Asphalt flue gas processing method and its incinerator

A technology for asphalt flue gas and treatment method, which is applied in incinerators, combustion methods, separation methods, etc., can solve the problems of environmental pollution of asphalt flue gas, high operating costs, poor treatment effect, etc. full burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention: for the asphalt fumes from the kneader and molding machine, the asphalt fumes are passed into an incinerator with a smoke pipe for burning, and then the asphalt fumes formed by the incinerated asphalt fumes are Tail gas emission; when the asphalt fume is passed into the incinerator for incineration, it is better to add natural gas and air to the incinerator to mix with the asphalt fume before incineration, so that the asphalt in the flue gas can be better burned When exhausting the tail gas, in order to prevent the tail gas from containing unburned asphalt, the exhausted tail gas can be returned to the incinerator to be incinerated again before being discharged.

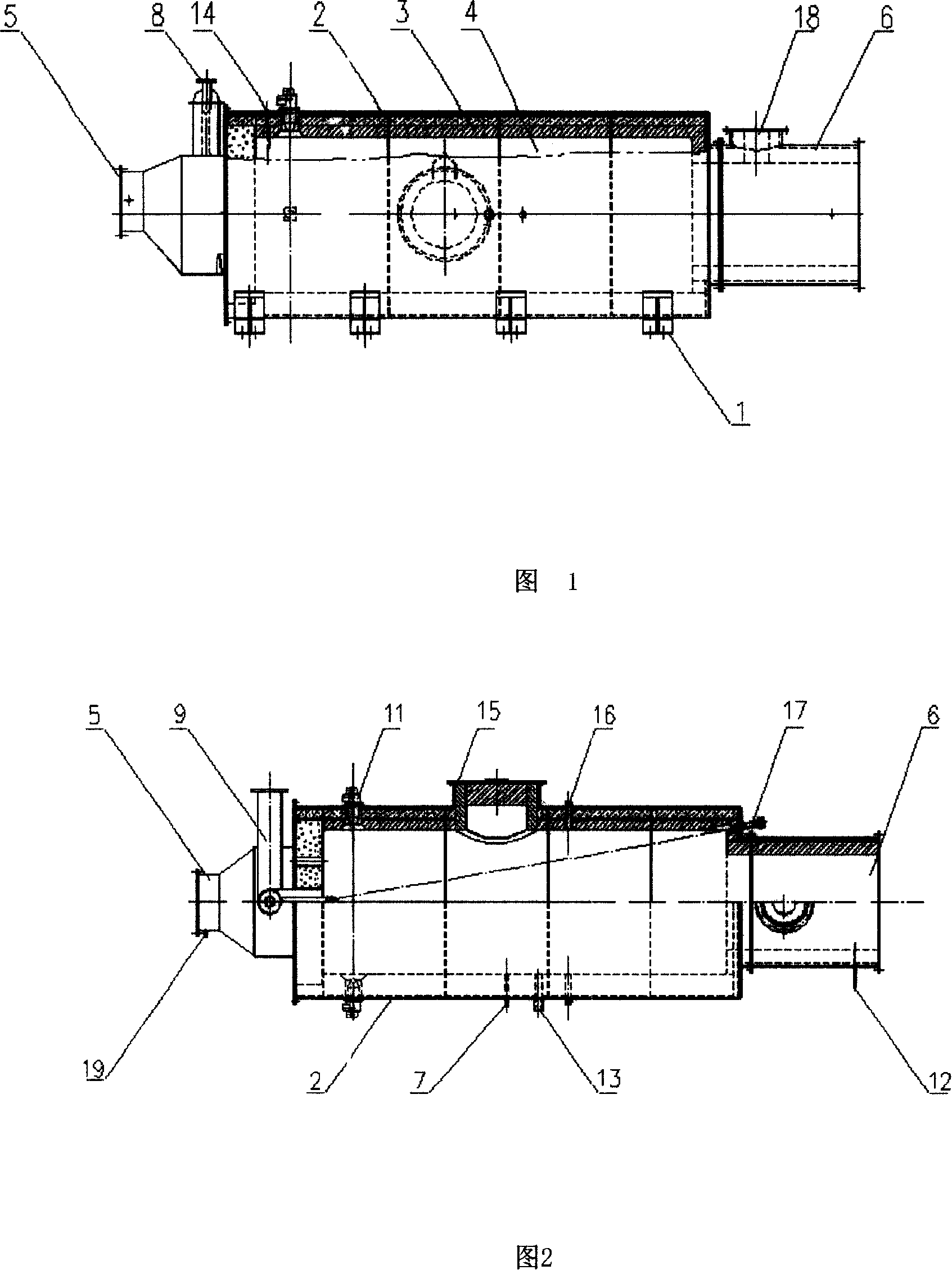

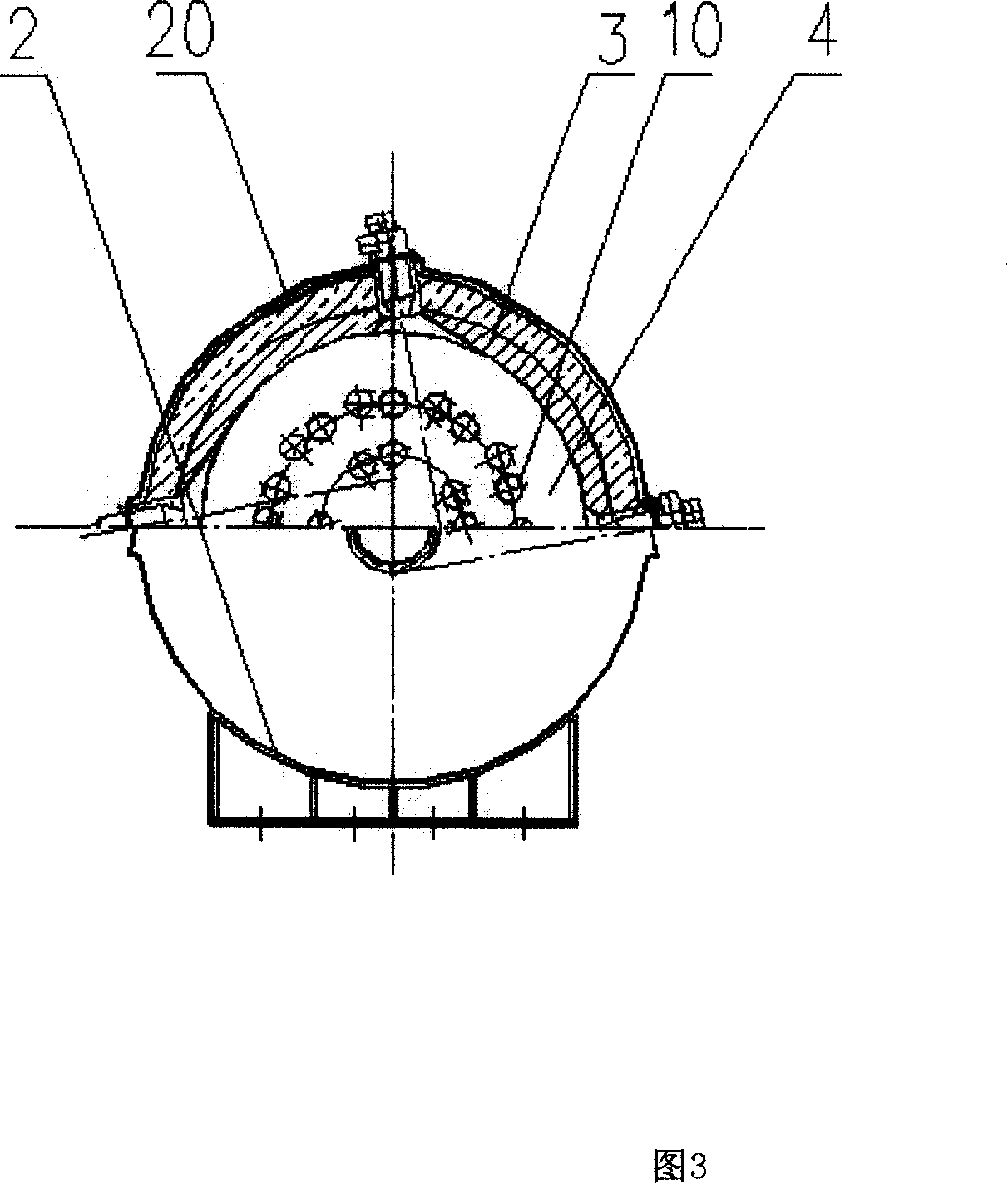

[0019] When adopting the method of the present invention to process bitumen flue gas, can adopt the incinerator in the prior art to incinerate, but preferably adopt the bitumen flue gas incinerator of the present invention to incinerate as well. When making the asphalt flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com