Energy-saving roller kiln for polished tiles

A roller kiln, energy-saving technology, applied in the kiln field, can solve problems such as single kiln structure, difficulty in greatly increasing output, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

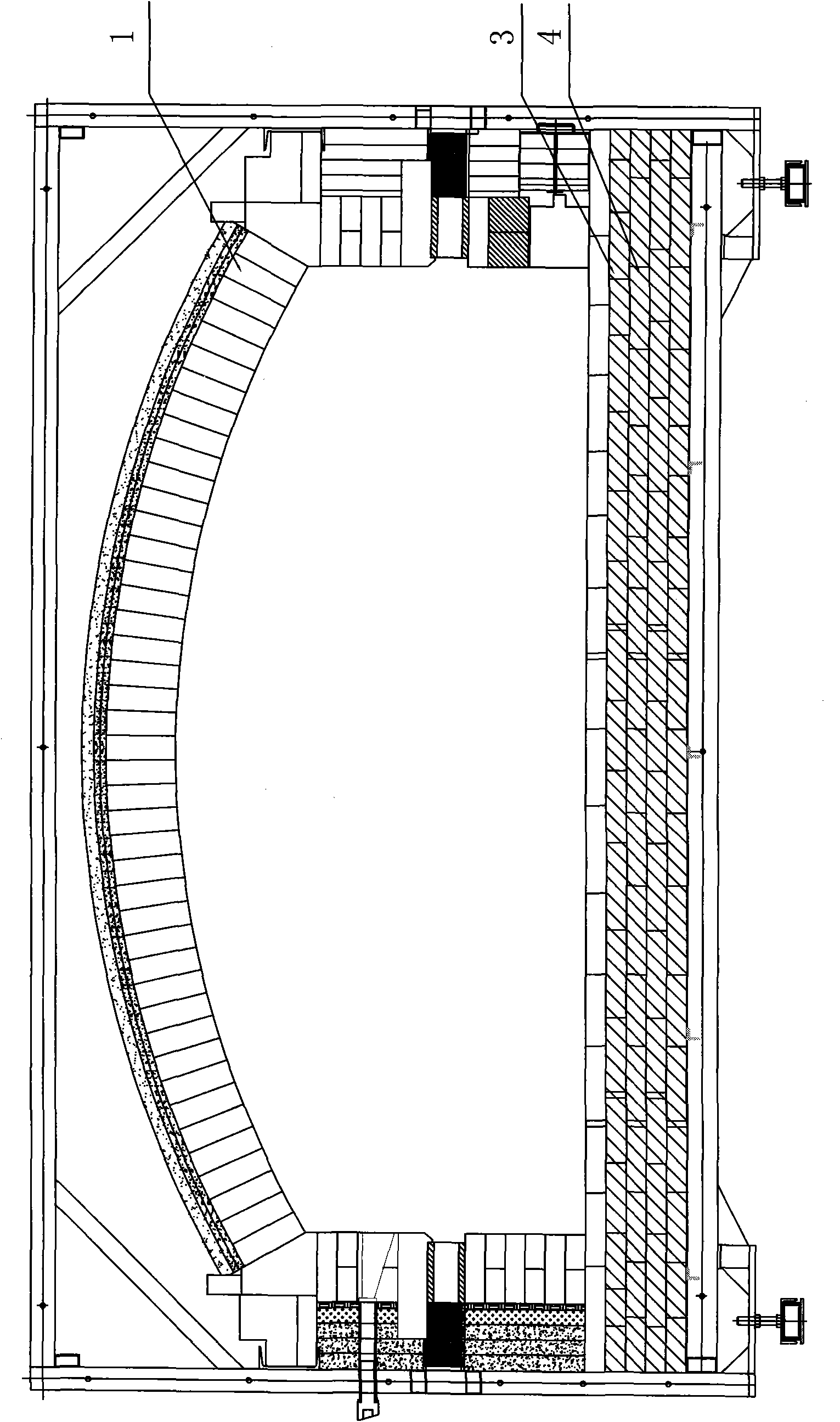

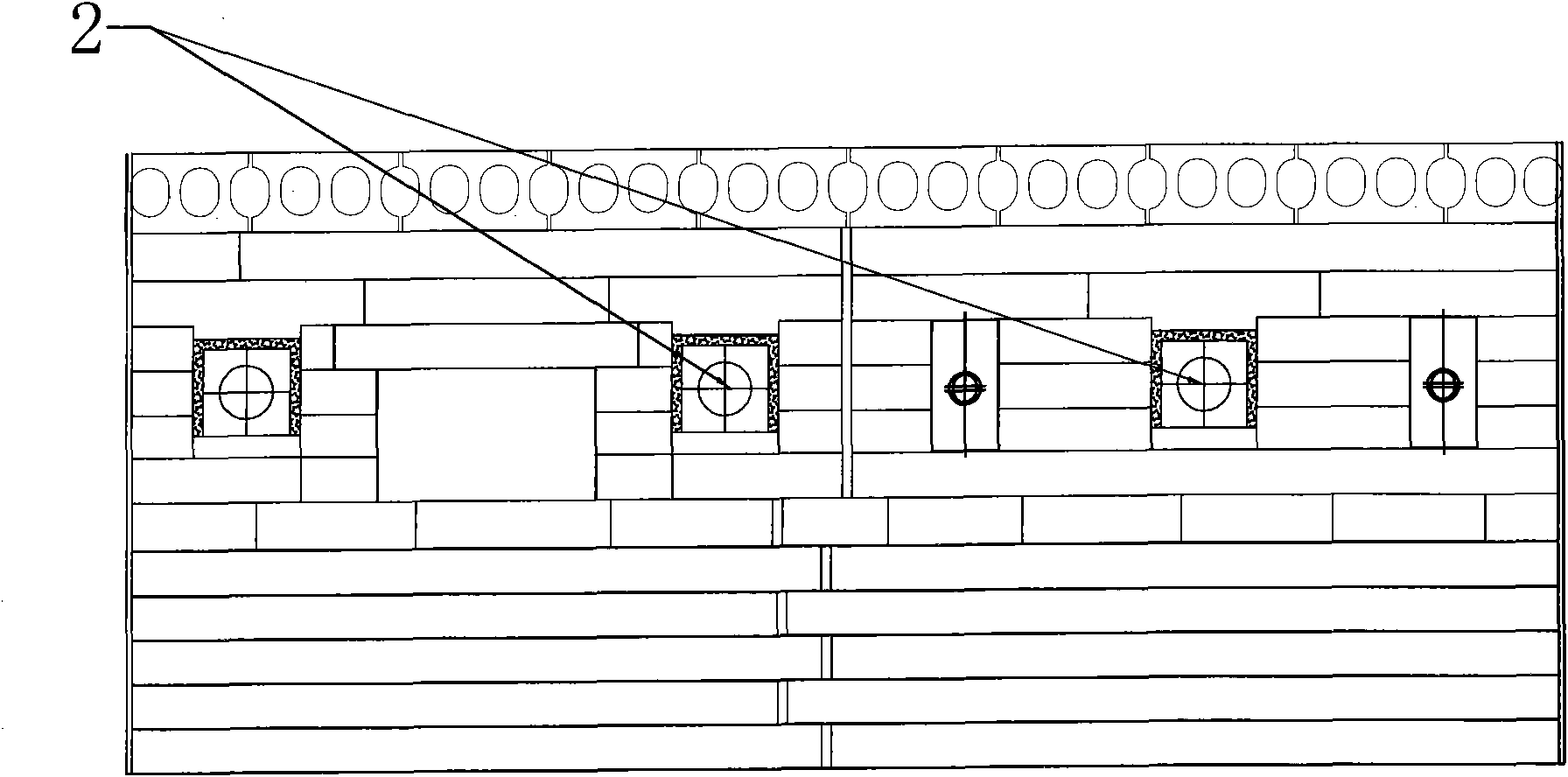

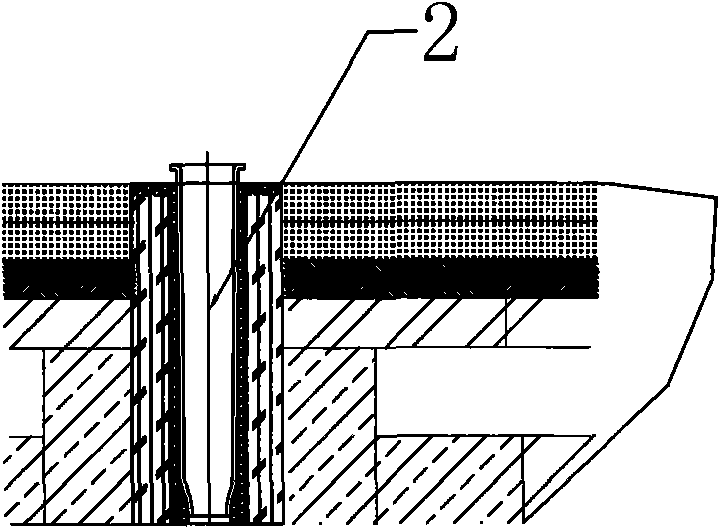

[0013] Attached below figure 1 to attach Figure 5 To further illustrate the present invention, the preferred embodiment of the present invention is: the kiln roof and kiln bottom of the energy-saving roller kiln described in this embodiment are both built by mullite insulation bricks 1, and the kiln roof after the masonry is an arch The top and the inner width of the kiln body firing area are 3100mm, the second layer of the kiln bottom is high-alumina poly light ball insulation brick 3, and the lower three layers of the kiln bottom are lightweight clay bricks 4; Into the silicon carbide sleeve. A plurality of long spray gun silicon carbide sleeves 7 and short spray gun silicon carbide sleeves 5 staggered from each other are installed in the silicon carbide sleeve, and an encryption gun silicon carbide sleeve 2 is installed in the oxidation zone of the kiln body, and the encryption gun silicon carbide sleeve 2 is a single section 2160mm configuration six. After adopting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com