Waste gas purifying spray system

A technology for spraying system and exhaust gas purification, which is applied in chemical instruments and methods, combined devices, dispersed particle separation, etc., can solve the problems of difficult purification of harmful gases, unsatisfactory effects of exhaust gas treatment, etc., and achieve stable operation and a good society. With economic benefits, heat dissipation and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

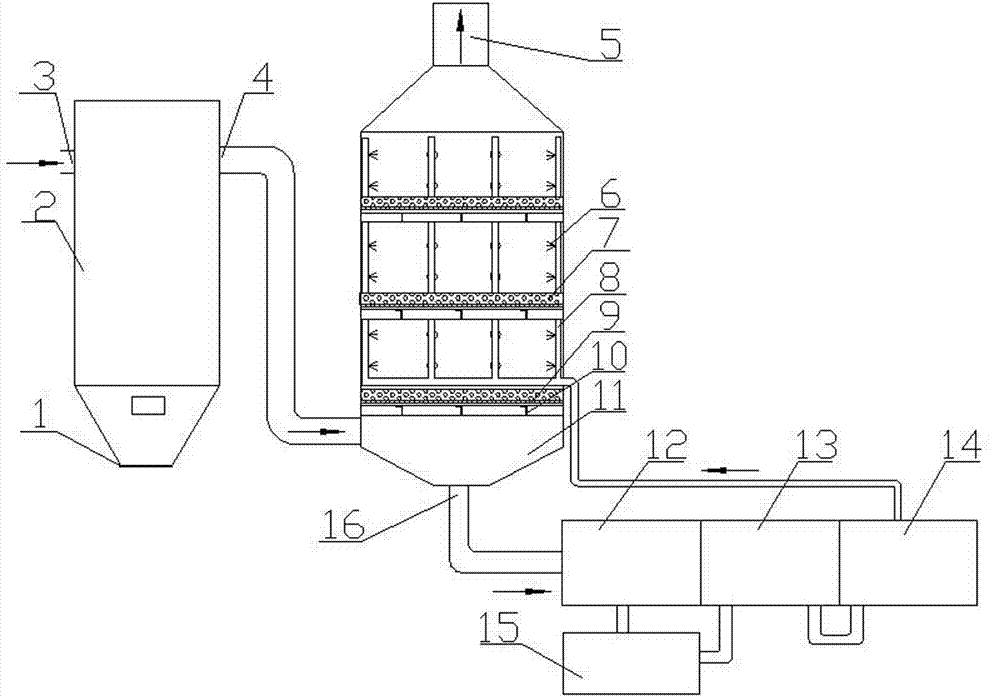

[0016] Referring to the accompanying drawings, the waste gas purification spray system includes a waste gas inlet 3, a cyclone separator 2, and a waste gas outlet 16. The bottom end of the cyclone separator 2 is provided with a gray plate 1, and the waste gas outlet 4 is connected to a Spray tower 11, the top of spray tower 11 is provided with pure gas outlet 5, and the bottom of spray tower 11 is provided with waste water outlet 16, it is characterized in that: described spray tower 11 is set as three layers, and each layer all passes through The angle iron bracket 12 is fixed with a filter screen 9, and a layer of ceramic hollow tubes 7 is stacked in disorder on the filter screen 9; several water spray pipes 8 are evenly arranged on the inner periphery of the spray tower 11 from bottom to top, and the inside of the water spray pipe 8 is evenly arranged. Several spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com