Model adhesive for fused cast zircon-corundum bricks

A technology of zirconium corundum bricks and binders, applied in the direction of adhesives, inorganic adhesives, etc., can solve the problems of difficult operation, affecting the quality of finished bricks, easy deformation, etc., and achieve the effect of difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

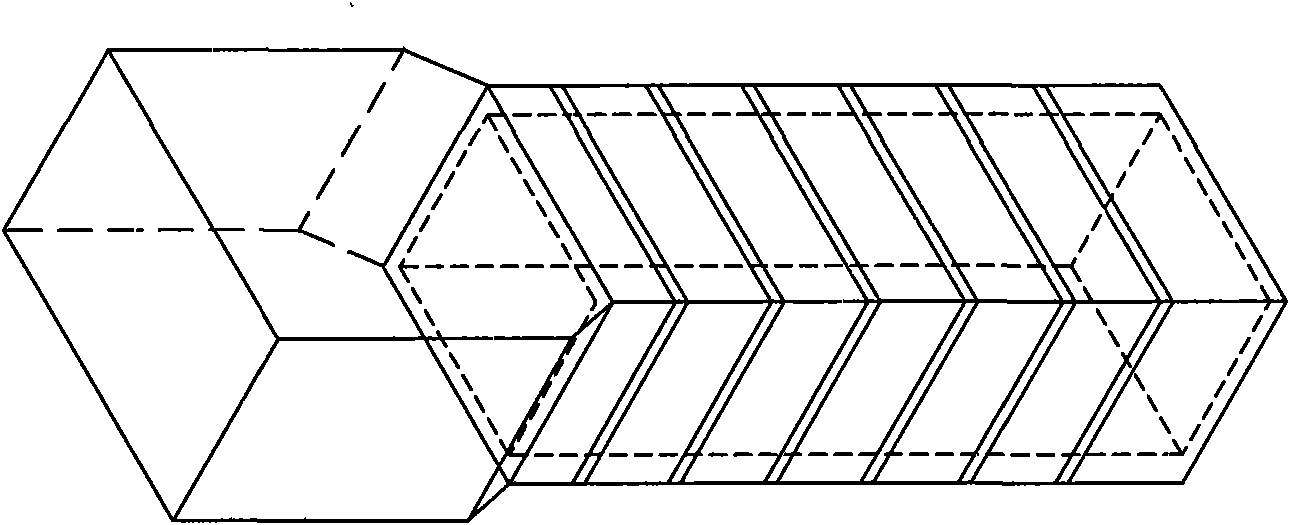

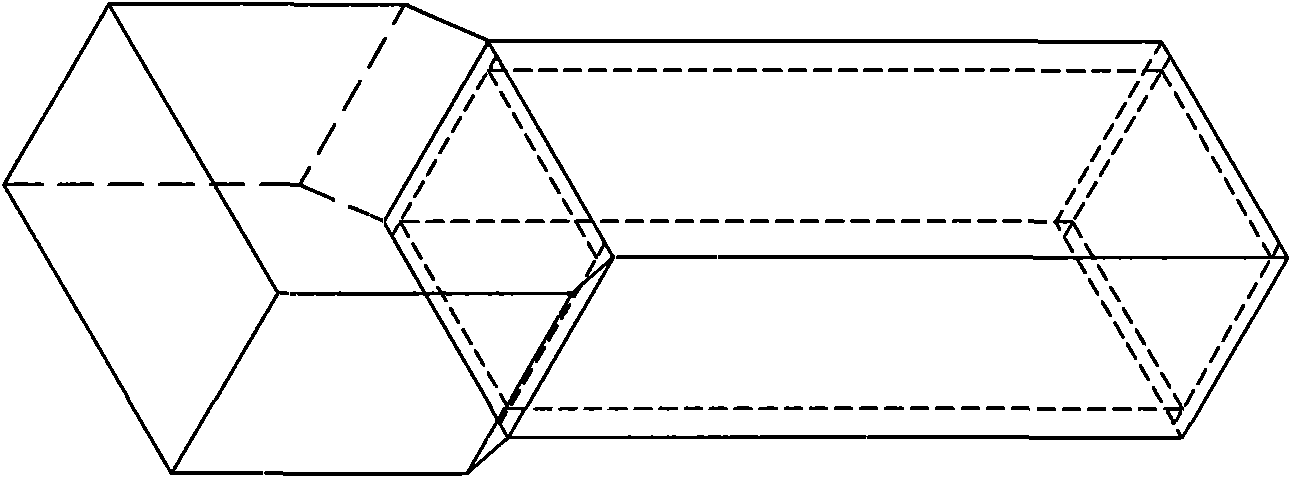

[0016] According to the required amount of one kilogram of binder per ton of casting mold, 80 parts of quartz powder with a particle size of ≥180 mesh, 0.8 part of 400# Portland cement, 4 parts of light clay powder, and 0.2 part of sodium fluorosilicate Put it on the steel plate and mix it for 3-5 minutes until it reaches a uniform state, then put the mixed material into the plastic bucket, add 12 parts of 40 Baume degree water glass, stir it with a wooden stick for 2-3 minutes, and then it can be used for sticking. figure 2 Shown is the whole model bonded with this adhesive. The model is simple to manufacture, high in strength, convenient in casting, and accurate in finished product size, which reduces the amount of cutting and grinding in the later stage.

Embodiment 2

[0018] According to the required amount of one kilogram of binder per ton of casting mold, 88.8 parts of quartz powder with a particle size ≥ 180 mesh, 1 part of 400# Portland cement, 5 parts of light clay powder, and 0.3 parts of sodium fluorosilicate Put it on a special steel plate and mix it for 3-5 minutes until it reaches a uniform state, then put the mixed material into the plastic bucket, add 14 parts of 40 Baume degree water glass, stir it with a wooden stick for 2-3 minutes, and then it can be used for sticking. . figure 2 Shown is the whole model bonded with this adhesive. The model is simple to manufacture, high in strength, convenient in casting, and accurate in finished product size, which reduces the amount of cutting and grinding in the later stage.

Embodiment 3

[0020] According to the required amount of one kilogram of binder per ton of casting mold, 90 parts of quartz powder with a particle size ≥ 180 mesh, 1.2 parts of 400# Portland cement, 6 parts of light clay powder, and 0.4 parts of sodium fluorosilicate Put it on a special steel plate and mix it for 3-5 minutes until it reaches a uniform state, then put the mixed material into the plastic bucket, add 15 parts of 40 Baume degree water glass, stir it with a wooden stick for 2-3 minutes, and then it can be used for sticking. . figure 2 Shown is the whole model bonded with this adhesive. In this way, the operation is simple and convenient during model making and casting, the strength of the model is greatly improved, the size of the finished product is more accurate, the dimensional accuracy of the product is guaranteed, the amount of cutting and grinding is reduced, and the inner quality and appearance of the product are greatly improved. Great improvement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com