Energy-saving glazing roller kiln for producing interior wall bricks

A technology of roller kiln and glaze firing, which is applied in the field of kiln, and can solve the problems of dirty brick surface, single, difficult to greatly increase the output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

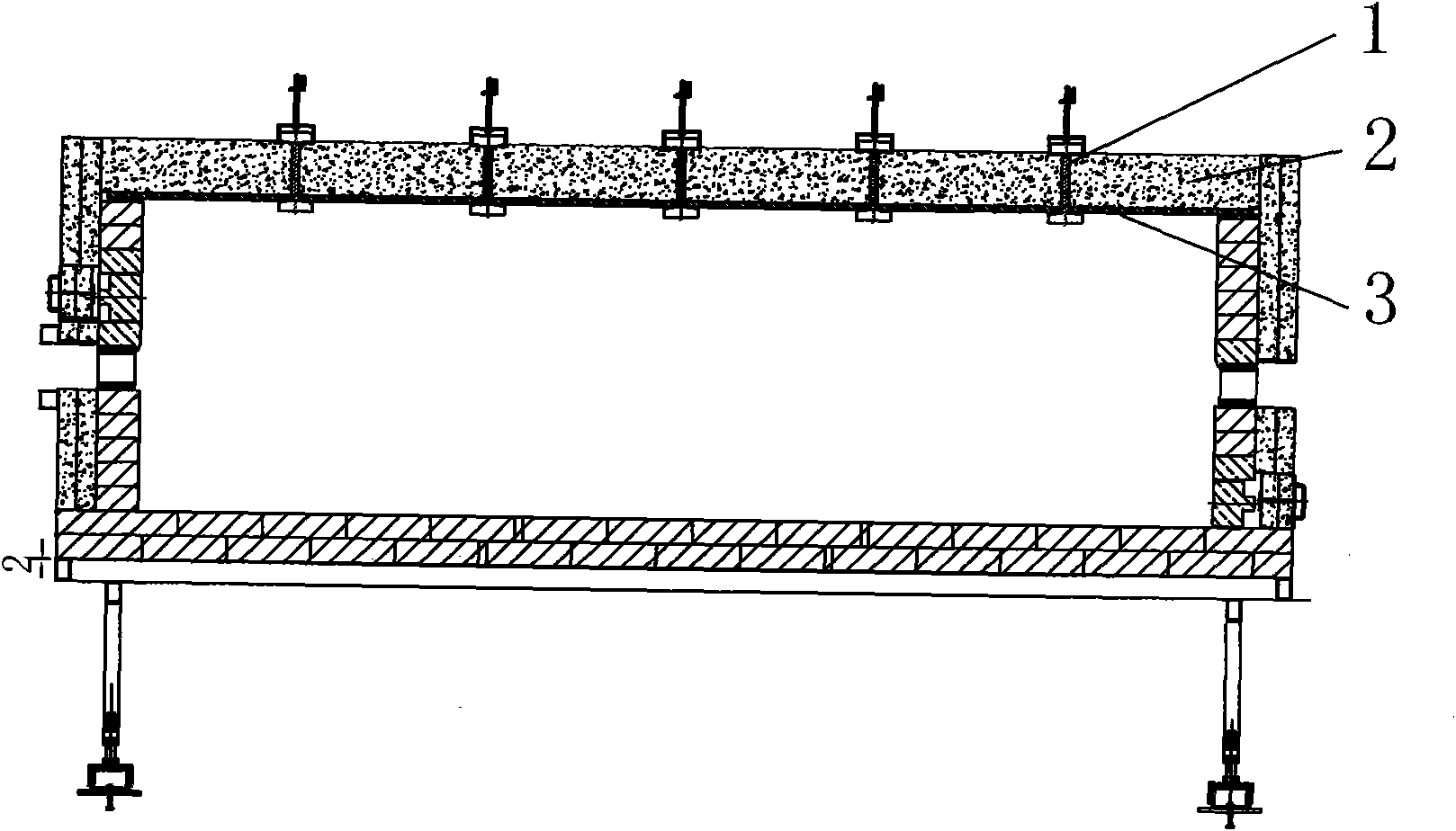

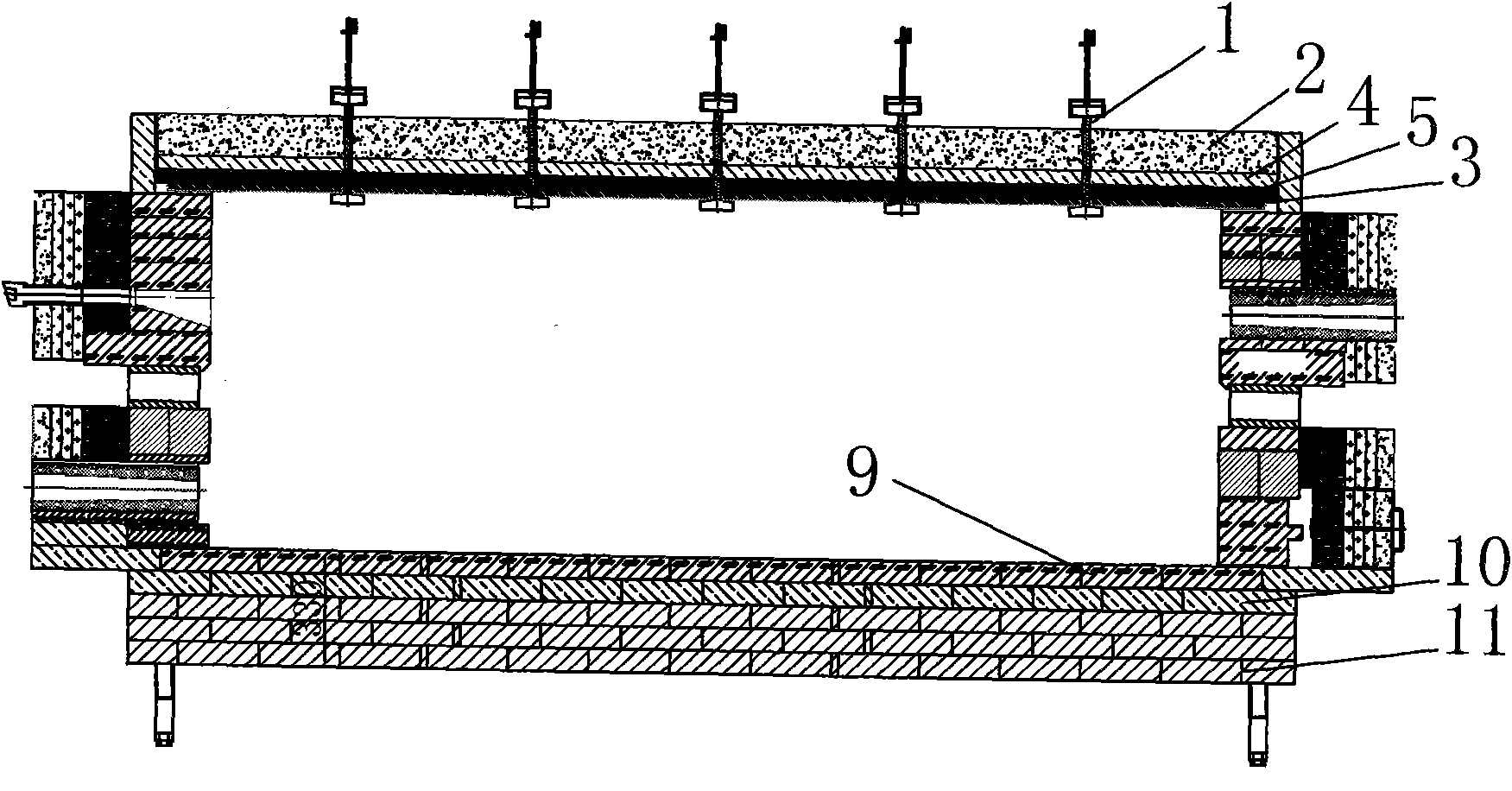

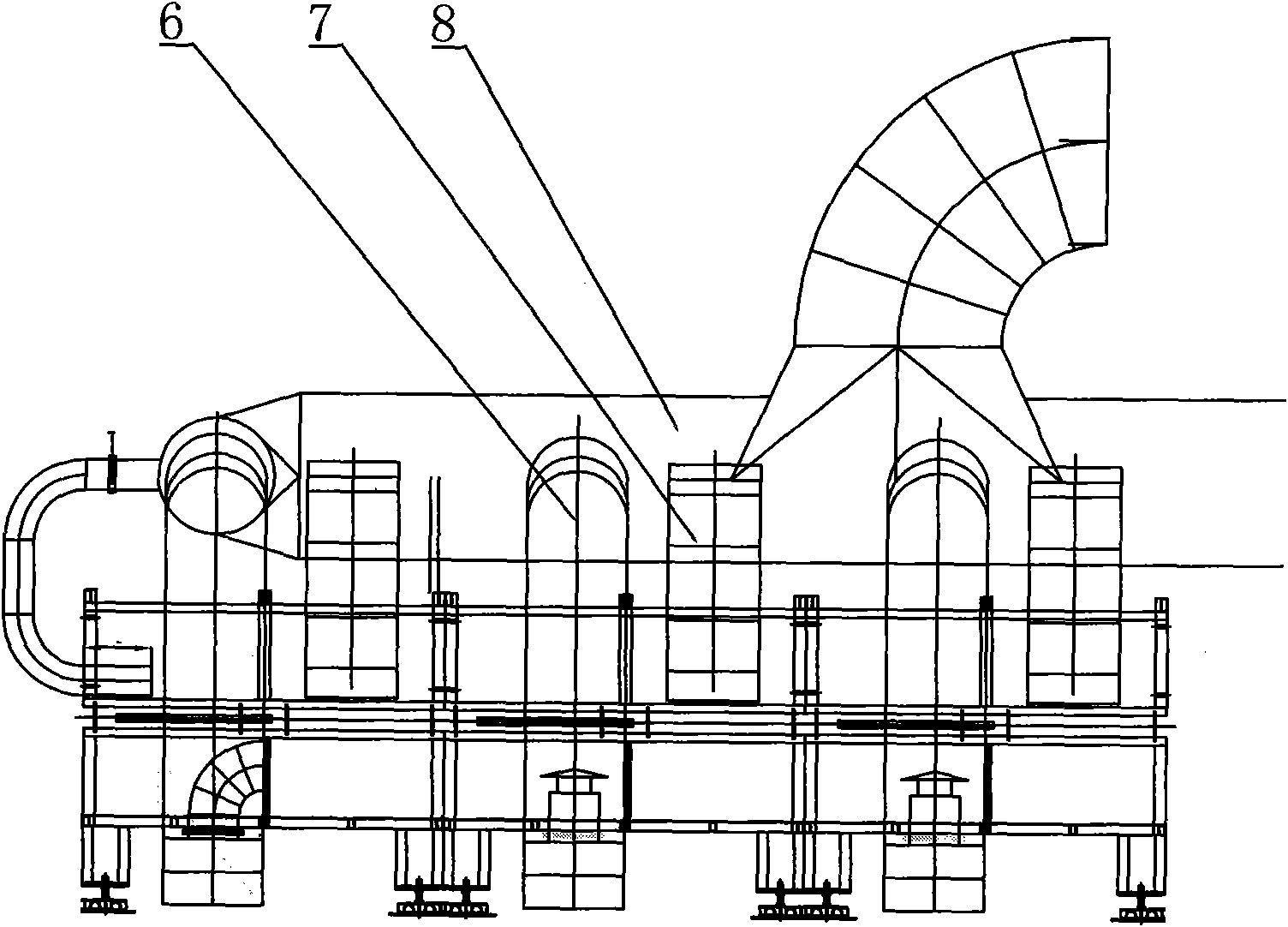

[0013] Attached below figure 1 to attach Figure 4 To further illustrate the present invention, the preferred embodiment of the present invention is: the energy-saving glaze firing roller kiln described in this embodiment includes a smoke exhaust area, a firing area, and a cooling area, and the smoke exhaust area and firing area 1. The kiln roof in the cooling zone is all built with a hanging cotton board structure. The hanging cotton board structure includes an I-shaped hanging board brick 1, an aluminum silicate cotton blanket 2, and a cordierite ceiling board 3, wherein the I-shaped The hanging brick 1 is fixed on the kiln frame, and supports the cordierite ceiling board 3, and the cordierite ceiling board 3 is covered with an aluminum silicate cotton blanket 2. A high-purity cotton blanket 4 and a zirconium-containing cotton blanket 5 are also covered between the cordierite ceiling board 3 and the aluminum silicate cotton blanket 2 located in the firing area, wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com