Novel manufacturing and installing method for cable holder

A technology of a cable bracket and an installation method is applied in the field of power transmission and transformation cables to achieve the effect of improving installation efficiency and convenient and quick replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

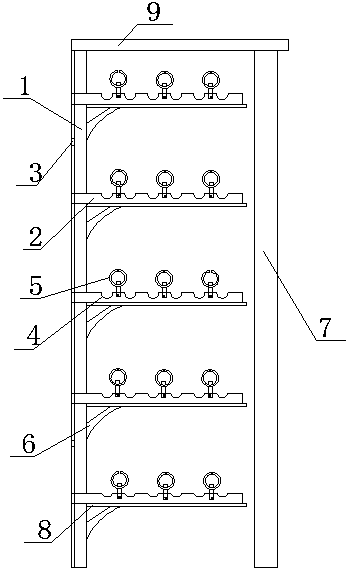

[0028] like figure 1 A new type of cable support is shown, and its production and installation method includes the following steps:

[0029] 1) According to the actual measurement of the cable trench at the construction site, select, straighten and cut the cable support;

[0030] The anti-corrosion and fire-proof effects of the cable bracket are closely related to the selection of the bracket material. For example, when a cable network needs to be shielded from electrical interference or there is a requirement to protect against external influences, a trough-type composite anti-corrosion shielding cable bridge bracket should be used, and a composite epoxy resin anti-corrosion and flame-retardant cable bracket should be used in a strong corrosive environment. . In the scheme of the present invention, considering the comprehensive effect, the cable support is made of composite materials. The composite material includes glass fiber and thermosetting resin, which has high streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com