Transverse double-connecting rod type carrying pin mobile mechanism for crane

A plug-in mechanism and bearing pin technology, applied in cranes and other directions, can solve problems such as being unable to adapt to the current production situation, and achieve the effects of easy disassembly, stable and reliable performance, high reliability and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

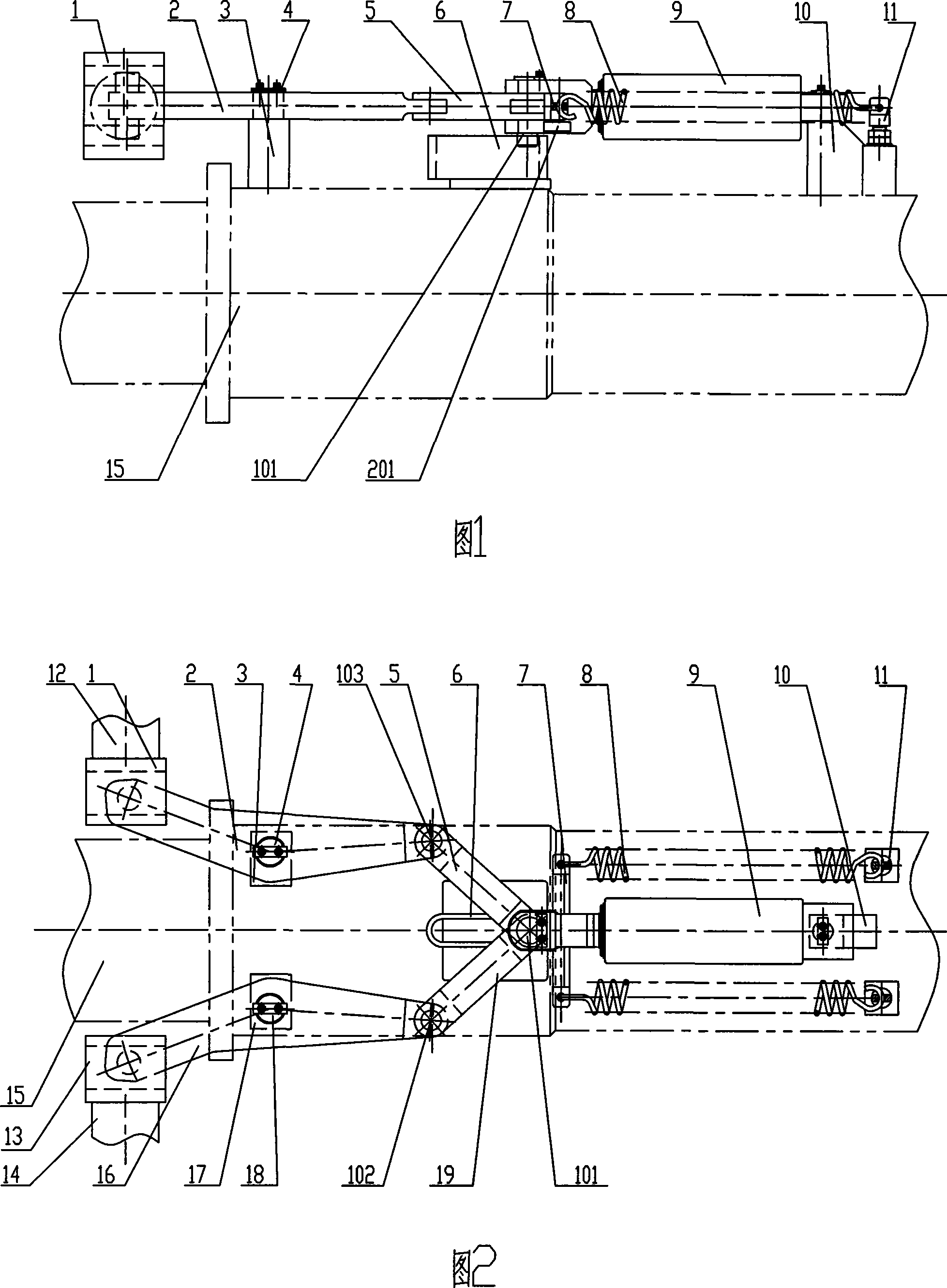

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] As shown in Figures 1 and 2, a first bearing pin 12 and a second bearing pin 14 are arranged symmetrically on both sides of the telescopic oil cylinder 15, and the first bearing pin 12 and the second bearing pin 14 are symmetrically arranged at the tail of the boom. The spring bears outwards and is in the latch state. The first support 3 and the second support 17 are fixed on both sides of the top of the telescopic oil cylinder 15, the middle part of the first swing link 2 and the second swing link 16 is provided with a mounting hole, the first swing link 2 and the second swing link 16 is installed on the first support 3 and the second support 17 respectively through the first pin 4 and the second pin 18. One end of the first fork 2 band shaft can enter the middle of the first pin-pull plate 1, and one end of the second fork 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com