Cam type separated retractable pin mechanism for crane

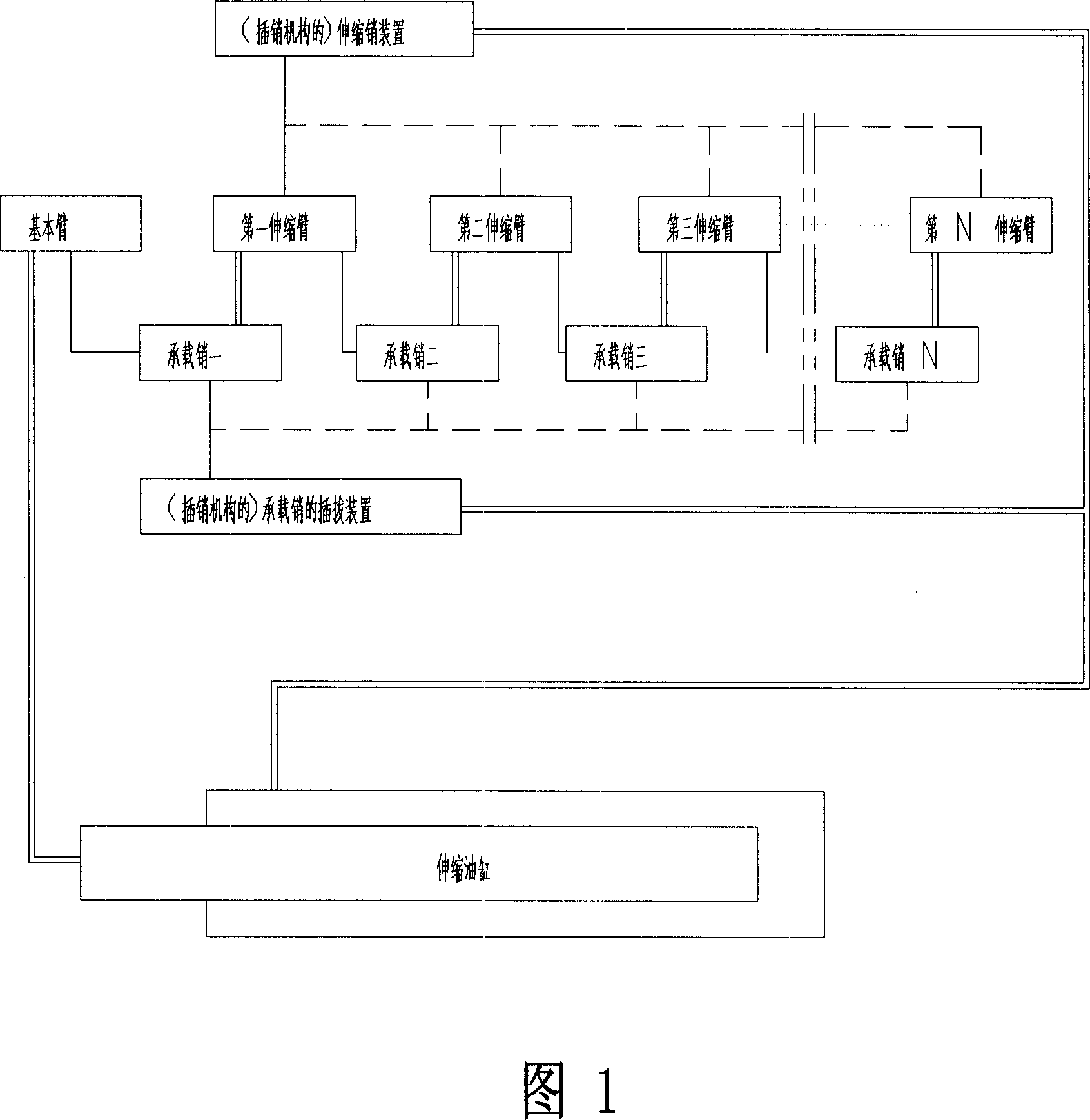

A telescopic pin and cam type technology, which is applied to cranes and other directions, can solve problems such as damage, heavy maintenance workload, and device jamming, and achieve the effect of ensuring reliability, high efficiency requirements, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

