Exterior wall putty

A technology of external wall putty and molecular weight, applied in the direction of filling slurry, etc., can solve the problems of inability to pay attention to heat preservation, waterproof, strength, moisture absorption rate, inability to take into account the service life, dependence on aesthetics, etc., to prevent the wall from discoloring and falling off , good anti-collision characteristics, excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

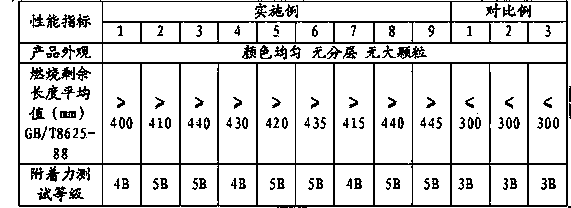

Examples

Embodiment 1

[0046] The exterior wall putty is formulated according to formula 1, wherein the polymer powder is a mixture of modified polyethylene and polypropylene; the specific modification is 30 parts by weight of ultra-high molecular weight polyethylene with a molecular weight of 4-7 million and 15 parts Add 4 parts of aluminum dihydrogen phosphate, C 12 h 25 SO 3 0.5 parts of Na, 3 parts of EPDM, 6 parts of aluminate coupling agent and 3 parts of phosphite were kneaded in an internal mixer at 110°C for 40 minutes.

[0047] The glue formula is:

[0048] 25 parts of phthalic anhydride, 10 parts of triethylene glycol, 15 parts of glutaric acid, 8 parts of butanetriol, 5 parts of zinc oxide powder, 3 parts of magnesium oxide, 15 parts of neoprene rubber, 70 parts of elastic glue, 2 parts of softening oil, 15 parts of dimethyl carbonate, 30 parts of ethylbenzene, 3 parts of flame retardant.

[0049] The flame retardant consists of the following components in parts by weight: 50 parts o...

Embodiment 2

[0051]The composition of the polymer powder, the formula of the rubber compound and the formula of the flame retardant are the same as in the first embodiment, except that the putty for the external wall is formulated according to the second formula.

Embodiment 3

[0053] The composition of the polymer powder, the formula of the rubber compound and the formula of the flame retardant are the same as in the first embodiment, except that the putty for the external wall is formulated according to the third formula.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com