Fluidized calcining furnace ball arc furnace top and method of forming same

A technology of fluidized roasting and furnace roof, which is applied in the direction of fluidized bed furnace, furnace crown/roof, furnace, etc., can solve the problems of thermal expansion coefficient mismatch, furnace roof damage, etc., and achieve short construction period and continuous heat conduction form , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

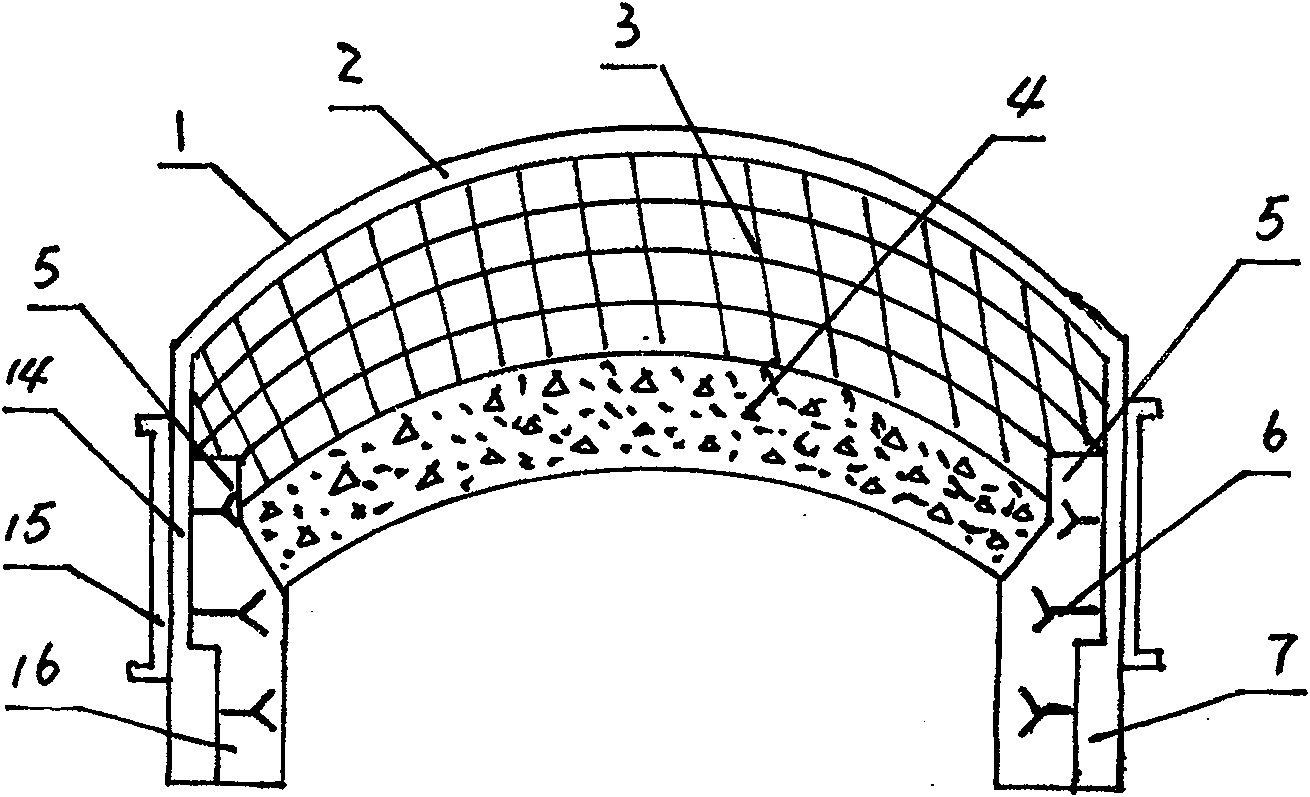

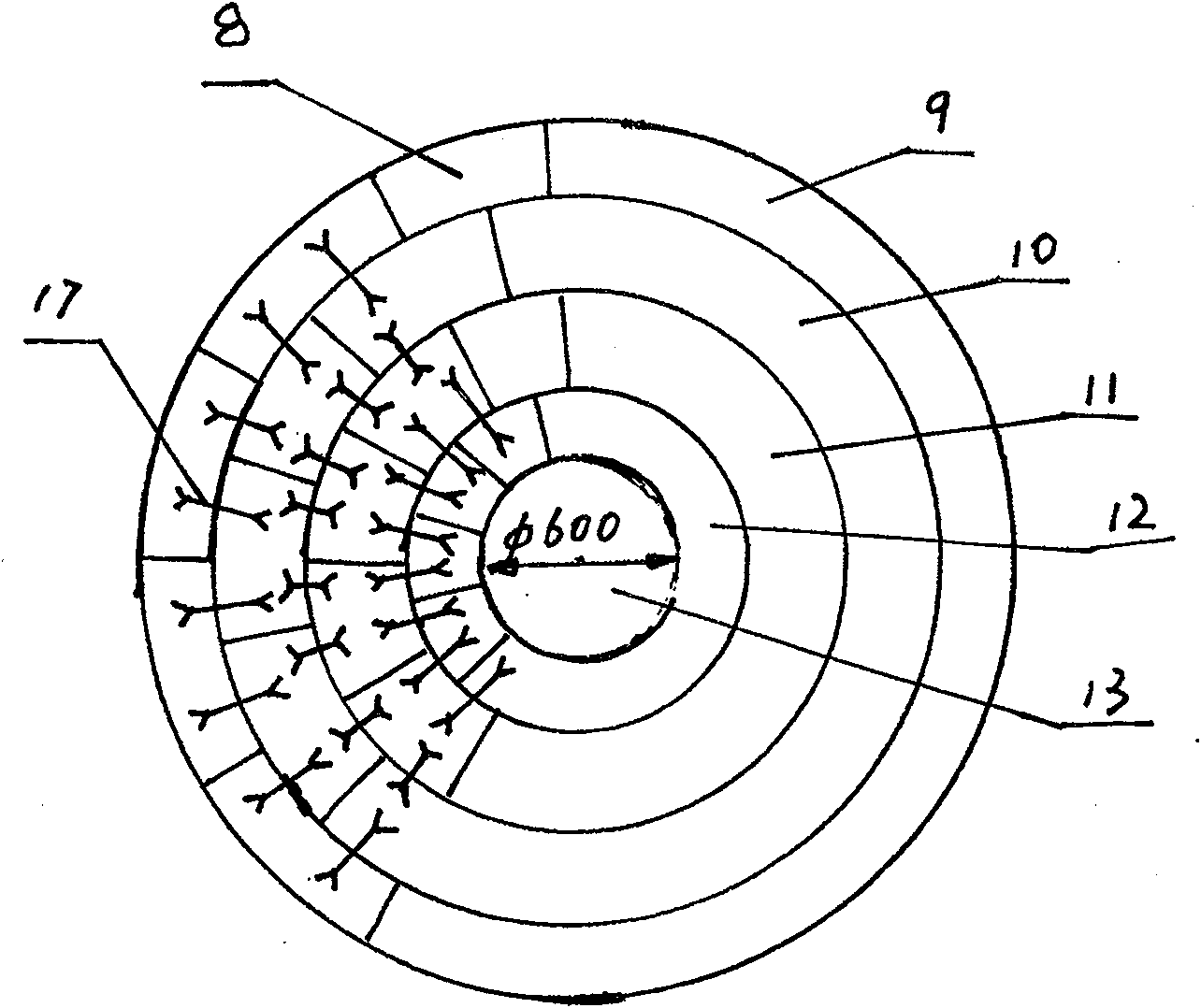

[0045] Taking the spherical arch roof of a 45m2 fluidized roaster as an example, the roof structure: the overall structure of the roof is set to three layers, the outer layer of the roof is set as a steel shell, the middle is an insulation layer, and the inner layer is an amorphous refractory Light heat-preserving castables, in the integral casting furnace lining, a plurality of stainless steel anchors are provided as the skeleton, and the heavy wear-resistant castable working lining 4 is connected with the arch angle ring beam 5 and the side wall reinforced channel steel to form a whole. 1. Working conditions: ①. Working temperature: 800-1000℃. ②, working medium: SO 2 , SO 3 , mine dust, A S, F and so on. 2. Roof structure: ①, spherical vault; ②, spherical arch radius: SR = 9000mm; ③, arch height: H = 1206mm; ④, furnace roof refractory layer thickness: f = 300mm. The forming method adopts the following steps: 1. Work preparation: (1), the mold conforms to the design requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com