Double-arm transmission robot applied to high-cleanliness environment

A technology with high cleanliness and robotics, applied in the direction of conveyor objects, manipulators, transportation and packaging, etc., can solve difficult problems, achieve high efficiency requirements, and meet the effect of cleanliness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing:

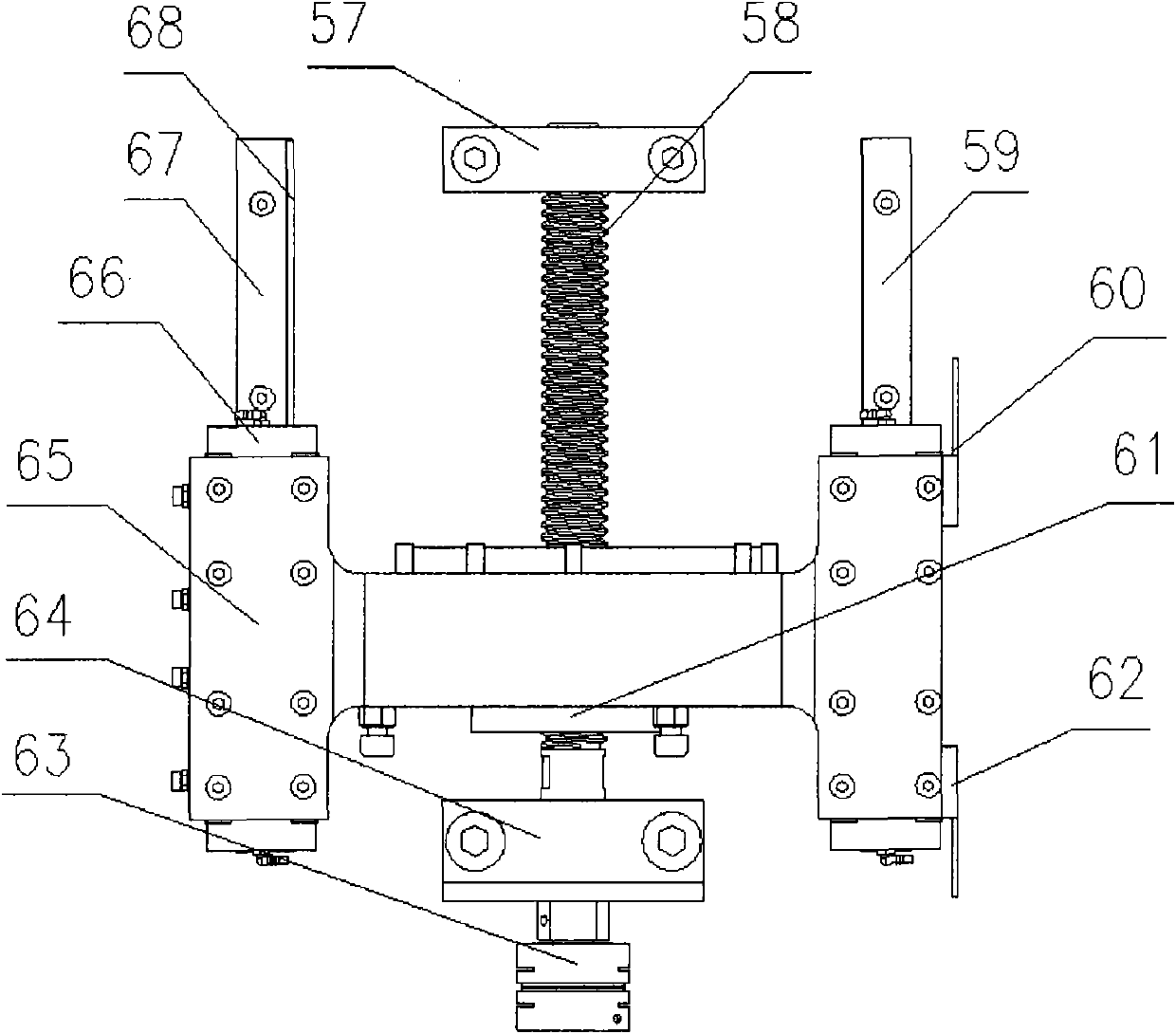

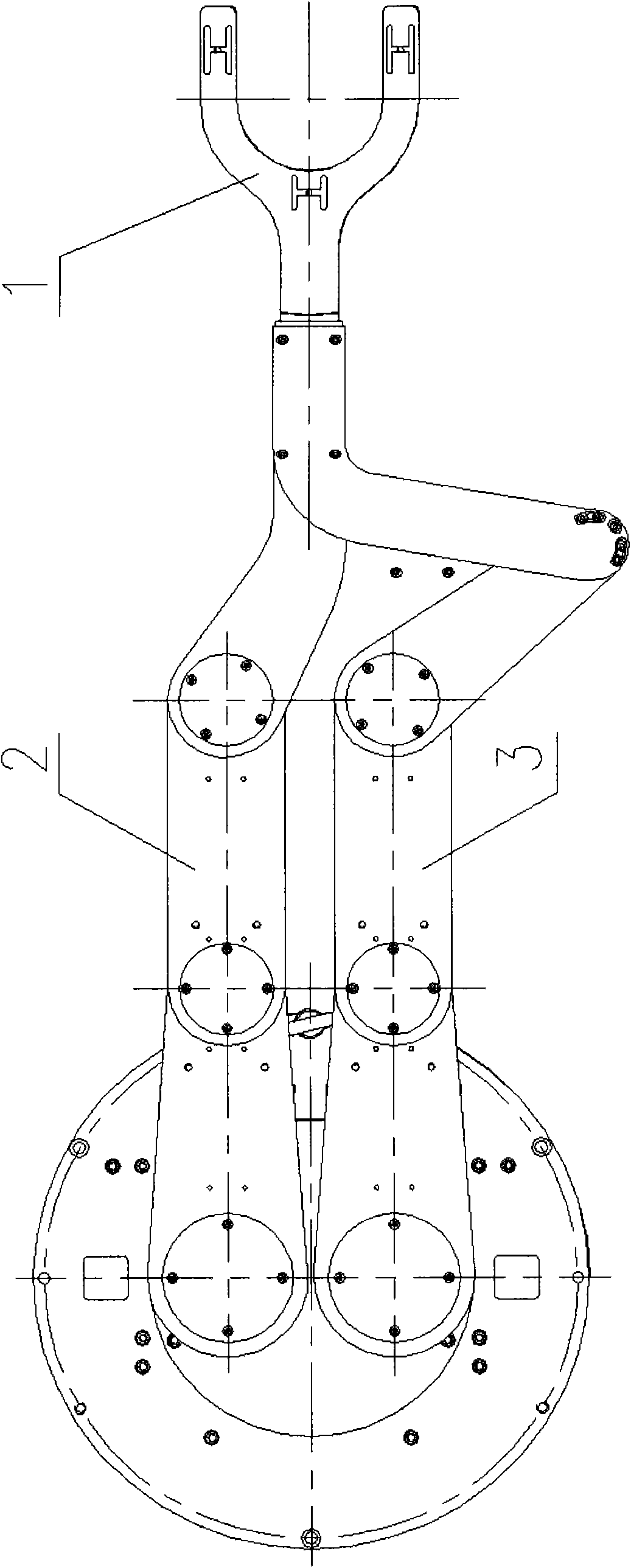

