three is as follows:

[0058] The operator pours walnuts into the hopper in batches, and the walnuts automatically enter the loading position under the action of their own weight. At the same time, they start the push cylinder and push the walnut push rod to realize the automatic feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com