External wall heat-insulation material for constructional engineering and preparation method thereof

A technology for external wall insulation and construction engineering, applied in the field of construction engineering materials, can solve the problems of poor heat resistance and aging resistance, decreased performance of thermal insulation materials, and high toxicity to human body, achieve stable performance, and improve flame retardant and fireproof performance. , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

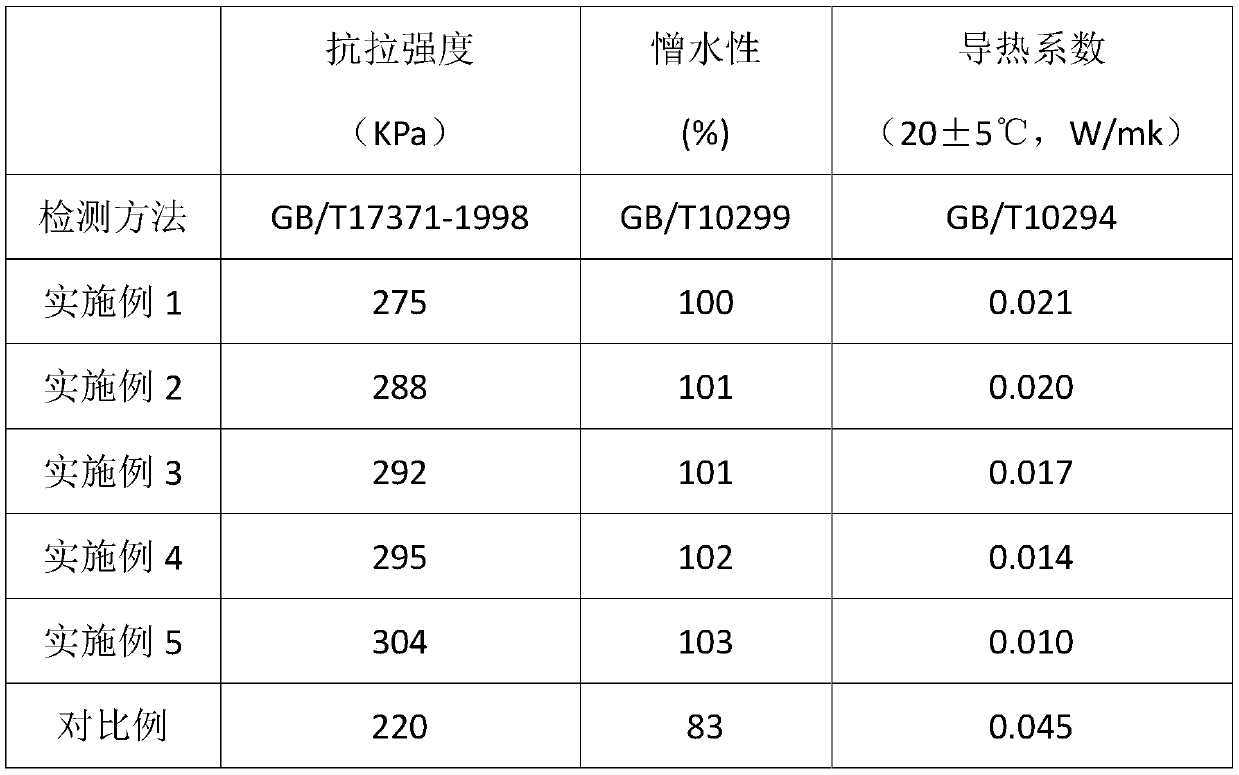

Examples

Embodiment 1

[0031] A construction engineering exterior wall insulation material, comprising the following raw materials in parts by weight: 15 parts of water-quenched slag, 20 parts of Portland cement, 10 parts of hollow spherical zirconia, 5 parts of silicon micropowder, 10 parts of glass wool, ceramic fiber wool 10 parts, 5 parts of hollow ceramic microbeads, 3 parts of expansive clay, 5 parts of attapulgite, 5 parts of functional additives based on PSS-biphenylvinylsiloxy-heptacyclopentyl substitute, dodecyl 1 part of dimethyl amine oxide, 1 part of polyurethane, 25 parts of water.

[0032] The preparation method of the hollow spherical zirconia comprises the following steps: dispersing 100 g of tetrabutyl zirconate in 2000 g of ethanol, stirring to obtain an ethanol suspension of tetrabutyl zirconate, and then transferring it to a reaction kettle and heating it at 190° C. After reacting at room temperature for 4 hours, after cooling to room temperature, centrifuge washing, drying, and...

Embodiment 2

[0038]A construction engineering exterior wall insulation material, comprising the following raw materials in parts by weight: 17 parts of water-quenched slag, 23 parts of Portland cement, 12 parts of hollow spherical zirconia, 6 parts of silicon micropowder, 12 parts of glass wool, ceramic fiber wool 12 parts, 6 parts of hollow ceramic microbeads, 4 parts of expansive clay, 6 parts of attapulgite, 6 parts of functional additives based on PSS-biphenylvinylsiloxy-heptacyclopentyl substitute, N-12 2 parts of alkyl ethanolamine, 2 parts of polyurethane, 27 parts of water.

[0039] The preparation method of the hollow spherical zirconia comprises the following steps: dispersing 100 g of tetrabutyl zirconate in 2200 g of isopropanol, stirring to obtain a suspension of tetrabutyl zirconate in isopropanol, and then transferring it to a reaction kettle , reacted at 195°C for 5 hours, cooled to room temperature, centrifugally washed, dried, and calcined at high temperature to obtain ho...

Embodiment 3

[0045] A construction engineering exterior wall insulation material, comprising the following raw materials in parts by weight: 18 parts of water-quenched slag, 25 parts of Portland cement, 13 parts of hollow spherical zirconia, 8 parts of silicon micropowder, 16 parts of glass wool, ceramic fiber wool 15 parts, 7 parts of hollow ceramic microbeads, 5 parts of expansive clay, 8 parts of attapulgite, 8 parts of functional additives based on PSS-biphenylvinylsiloxy-heptacyclopentyl substitute, 3 parts of hydrogen peroxide, 1 part polyurethane, 29 parts water.

[0046] The preparation method of the hollow spherical zirconia comprises the following steps: dispersing 100 g of tetrabutyl zirconate in 2550 g of ethylene glycol, stirring to obtain an ethylene glycol suspension of tetrabutyl zirconate, and then transferring it to a reaction kettle , reacted at 200°C for 6 hours, cooled to room temperature, centrifugally washed, dried, and calcined at high temperature to obtain hollow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com