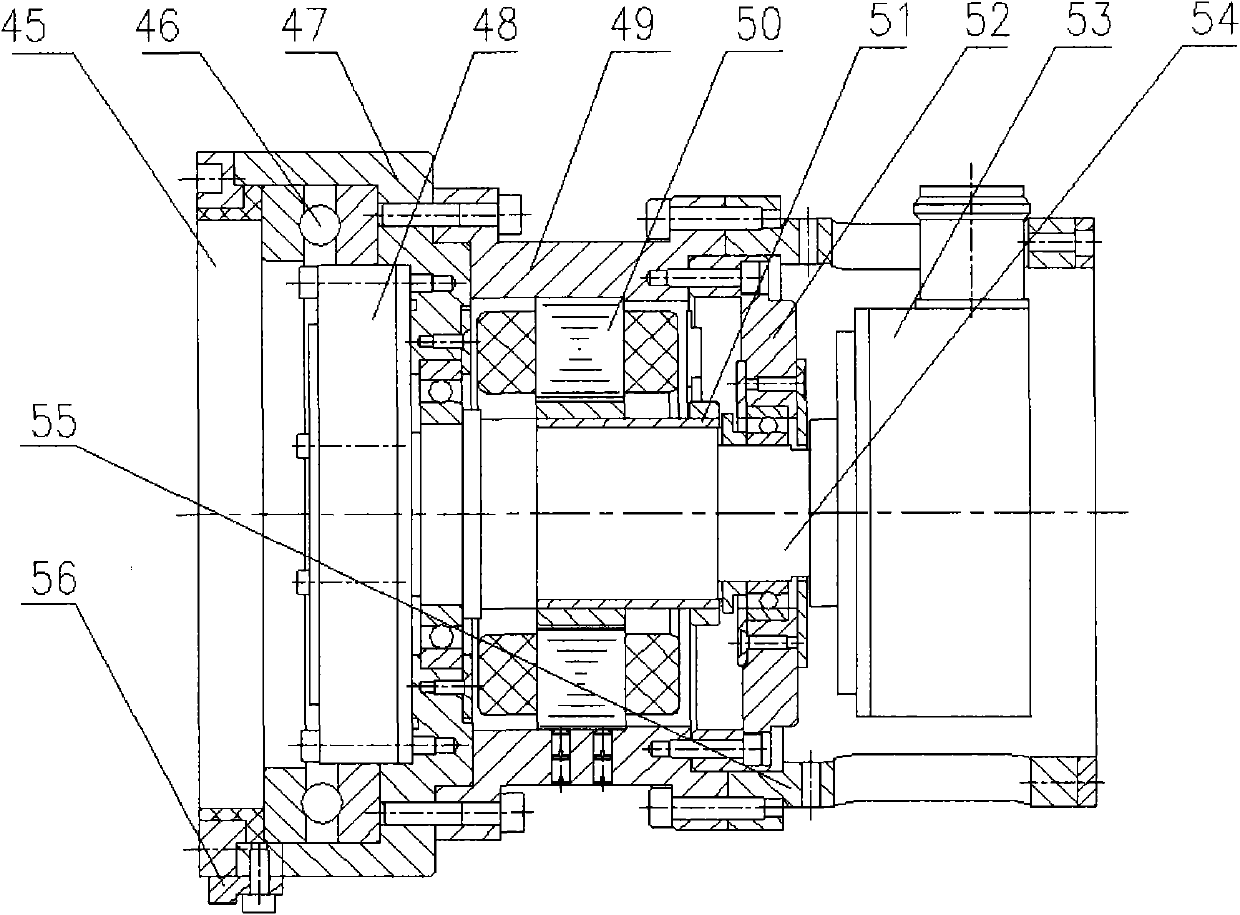

[0040] Referring to the accompanying drawings, a dual-arm robot for large-diameter semiconductor wafer transfer and high-precision fixed-point placement in a high-clean environment includes FORK combination 1; R-axis left mechanical arm combination 2; R-axis right mechanical arm Combination 3; R-axis left arm drive device combination 4; R-axis right arm drive device combination 5; T-axis combination 6; Z-axis guide rail mechanism combination 7; Z-axis screw mechanism combination 8; Z-axis drive device combination 9; large column Combination 10; Case supporting mechanism combination 11. Among them, FORK combination 1 includes trachea joint 12, FORK adjustment chuck combination 13, air path sealant 14, and FORK 15; R-axis left mechanical arm combination 2 (R-axis right mechanical arm structure is similar) includes R-axis big arm active synchronous transmission Wheel 16, R-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com