Method for enhancing thermal-insulation performance of well-frame wall body by adopting light raw soil material and composite thermal-insulation wall body

A dry wall and thermal insulation performance technology, which is applied in the processing of building materials, thermal insulation, walls, etc., can solve the problems of large wall gaps, large firewood consumption, poor thermal insulation performance, etc., and reduce wall gaps , low cost, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

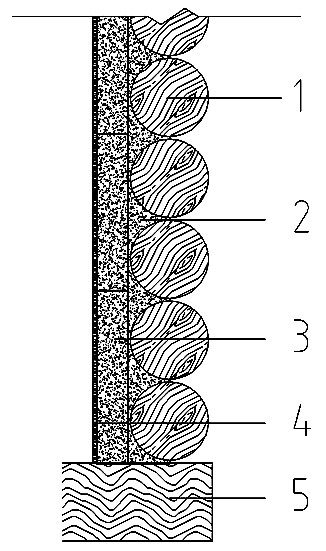

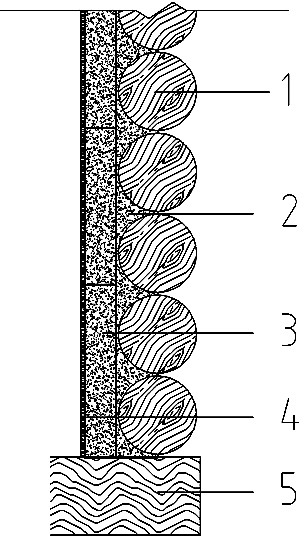

[0024] Embodiment 1: see figure 1 , the method for enhancing the thermal insulation performance of the well dry wall with light raw earth materials is to wet the inner surface of the wooden flute of the well dry building wall with water, and then use raw soil, cement and plant fiber to add water and mix the lightweight Using high-quality clay slurry, fill the gaps on the inner surface of the wooden flute of the well dry wall, and then use cement mortar to build lightweight clay blocks prefabricated with light clay slurry on the outer surface of the filling layer to form 30mm thick wall insulation. On the exterior of the wall insulation layer, a 3mm thick surface layer is formed by plastering with a mixture of raw soil and cement as a surface decoration.

[0025] The lightweight clay slurry used in this method is obtained by mixing dry-based raw soil, cement and wheat straw with a length of 10mm in a mass ratio of 6:2:2, and then adding water in a mass percentage of 30% and m...

Embodiment 2

[0027] Example 2: see figure 1 , The method for enhancing the thermal insulation performance of the well dry wall with the light raw earth material and the obtained well dry wall thermal insulation wall structure are the same as in Example 1. The difference is: the lightweight clay slurry is obtained by mixing dry base soil, cement and 30mm long bamboo filaments in a mass ratio of 5:3:3, and then adding water at a mass percentage of 30% to mix evenly. The slurry; the raw soil and cement mixed slurry used in the plastering surface layer is obtained by mixing the dry base raw soil and cement at a mass ratio of 5:1, and then adding water to mix uniformly at a mass percentage of 30%. slurry. In the lightweight clay leveling layer 2 and the lightweight clay block insulation layer 3, the mass ratio of dry base raw soil, cement and plant fiber is 5:3:3; in the plastering surface layer 4, the mass ratio of raw soil to cement The ratio is 5:1; the wall insulation layer 3 is 150mm th...

Embodiment 3

[0028] Embodiment 3: see figure 1 , The method for enhancing the thermal insulation performance of the well dry wall with the light raw earth material and the obtained well dry wall thermal insulation wall structure are the same as in Example 1. The difference is: the lightweight clay slurry is obtained by mixing dry base soil, cement and weed straw with a length of 40mm in a mass ratio of 5:4:2.5, and then adding water at a mass percentage of 32% to mix evenly. The raw soil and cement mixed slurry used in the plastering surface layer is obtained by mixing dry-based raw soil and cement at a mass ratio of 4:1, and then adding water at a mass percentage of 25% to mix evenly slurry. In the lightweight clay leveling layer 2 and the lightweight clay block insulation layer 3, the mass ratio of dry soil, cement and plant fiber is 5:4:2.5; in the plastering surface layer 4, the mass ratio of raw soil to cement The ratio is 4:1; the wall insulation layer 3 is 100mm thick, and the pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com