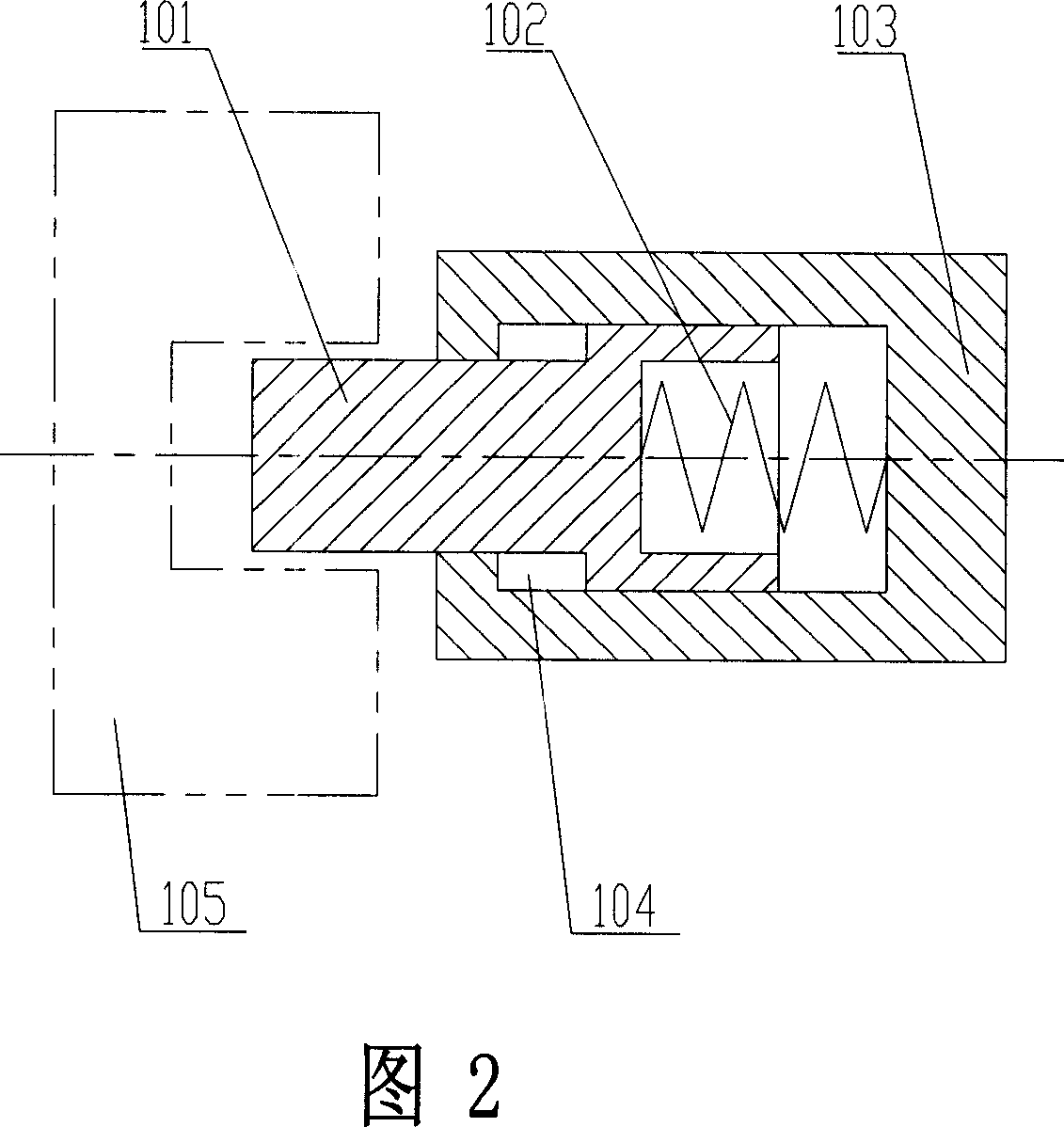

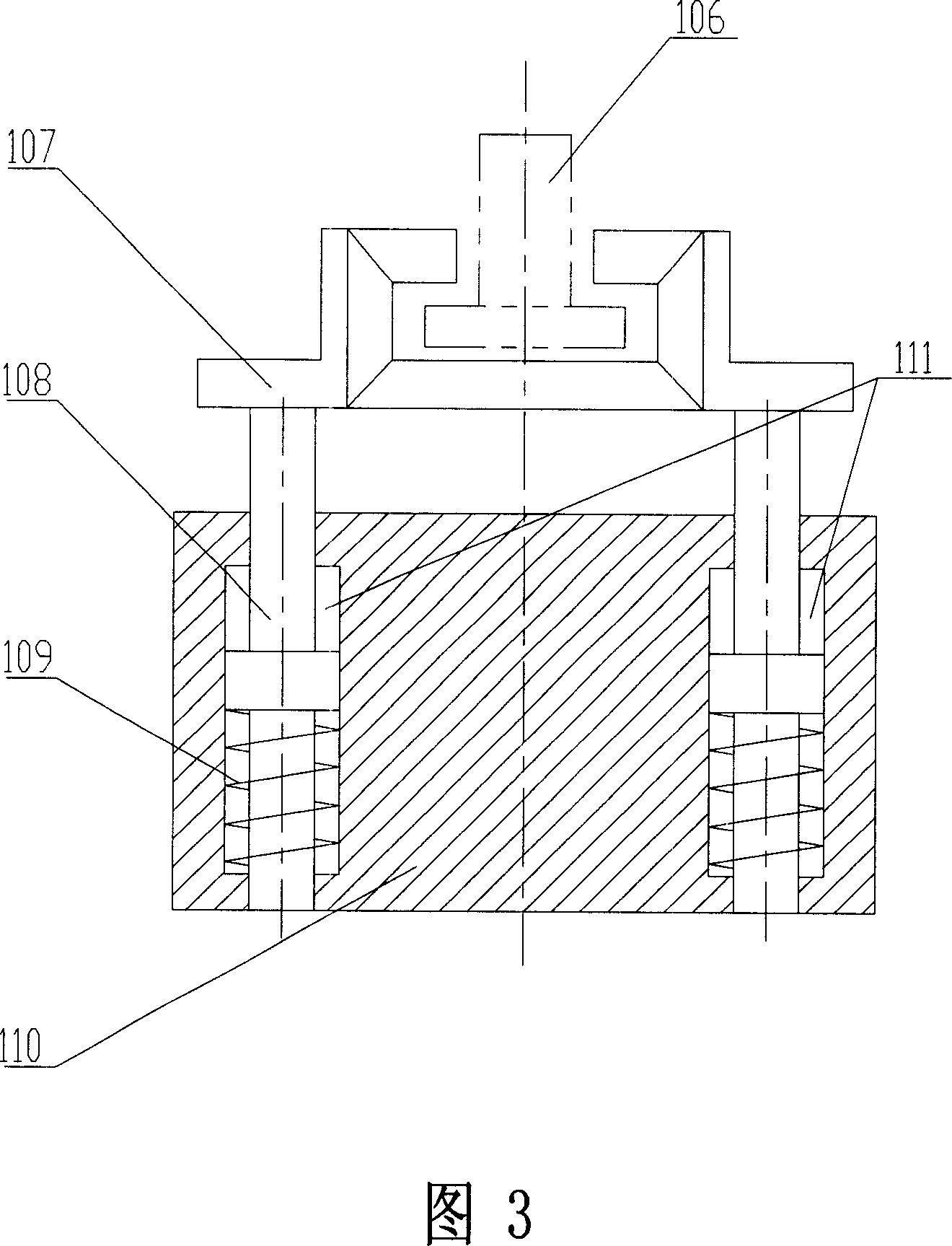

[0033] As shown in Figures 5 to 9, the cam-type split telescopic pin mechanism for cranes of the present invention includes an upper cover plate 1, a sliding plate 2, a telescopic pin 4, an upper part of the main body 3, a lower part of the main body 5, a return spring 6, a lower The cover plate 7 and the connecting plate 8, the upper part 3 of the main body and the lower part 5 of the main body are connected by fasteners to form the main body of the telescopic pin mechanism, and other movable parts are positioned and guided by the overall structure; the upper cover plate 1 and the lower cover plate 7 respectively The cover is arranged on the outside of the upper part 3 of the main body and the lower part 5 of the main body. The upper cover plate 1 and the lower cover plate 7 are used to ensure that the sliding plate 2 moves in the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com